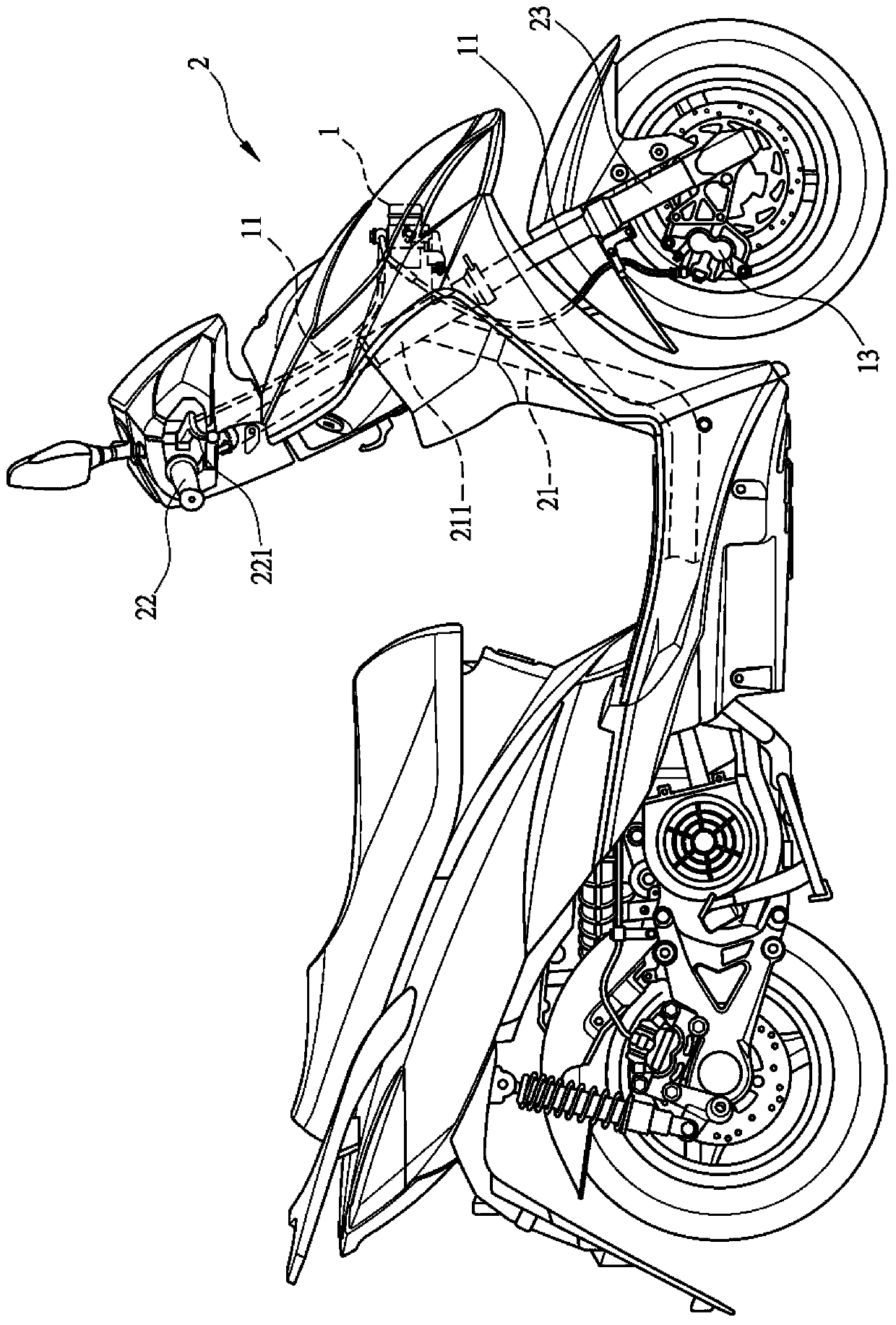

Motorcycle anti-skid brake system structure

A system structure and motorcycle technology, applied in bicycle accessories, bicycle brakes, etc., can solve the problems that the anti-skid brake system unit cannot effectively control the actuation of the disc brake caliper, the oil pipe is excessively bent, and the oil flow is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to understand the structure of the present invention and the effect that can be achieved more easily, the description is as follows in conjunction with the accompanying drawings;

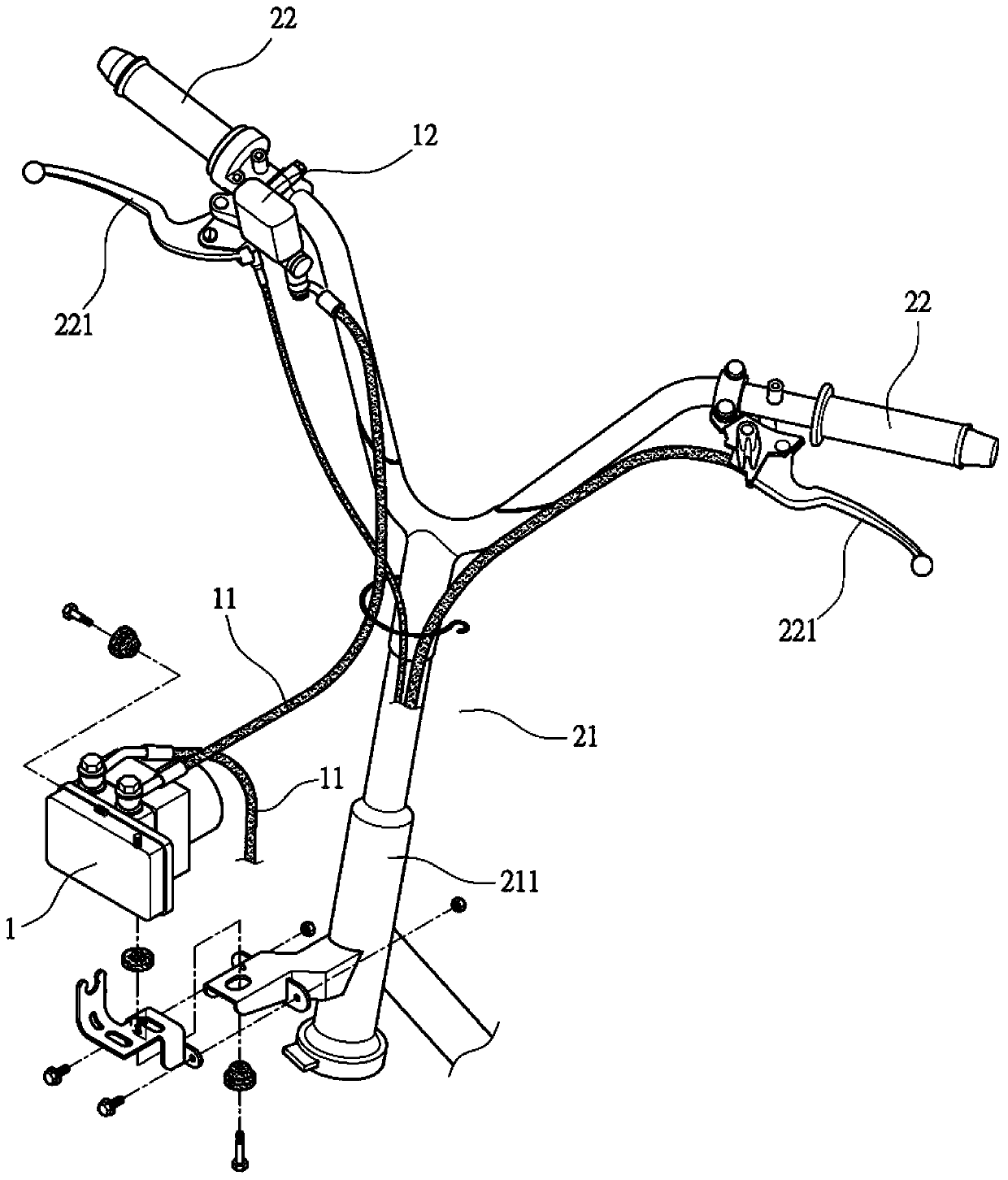

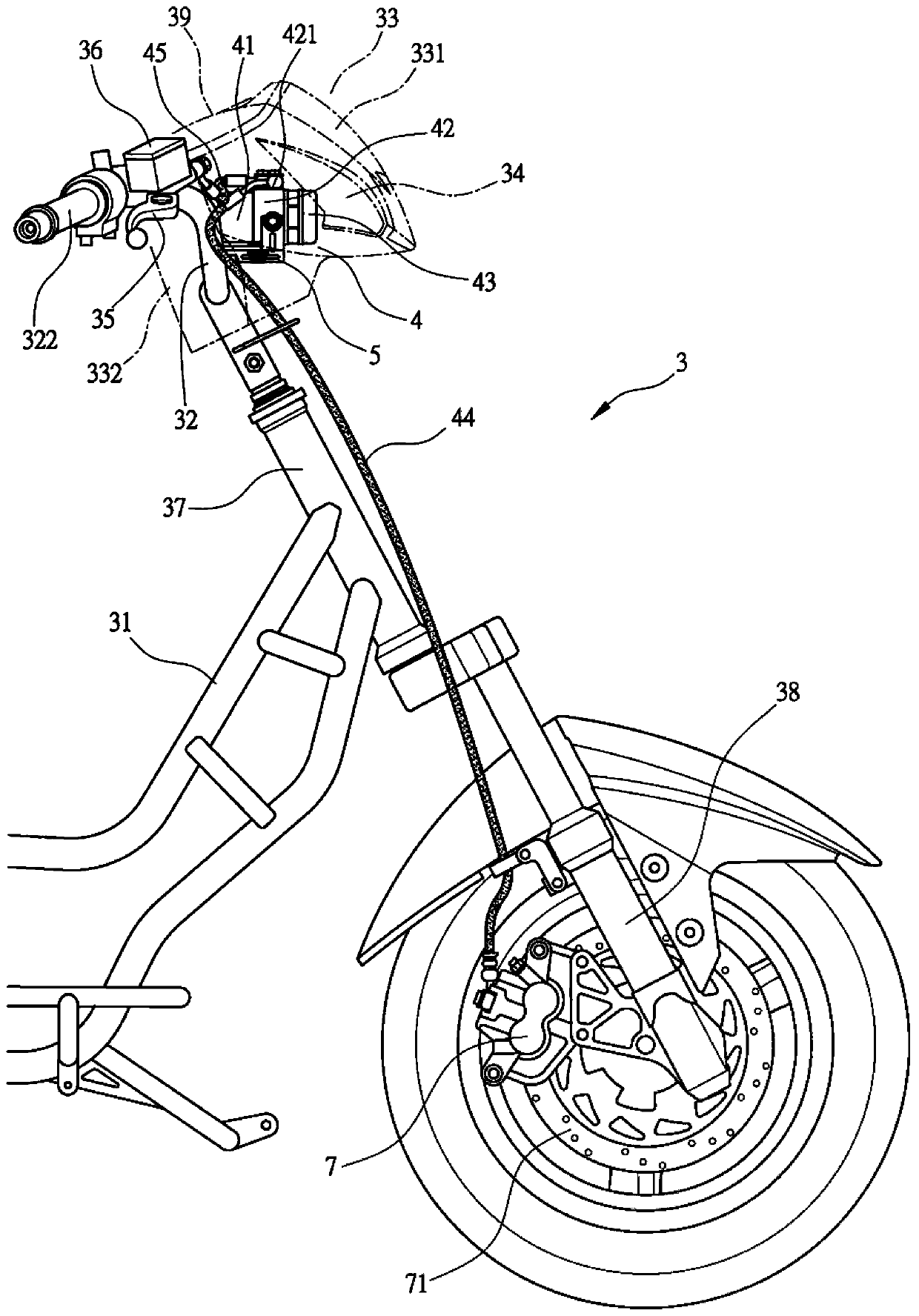

[0020] First, see image 3 , 4 , 5, and 6, the front of the motorcycle 3 frame unit 31 is provided with a steering handle 32, and the steering handle 32 is covered with a head cover 33, and the head cover 33 has a front cover 331 and a rear cover 332. The front cover 331 of the cover 33 is provided with a pair of direction lamp groups 34 arranged in a left and right direction towards the front of the motorcycle 3 , and the instrument 39 is provided on the head cover 33 . The concave portion 321 of the steering handle 32 is equipped with the anti-skid braking system unit 4, more specifically, the bracket 5 is installed on the side of the bottom surface of the concave portion 321 of the steering handle 32, and the handle portion of the steering handle 32 322 is provided with brake ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com