Patents

Literature

30results about How to "Guaranteed fuel supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

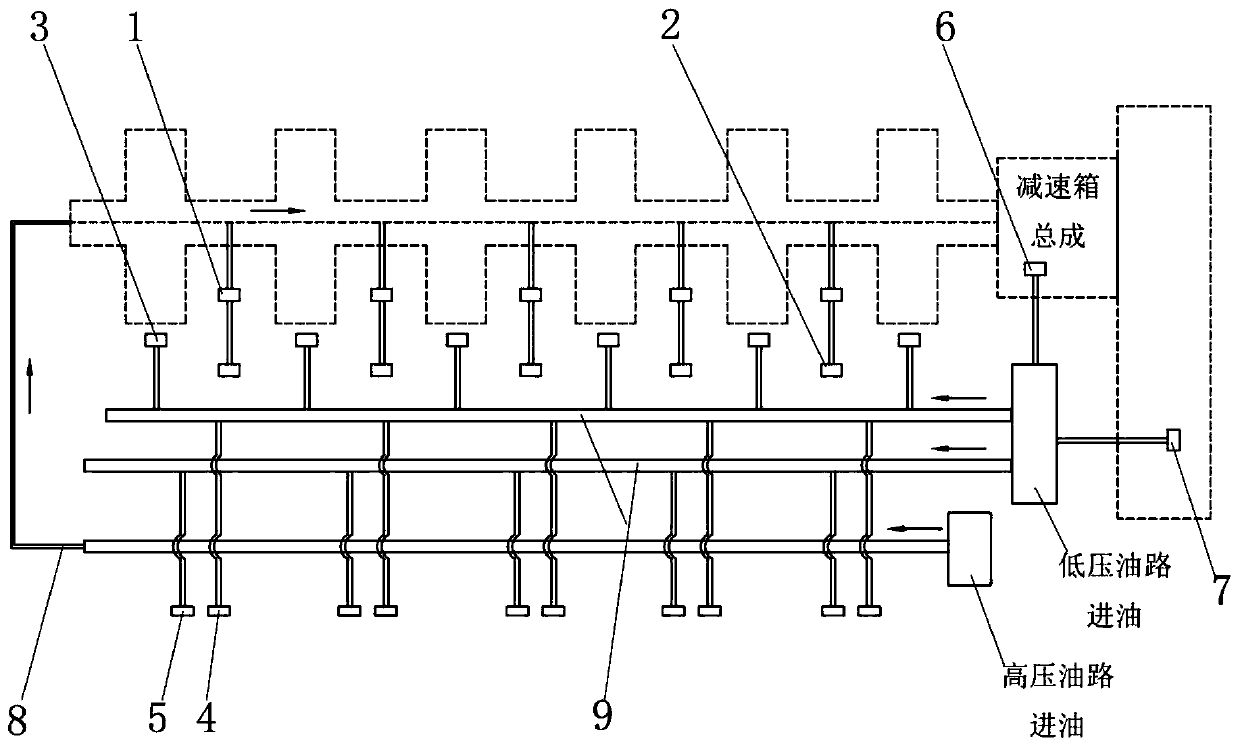

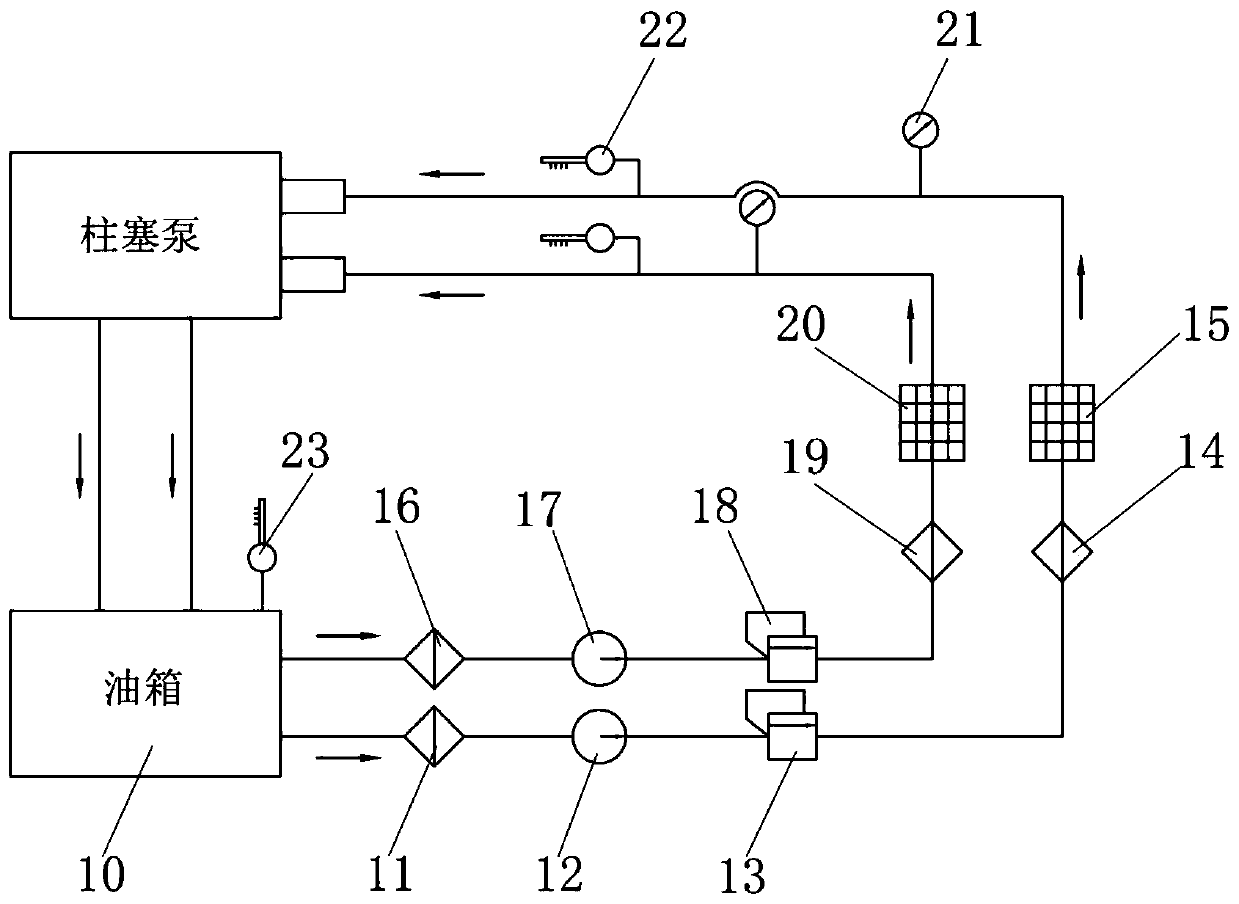

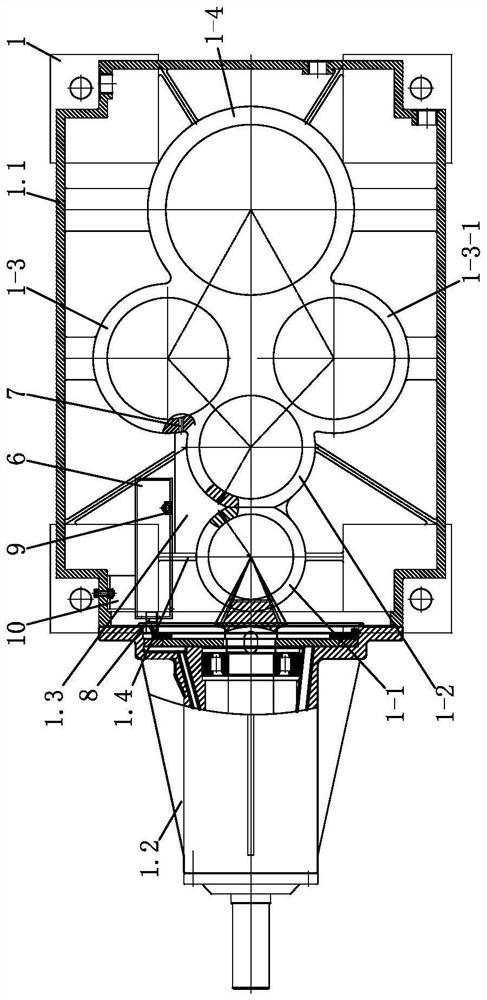

High-low pressure lubricating system for high power plunger pump

PendingCN111188763AAvoid uneven distributionIncrease profitPositive displacement pump componentsLiquid fuel engine componentsPlunger pumpOil supply

The invention discloses a high-low pressure lubricating system for a high power plunger pump. The system comprises a high pressure oilway and a low pressure oilway. The high pressure oilway lubricatesa connecting bearing bush and a crosshead bearing bush in the plunger pump, and the low pressure oilway lubricates a crankshaft bearing, a crosshead slide rail, a reduction box bearing and a reduction box gear pair in the plunger pump. The system has the beneficial effects that oil-taking is carried out by the high pressure oilway and the low pressure oilway, and the high pressure oilway lubricates the connecting bearing bush and the crosshead bearing bush in the plunger pump, and the low pressure oilway lubricates the crankshaft bearing, the crosshead slide rail, the reduction box bearing and the reduction box gear pair in the plunger pump; by supplying oil by two oil pumps, the oil supply mount of each oilway can be better guaranteed, lubricating oil is distributed better, the problem that the lubricating oil amount of each lubricating point is insufficient as the lubricating oil is not distributed uniformly due to too many lubricating branches is avoided, the utilization ratio of the lubricating oil is improved and abnormalities are reduced; the high pressure oilway and the lower pressure oilway adopt two-stage filtration, so that impurities in the lubricating oil can be reduced and the service lives of parts of the plunger pump are prolonged.

Owner:美国杰瑞国际有限公司

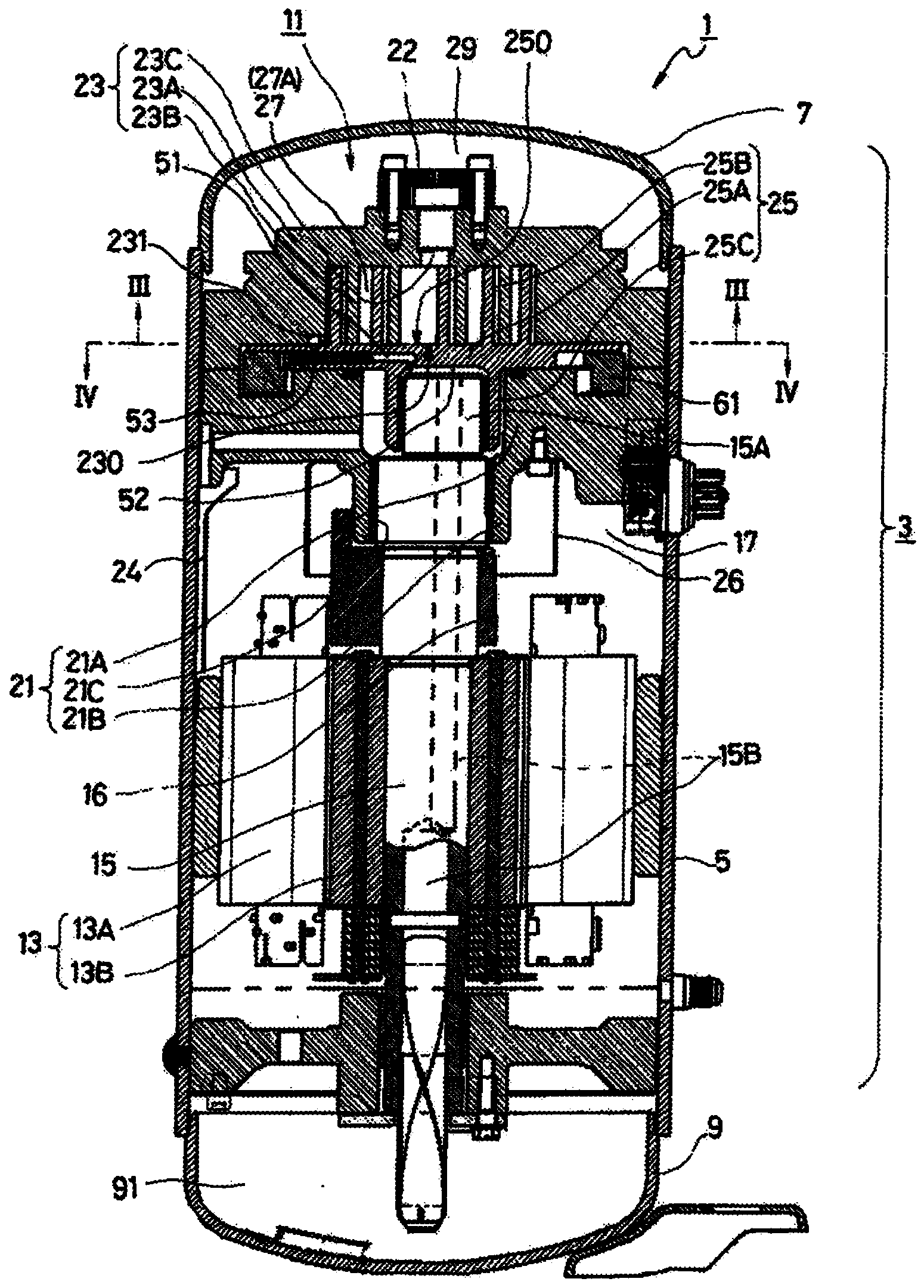

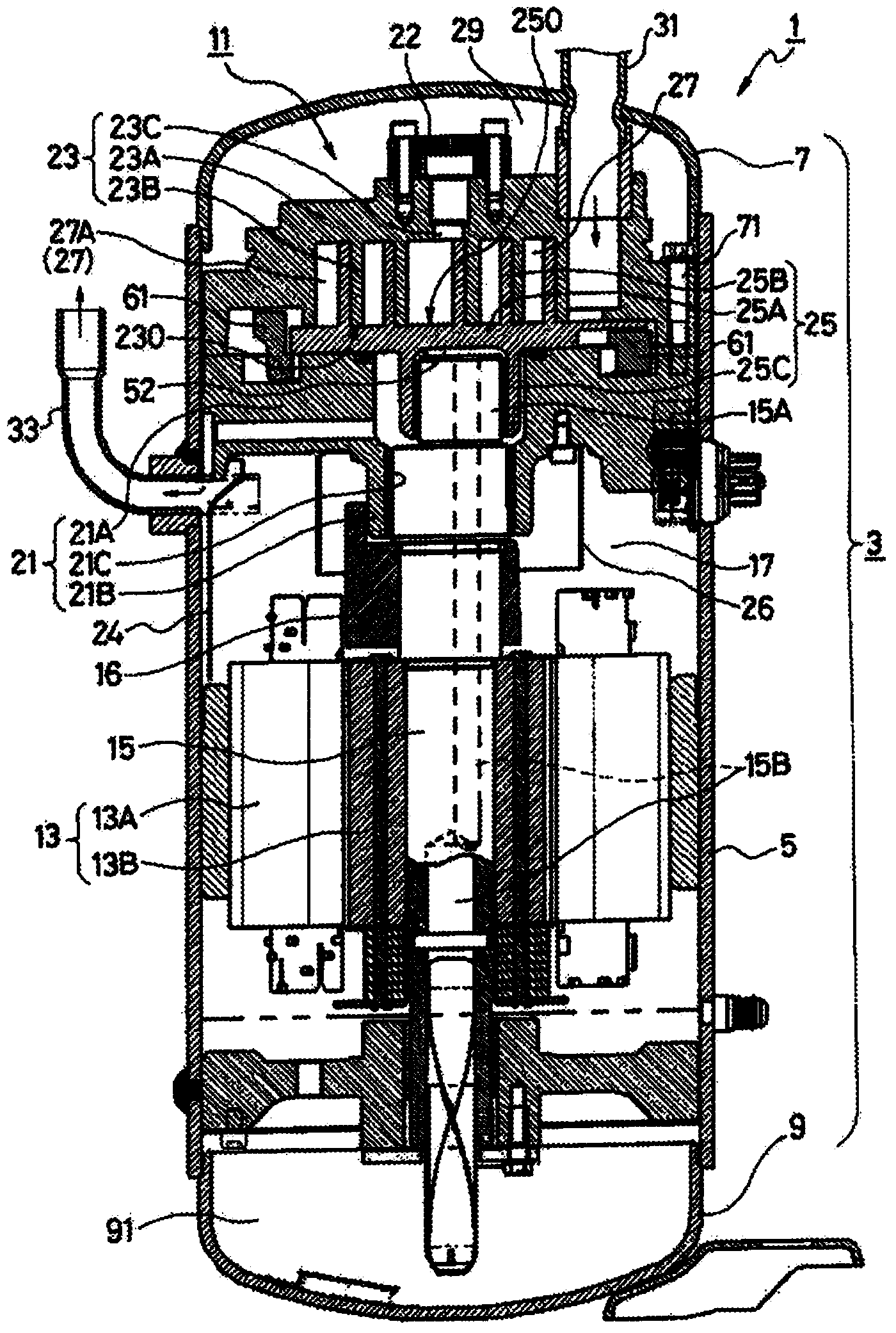

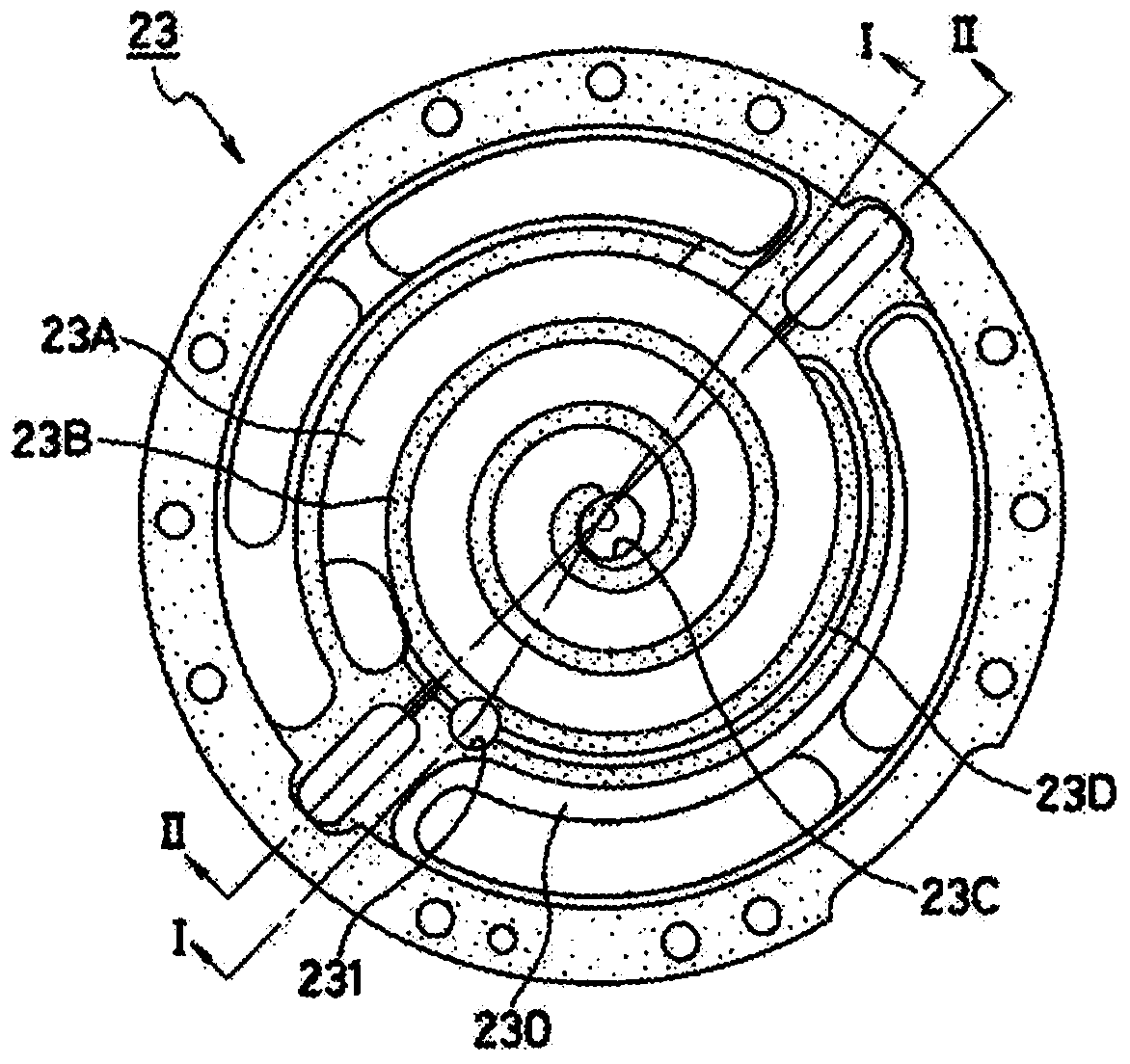

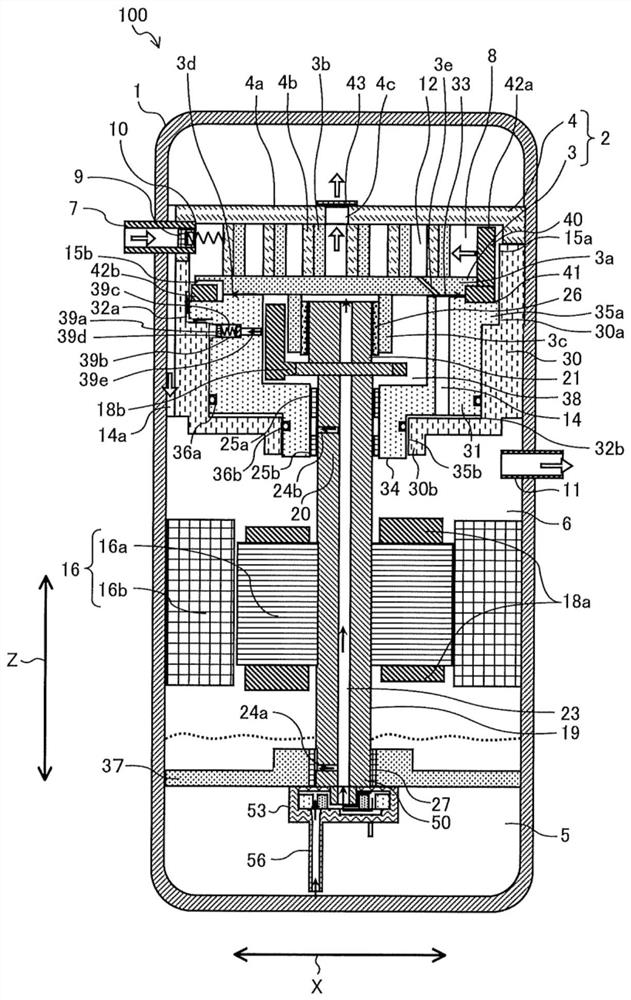

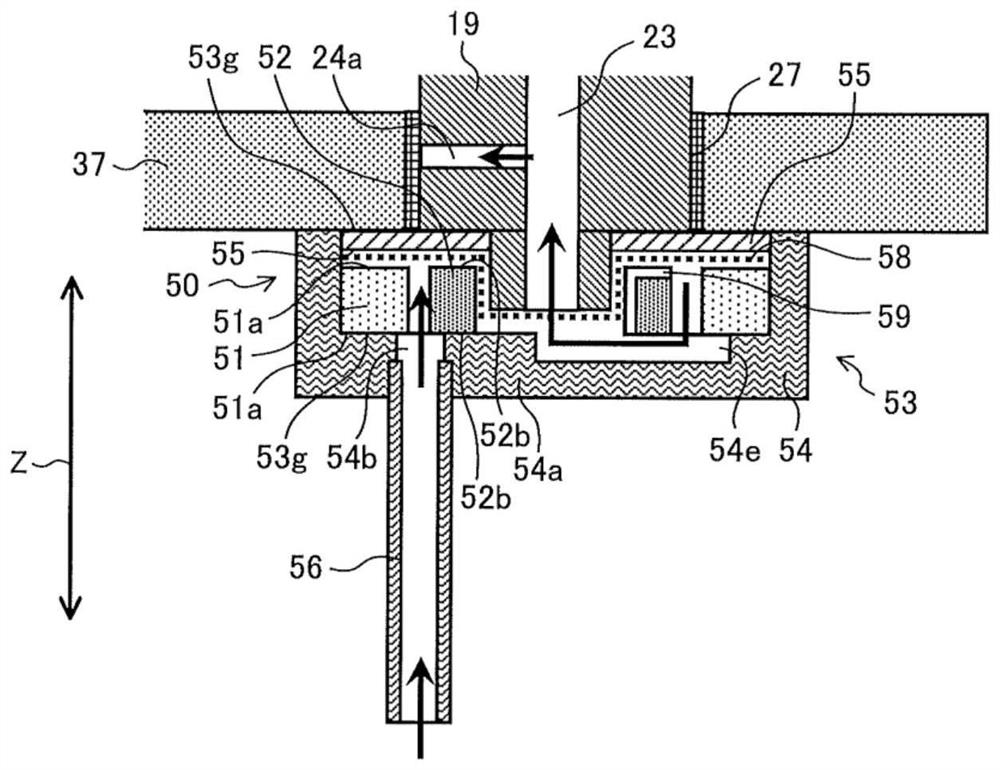

Scroll compressor

InactiveCN103459850AGuaranteed fuel supplyInhibit wearRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsLow speedHigh pressure

[Problem] To provide a scroll compressor capable of supplying more oil to secure the minimum oil supply quantity necessary even during low-speed rotation. [Solution] A scroll compressor includes: a communication passage (51) formed in a moving scroll (25), which discharges oil from a high-pressure portion in a casing to a space between panels of a fixed scroll (23) and the moving scroll (25); and a communication hole (53) formed in the communication passage (51) of the panel section of the moving scroll (25), the communication hole (53) approaching the vicinity of the entrance of a low-pressure portion (27A) of a compression chamber surrounded by wraps of both the fixed scroll (23) and the moving scroll (25), and extending to and opening at the panel surface. A narrow oil groove is formed in the fixed scroll (23) and supplies oil to the compression chamber. In the panel of the fixed scroll (23) approaching the wall surface portion of the moving scroll (25), an oil receiving hole (231) is formed in the oil groove, with the oil receiving hole (231) constantly overlapping and communicating with the communication hole (53) as the moving scroll (25) revolves so as to orbit on the top surface of the fixed scroll (23).

Owner:SANYO ELECTRIC CO LTD

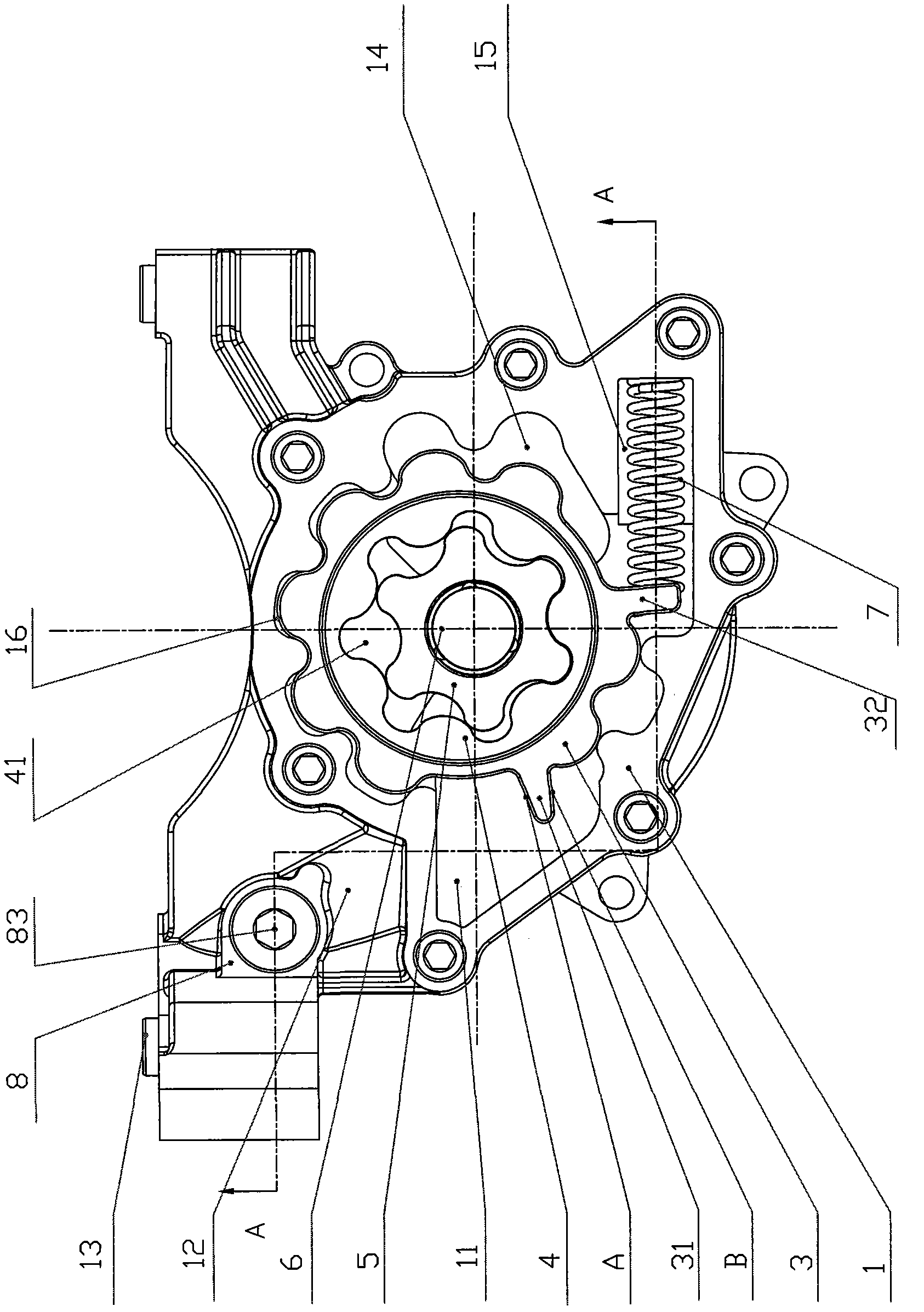

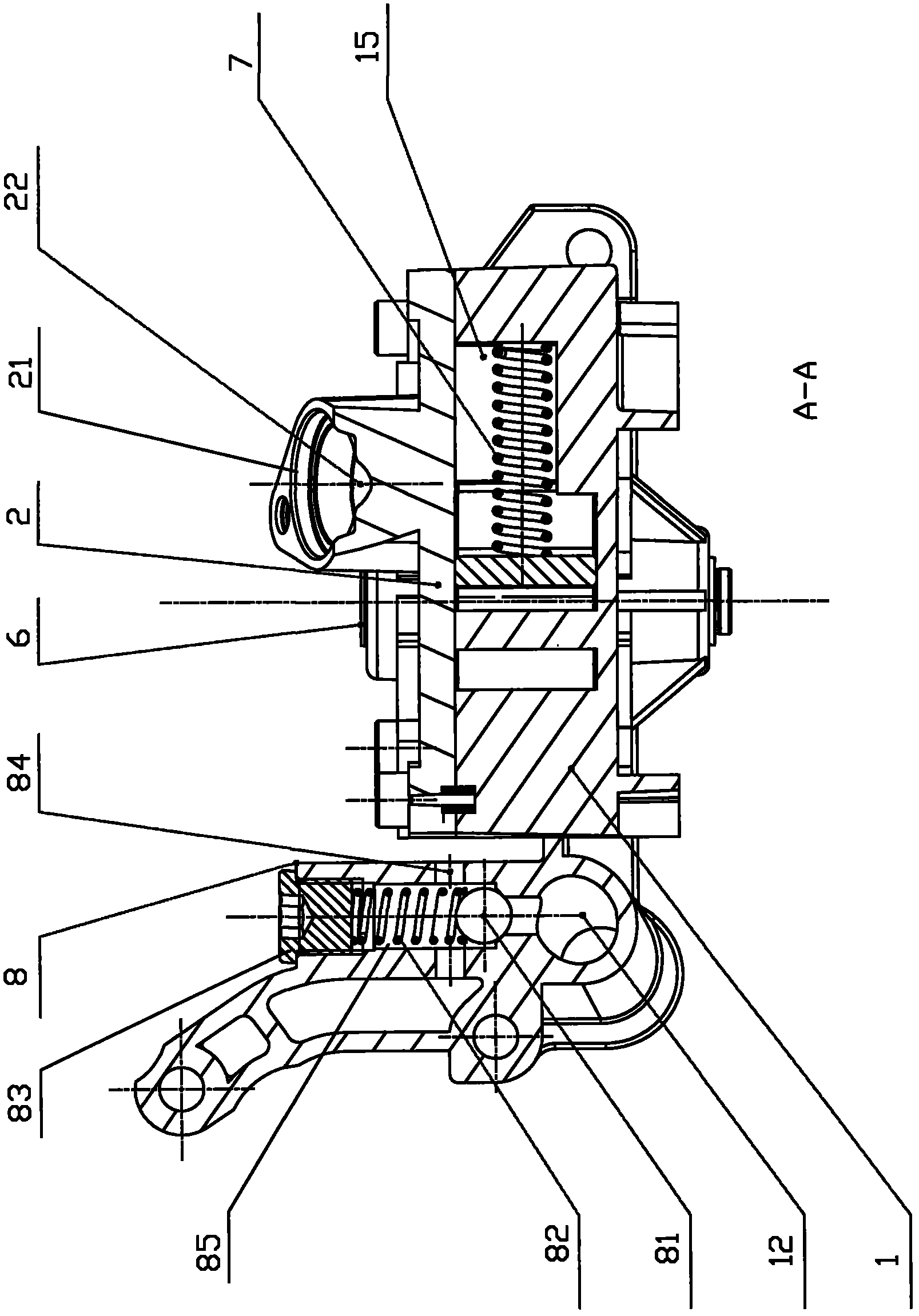

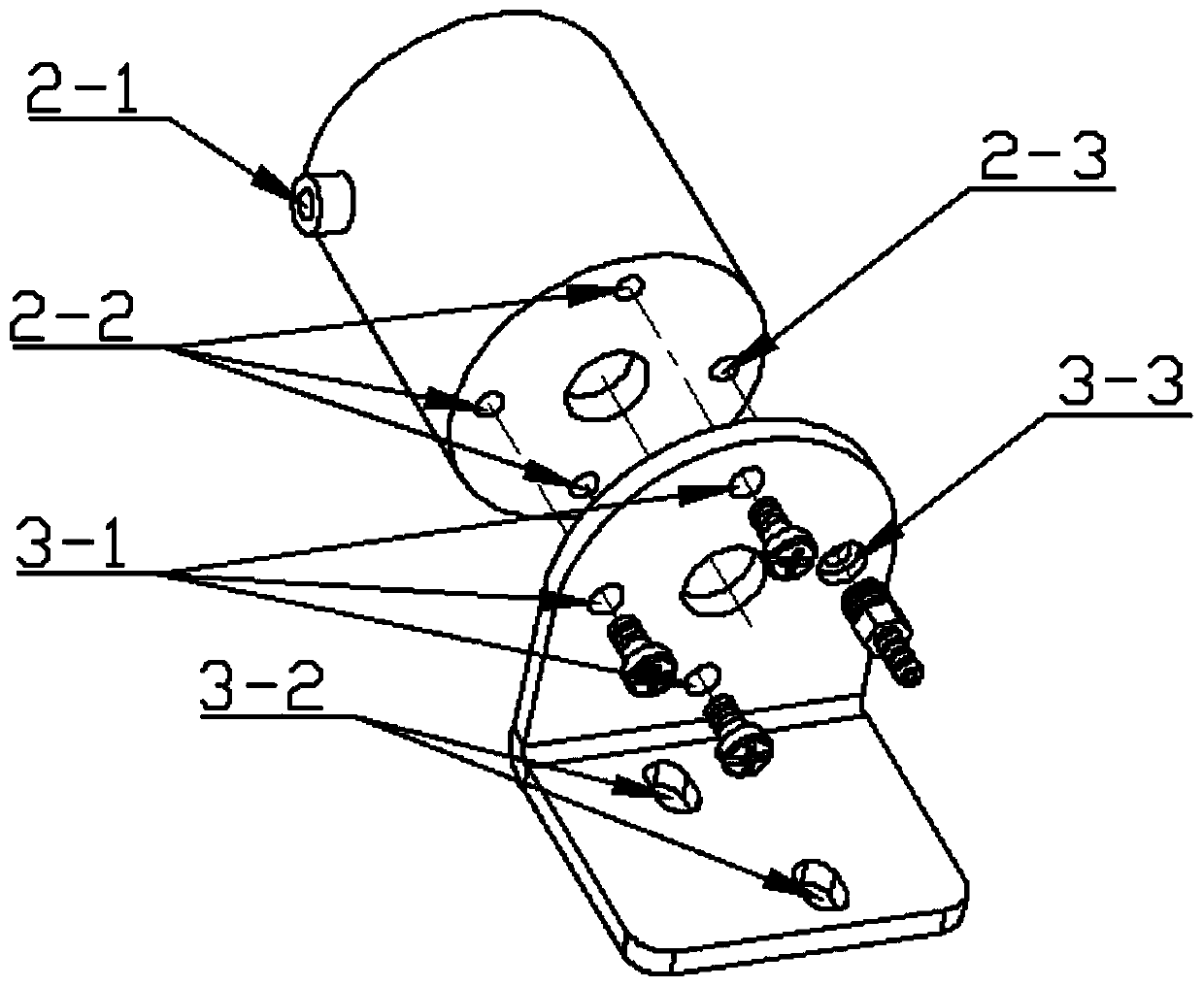

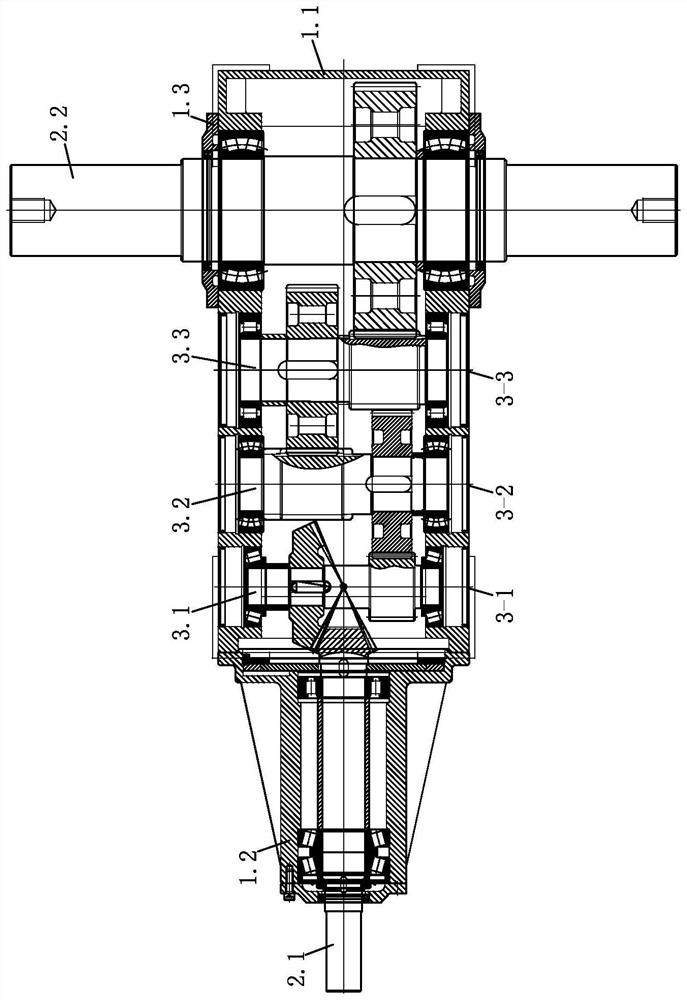

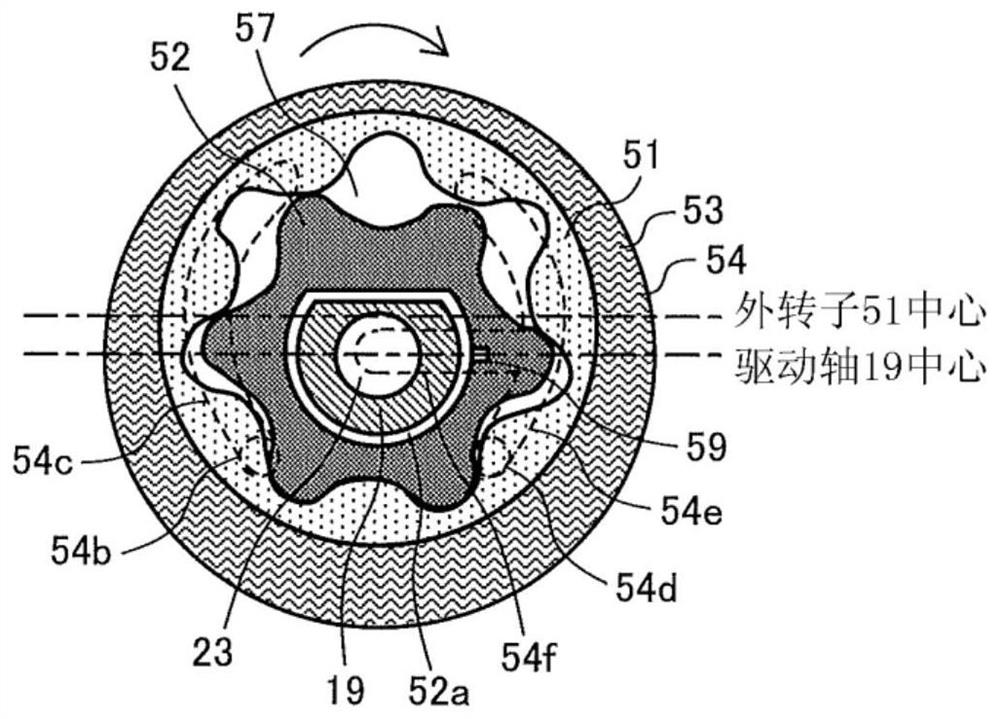

Variable rotor oil pump regulated and controlled by wave wheel

InactiveCN102095068AGuaranteed fuel supplyEffective protectionLubricating pumpsLubrication check valvesInterference fitDrive shaft

The invention discloses a variable rotor oil pump regulated and controlled by a wave wheel. The variable rotor oil pump is composed of a pump body, a pump cover, a wave wheel regulating and controlling ring, an outer rotor, an inner rotor, a transmission shaft, a spring and a safety valve component, wherein the pump body and the pump cover are connected through a bolt; the wave wheel regulating and controlling ring and the spring are installed in a wave wheel ring hole and a spring groove hole which are positioned on the pump body, the middle part of the transmission shaft is in interference fit with the inner rotor, and the transmission shaft, the inner rotor and the outer rotor are installed in an intermediate hole on the wave wheel regulating and controlling ring and the shaft holes of the pump body and the pump cover; two sides and bottom surface of the wave wheel ring hole of in the pump body are provided with an oil inlet chamber, an oil outlet chamber, an oil outlet duct and an oil outlet, and the oil outlet is communicated with the oil duct of an engine; the oil outlet duct of the pump body is provided with the safety valve hole, the safety valve hole is communicated with the oil outlet duct, the passageway of the safety valve hole is provided with an oil drainage hole, and the safety valve hole is internally provided with the safety valve component; and the combination surface of the pump cover and the pump body is provided with an oil inlet duct and an oil inlet, the oil inlet is communicated with an oil absorption device, and the oil inlet duct is communicated with the oil inlet chamber of the pump body.

Owner:HUNAN OIL PUMP

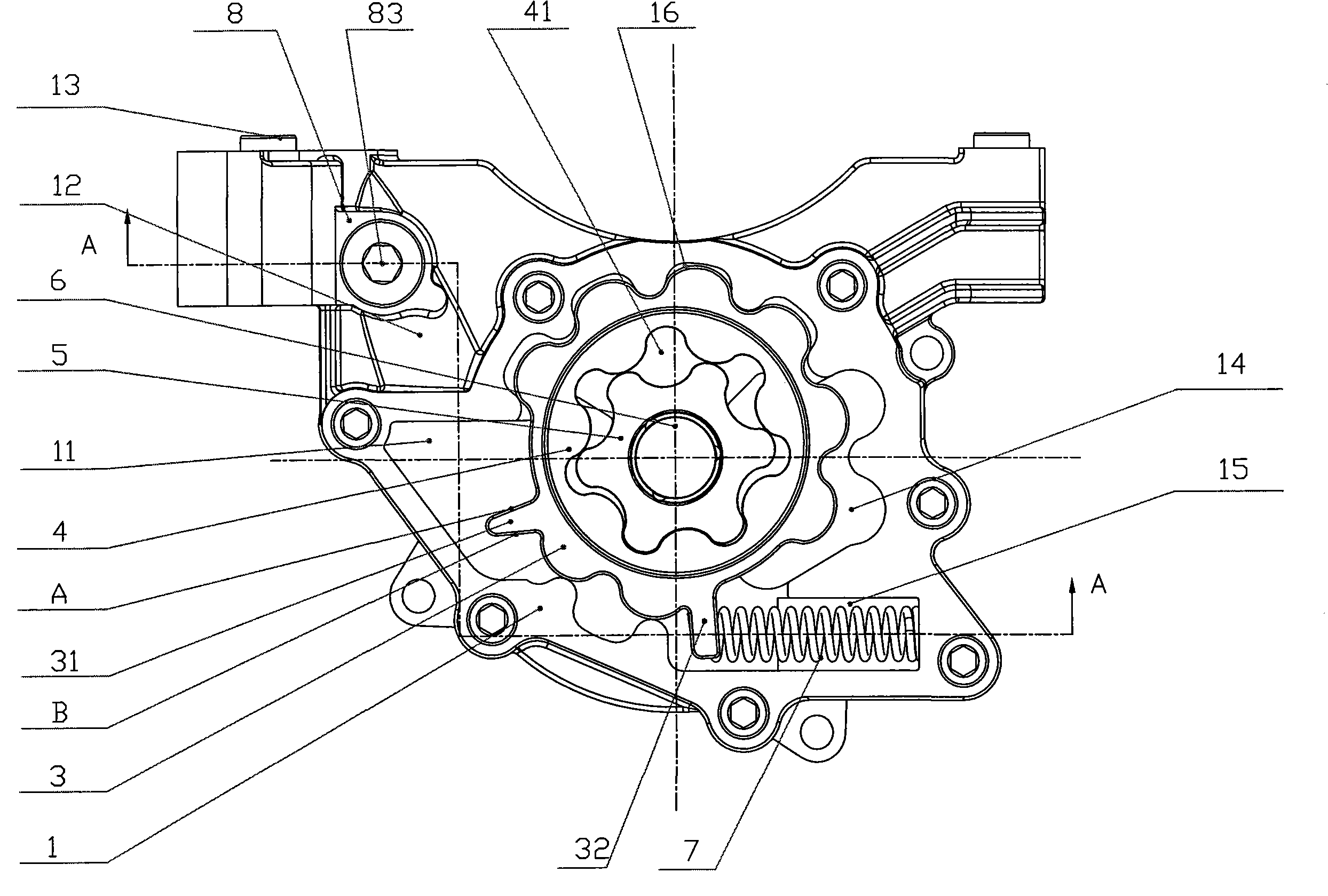

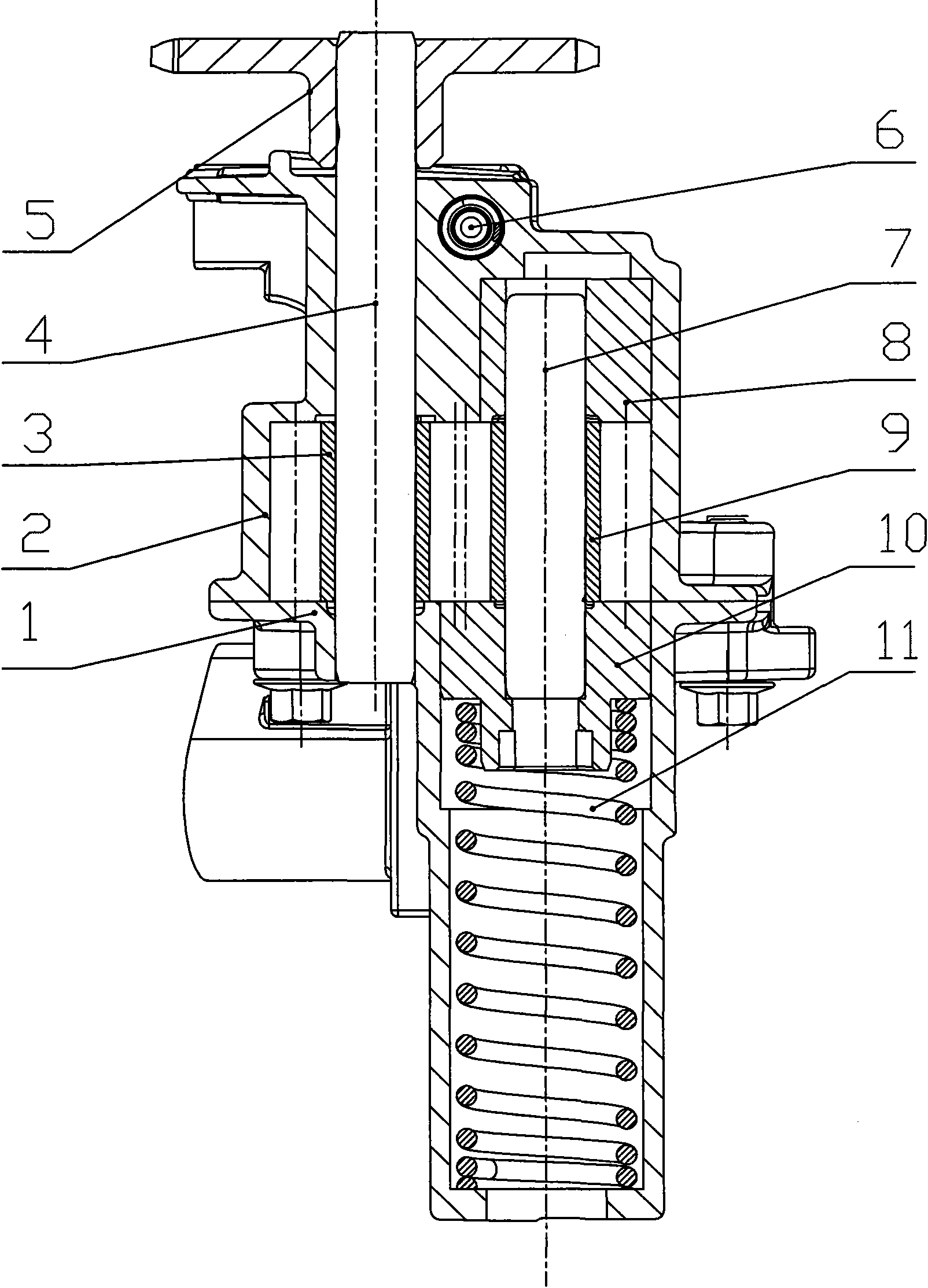

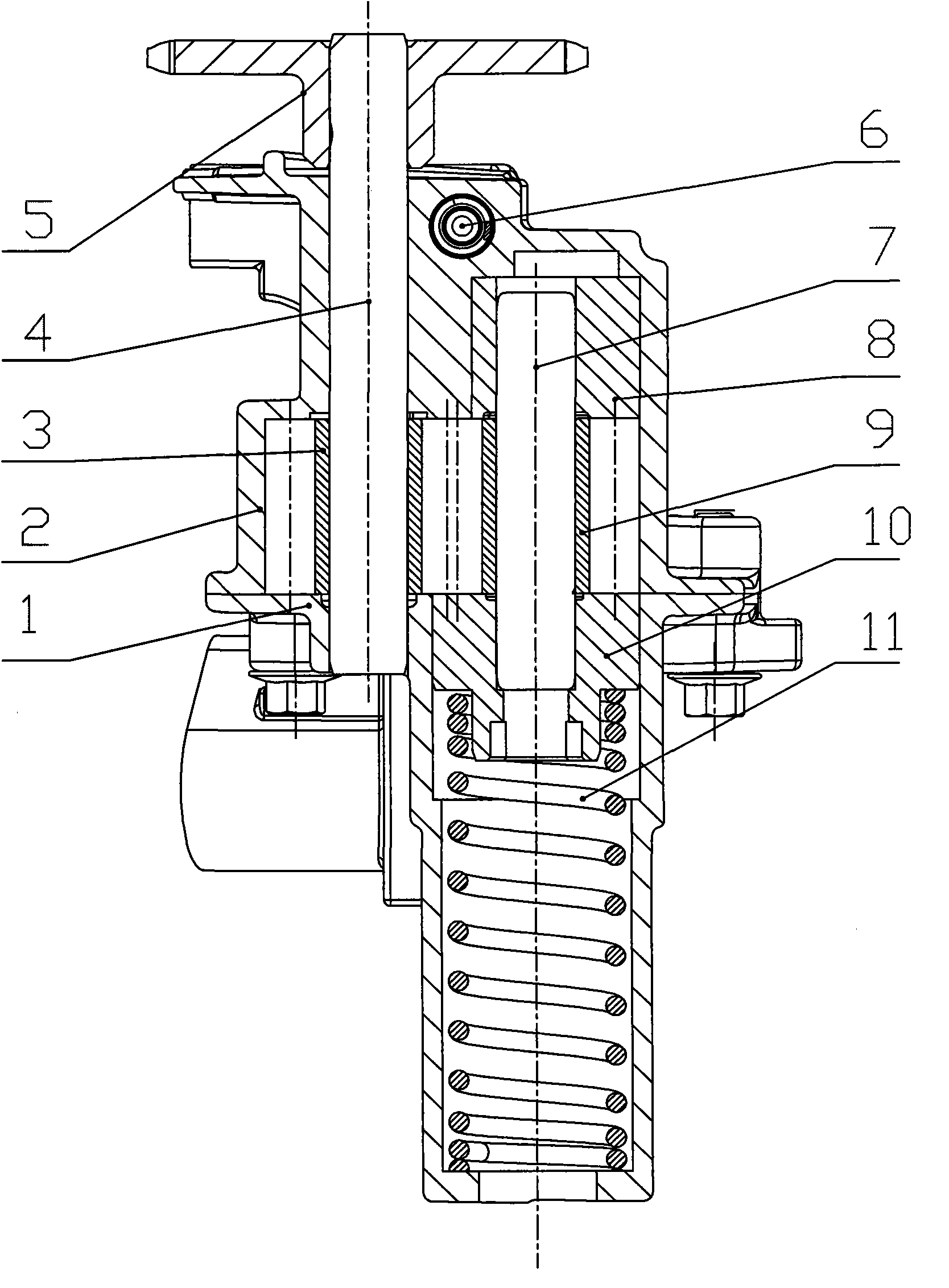

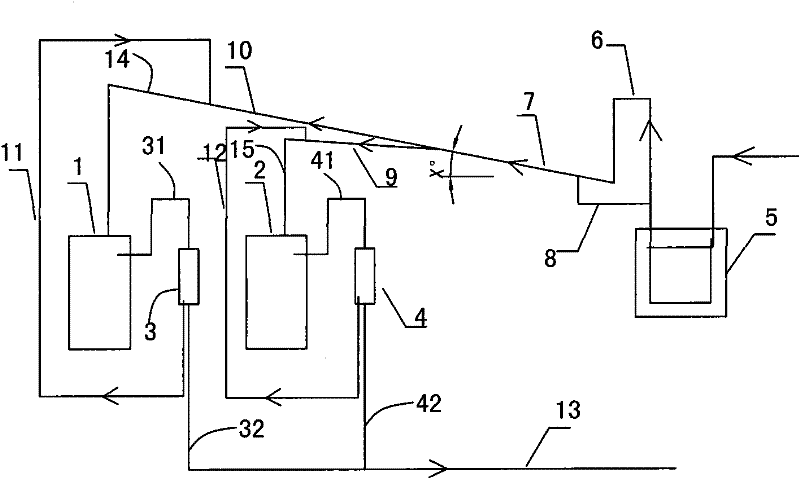

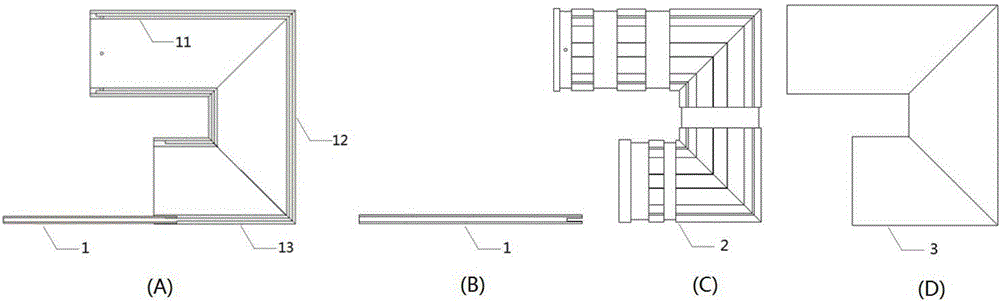

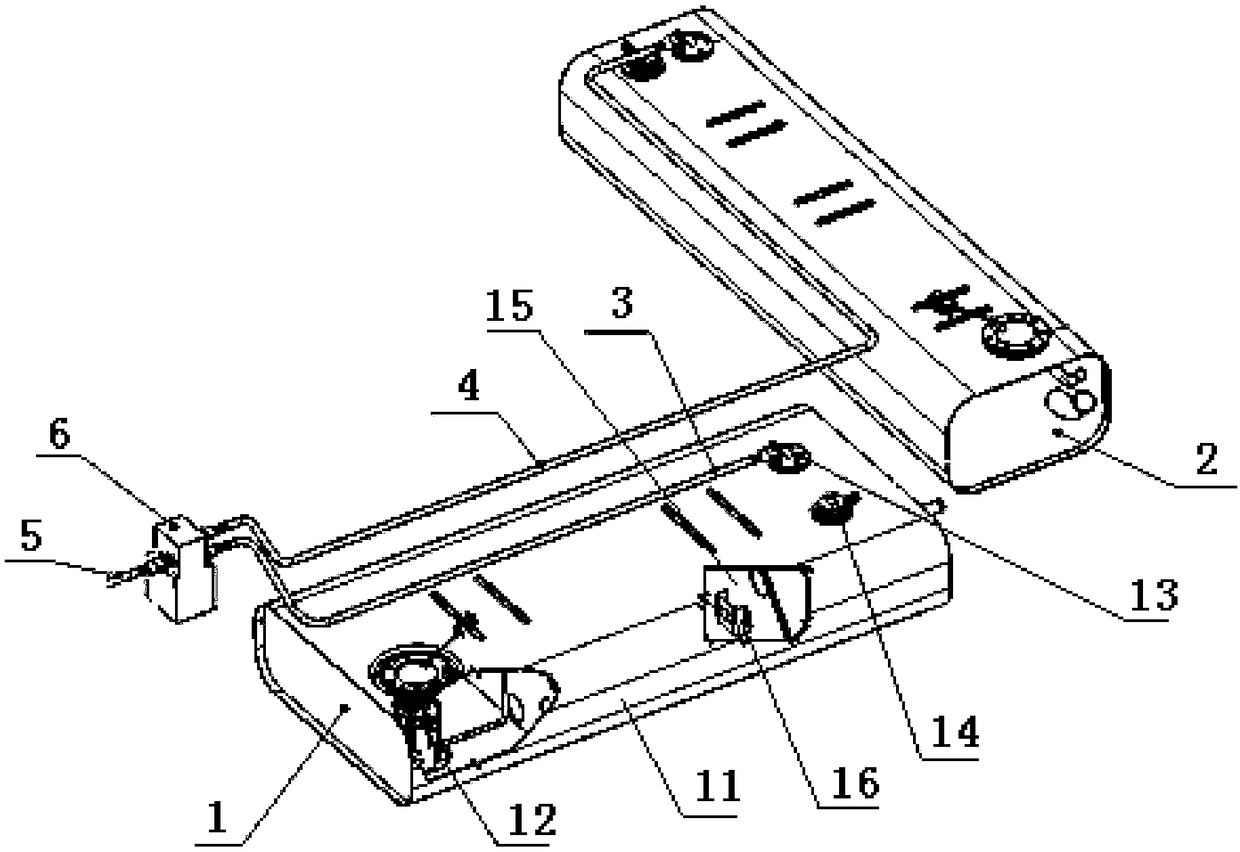

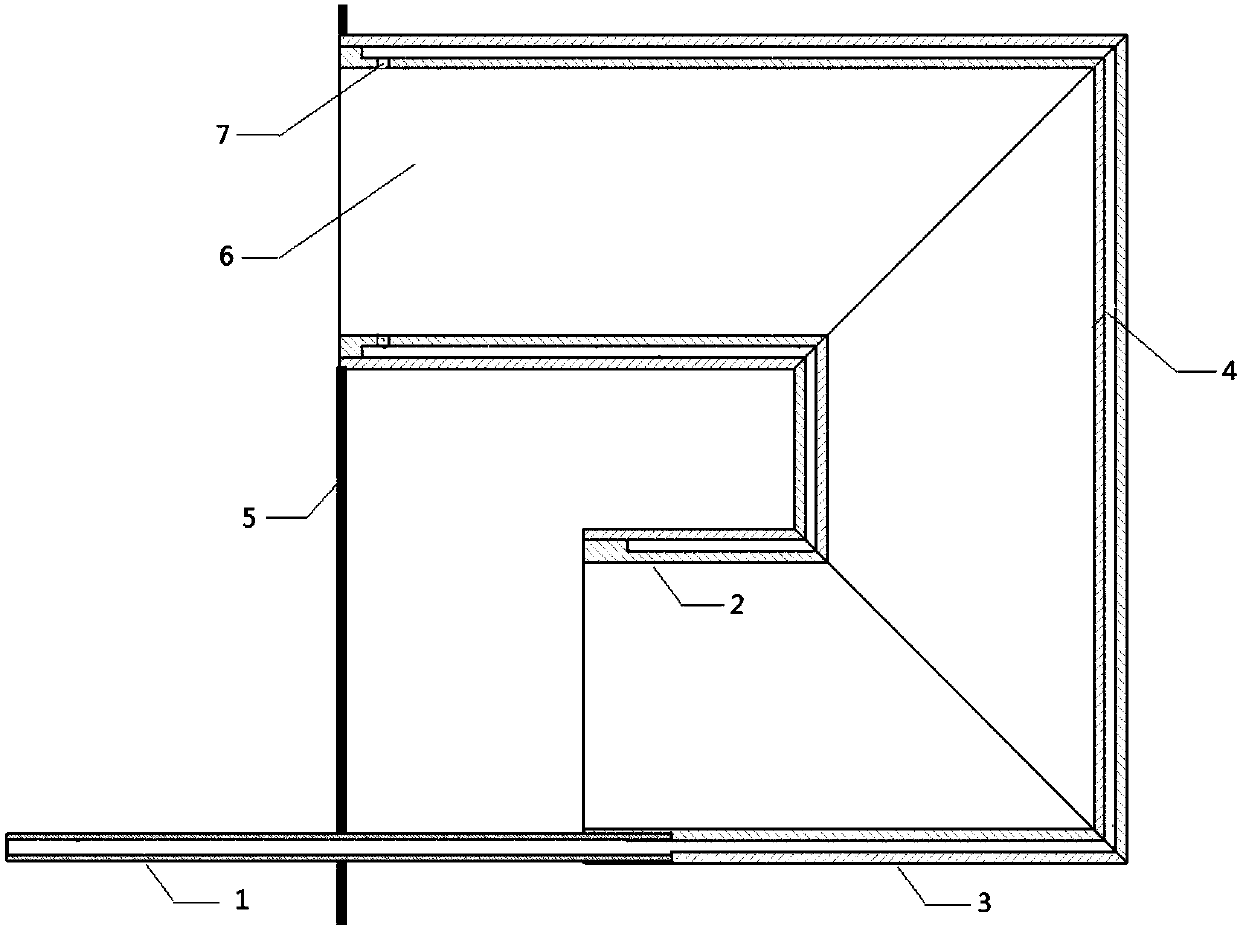

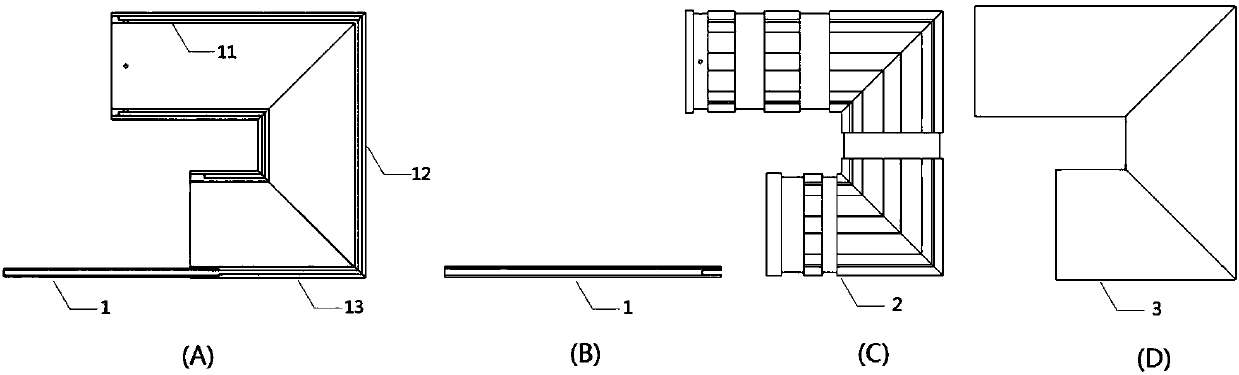

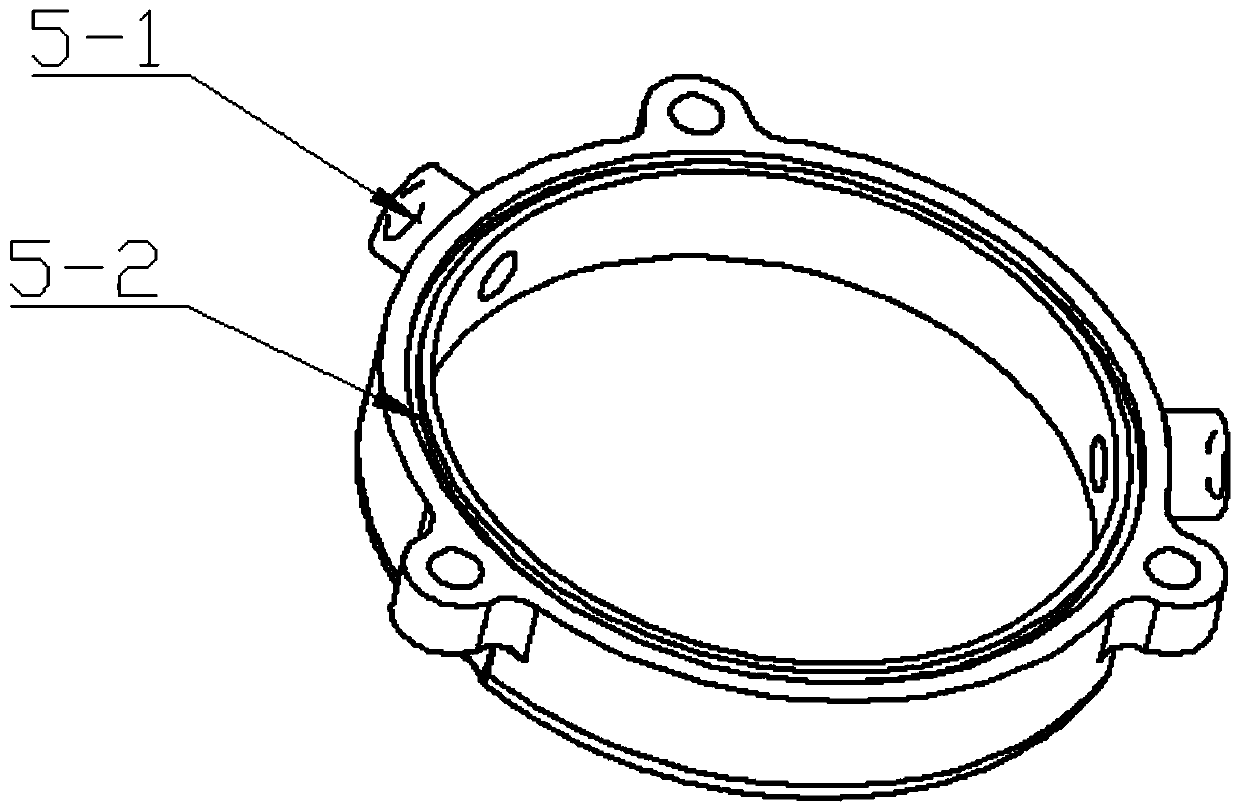

Variable-displacement gear-type oil pump

InactiveCN101881368AReduce the temperatureImprove lubrication performanceLubricating pumpsEngineeringVariable displacement

The invention provides a variable-displacement gear-type oil pump comprising a pump cover 1, a pump body 2, a driving gear 3, a driving shaft 4, a transmission gear 5, adjustment valve components 6, a driven shaft 7, a segmental sliding block 8, a driven gear 9, a whole-circle sliding block 10 and a spring 11, wherein the driving shaft 4 is mounted in the axial hole of the pump body 2 and the pump cover 1; the transmission gear 5 is in press fit with the outer end of the driving shaft 4; the driving gear 3 in interference fit is mounted in the middle of the driving shaft 4 to constitute a transmission component; the driven shaft 7, the segmental sliding block 8, the driven gear 9, the whole-circle sliding block 10 and the spring 11 constitute a variable component; the adjustment valve components 6 are arranged at intervals on the outer edge of the segmental sliding block which is separated from the driving shaft 4; and the transmission component of the driving gear 3 and the variable component of the driven gear 9 are arranged oppositely, and the transmission component of the driving gear 3, the variable component of the driven gear 9 and the adjustment valve components 6 can be combined into the variable-displacement gear-type oil pump. Accordingly, the invention can reduce the temperature of the lubricating oil, improve the lubricating performance of the engine oil, reduce the power loss of the engine, improve the efficiency and economical efficiency of the engine and reduce the production cost.

Owner:HUNAN OIL PUMP

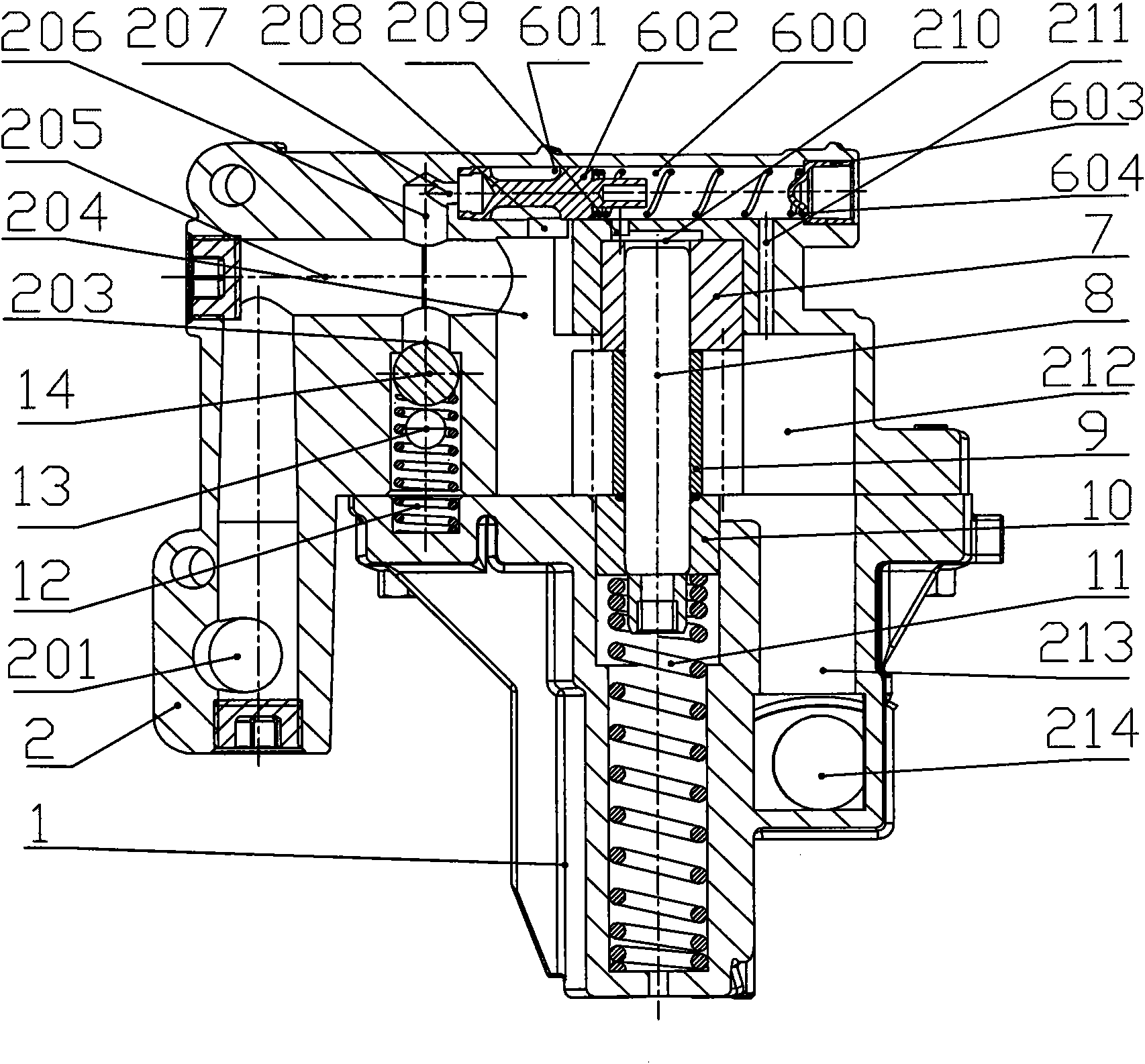

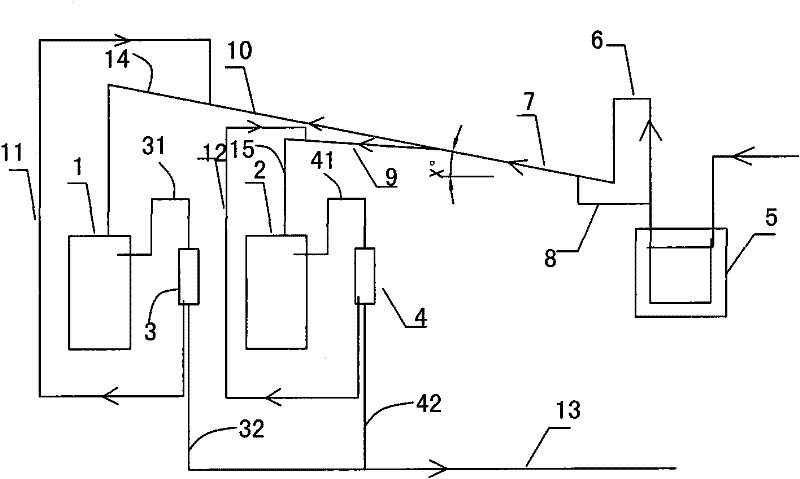

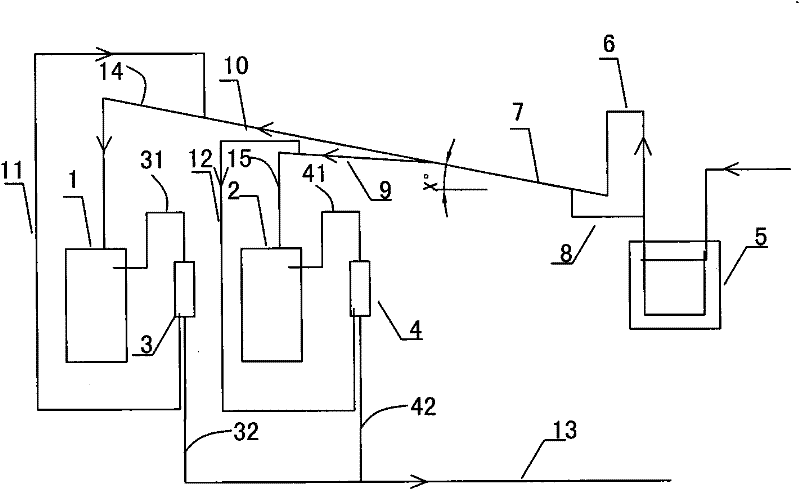

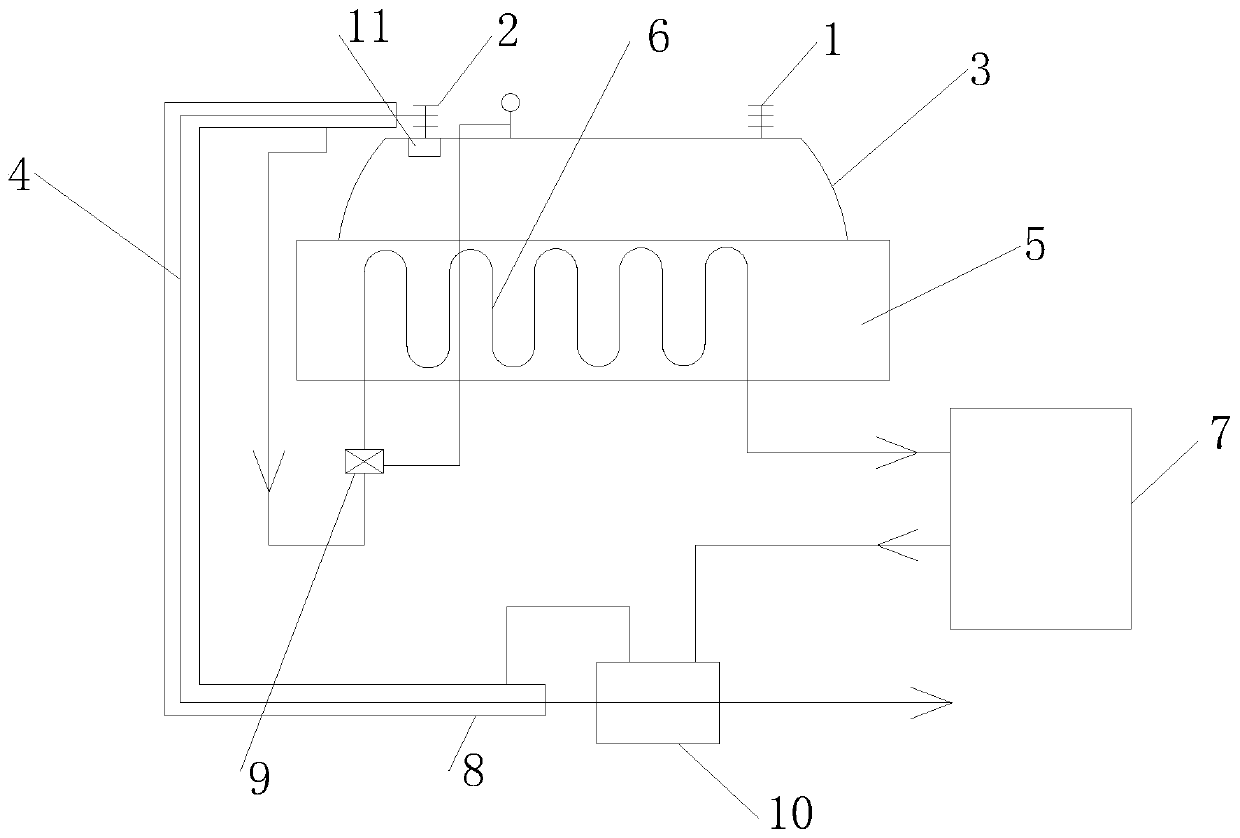

Parallel system of multiple high-pressure cavity compressors

The invention discloses a parallel system of multiple high-pressure cavity compressors. Due to the design of an inverse U-shaped pipe, an overflow pipe and an oblique main pipe, the refrigerating machine oil reflowing from an oil separator is prevented from flowing back to compressors when all the compressors stop running, and more oil reflowing from the oil separator can be stored in a vapor-liquid separator through the overflow pipe so as to prevent liquid blockage; when the compressors run in low loads and the coolant flow rate of an air suction pipe is low, the oil can be prevented from flowing back to the vapor-liquid separator; after a certain oil quantity is accumulated in the oblique main pipe, the oil is directly recycled to the compressors, so that the oil supply of the compressors is ensured; and the system can avoid liquid compression or liquid blockage of the compressors in each state of the compressors, so that the reliability of the compressor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

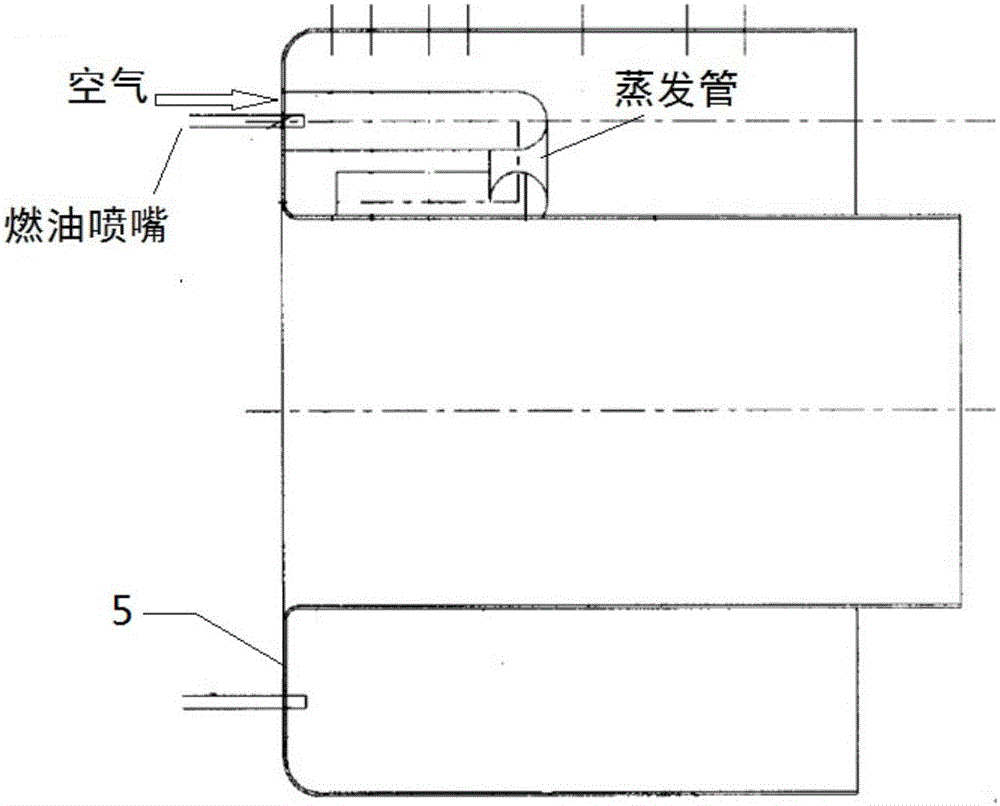

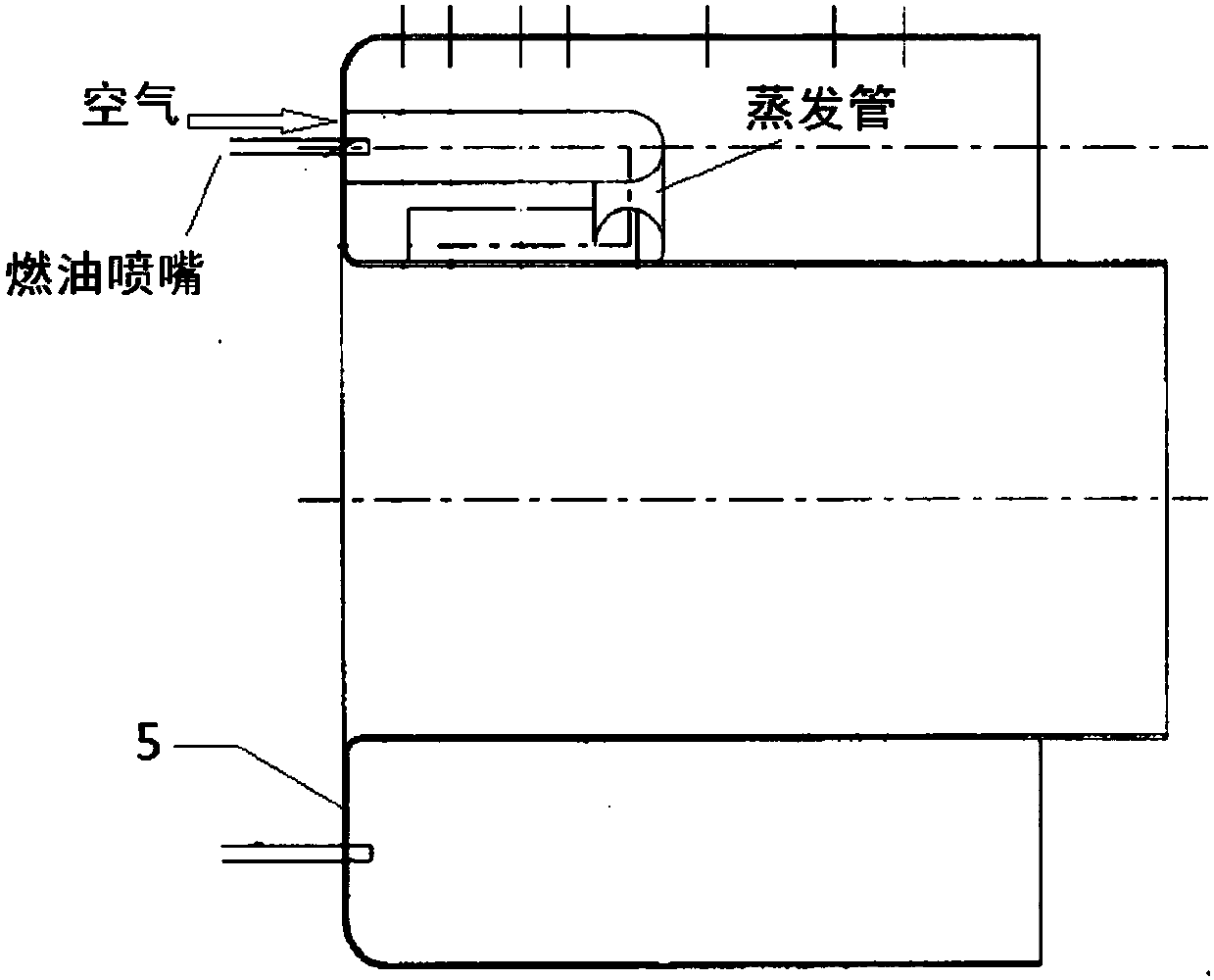

Fuel-cooled type evaporating pipe structure

ActiveCN105716120AIncrease warm-upSpeed up evaporationContinuous combustion chamberThermal stateCombustor

The invention relates to a fuel-cooled type evaporating pipe structure. The evaporating pipe structure is applicable to engines and combustion chamber components of other burners, a closed fuel cooling cavity is formed between an evaporating pipe inner sleeve and an evaporating pipe outer sleeve, a fuel inlet pipe extends into the fuel cooling cavity in the outlet section position of the evaporating pipe, at least one row of fuel nozzles evenly distributed in the circumferential direction are arranged along the inlet section of the evaporating pipe inner sleeve, grooves communicating with one another are formed in the outer surface of the evaporating pipe inner sleeve, and fuel is delivered to the outlet section from the inlet section of the fuel cooling cavity along the grooves and is sprayed into the evaporating pipe at the inlet section. According to the structure, the fuel arrives at the fuel nozzles at the inlet section of the evaporating pipe from the inner cavity of the outlet section of the evaporating pipe and cools the wall surface of the evaporating pipe, and thermal state ablation protection of the evaporating pipe is completed; each way of fuel is preheated independently, the preheating degree of the fuel is increased, and the evaporating and premixing effect of the fuel is enhanced. By the aid of the overall design, cooling protection of the evaporating pipe is realized, and the service life is prolonged; high-intensity preheating of the fuel is realized, and the evaporating and premixing degree is increased.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI +1

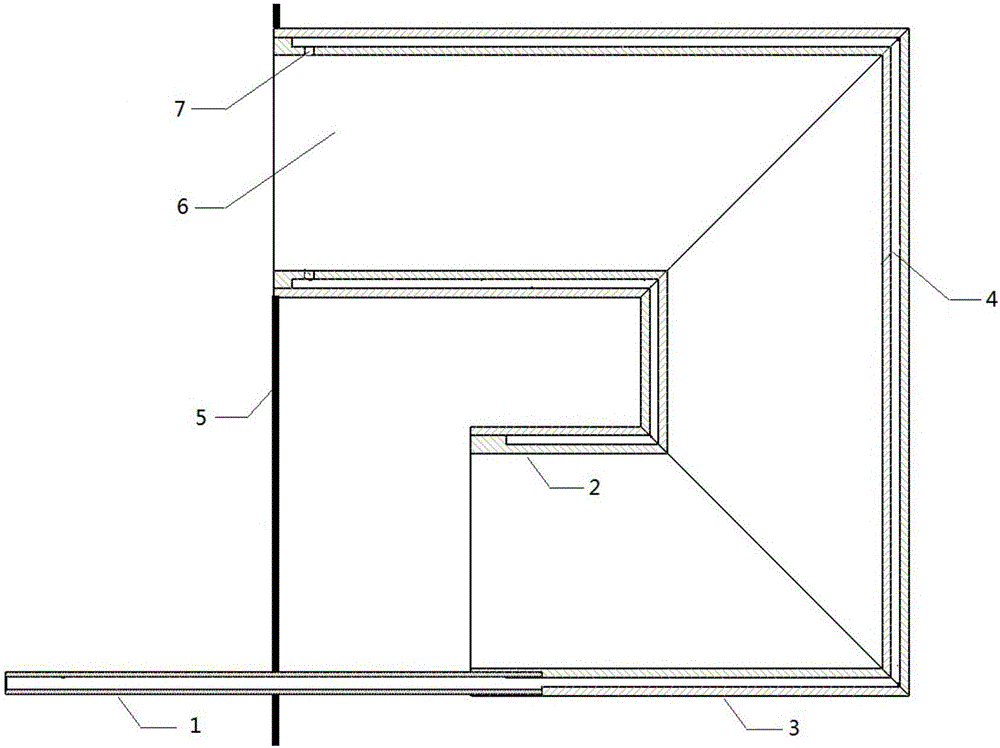

Fuel-tank of motor vehicle

PendingCN108891255AReduced risk of oil failureGuaranteed fuel supplyUnderstructuresFuel supplyShortest distanceFuel tank

A motor vehicle fuel tank It belongs to the field of fuel tank, comprises a tank body and an oil suction pipe, A partition plate is arranged inside the tank body to divide the tank body into a crude oil tank and an oil suction tank, The filling port is located in the crude oil tank, As that space length of the oil suction tank is small than the space length of the crude oil tank, the suction pipeextends into the suction tank to suck fuel, As that oil is supply by extending the oil suction pipe into the oil suction tank with small space length, The risk that the original suction pipe can not suck oil due to the excessively long original tank body can be reduced, and since the liquid level change of the suction tank with the smaller space length is far smaller than that of the original tankwith the larger space length when the whole tank is inclined, the fuel supply can be ensured when the suction pipe can face the gradient of the shorter distance.

Owner:高密市中科容器厂

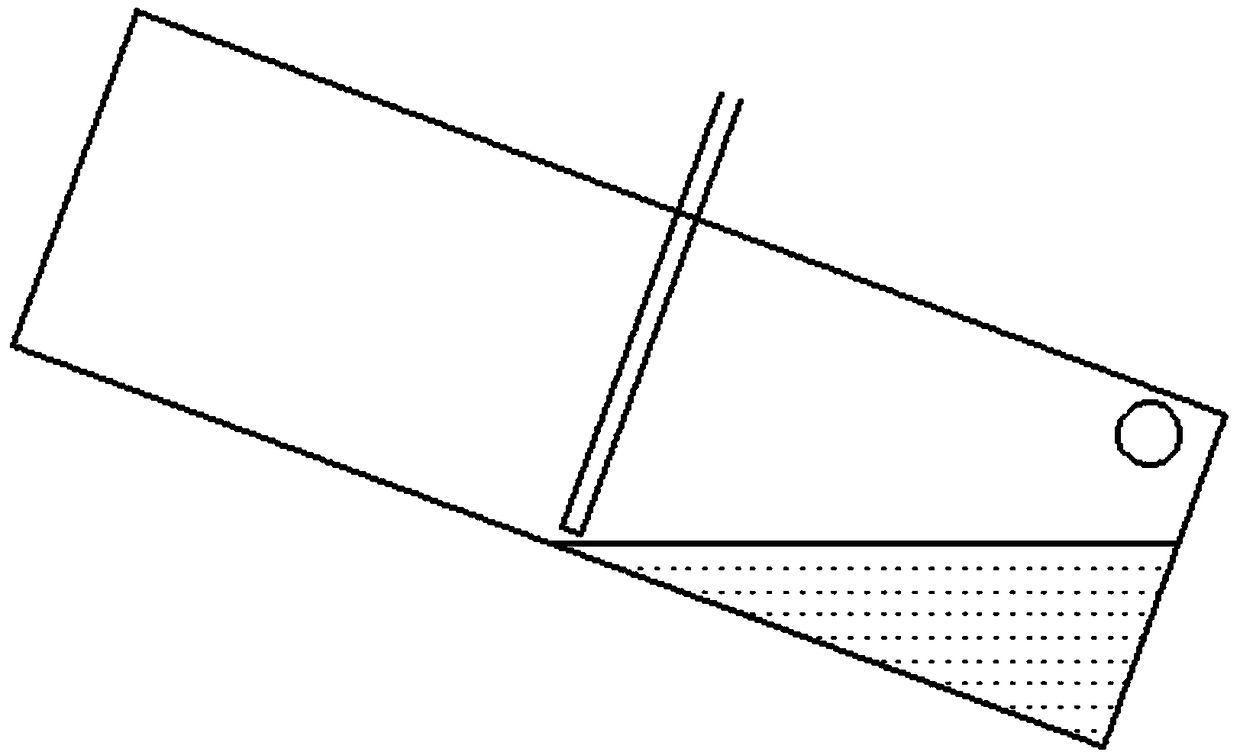

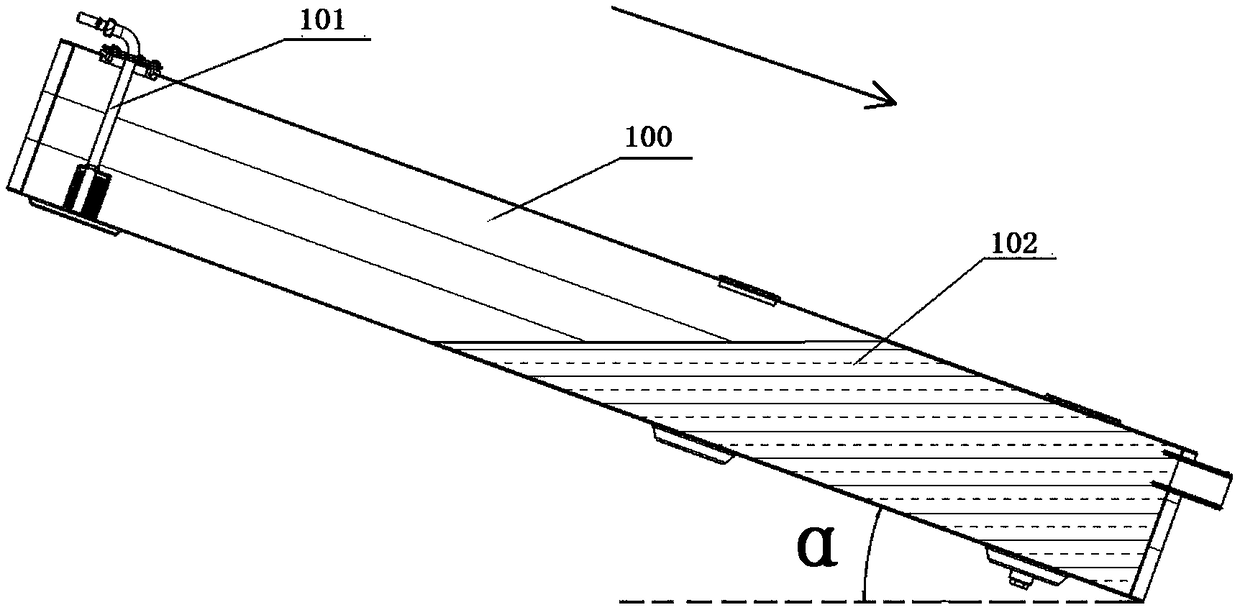

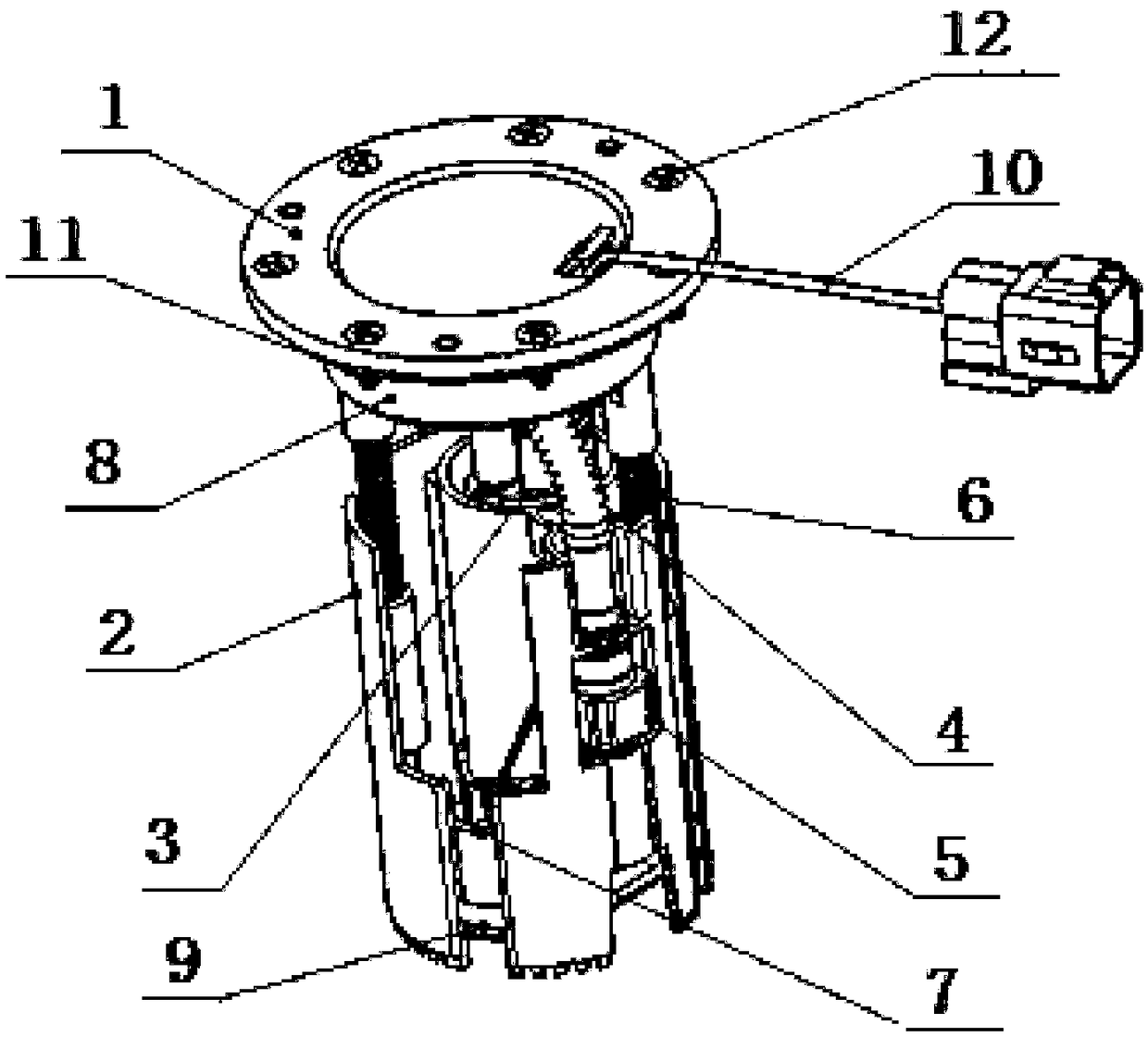

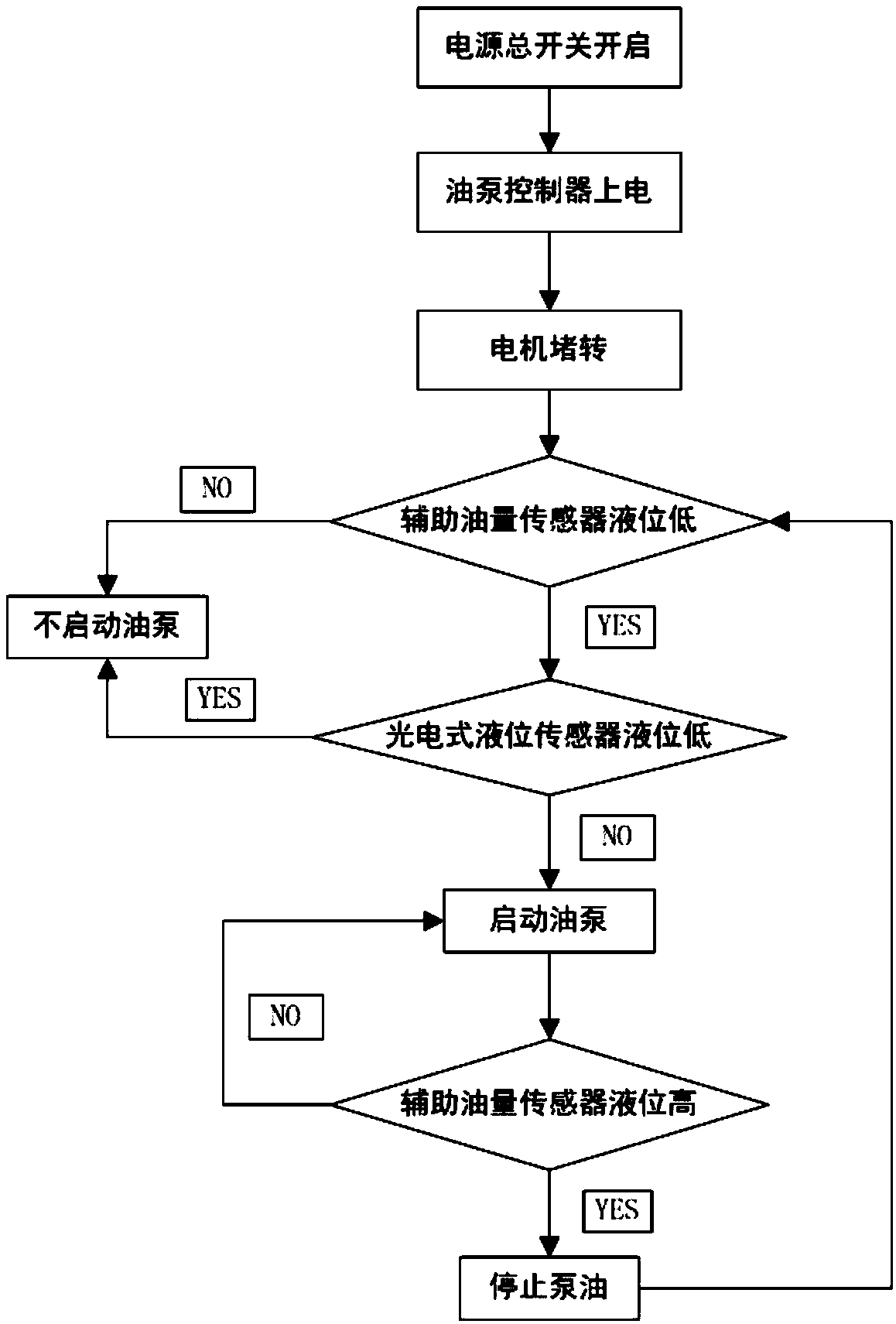

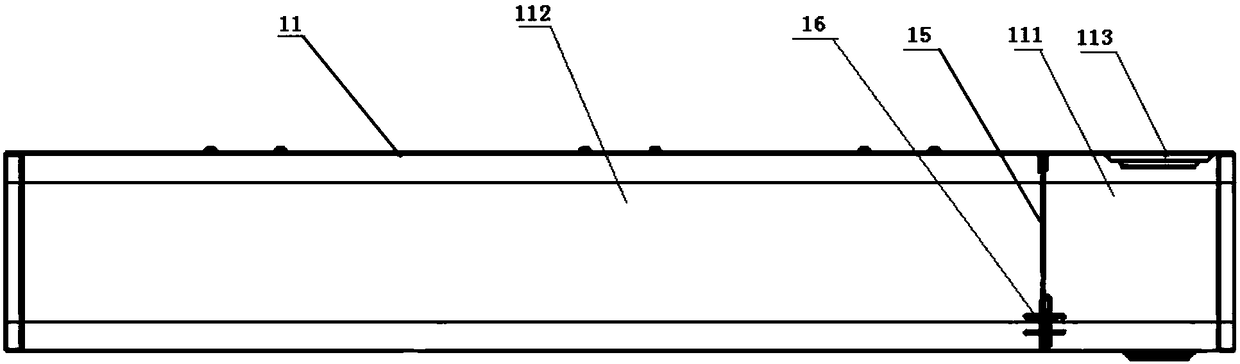

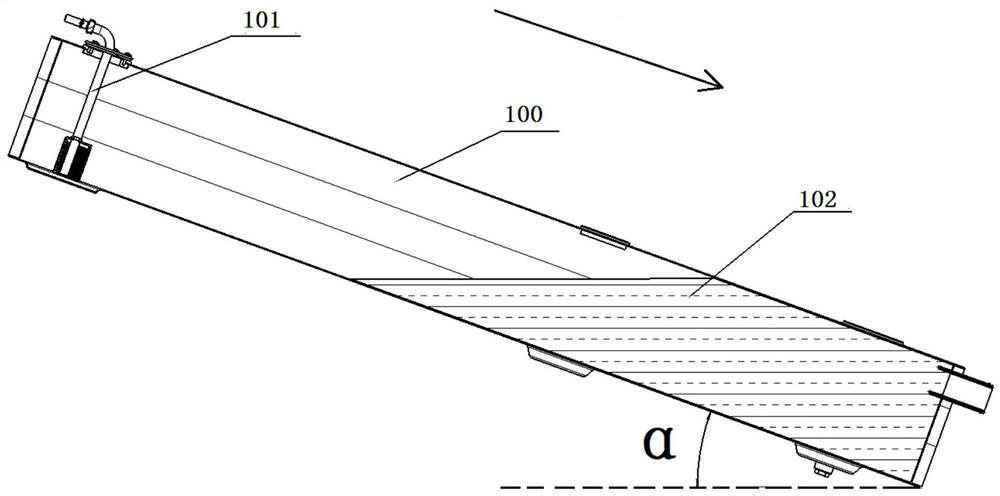

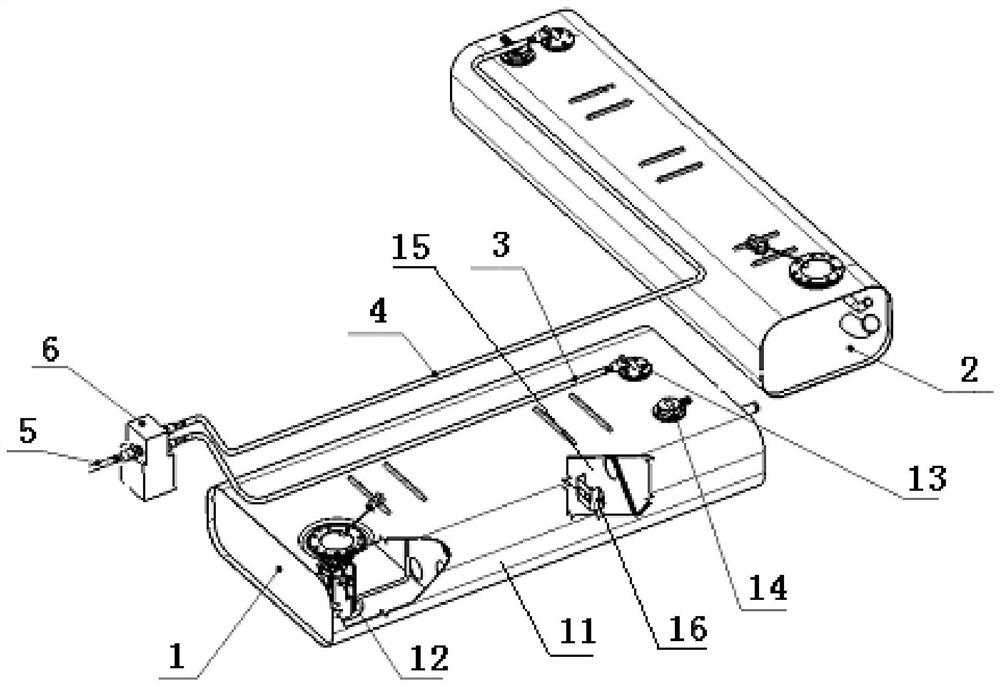

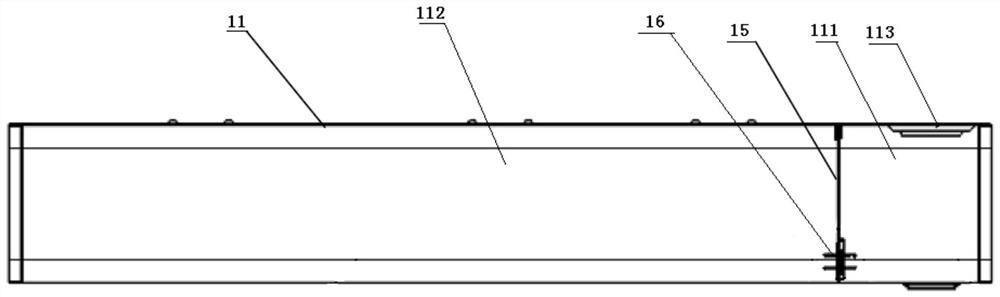

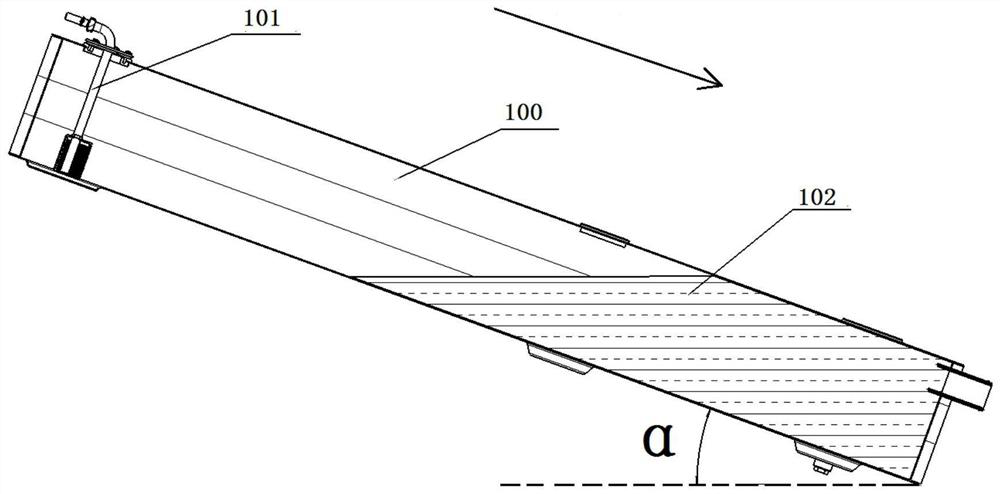

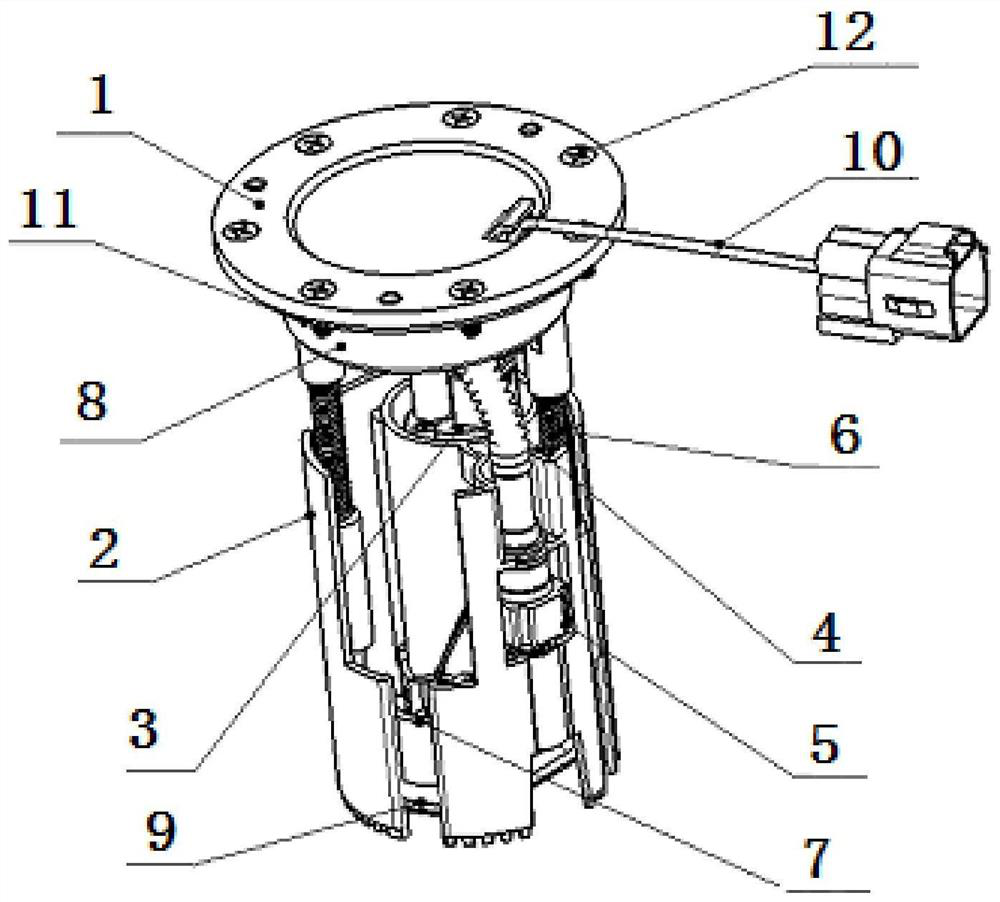

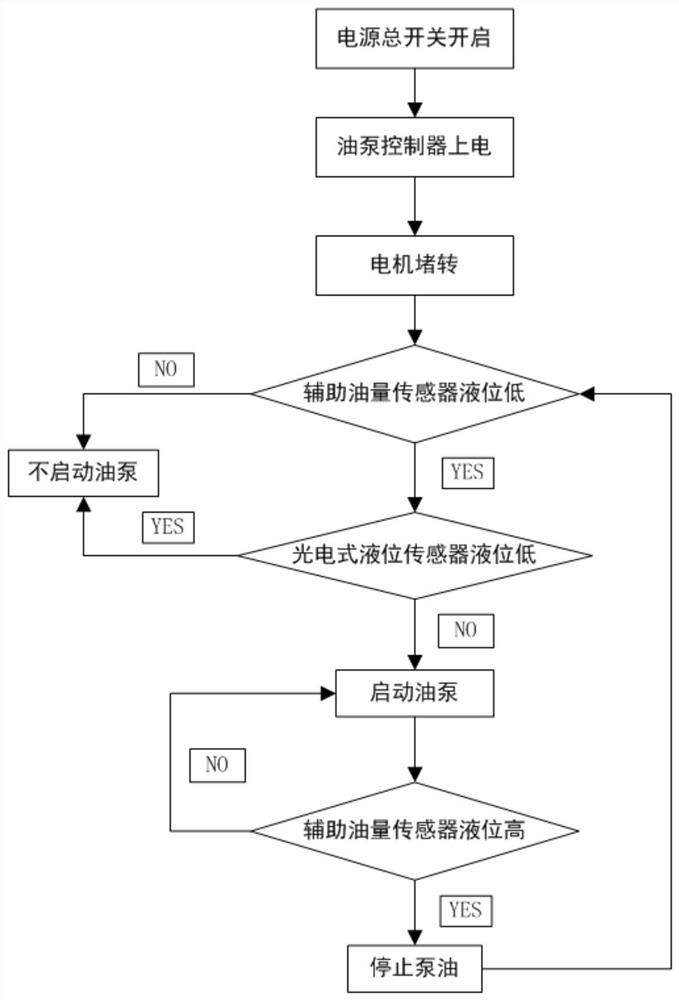

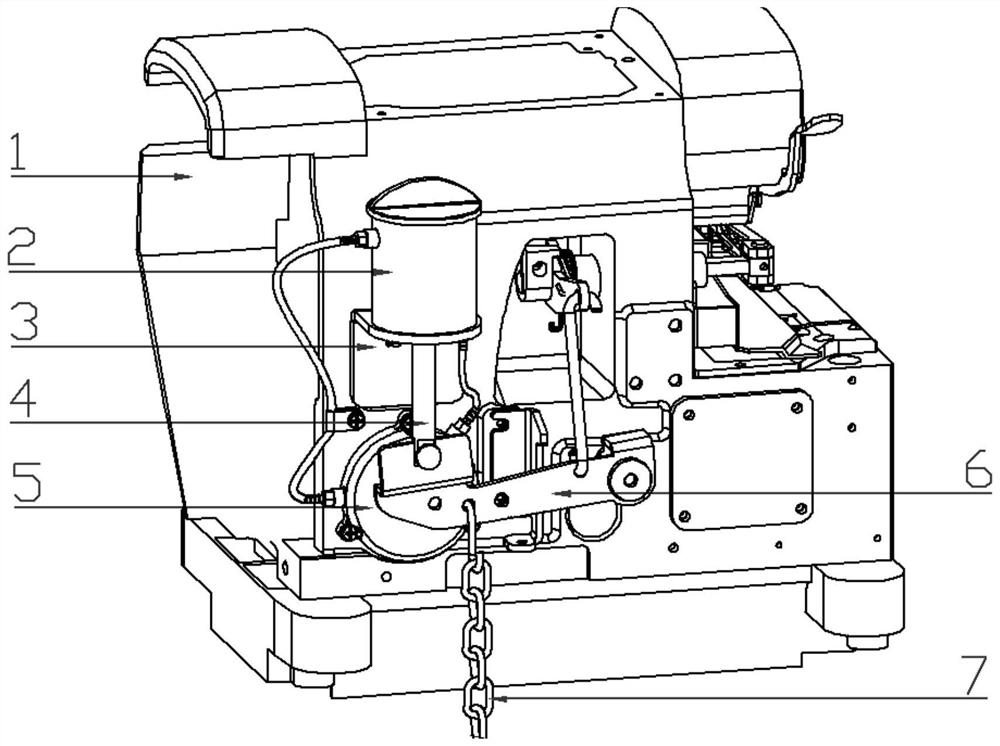

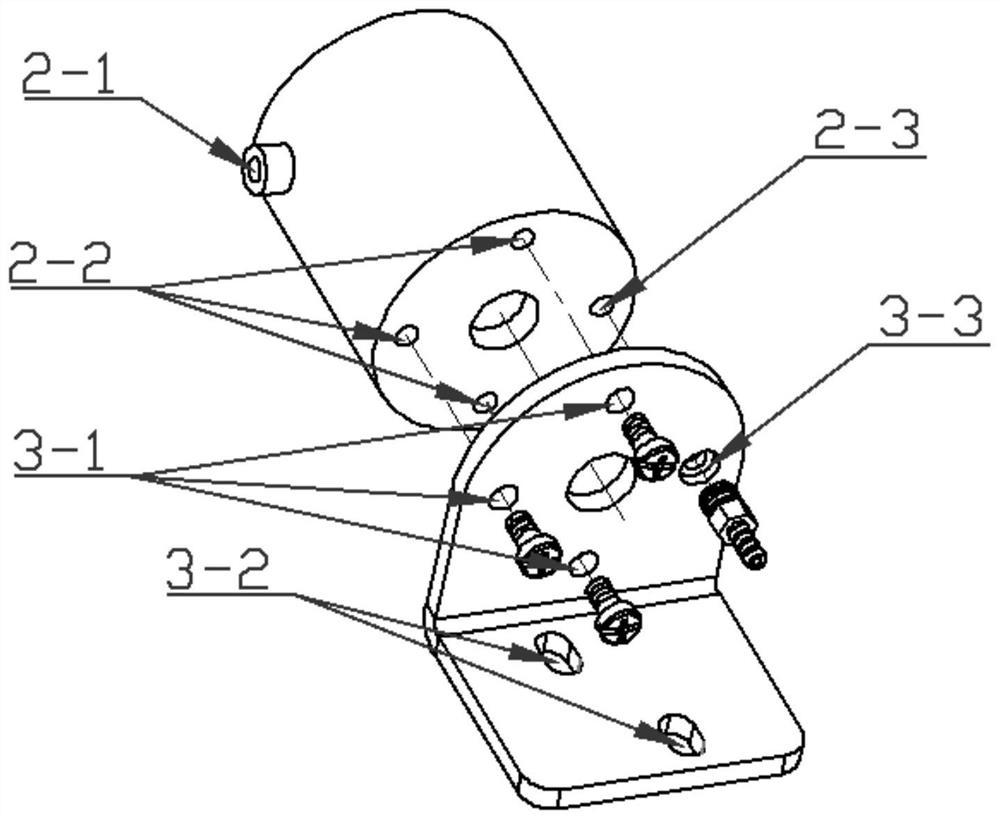

Diesel oil delivery pump assembly for gradient self-adaptation system

ActiveCN109113904AGuaranteed fuel supplyEasy to installMachines/enginesLiquid fuel feedersFuel oilSelf adaptive

The invention relates to an automobile oil delivery pump, in particular to a diesel oil delivery pump assembly for a gradient self-adaptation system. The oil delivery pump assembly comprises a flange,a shell and an oil delivery pump body. The oil delivery pump assembly is arranged in a fuel oil tank and located at the opposite end of an oil sucking pipe of the fuel oil tank, it can be guaranteedthat the position near the oil sucking pipe is always filled with fuel oil, and normal fuel oil supply of an engine is guaranteed. The oil delivery pump assembly is fixed to the fuel oil tank throughthe flange, the shell of the oil delivery pump assembly abuts against the interior of the bottom of the fuel oil tank, the bottom of the flange and the shell are connected through elastic connecting pipe columns, it can be guaranteed that the oil delivery pump assembly is firmly mounted in the fuel oil tank and does not shake at will along with operation of a vehicle, and under the condition thatthe plane rigidity of the metal fuel oil tank is poor, and the bottom of the metal fuel oil tank is uneven, the elastic connecting pipe columns can also compensate for the bottom unevenness of the fuel oil tank.

Owner:DONGFENG MOTOR CORP HUBEI

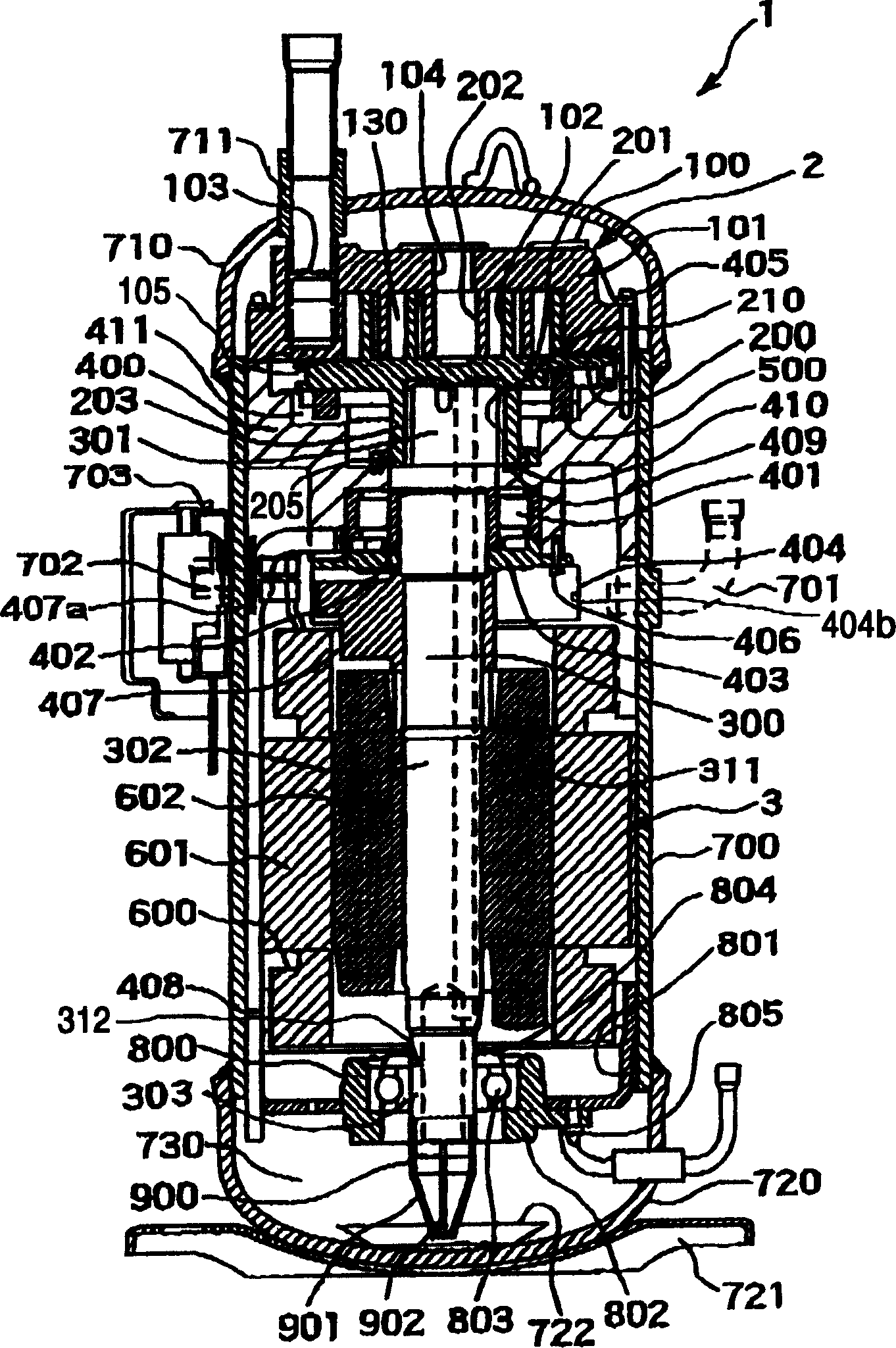

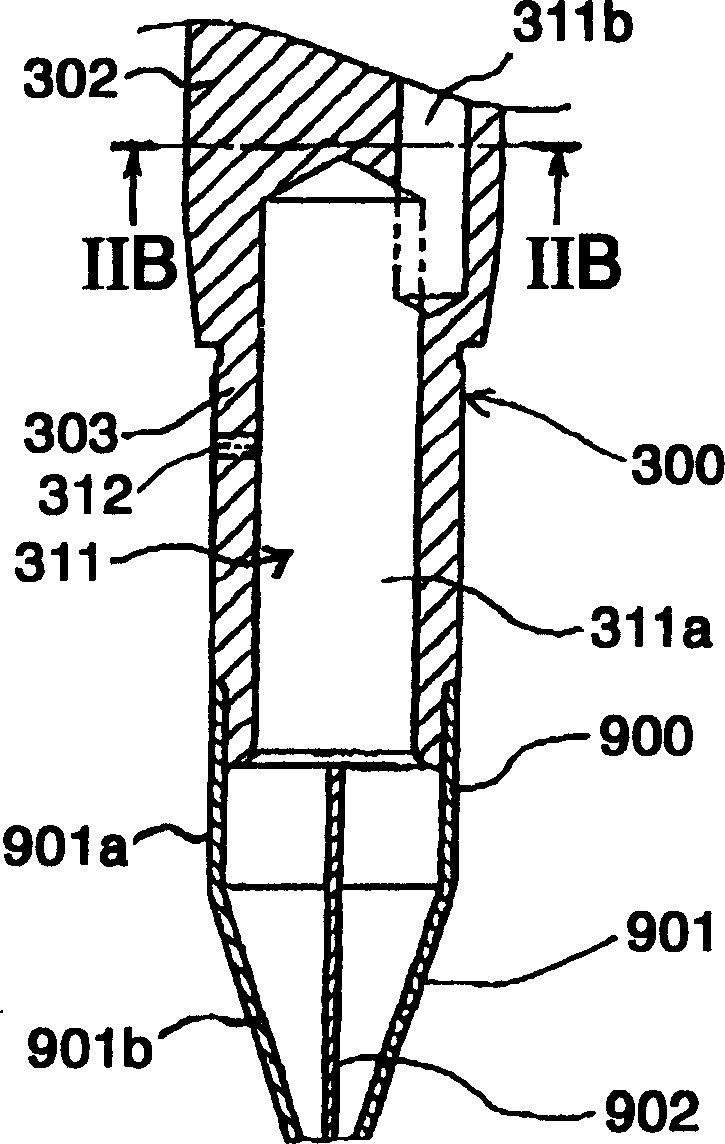

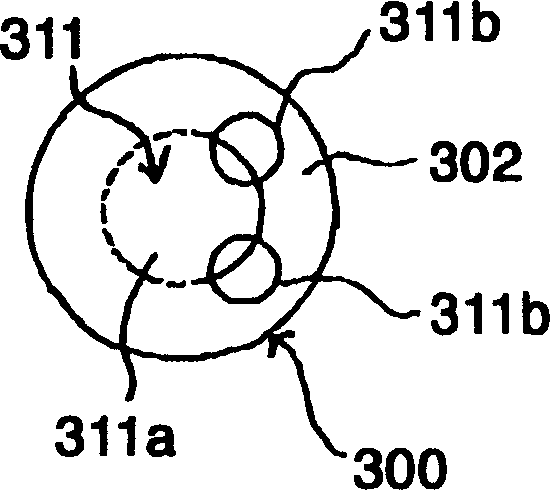

Fluid compressor

InactiveCN1616828AGuaranteed fuel supplyImprove reliabilityRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsEngineeringCentrifugal pump

A fluid compressor, a fluid compressor (1), comprising: a rotating shaft (300) having a compression mechanism (2) and an oil passage (311), an electric motor (600), bearings (401, 803), and an oil passage (311) Centrifugal pump section (900) for oil supply. The rotating shaft (300) has a main shaft part (302), a crank pin (301) eccentrically arranged on the main shaft part (302), and an auxiliary bearing support part (303) smaller in diameter than the main shaft part (302). The oil passage (311) has a first oil passage (311a) extending from the lower end of the auxiliary bearing support part (303) to the lower part of the main shaft part (302), and communicates with the first oil passage (311a) and extends to the crank The second oil passage (311b) at the upper end of the pin (301). The second oil passage (311b) has a diameter smaller than that of the first oil passage (311a), has an outer passage portion, and is formed in plural within the plane range of the crank pin (301).

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

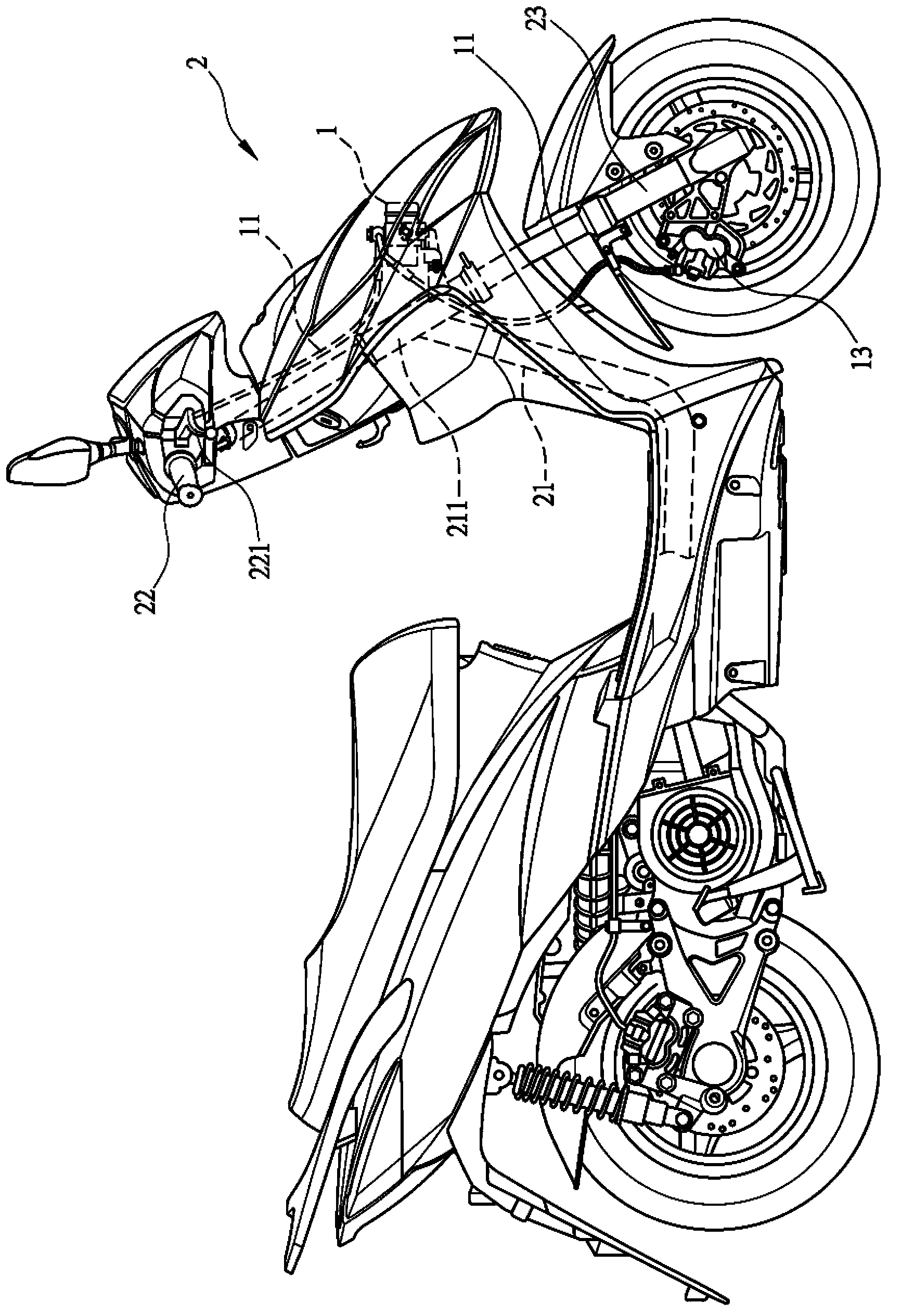

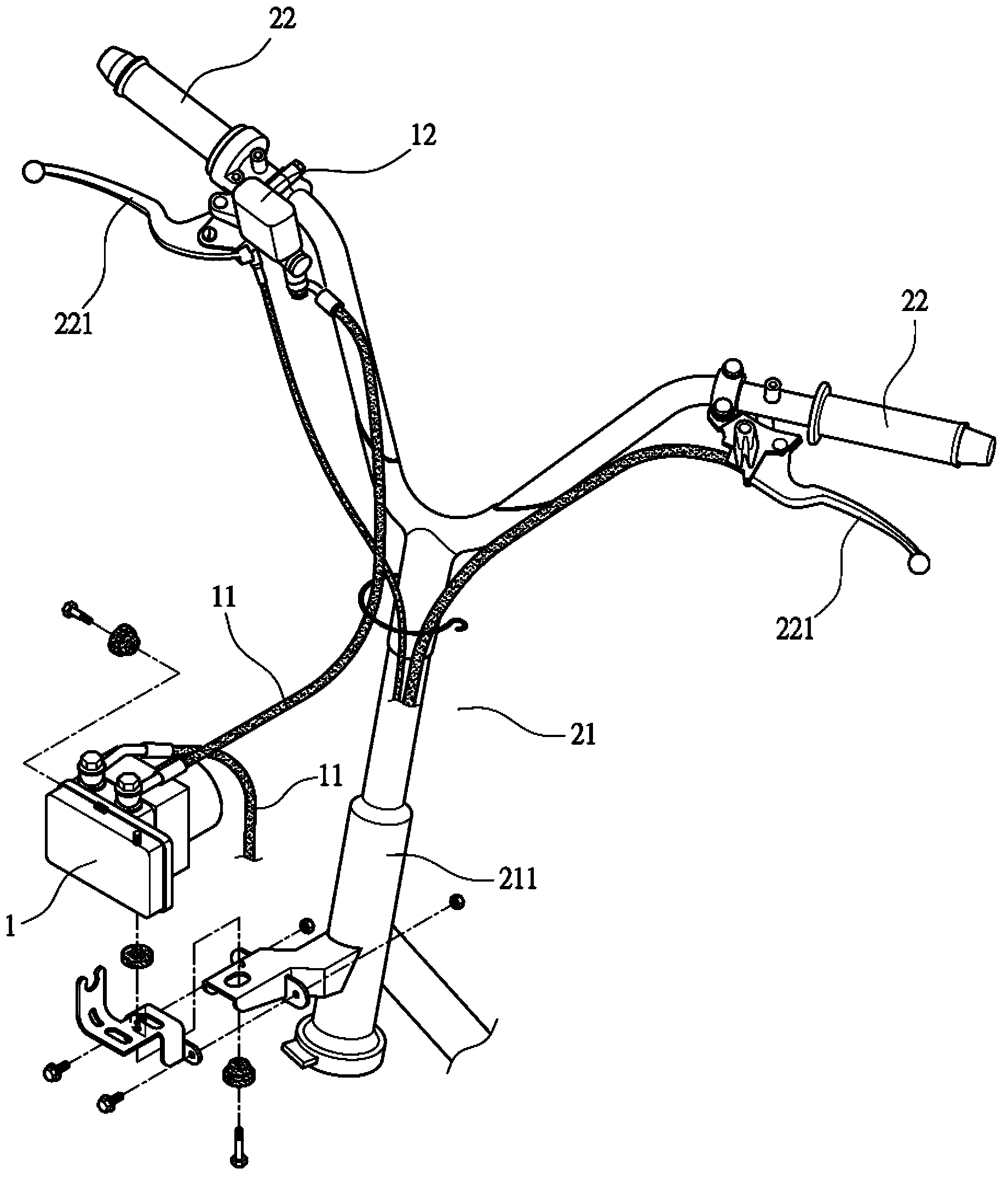

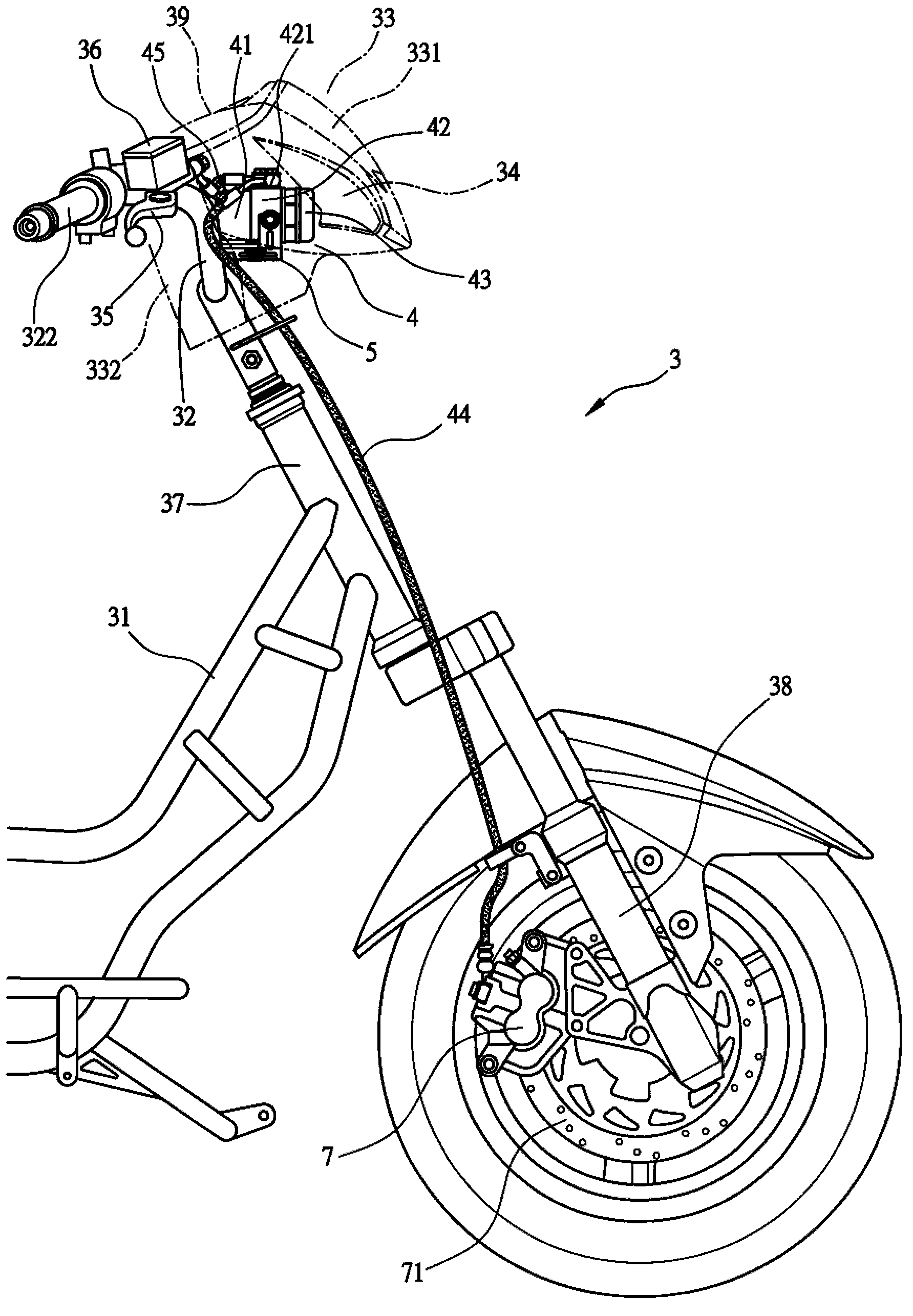

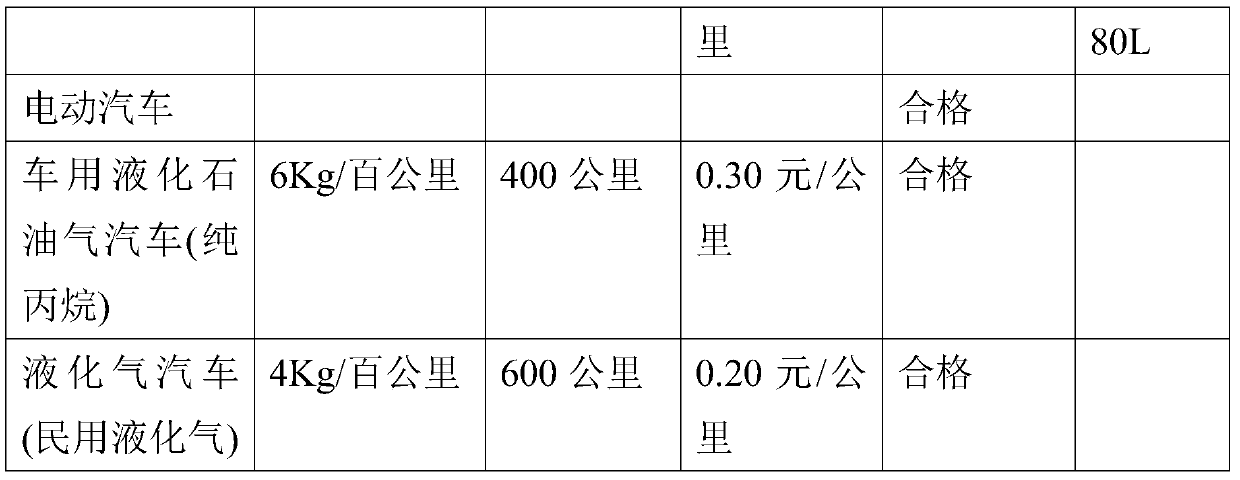

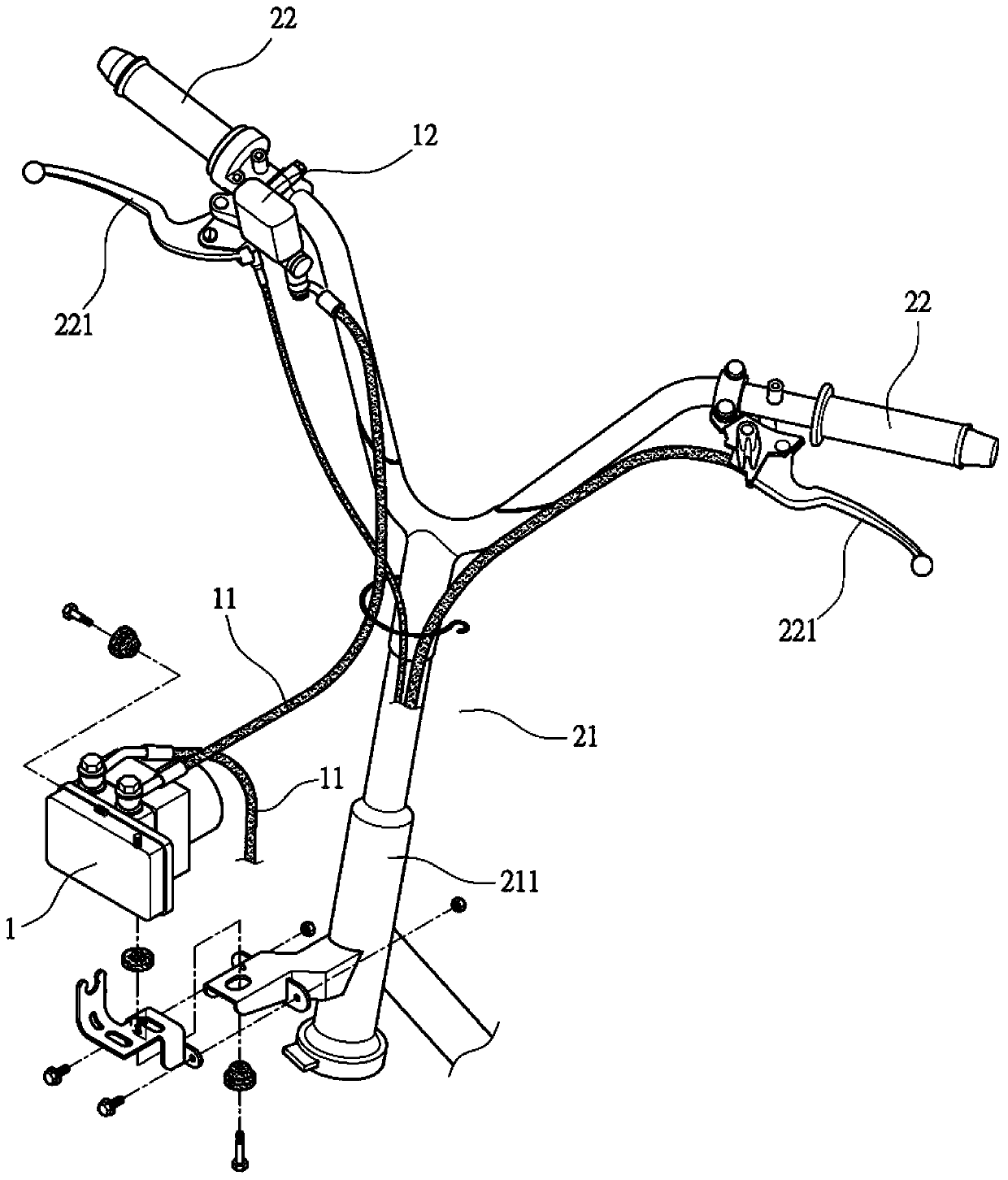

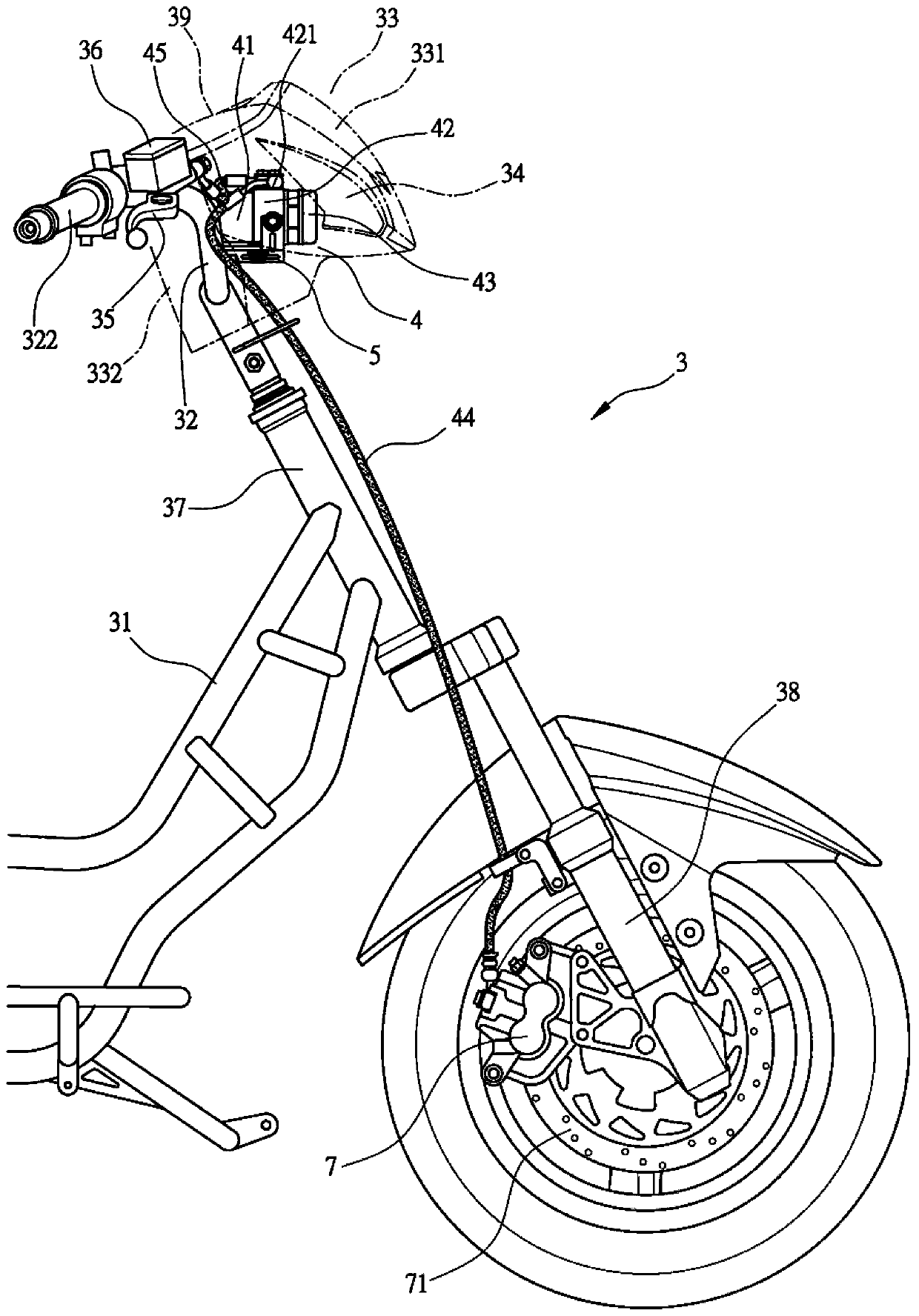

Motorcycle antiskid brake system structure

The invention provides a motorcycle antiskid brake system structure which comprises a motorcycle frame unit and steering handles. The handles are arranged on a motorcycle head cover in a covering mode. The motorcycle head cover is provided with a console. The handles are provided with an antiskid brake system unit. The holding parts of the handles are provided with braking pull handles and a brake oil pump. The system unit comprises a power motor, a brake body and a controller. The power motor and the controller are connected to the brake body. The brake body is provided with a brake oil pipe combination part. The combination part is connected with disc brake calipers and the brake oil pump respectively through a disc brake calipers oil pipe and a brake oil pump oil pipe. The system unit is fixed to the concave parts of the handles through a support and is covered by the motorcycle head cover. By means of the motorcycle antiskid brake system structure, the disc brake calipers oil pipe can be connected to the disc brake calipers directly downwards from the handles, and even dispersion is conducted through the disc brake calipers oil pipe longer in length in the bending process of the disc brake calipers oil pipe. Losses caused by excessively bending of the disc brake calipers oil pipe are avoided, the oil supply quantity of the disc brake calipers oil pipe is guaranteed, and the system unit is actually made to control the disc brake calipers to act.

Owner:KYMCO

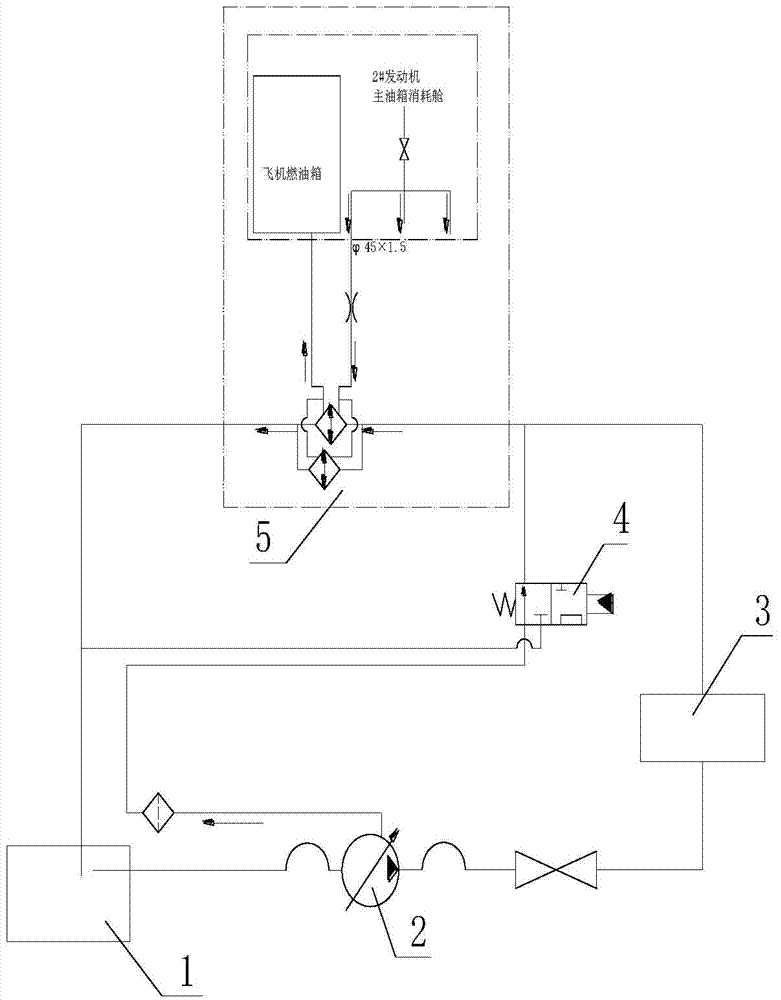

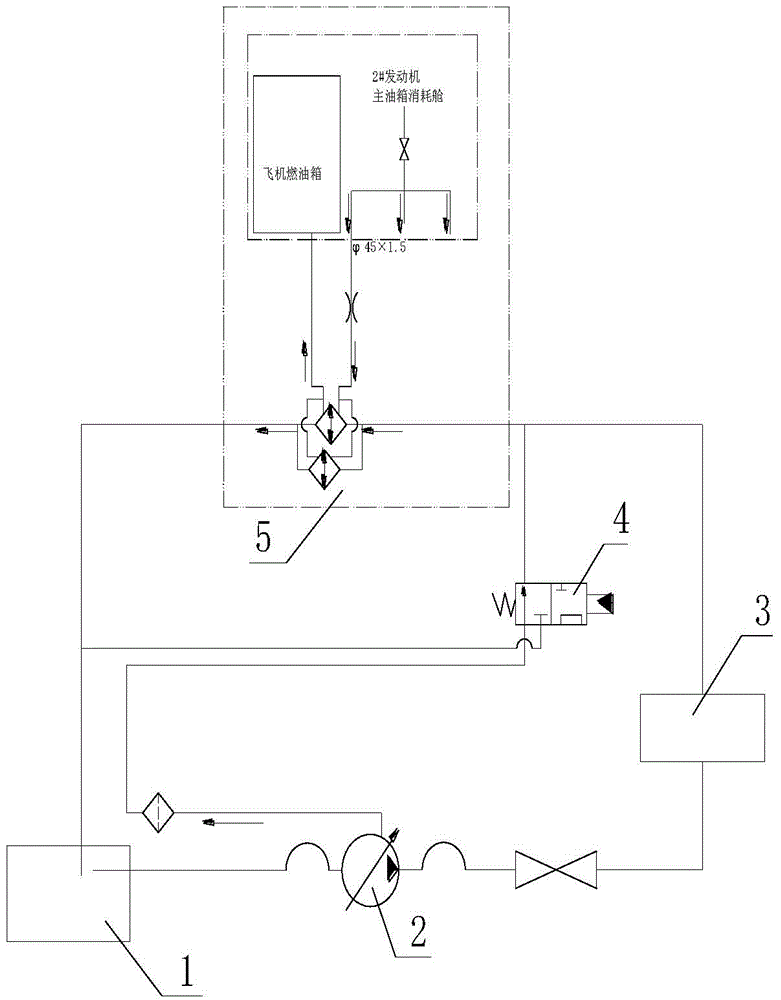

Method for adjusting return oil pressure of hydraulic pump shell

ActiveCN103527564AGuaranteed to workImprove cooling effectFluid-pressure actuator testingFluid-pressure actuator componentsAviationHydraulic pump

The invention belongs to the technical field of aviation, and relates to an engine aerial test hydraulic load simulating device, in particular to a method for adjusting return oil pressure of a hydraulic pump shell. According to the method for adjusting the return oil pressure of the hydraulic pump shell, return oil of the hydraulic pump shell returns to a hydraulic oil tank through different pipelines by powering on and powering off of an electromagnetic directional valve under limited conditions in an engine aerial test, and it is ensured that the return oil pressure of the hydraulic pump shell meets the requirement for work of a hydraulic pump.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

A method for adjusting the oil return pressure of a hydraulic pump casing

ActiveCN103527564BGuaranteed to workImprove cooling effectFluid-pressure actuator testingFluid-pressure actuator componentsAviationHydraulic pump

The invention belongs to the technical field of aviation, and relates to an engine aerial test hydraulic load simulating device, in particular to a method for adjusting return oil pressure of a hydraulic pump shell. According to the method for adjusting the return oil pressure of the hydraulic pump shell, return oil of the hydraulic pump shell returns to a hydraulic oil tank through different pipelines by powering on and powering off of an electromagnetic directional valve under limited conditions in an engine aerial test, and it is ensured that the return oil pressure of the hydraulic pump shell meets the requirement for work of a hydraulic pump.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

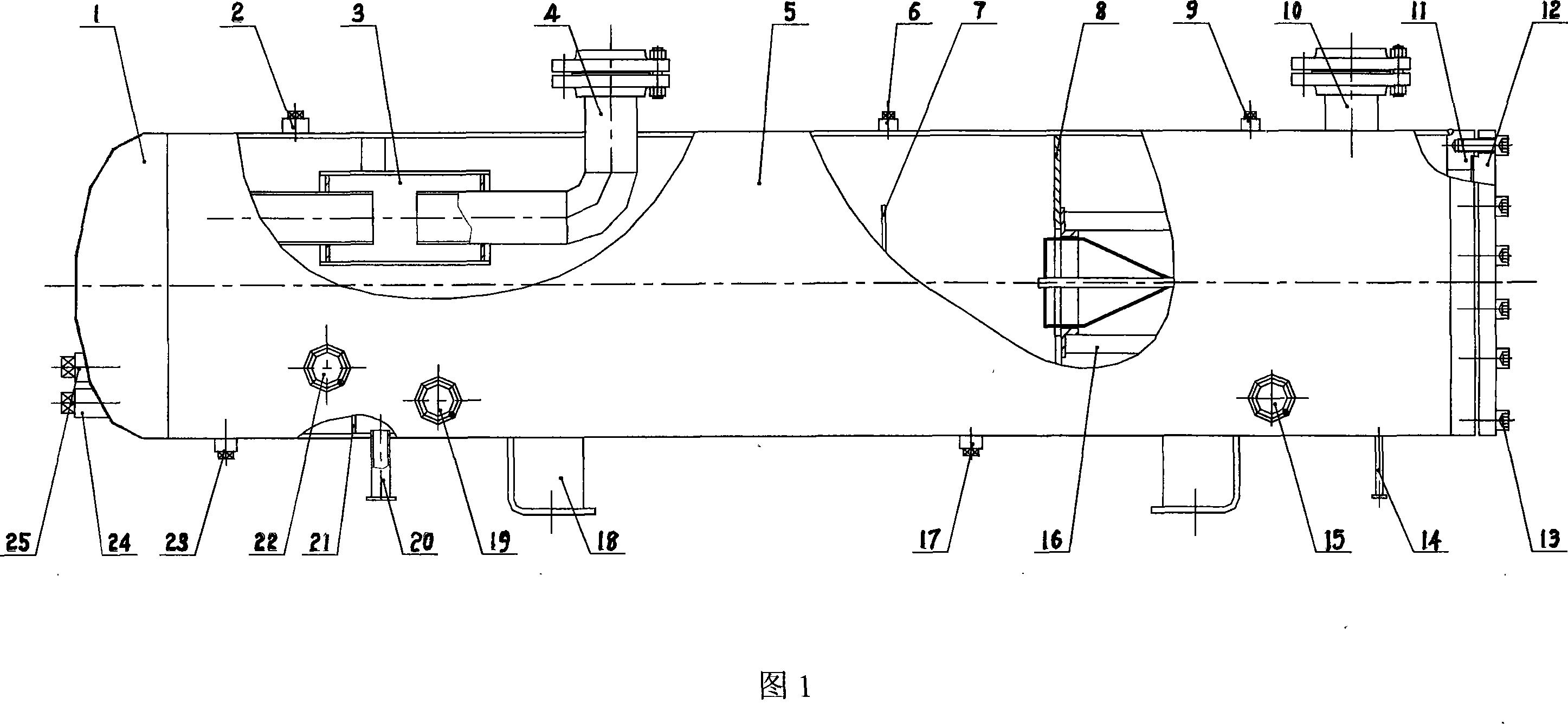

Oil separator for freon

InactiveCN101126568AImprove separation efficiencyGuaranteed lubrication effectRefrigeration componentsOil separationFreon

The utility model discloses a Freon oil separator, wherein, the internal end of an air inlet pipe (4) is connected with a silencer (3); the front end of the silencer (3) is towards to a gland (1); an electric heater interface (24) and an oil switch interface (25) are positioned on the gland (1); the oil switch interface (25) is arranged on the top of the electric heater interface (24). Engine oil separation efficiency is increased from 2000 ppm in the past to 20 ppm now.

Owner:YANTAI MOON

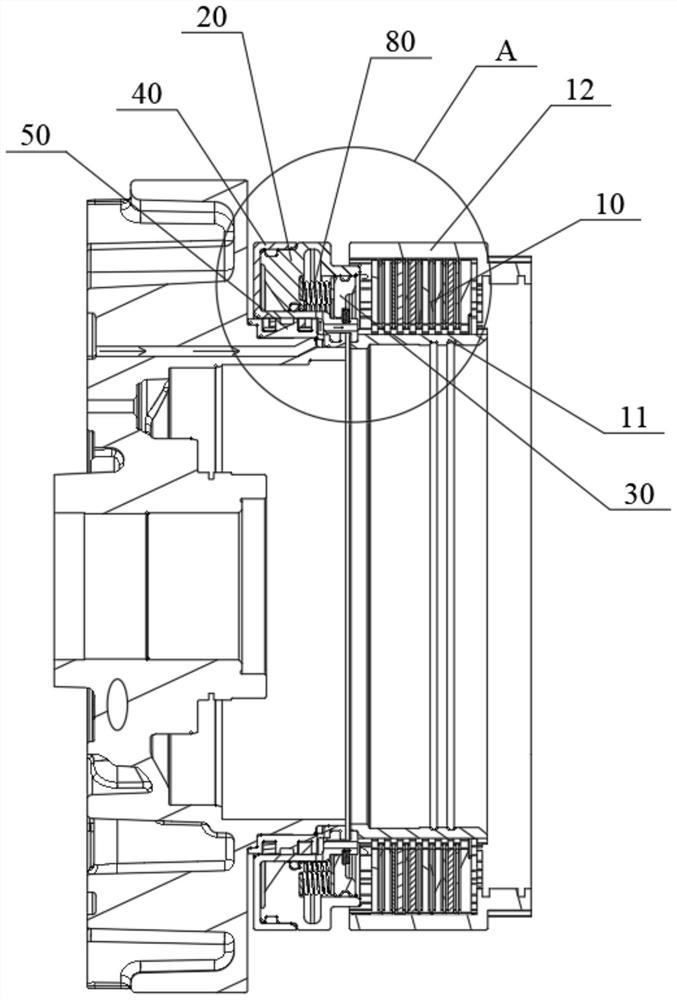

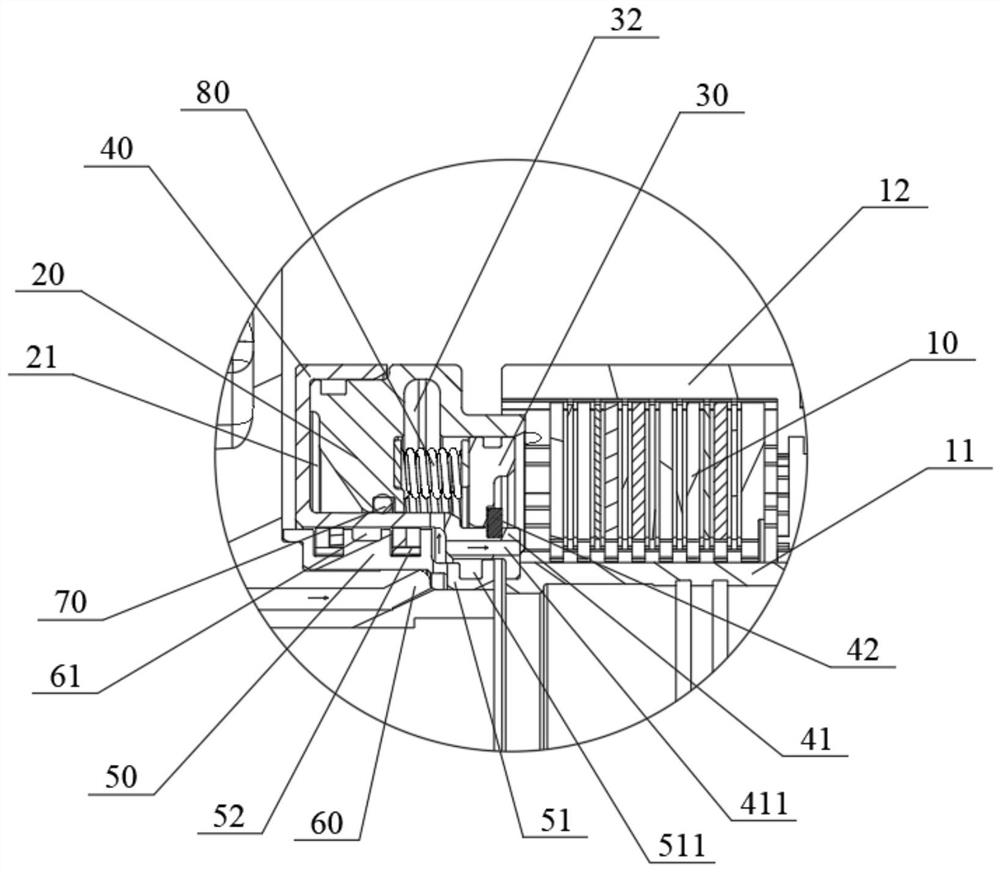

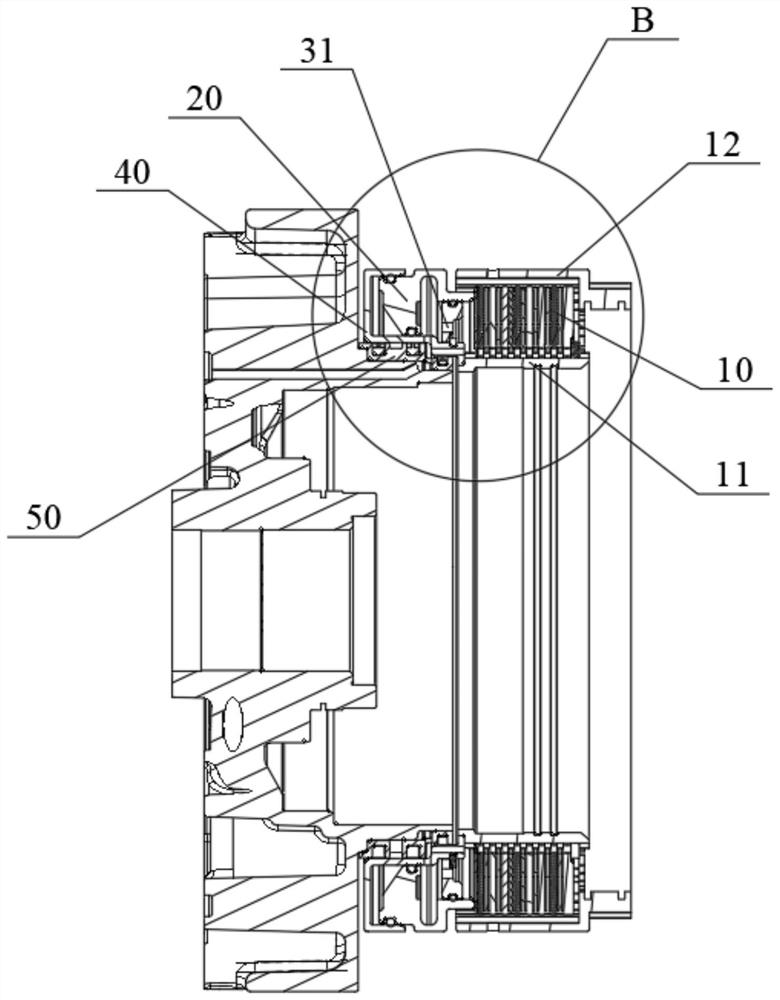

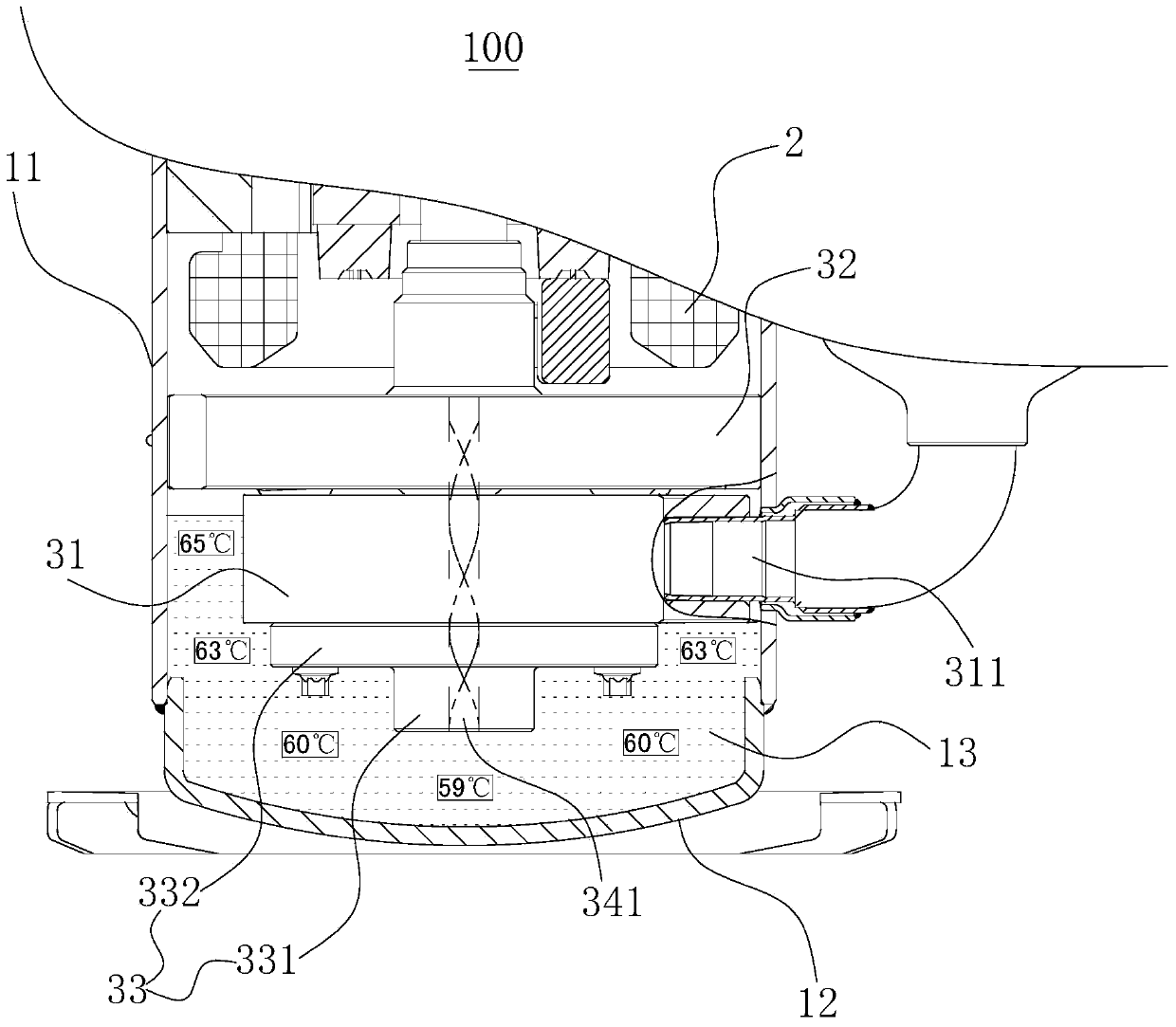

Starting clutch for transmission

PendingCN111609050AImprove replenishment efficiencyReduce the temperaturePiston ringsFluid actuated clutchesAutomatic transmissionEngineering

The invention relates to the technical field of automatic transmissions, and provides a starting clutch for a transmission. The starting clutch comprises a piston device and a friction device. The friction device comprises a friction plate set, an inner hub and an outer hub. An oil cavity is formed between the inner hub and the friction plate set. The piston device comprises a main piston and a balance piston, and a balance piston cavity is formed between the main piston and the balance piston. The main piston is arranged on a piston support. The piston support is provided with an oil supply part, an oil supply channel is formed in the oil supply part, a sealing steel sleeve is arranged on the inner side of the piston support, and the sealing steel sleeve is provided with a sealing part. When oil is supplied, part of hydraulic oil enters the balance piston cavity through a first oil way, the other part of the hydraulic oil directly enters the oil cavity of the friction plate set, and the supplementing efficiency of the hydraulic oil is improved; the sealing steel sleeve extends to the inner side of the oil supply part, and a first sealing element is arranged, so that the hydraulicoil is prevented from flowing away from the gap of the clutch, and waste of the hydraulic oil is avoided; and meanwhile, the oil supply amount of the friction plate set is ensured.

Owner:SHENGRUI TRANSMISSION

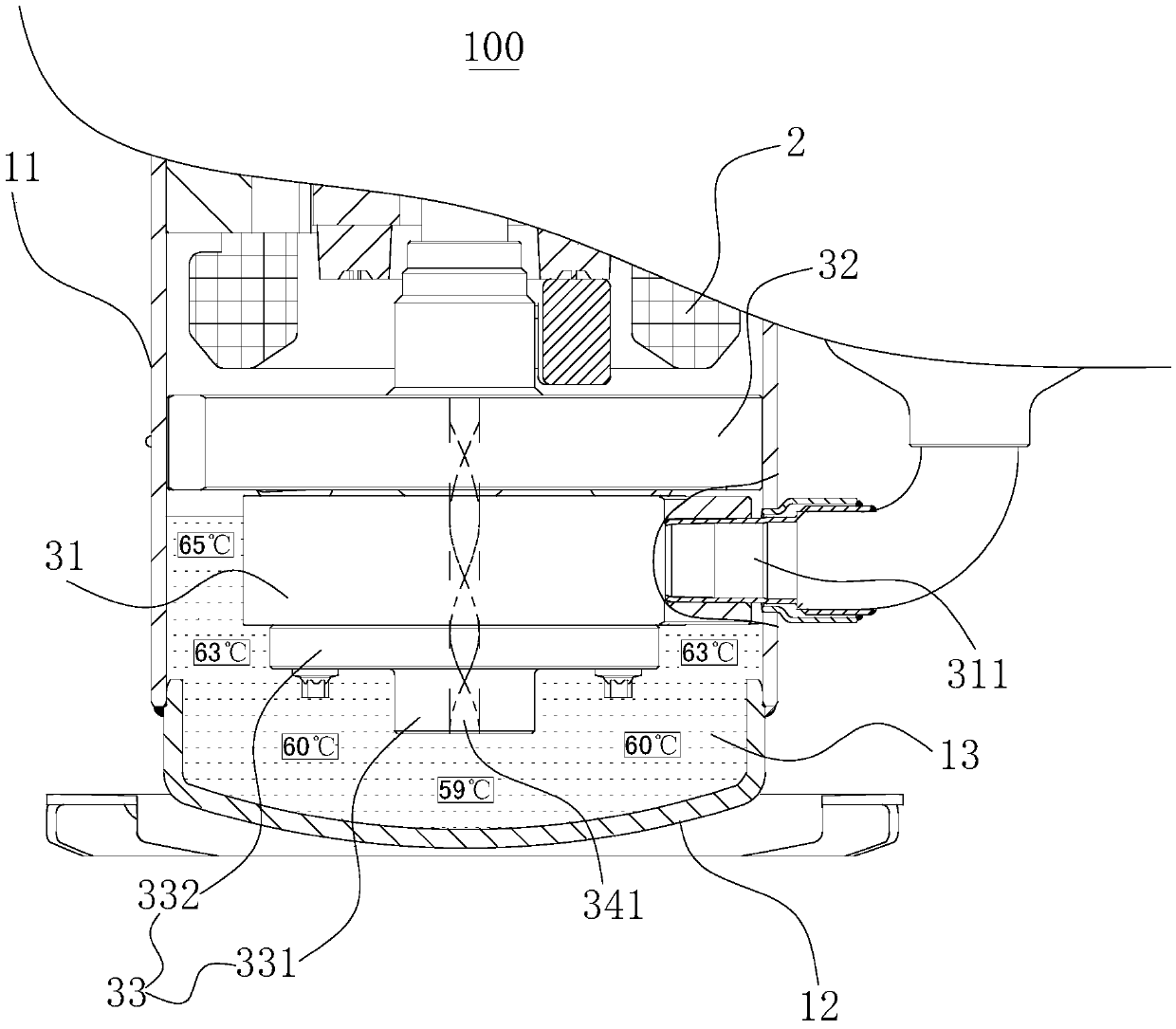

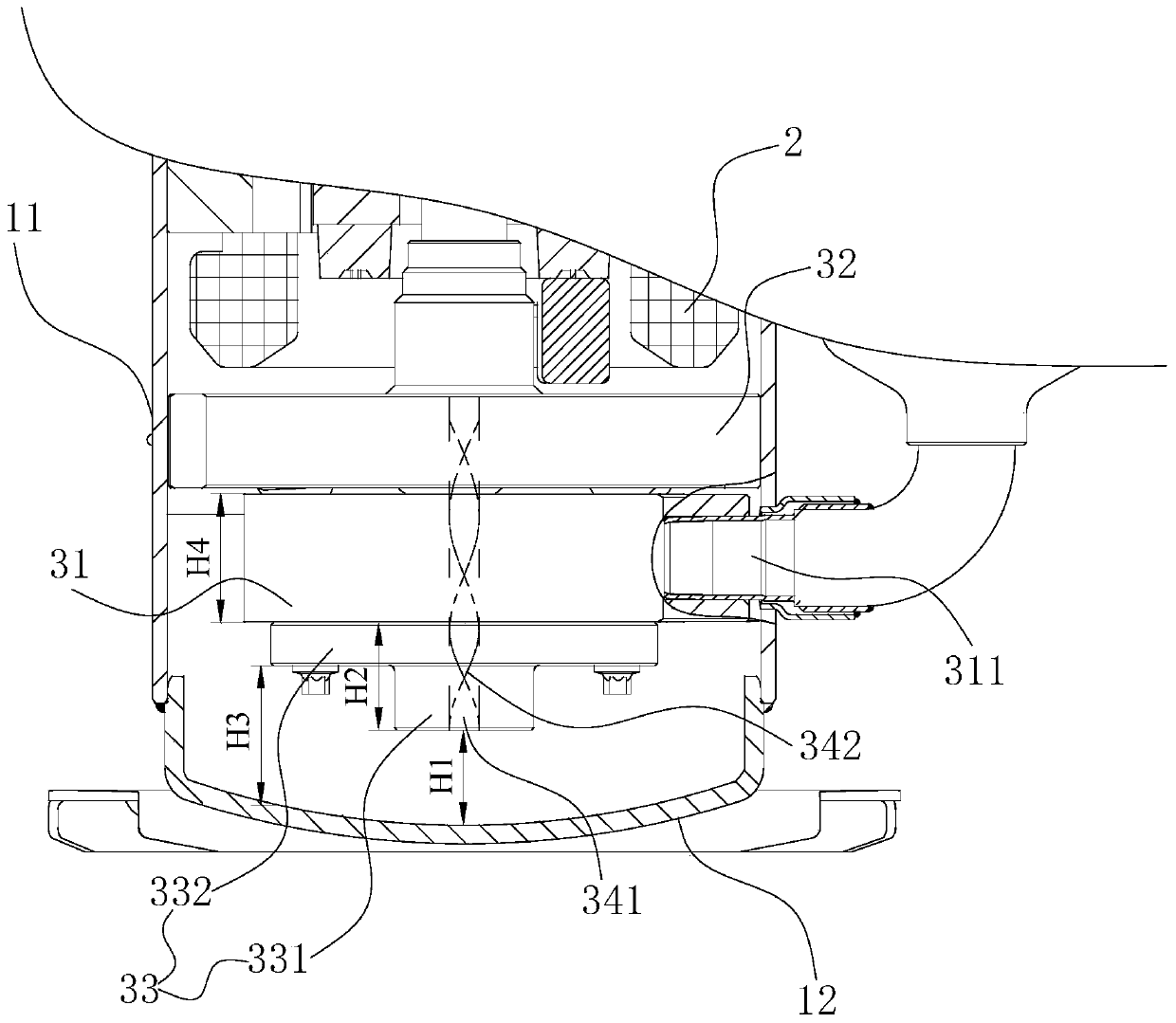

Rotary compressor

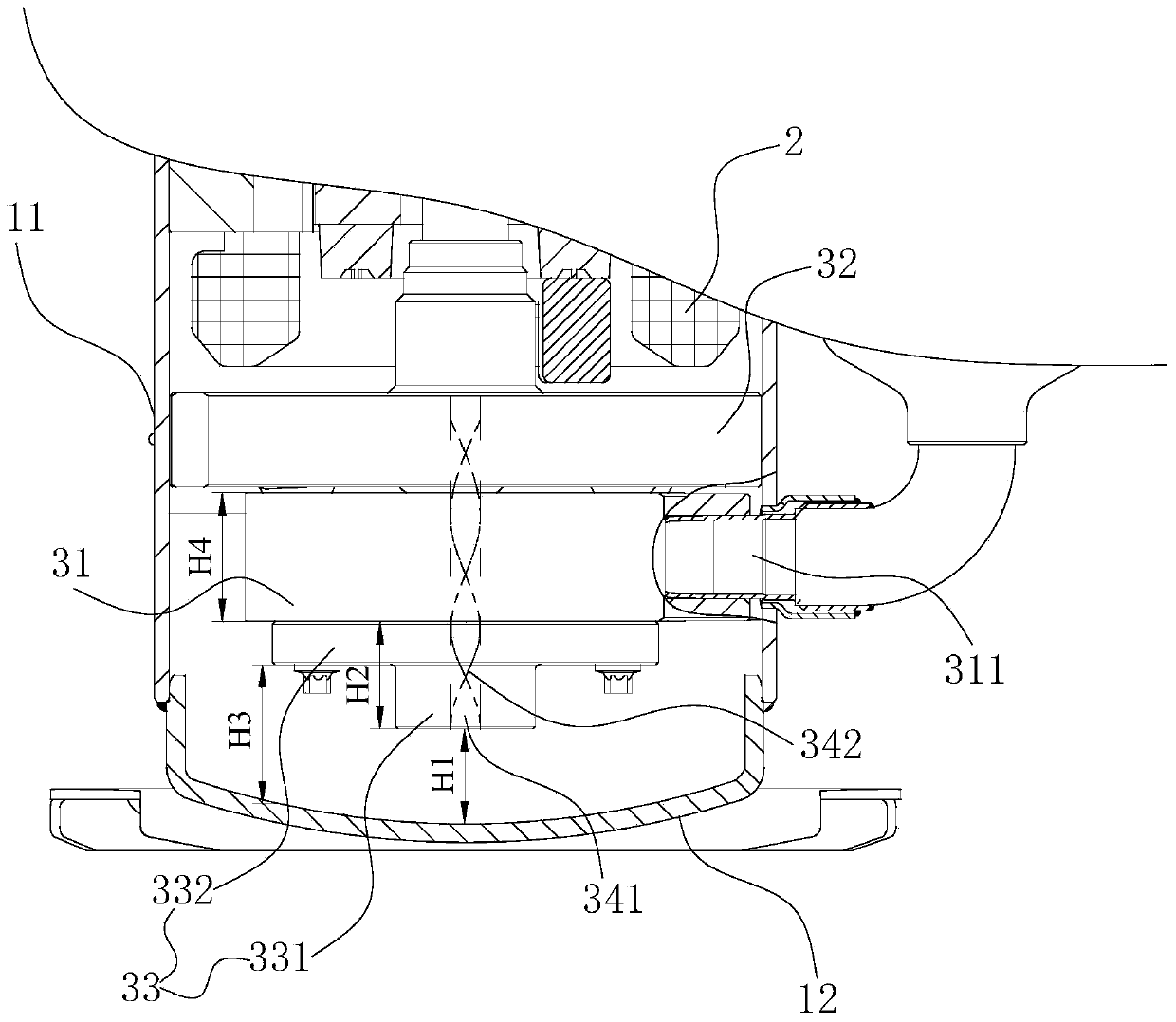

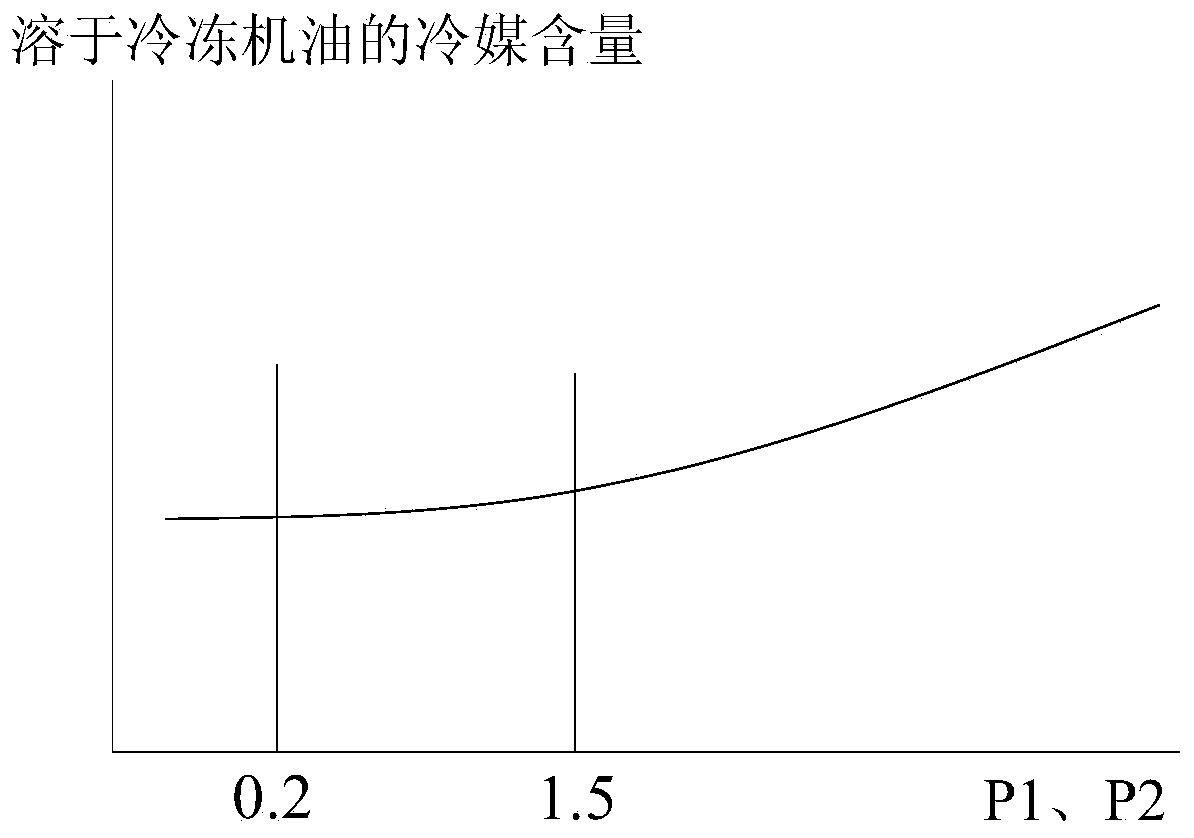

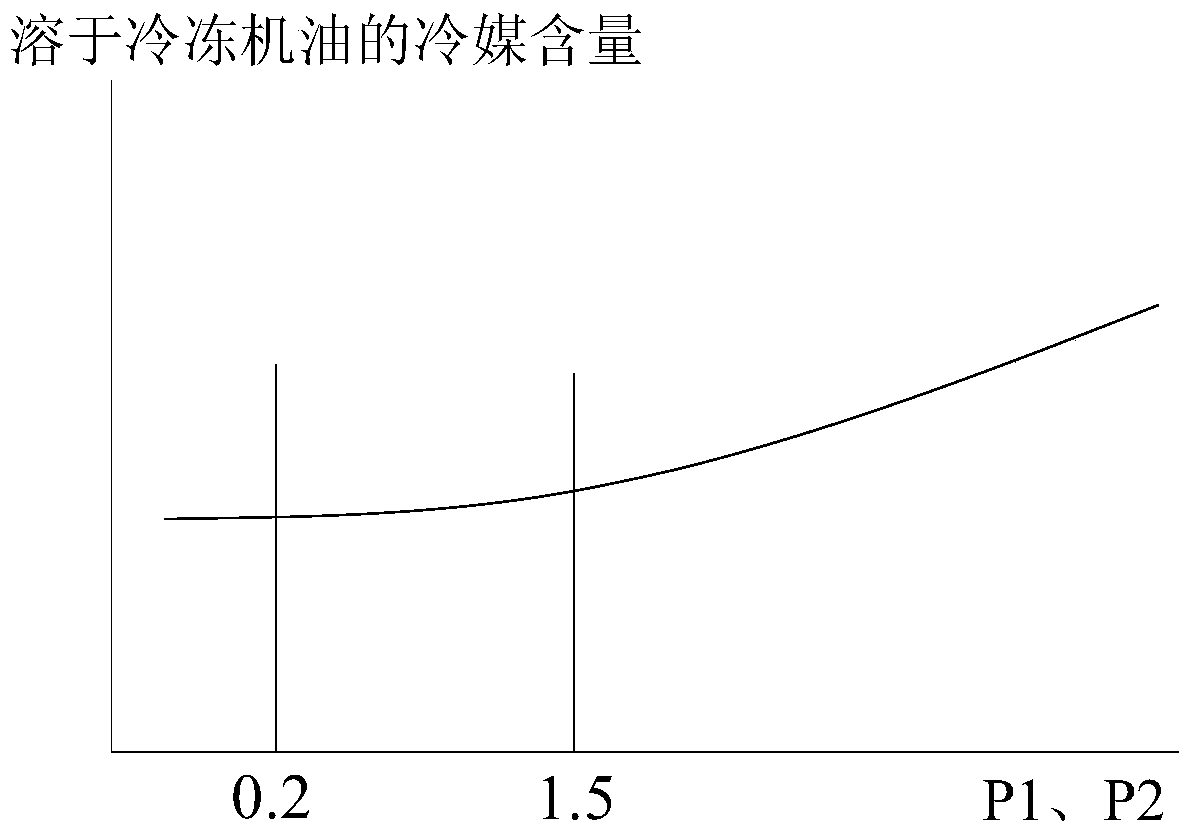

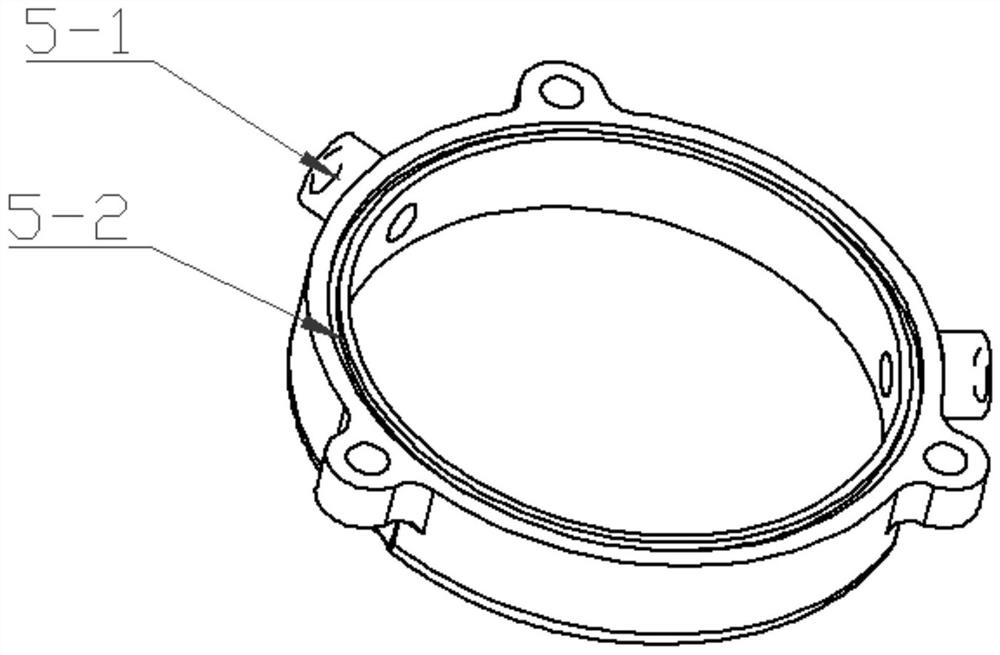

InactiveCN104196726AGuaranteed fuel supplyGuaranteed qualityRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsEngineeringOil quality

The invention discloses a rotary compressor comprising a shell, a motor and a compressing mechanism, wherein the shell comprises a lower shell assembly; the compressing mechanism comprises a main bearing, an air cylinder and an auxiliary bearing assembly; the auxiliary bearing assembly comprises an auxiliary bearing comprising a hub part and a flange part; when the delivery volume V of a compression chamber is smaller than 13cm<3> / rev, 0.1<=P1 / P2<=1.2; when 13cm<3> / rev<=V<=24cm<3> / rev, 0.1<=P1 / P2<=1.5; when V>24cm<3> / rev, 0.1<=P1 / P2<=2; and P1=H1 / H2, P2=H3 / H4, H1 represents for a vertical distance from the center of the lower surface of the hub part to the lower shell assembly, H3 represents for a vertical distance from the edge of the lower surface of the flange part to the lower shell assembly, and H2 and H4 respectively represent for the heights of the auxiliary bearing assembly and the air cylinder. According to the rotary compressor disclosed by the invention, the quantity of a refrigerant which is stored in an oil pool and is dissolved into refrigerating machine oil can be reduced, the dissolution viscosity of the refrigerating machine oil is increased, and the oil supply and supplied oil quality of the rotary compressor are ensured.

Owner:GUANGDONG MEIZHI COMPRESSOR

Oil separator for Freon

InactiveCN100473923CImprove separation efficiencyGuaranteed lubrication effectRefrigeration componentsOil separationFreon

The utility model discloses a Freon oil separator, wherein, the internal end of an air inlet pipe (4) is connected with a silencer (3); the front end of the silencer (3) is towards to a gland (1); an electric heater interface (24) and an oil switch interface (25) are positioned on the gland (1); the oil switch interface (25) is arranged on the top of the electric heater interface (24). Engine oil separation efficiency is increased from 2000 ppm in the past to 20 ppm now.

Owner:YANTAI MOON

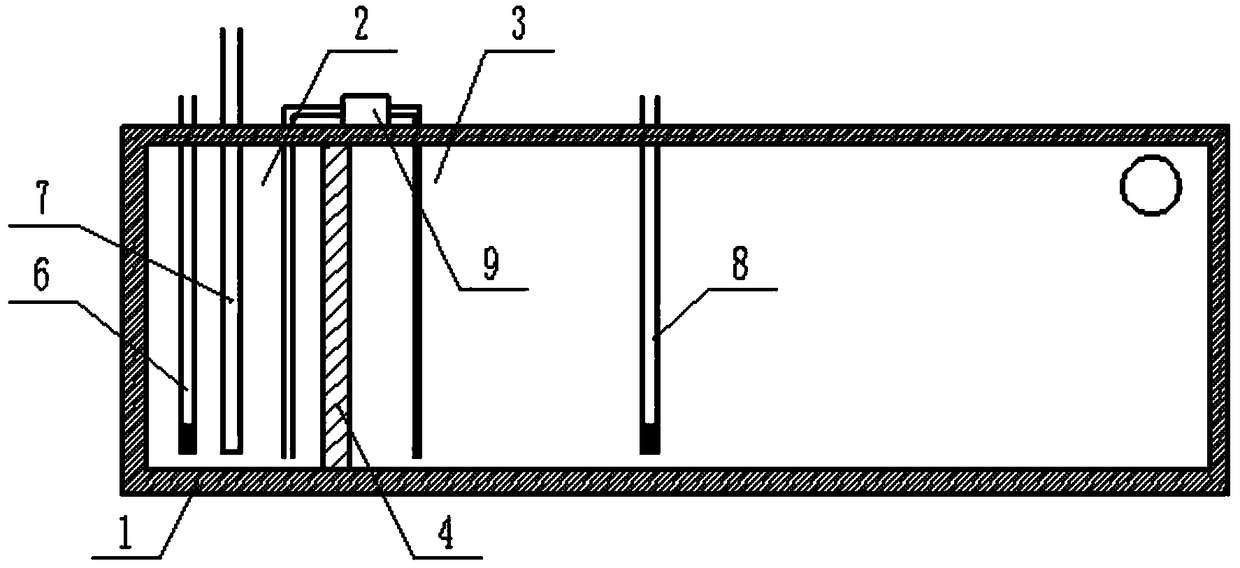

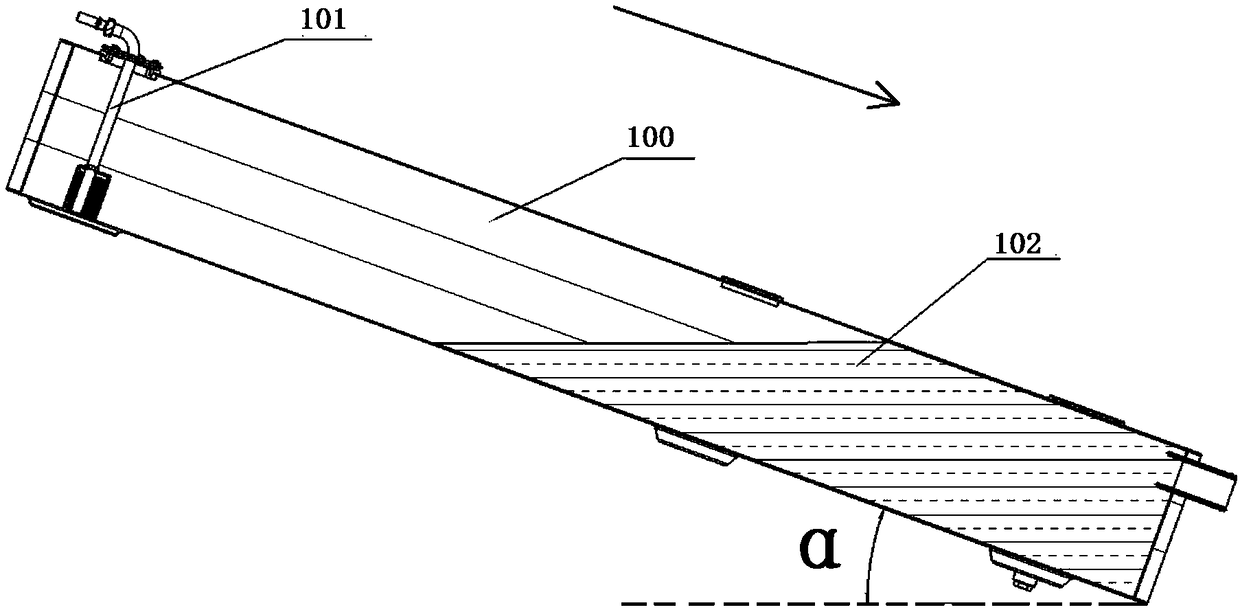

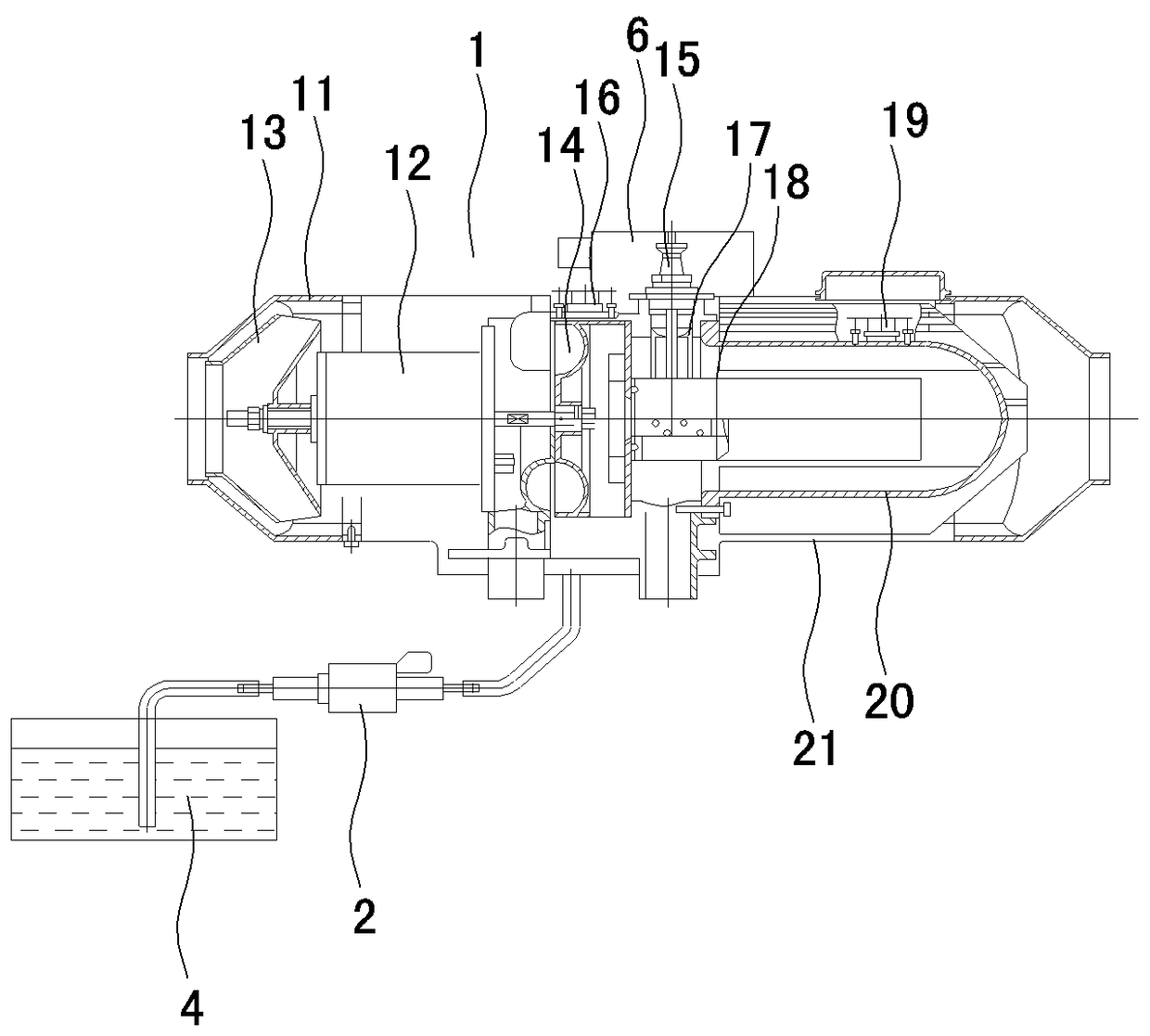

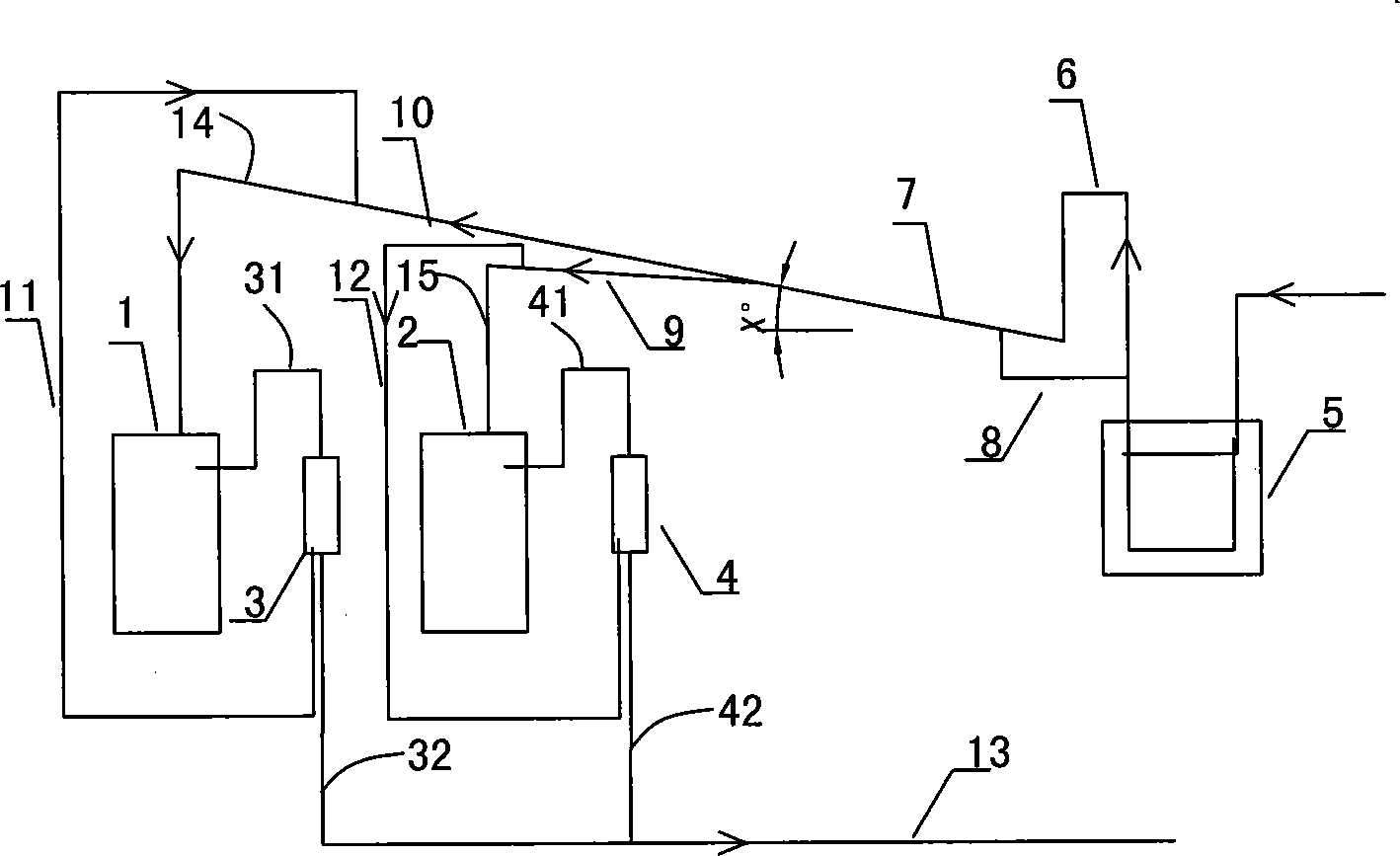

Oil supplying system of slope self-adaption diesel engine

ActiveCN109252993AGuaranteed fuel supplyGuaranteed to be fullUnderstructuresMachines/enginesFuel tankFuel oil

The invention relates to automobile oil supplying systems, in particular to an oil supplying system of a slope self-adaption diesel engine. The oil supplying system comprises a main oil tank assembly,an isolation plate is arranged in the main oil tank body, the main oil tank body is divided into a first oil cavity including an oil suction pipe and a second oil cavity including an oil delivery pump assembly by the isolation plate, the oil delivery pump assembly is communicated with the first oil cavity through an oil pipe to pump fuel oil in the second oil cavity into the first oil cavity, sothat it is ensured that the periphery of the oil suction pipe is always filled with the fuel oil, and normal fuel oil supplying of the engine is ensured; the interior of the main oil tank body is divided into the first oil cavity including the oil suction pipe and the second oil cavity including the oil delivery pump assembly by the isolation plate, a single-way valve is arranged on the isolationplate to allow the fuel oil in the fuel tank to flow only from one end of the oil delivery pump to the end provided with the oil suction, the fuel oil in the fuel oil tank is prevented from flowing from the end provided with the oil suction pipe to one end of the oil delivery pump assembly, and the normal fuel oil supplying of the engine is further ensured.

Owner:DONGFENG MOTOR CORP HUBEI

A Gradient Adaptive Diesel Engine Fuel Supply System

ActiveCN109252993BGuaranteed fuel supplyGuaranteed to be fullUnderstructuresMachines/enginesFuel tankFuel oil

The invention relates to automobile oil supplying systems, in particular to an oil supplying system of a slope self-adaption diesel engine. The oil supplying system comprises a main oil tank assembly,an isolation plate is arranged in the main oil tank body, the main oil tank body is divided into a first oil cavity including an oil suction pipe and a second oil cavity including an oil delivery pump assembly by the isolation plate, the oil delivery pump assembly is communicated with the first oil cavity through an oil pipe to pump fuel oil in the second oil cavity into the first oil cavity, sothat it is ensured that the periphery of the oil suction pipe is always filled with the fuel oil, and normal fuel oil supplying of the engine is ensured; the interior of the main oil tank body is divided into the first oil cavity including the oil suction pipe and the second oil cavity including the oil delivery pump assembly by the isolation plate, a single-way valve is arranged on the isolationplate to allow the fuel oil in the fuel tank to flow only from one end of the oil delivery pump to the end provided with the oil suction, the fuel oil in the fuel oil tank is prevented from flowing from the end provided with the oil suction pipe to one end of the oil delivery pump assembly, and the normal fuel oil supplying of the engine is further ensured.

Owner:DONGFENG MOTOR CORP HUBEI

A fuel-cooled evaporator tube structure

ActiveCN105716120BGuaranteed fuel supplyIncrease warm-upContinuous combustion chamberCombustorThermal state

The invention relates to a fuel-cooled type evaporating pipe structure. The evaporating pipe structure is applicable to engines and combustion chamber components of other burners, a closed fuel cooling cavity is formed between an evaporating pipe inner sleeve and an evaporating pipe outer sleeve, a fuel inlet pipe extends into the fuel cooling cavity in the outlet section position of the evaporating pipe, at least one row of fuel nozzles evenly distributed in the circumferential direction are arranged along the inlet section of the evaporating pipe inner sleeve, grooves communicating with one another are formed in the outer surface of the evaporating pipe inner sleeve, and fuel is delivered to the outlet section from the inlet section of the fuel cooling cavity along the grooves and is sprayed into the evaporating pipe at the inlet section. According to the structure, the fuel arrives at the fuel nozzles at the inlet section of the evaporating pipe from the inner cavity of the outlet section of the evaporating pipe and cools the wall surface of the evaporating pipe, and thermal state ablation protection of the evaporating pipe is completed; each way of fuel is preheated independently, the preheating degree of the fuel is increased, and the evaporating and premixing effect of the fuel is enhanced. By the aid of the overall design, cooling protection of the evaporating pipe is realized, and the service life is prolonged; high-intensity preheating of the fuel is realized, and the evaporating and premixing degree is increased.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI +1

Sewing machine oil cooling system and sewing machine

ActiveCN110670261ATimely replacementGuaranteed cooling effectLubrication/cooling devicesPressersThermodynamicsWater flow

The invention discloses a sewing machine oil cooling system and a sewing machine. The sewing machine oil cooling system comprises: a cooling water accommodating cavity, arranged in a sewing machine housing and attached outside an oil storage component arranged on the sewing machine housing; a water storing device, used for providing cooling water to the cooling water accommodating cavity, and communicated with the cooling water accommodating cavity; and a transmission mechanism, connected with a pedal system of the sewing machine and capable of pushing cooling water to flow between the water storing device and the cooling water accommodating cavity under the driving of the pedal system. The cooling water accommodating cavity is additionally arranged outside the oil storage component on thesewing machine, so that the oil can be cooled, partitioning an oil pan is not required, the oil supply of the oil pan can be guaranteed, and the risk of insufficient oil supply is reduced. The existing pedal system in the sewing machine is adopted, the water flow between the water storing device and the cooling water accommodating cavity can be controlled during sewing, the cooling capacity of the water in the cooling water accommodating cavity can be guaranteed, adding a driving device is not required, the cost can be saved, and the occupied space can be lessened.

Owner:JACK SEWING MASCH CO LTD

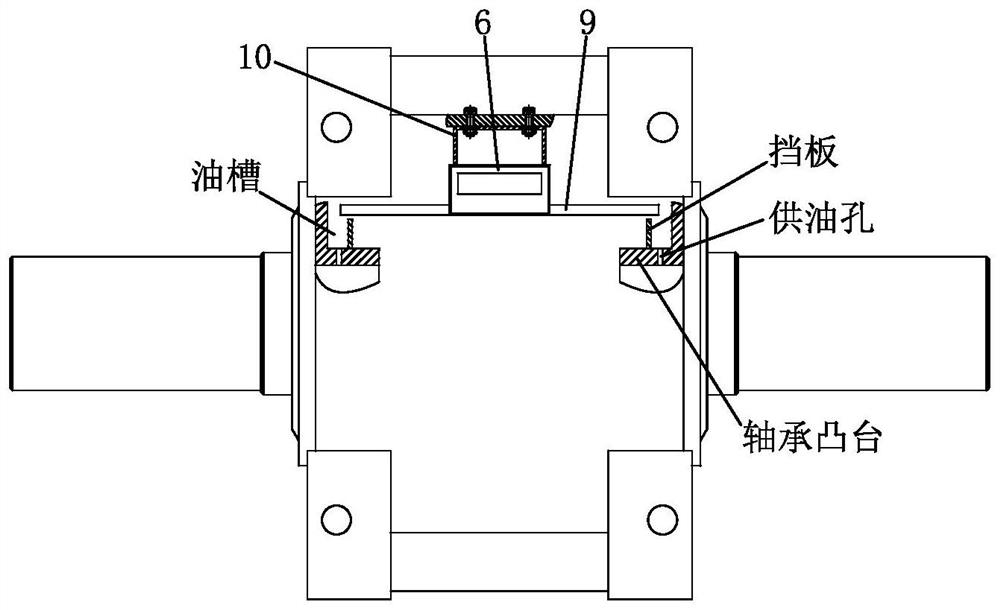

Self-lubricating speed reducer

The invention relates to a speed reduction transmission device. The self-lubricating speed reducer has the advantages of being firm, durable, stable in operation and good in lubricating effect. According to the technical scheme, the self-lubricating speed reducer comprises a machine shell, an input shaft, an output shaft and a transmission mechanism, wherein the input shaft and the output shaft are rotatably positioned on the machine shell, and the transmission mechanism transmits power between the input shaft and the output shaft. The oil pump is characterized in that an oil pumping mechanism driven by the driving shaft and an oil distributing mechanism for distributing lubricating oil supplied by the oil pumping mechanism to all lubricating points are further arranged in the machine shell; the oil pumping mechanism comprises a pressing plate fixed to the end cover, an oil supply cavity located between the end cover and the pressing plate, and an impeller arranged in the oil supply cavity and driven by the driving shaft. An oil inlet and an oil outlet are formed in the bottom and the top of the pressing plate respectively, and lubricating oil can be driven by the impeller to move from the oil inlet to the oil outlet in the circumferential direction of the oil supply cavity.

Owner:HANGZHOU XINGHE TRANSMISSION MACHINERY RES INST CO LTD

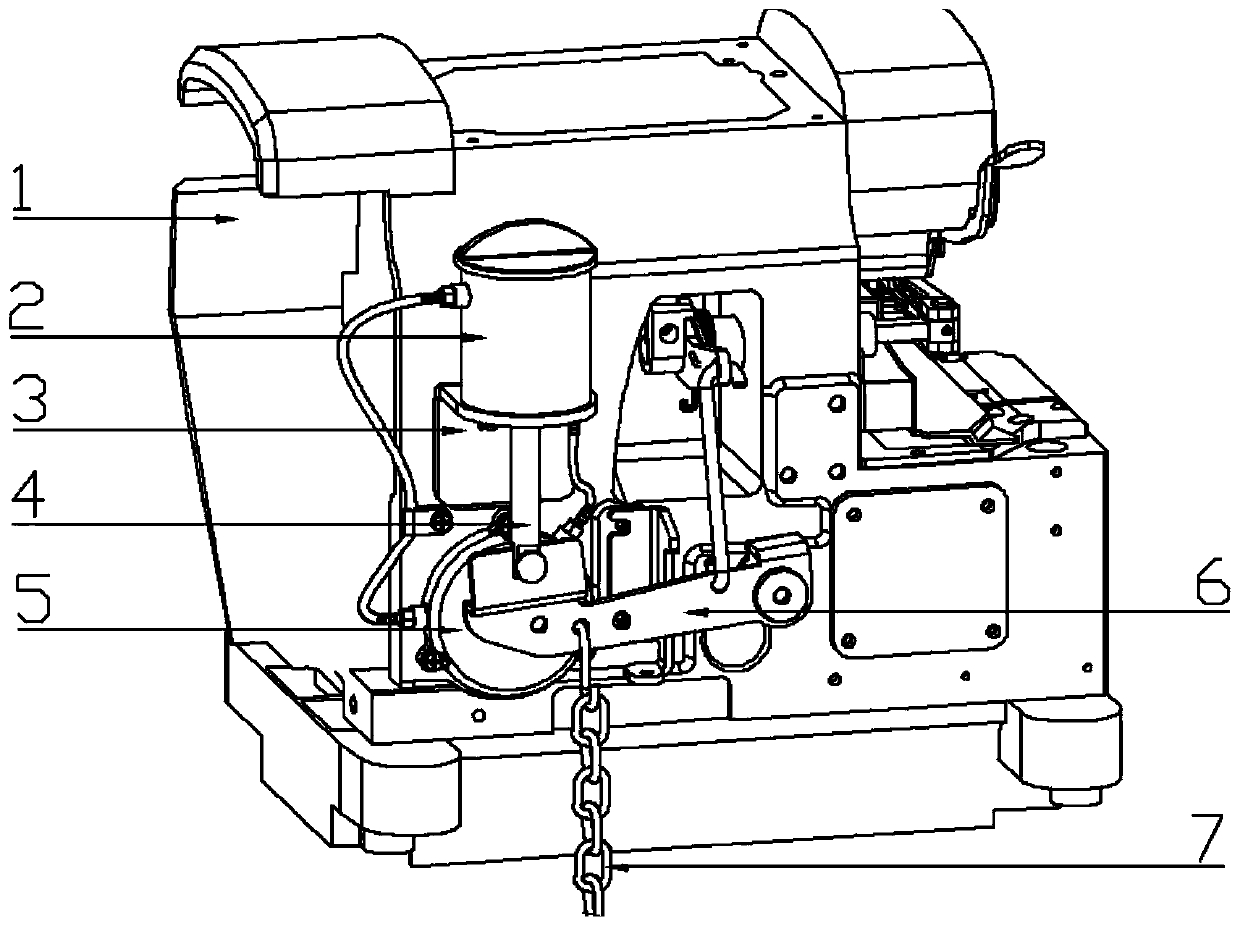

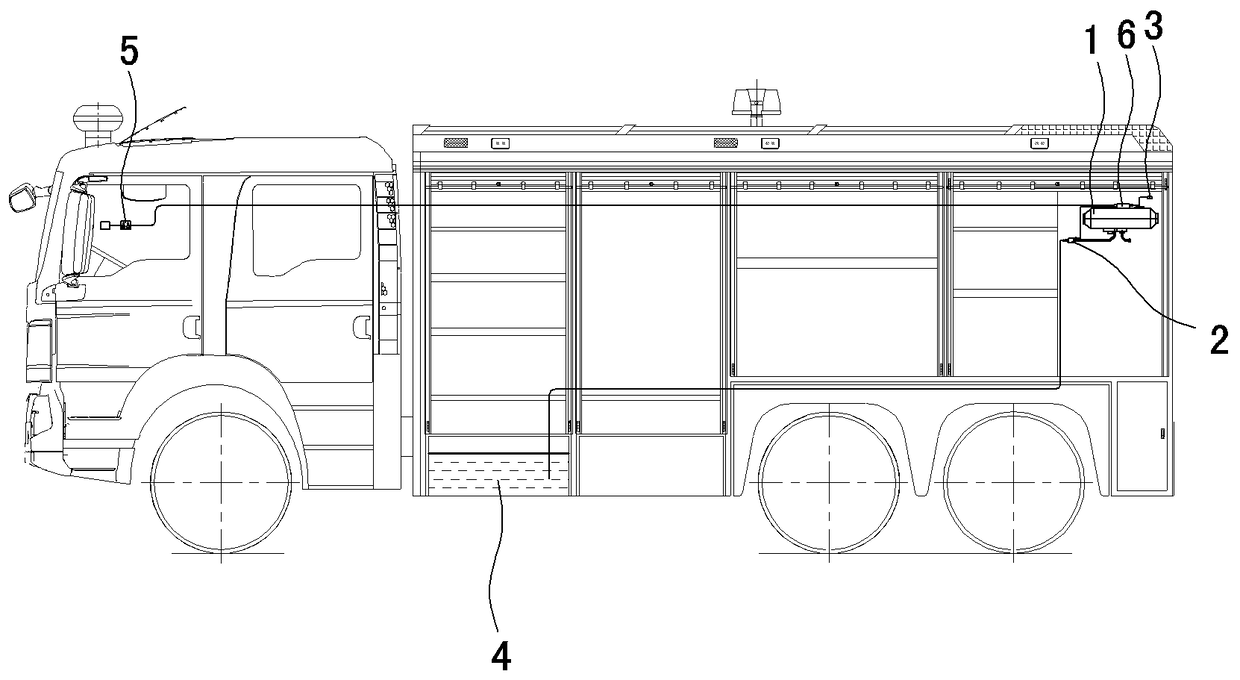

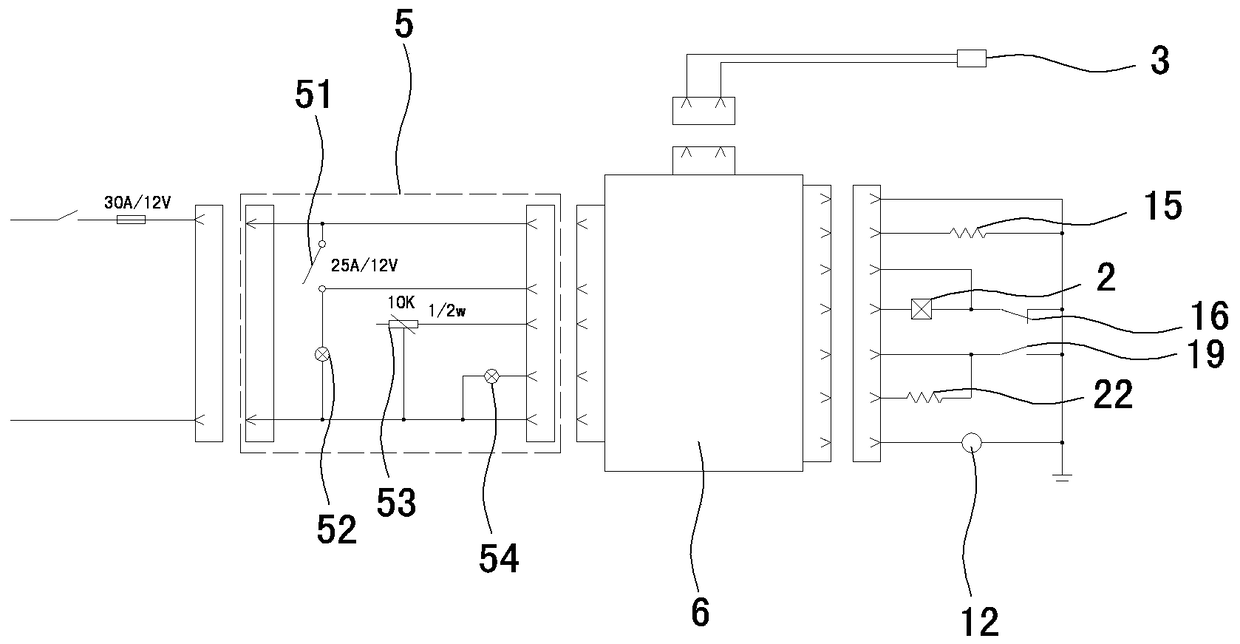

Fire fighting truck water pump chamber automatic heating system

PendingCN108744361AGuaranteed fuel supplyGuaranteed uptimeAir heatersFire rescuePump chamberNegative power

The invention relates to a fire fighting truck water pump chamber automatic heating system. The fire fighting truck water pump chamber automatic heating system comprises a fan heater (1), an electromagnetic pump (2), a temperature sensor (3), a fire fighting truck oil tank (4) and a fan heater switch plate (5), wherein the fan heater, the electromagnetic pump and the temperature sensor are mountedin a fire fighting truck water pump chamber; an oil outlet of the electromagnetic pump communicates with the fan heater; an oil inlet of the electromagnetic pump communicates with the fire fighting truck oil tank; the electromagnetic pump is connected with a fan heater controller (6); the temperature sensor is connected with the fan heater controller; the fan heater switch plate is mounted in a fire fighting truck cab; a fan heater switch (51), a power light (52) and a thermoregulation potentiometer (53) are arranged on the fan heater switch plate; and the positive power output end and the negative power output end of the fan heater switch plate are connected with the fan heater controller. The fire fighting truck oil tank is used for supplying oil to the fan heater, thus, oil supply of the fan heater is ensured, the phenomenon of burn-in of the fan heater caused by oil shortage is avoided, and long-term reliable operation of the fan heater is facilitated.

Owner:MUDANJIANG SENTIAN SPECIAL VEHICLE REFITTING

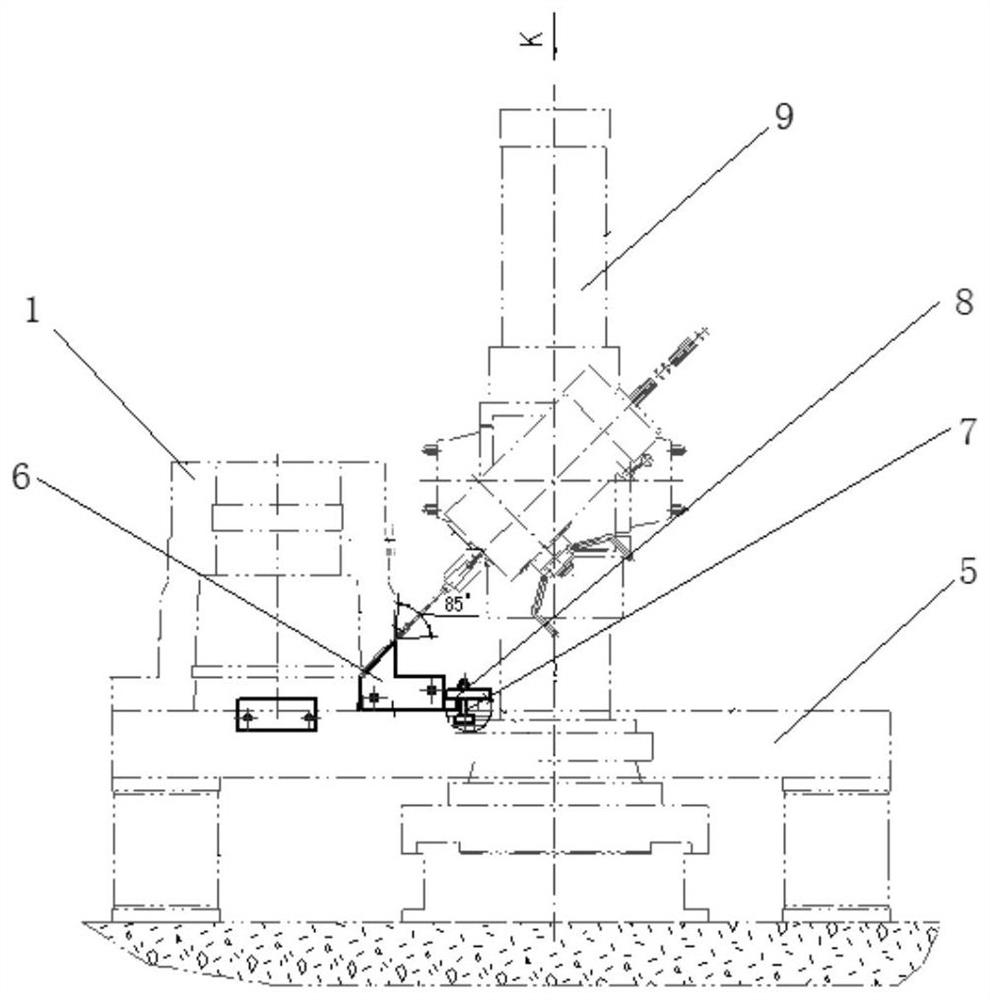

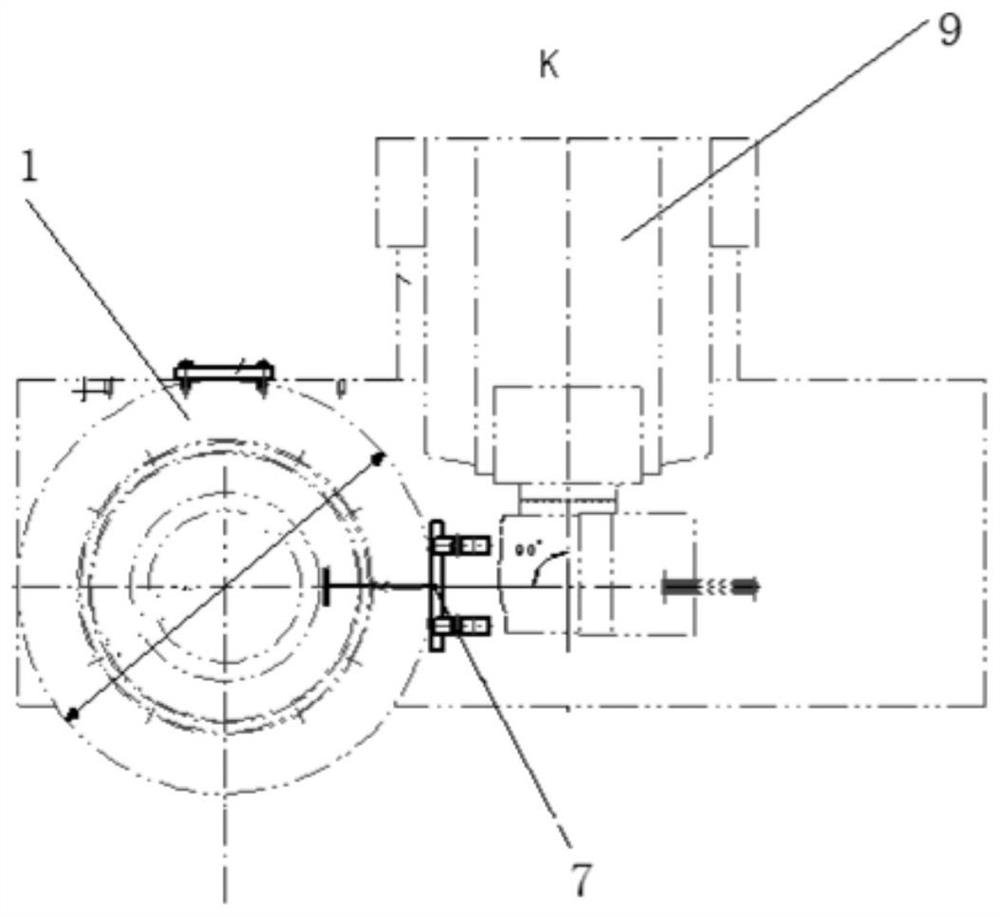

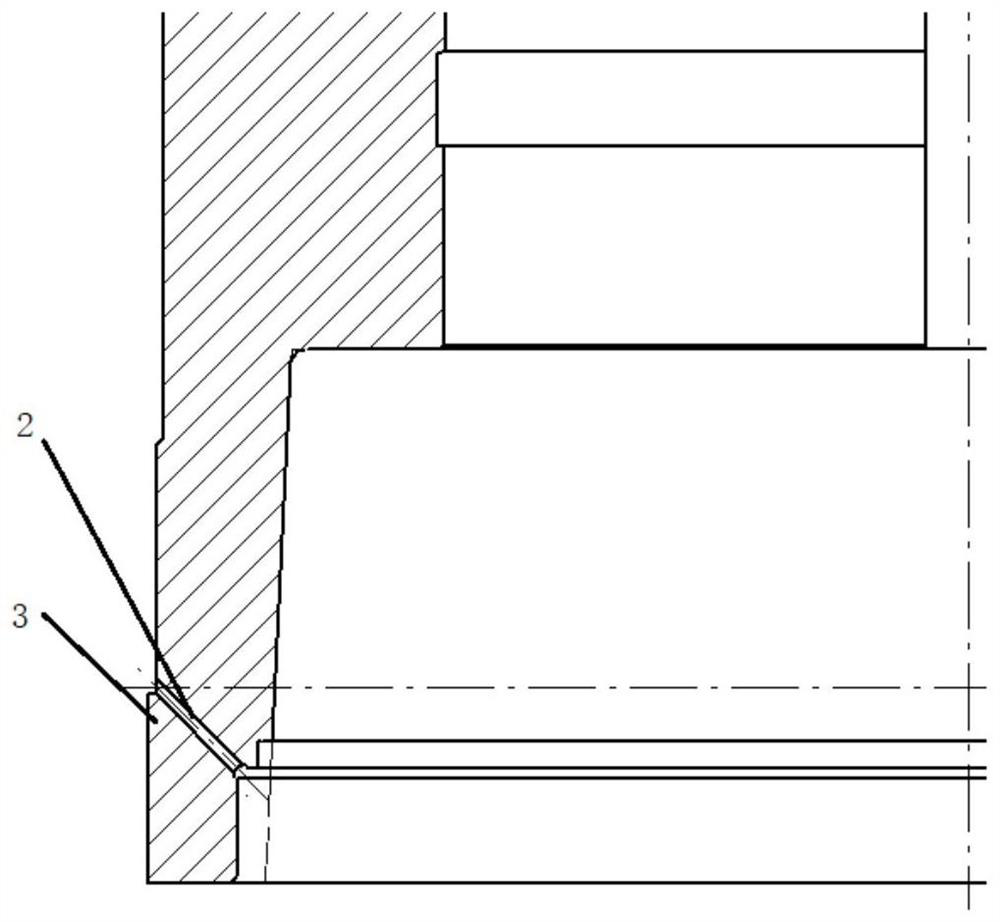

Inclined oil hole machining method for sliding rotor of water turbine

ActiveCN114406698AGuaranteed drilling accuracyGuaranteed manufacturing accuracyHydro energy generationOther manufacturing equipments/toolsThermodynamicsPilot hole

The invention relates to the technical field of water turbine rotor machining, and discloses a water turbine sliding rotor inclined oil hole machining method which comprises the following steps that 1, a step is turned on the outer circumference of a sliding rotor; 2, a drill bit positioning sample plate and square iron are installed and scribed; 3, proofing and punching holes in the steps; 4, aligning the center of the initial inclined oil hole; 5, drilling a guide hole; 6, drilling an inclined oil hole; 7, aligning the centers of other inclined oil holes; and 8, repeating the step 5 and the step 6. Alignment of the inclined oil hole of the sliding rotor is more convenient and faster, the manufacturing precision of the inclined oil hole is improved, the waste product yield is reduced, and the oil supply amount of the inclined oil hole is guaranteed.

Owner:CHONGQING WATER TURBINE WORKS

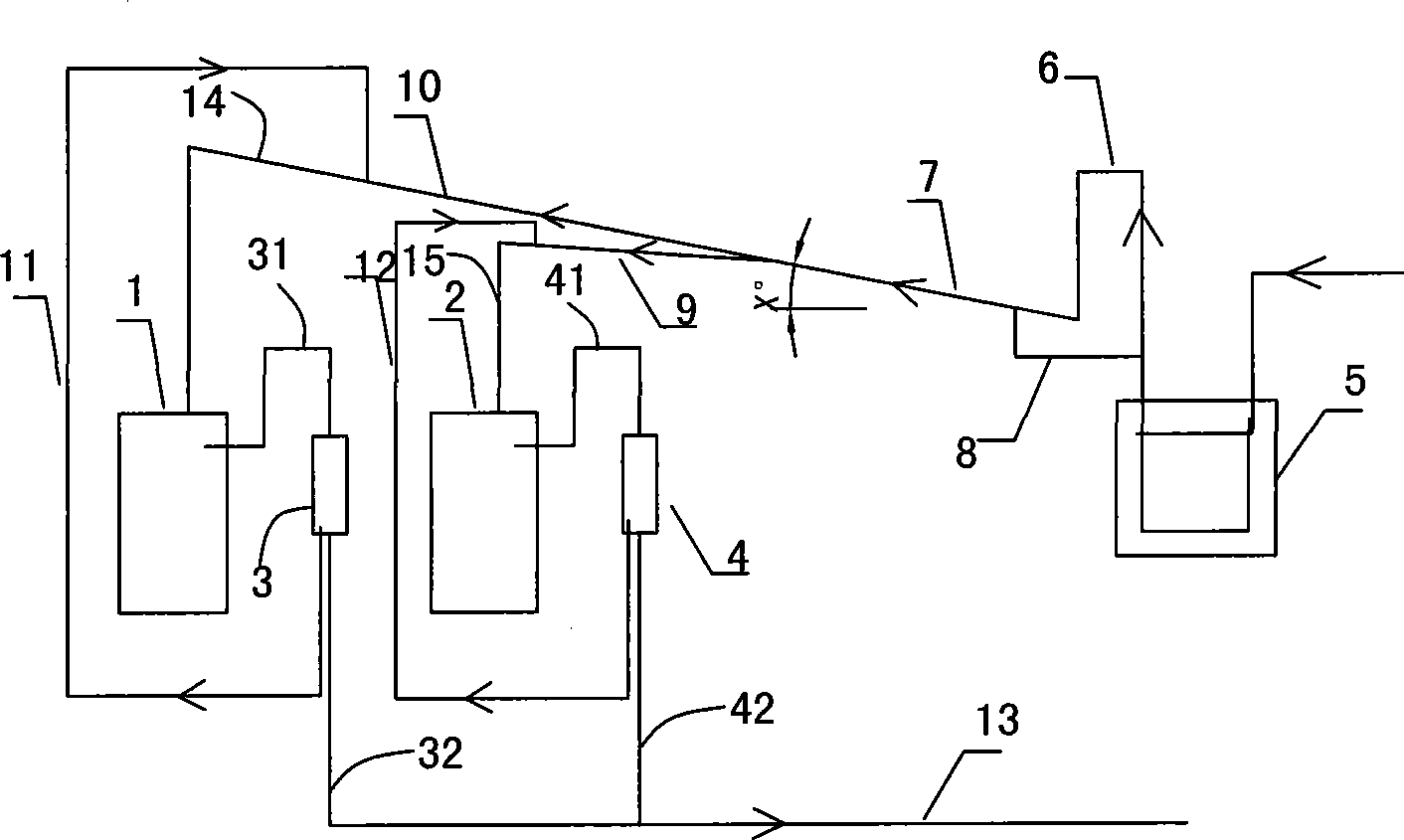

Parallel system of multiple high-pressure cavity compressors

ActiveCN102455084BGuaranteed fuel supplyAvoid hydraulic compressionCompressorVapor–liquid separatorEngineering

The invention discloses a parallel system of multiple high-pressure cavity compressors. Due to the design of an inverse U-shaped pipe, an overflow pipe and an oblique main pipe, the refrigerating machine oil reflowing from an oil separator is prevented from flowing back to compressors when all the compressors stop running, and more oil reflowing from the oil separator can be stored in a vapor-liquid separator through the overflow pipe so as to prevent liquid blockage; when the compressors run in low loads and the coolant flow rate of an air suction pipe is low, the oil can be prevented from flowing back to the vapor-liquid separator; after a certain oil quantity is accumulated in the oblique main pipe, the oil is directly recycled to the compressors, so that the oil supply of the compressors is ensured; and the system can avoid liquid compression or liquid blockage of the compressors in each state of the compressors, so that the reliability of the compressor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Diesel fuel delivery pump assembly for slope adaptive system

ActiveCN109113904BGuaranteed fuel supplyEasy to installMachines/enginesLiquid fuel feedersFuel oilMechanical engineering

Owner:DONGFENG MOTOR CORP HUBEI

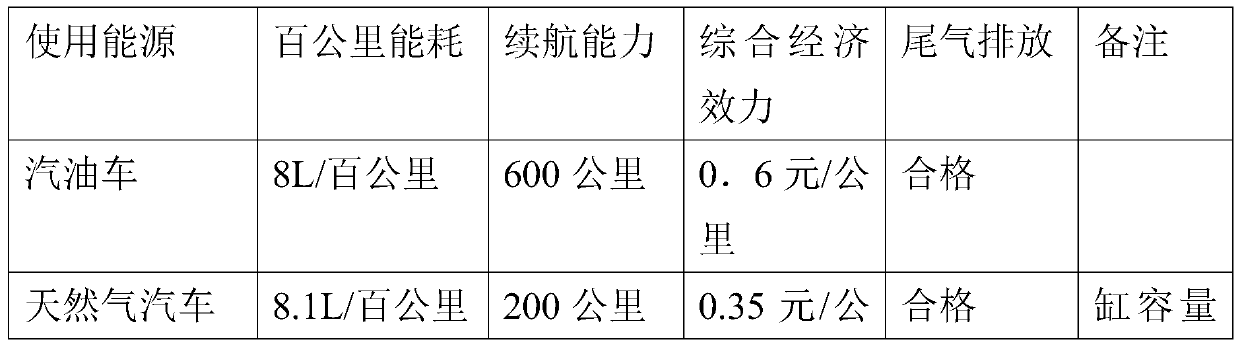

Liquefied gas vehicle gas supply insulation system

ActiveCN107891742BReduce cokingSmooth runningInternal combustion piston enginesFuel supply apparatusExhaust gas emissionsProcess engineering

The invention relates to the technical field of vehicles, in particular to a gas supply and heat preserving system of a liquefied gas vehicle. The system comprises a gas storage tank provided with a filling valve and a gas outlet valve, the gas outlet valve is connected to an engine through a material supply pipe, the gas storage tank is installed in a heating box, a coil pipe which abuts againstthe gas storage tank is arranged in the heating box, the input-output end of the coil pipe is connected to a cooling water system of the engine, the material supply pipe penetrates a hollow sleeve, the gaps between the sleeve and the material supply pipe are sealed, and a water inlet-outlet end is arranged on the sleeve and connected to the cooling water system of the engine. According to the system, civil liquefied gas is adopted as fuel, so that energy is saved, and the environment is protected; moreover, the gas storage tank and the material supply pipe are heated by means of engine coolingwater so that full gasification can be guaranteed, residues in the gas storage tank are avoided, the gas supply capability of the system is improved, and fuel supply of the engine is guaranteed; moreover, exhaust gas emission is clean, by accessing a heating system, gas which enters the engine is heated to about 80 DEG C, and the size of the gas expands 1.2 times.

Owner:ANHUI ZHIBO NEW MATERIAL TECH CO LTD

Motorcycle anti-skid brake system structure

The invention provides a motorcycle antiskid brake system structure which comprises a motorcycle frame unit and steering handles. The handles are arranged on a motorcycle head cover in a covering mode. The motorcycle head cover is provided with a console. The handles are provided with an antiskid brake system unit. The holding parts of the handles are provided with braking pull handles and a brake oil pump. The system unit comprises a power motor, a brake body and a controller. The power motor and the controller are connected to the brake body. The brake body is provided with a brake oil pipe combination part. The combination part is connected with disc brake calipers and the brake oil pump respectively through a disc brake calipers oil pipe and a brake oil pump oil pipe. The system unit is fixed to the concave parts of the handles through a support and is covered by the motorcycle head cover. By means of the motorcycle antiskid brake system structure, the disc brake calipers oil pipe can be connected to the disc brake calipers directly downwards from the handles, and even dispersion is conducted through the disc brake calipers oil pipe longer in length in the bending process of the disc brake calipers oil pipe. Losses caused by excessively bending of the disc brake calipers oil pipe are avoided, the oil supply quantity of the disc brake calipers oil pipe is guaranteed, and the system unit is actually made to control the disc brake calipers to act.

Owner:KYMCO

rotary compressor

InactiveCN104196726BGuaranteed fuel supplyGuaranteed qualityRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsEngineeringOil quality

The invention discloses a rotary compressor comprising a shell, a motor and a compressing mechanism, wherein the shell comprises a lower shell assembly; the compressing mechanism comprises a main bearing, an air cylinder and an auxiliary bearing assembly; the auxiliary bearing assembly comprises an auxiliary bearing comprising a hub part and a flange part; when the delivery volume V of a compression chamber is smaller than 13cm<3> / rev, 0.1<=P1 / P2<=1.2; when 13cm<3> / rev<=V<=24cm<3> / rev, 0.1<=P1 / P2<=1.5; when V>24cm<3> / rev, 0.1<=P1 / P2<=2; and P1=H1 / H2, P2=H3 / H4, H1 represents for a vertical distance from the center of the lower surface of the hub part to the lower shell assembly, H3 represents for a vertical distance from the edge of the lower surface of the flange part to the lower shell assembly, and H2 and H4 respectively represent for the heights of the auxiliary bearing assembly and the air cylinder. According to the rotary compressor disclosed by the invention, the quantity of a refrigerant which is stored in an oil pool and is dissolved into refrigerating machine oil can be reduced, the dissolution viscosity of the refrigerating machine oil is increased, and the oil supply and supplied oil quality of the rotary compressor are ensured.

Owner:GUANGDONG MEIZHI COMPRESSOR

Sewing machine oil cooling system and sewing machine

ActiveCN110670261BTimely replacementGuaranteed cooling effectLubrication/cooling devicesPressersThermodynamicsEngineering

The invention discloses a sewing machine oil cooling system and a sewing machine. The sewing machine oil cooling system includes: a cooling water chamber arranged on the sewing machine casing, the cooling water chamber is attached to the outside of the oil storage part arranged on the sewing machine casing; The water reservoir is connected to the cooling water chamber; connected to the transmission mechanism of the pedal system of the sewing machine, the transmission mechanism can drive the cooling water to flow between the water reservoir and the cooling water chamber driven by the pedal system. By adding a cooling water chamber outside the oil storage part on the sewing machine, the cooling of the oil can be realized without partitioning the oil pan, which can ensure the oil supply of the oil pan and reduce the risk of insufficient oil supply. Using the existing pedal system in the sewing machine, the flow of water between the water reservoir and the cooling water chamber can be controlled while sewing, and the cooling capacity of the water in the cooling water chamber can be guaranteed without additional drive devices. It is beneficial to save costs and reduce occupied space.

Owner:JACK SEWING MASCH CO LTD

Compressor

ActiveCN113785127AGuaranteed fuel supplyImprove reliabilityRotary piston pumpsRotary piston liquid enginesRotational axisDrive shaft

A compressor comprises a sealed container having: an oil accumulation space that accumulates oil; a compression mechanism portion that is accommodated in the sealed container and that compresses a working gas flowing into the sealed container; and a drive shaft that drives the compression mechanism portion, the drive shaft having an oil supply flow channel formed therein. The compressor also comprises an oil supply pump that is driven by the rotation of the drive shaft and that supplies the oil accumulated in the oil accumulation space to the oil supply flow channel of the drive shaft, and a bearing to which the oil is supplied from the oil supply flow channel and which supports the rotation of the drive shaft. A gap between the bearing and the drive shaft serves as a bearing flow channel through which the oil flows, the gap being set such that, within the oil flow channel in the oil supply pump, the flow channel resistance of a part of a clearance flow channel is less than the flow channel resistance of the bearing flow channel.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com