Oil separator for freon

A technology of oil separator and freon, which is applied in the direction of refrigeration components, refrigerators, lighting and heating equipment, etc., can solve the problems of not equipped with electric heater and oil level controller at the same time, electric heater empty burning, damage to system equipment, etc. , to achieve the effect of ensuring oil supply, lubricity and stable oil temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

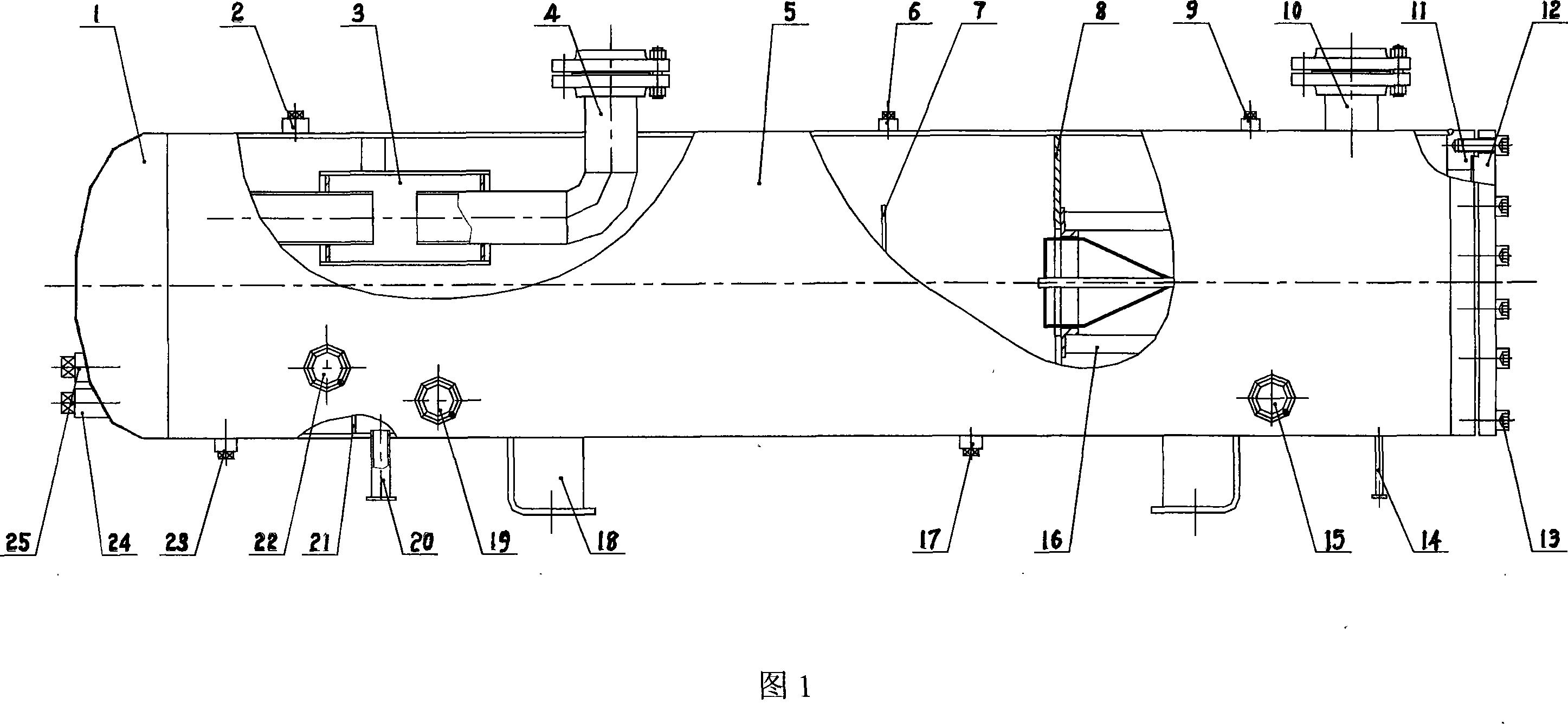

[0012] As shown in Fig. 1, the oil separator of the present invention comprises a cylinder 5, one end of the cylinder 5 is tailor-welded with a head 1, the other end of the cylinder 5 is welded with a detachable flange plate 11, and the flange plate 11 outside The sealing plate 12 and the flange plate 11 are connected by bolts 13 , and the sealing plate 12 closes the end of the cylinder 5 .

[0013] The cylinder wall of the cylinder 5 is provided with an air inlet pipe 4, an exhaust pipe 10, a pressure gauge interface 6, a safety valve interface 2, a spare interface 9, and the like. The inner end of the intake pipe 4 is connected with a muffler 3 , and the front end of the muffler 3 faces the sealing head 1 . An electric heater interface 24 and an oil level switch interface 25 are installed on the head 1 , and the oil level switch interface 25 is located on the upper part of the electric heater interface 24 .

[0014] The bottom of the cylinder 5 is provided with a drain outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com