Variable rotor oil pump regulated and controlled by wave wheel

A technology of rotor oil pump and impeller, applied in the direction of lubricating pump, mechanical equipment, engine components, etc., can solve the problems of increasing engine power loss, reducing engine economy, and increasing lubricating oil temperature, reducing conveying resistance, The effect of reducing oil pressure and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

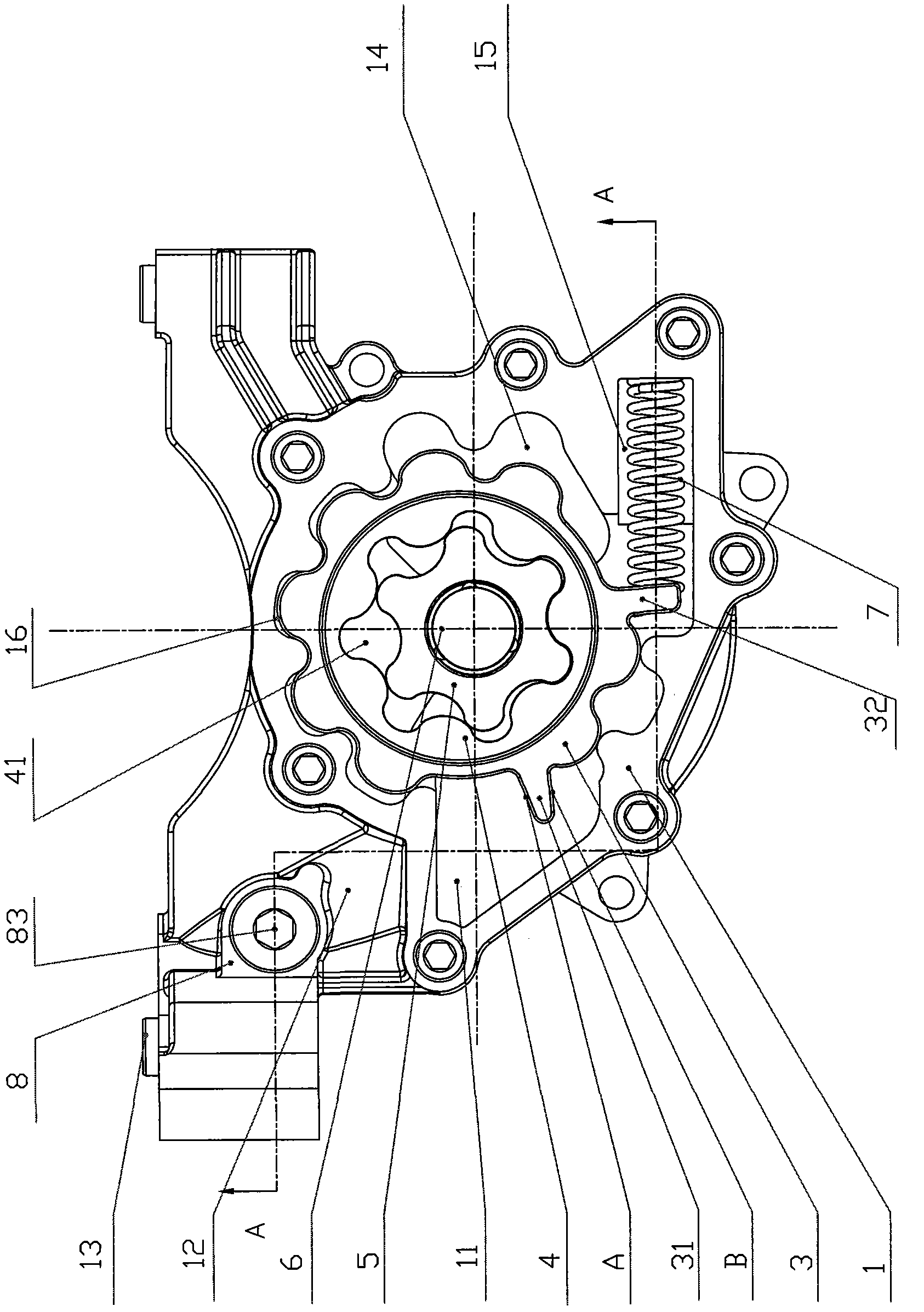

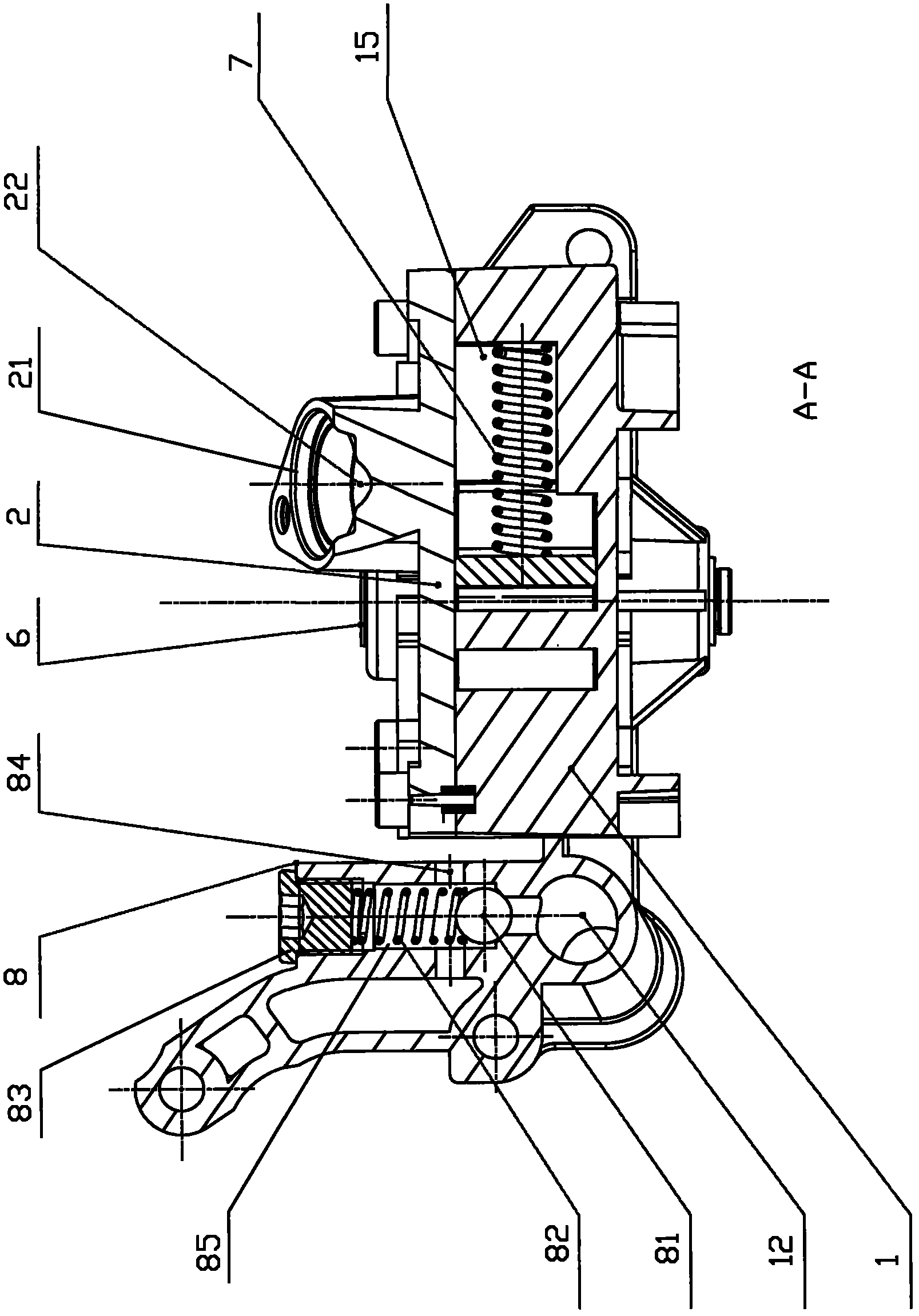

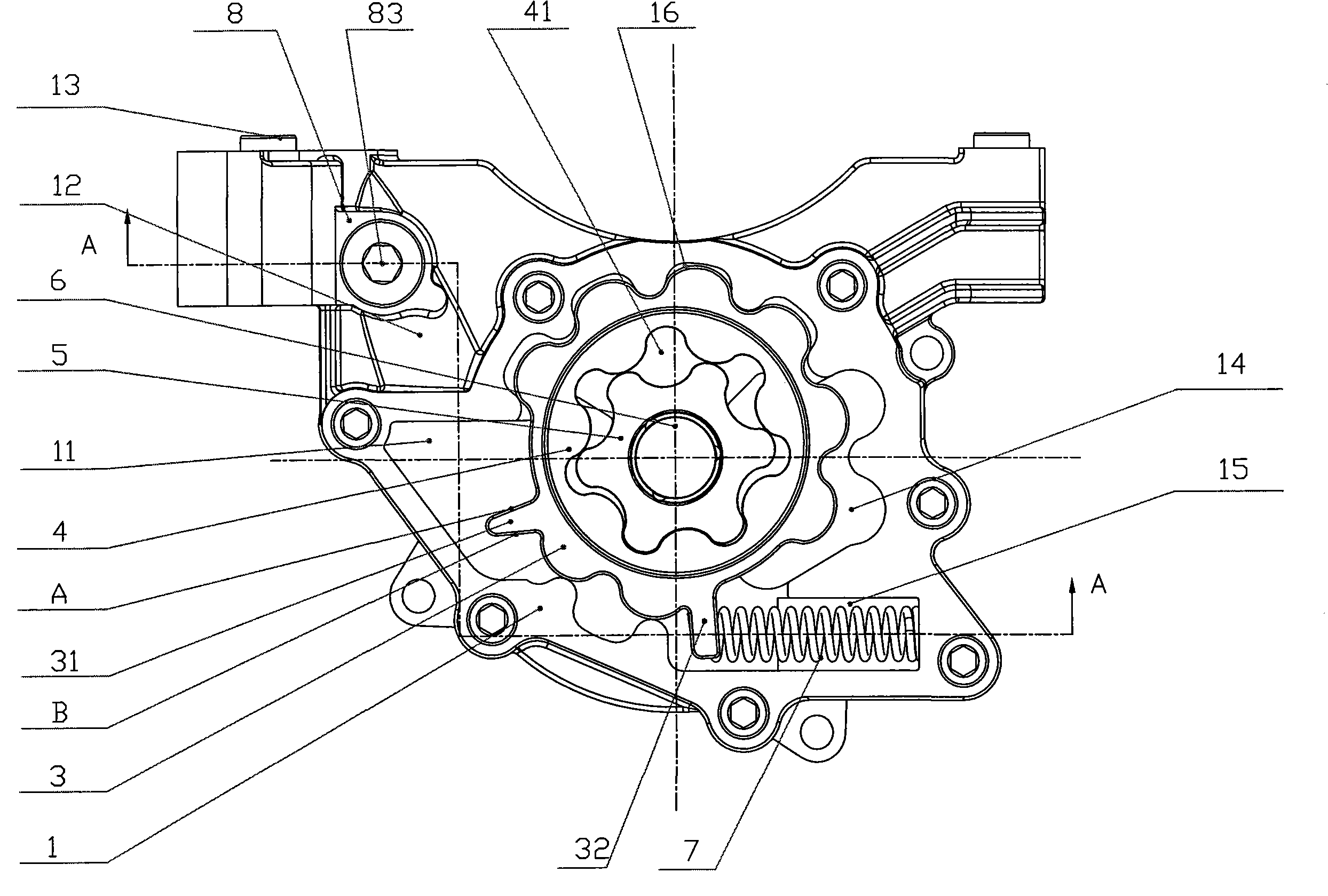

[0012] A variable rotor oil pump regulated by a pulsator, which is composed of a pump body 1, a pump cover 2, a pulsator regulating ring 3, an outer rotor 4, an inner rotor 5, a transmission shaft 6, a spring 7 and a safety valve component 8. The pulsator regulating ring 3 and the spring 7 are installed in the pulsator ring hole 16 and the spring slot 15 on the pump body 1. The middle part of the transmission shaft 6 is in an interference fit with the inner rotor 5, and is installed on the pulsator together with the outer rotor 4. The middle hole on the control ring 3 and the shaft hole of the pump body 1 and the pump cover 2. The two sides and bottom surface of the impeller ring hole 16 in the pump body 1 are provided with an oil inlet cavity 14 and an oil outlet cavity 11, an oil outlet 12 and an oil outlet 13, and the oil outlet 13 communicates with the oil passage of the engine. The outer side of the pulsator control ring 3 is provided with a leaf valve 31 and a return val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com