Variable-displacement gear-type oil pump

A gear machine and displacement technology, which is applied in the direction of lubricating pumps, mechanical equipment, engine components, etc., can solve the problems of affecting the normal operation of the engine, consuming more effective power of the engine, and reducing the economy of the engine, so as to improve efficiency and economy Sex, reduce temperature, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

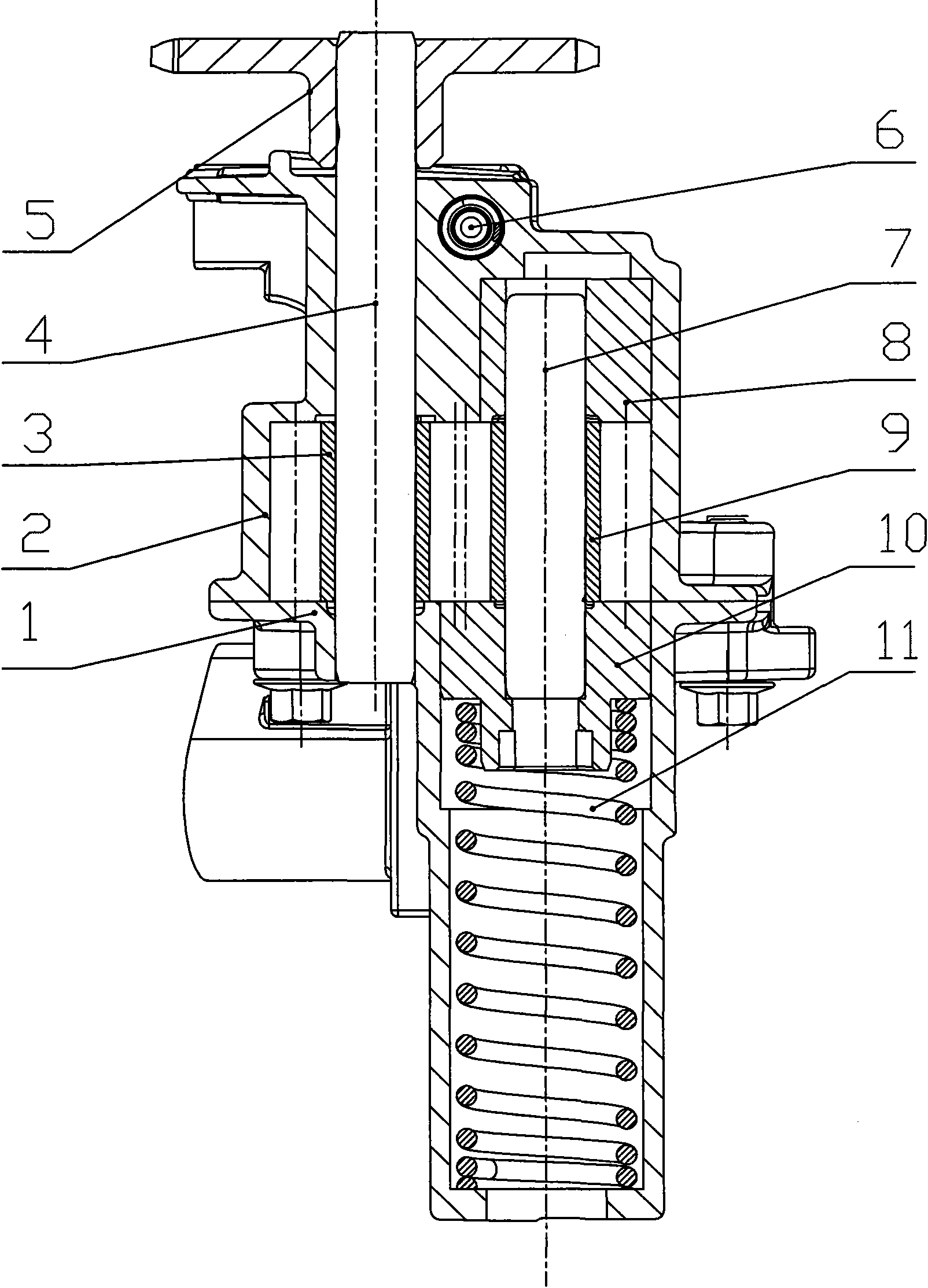

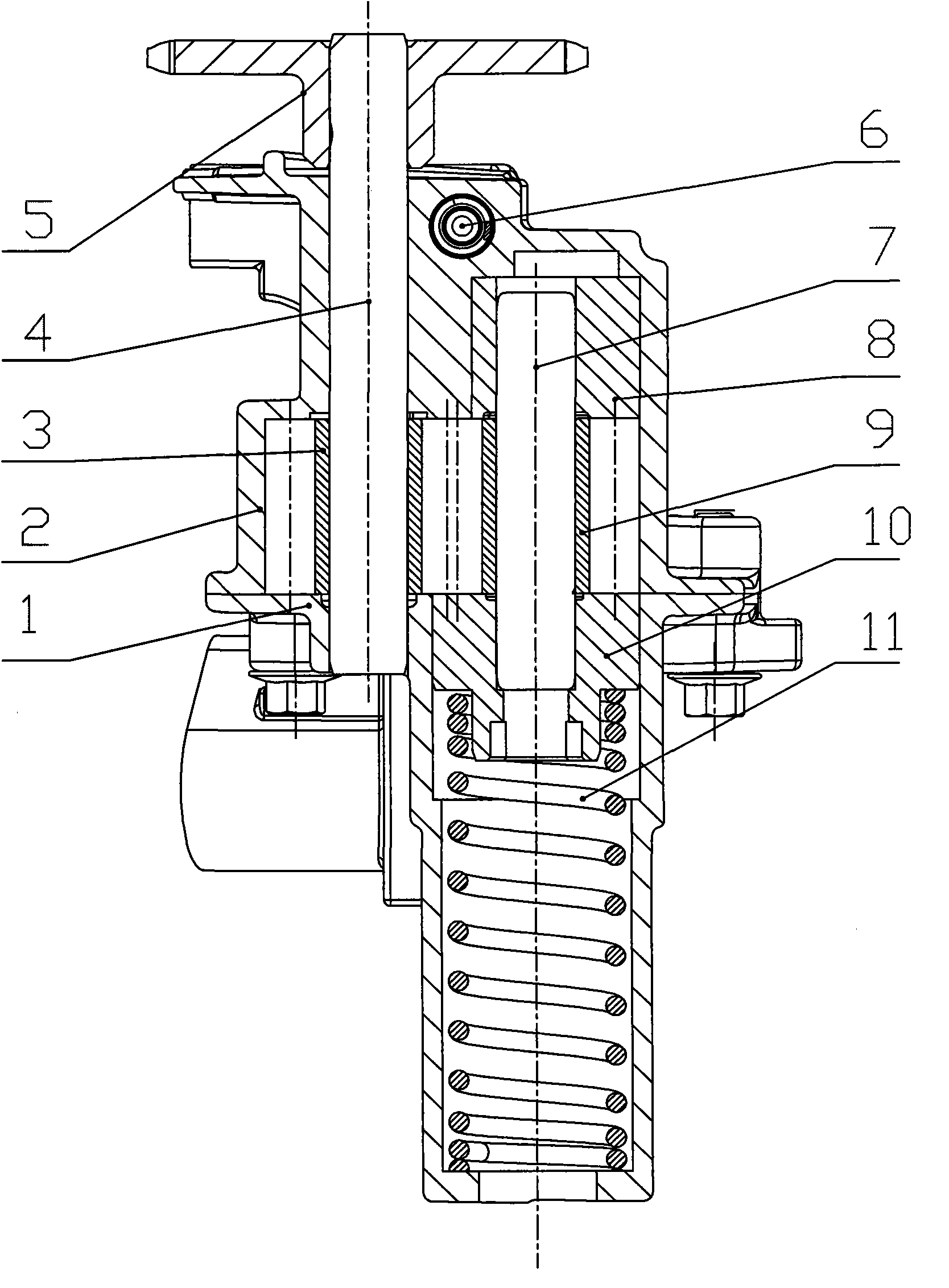

[0015] like figure 1 Shown: a gear oil pump with variable displacement, including a pump cover 1, a pump body 2, a driving gear 3, a driving shaft 4, a transmission gear 5, a control valve part 6, a driven shaft 7, a circular slider 8, The driven gear 9, the full circle slider 10 and the spring 11; the driving shaft 4 is installed in the shaft hole of the pump body 2 and the pump cover 1, the outer end is press-fitted with the transmission gear 5, and the driving gear 3 with interference fit is installed in the middle, Constitute the transmission part; the driven shaft 7, the missing circle slider 8, the driven gear 9, the full circle slider 10 and the spring 11 form variable parts; 4 separated outer edges; the transmission part of the driving gear 3 is arranged opposite to the variable part of the driven gear 9, and is combined with the control valve part 6 to form a variable displacement gear oil pump system.

Embodiment 2

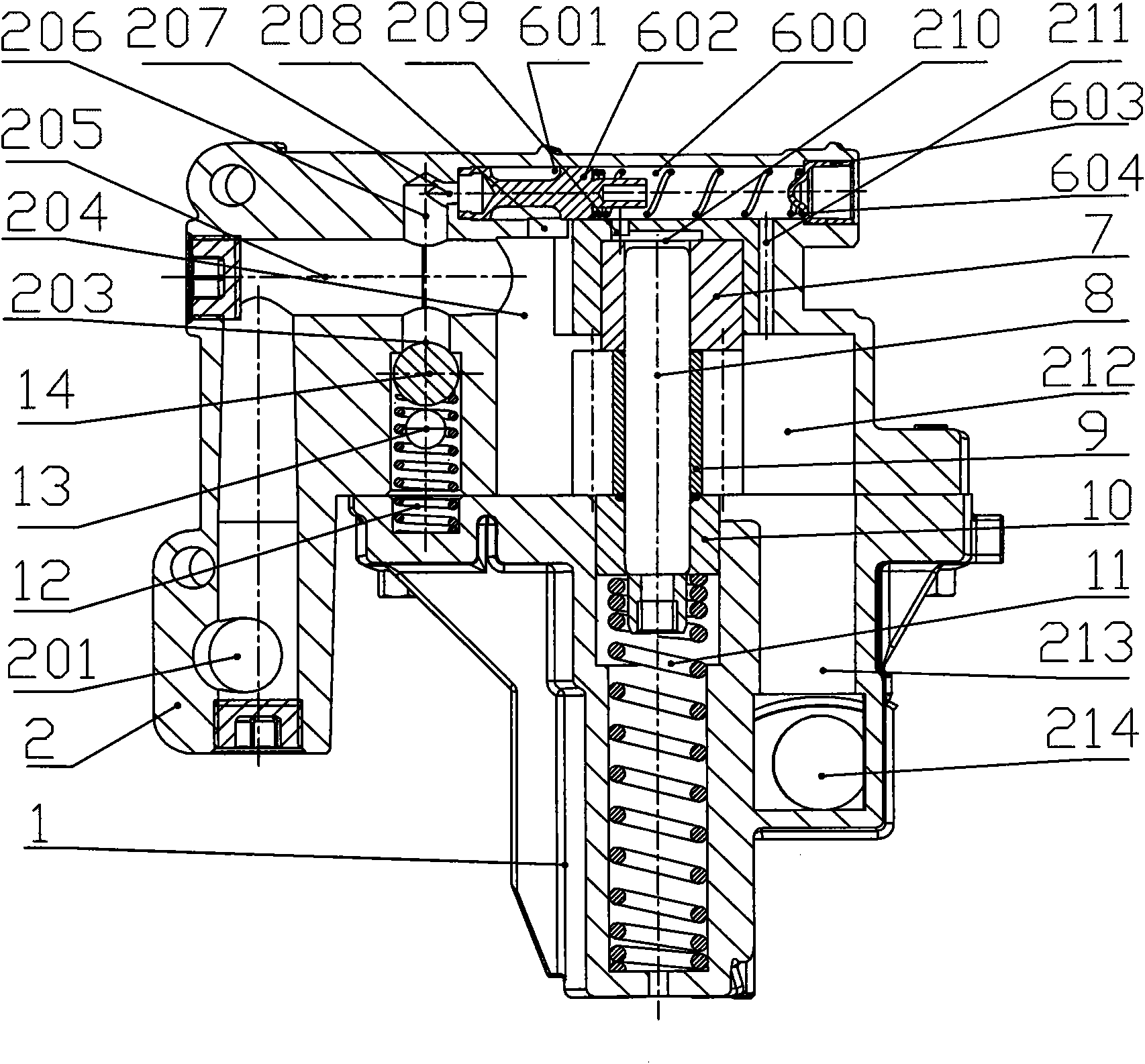

[0017] like figure 2 As shown, a variable displacement gear oil pump is formed by fastening two parts of the pump cover 1 and the pump body 2. The high pressure area of the pump body 2 is provided with an oil outlet 201, an oil outlet chamber 204 and an outlet The oil hole 205 forms the pressure oil passage; the safety valve steel ball 13 spring 12, and the oil discharge hole 202 and the safety valve hole 203 form a safety oil discharge passage; an oil inlet 214, an oil inlet 213 and The oil inlet cavity 212 forms a low-pressure oil inlet channel; it consists of a regulating plunger spool 602, a regulating spring 604, a regulating screw plug 603, and matching oil guide holes 206, valve bottom oil inlet holes 207, elongated oil holes 208, regulating Oil hole 209, annular groove 601, valve hole 600, missing circle oil cavity 210 and oil drain hole 211 form a variable control system; the variable is composed of a missing circle slider 7, a driven shaft 8, a driven gear 9, a fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com