Scroll compressor

A scroll compressor and movable scroll technology, which is applied in the direction of rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve the problems of difficult processing and high processing precision requirements for spiral passages, and achieve improved reliability, Effect of suppressing wear and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

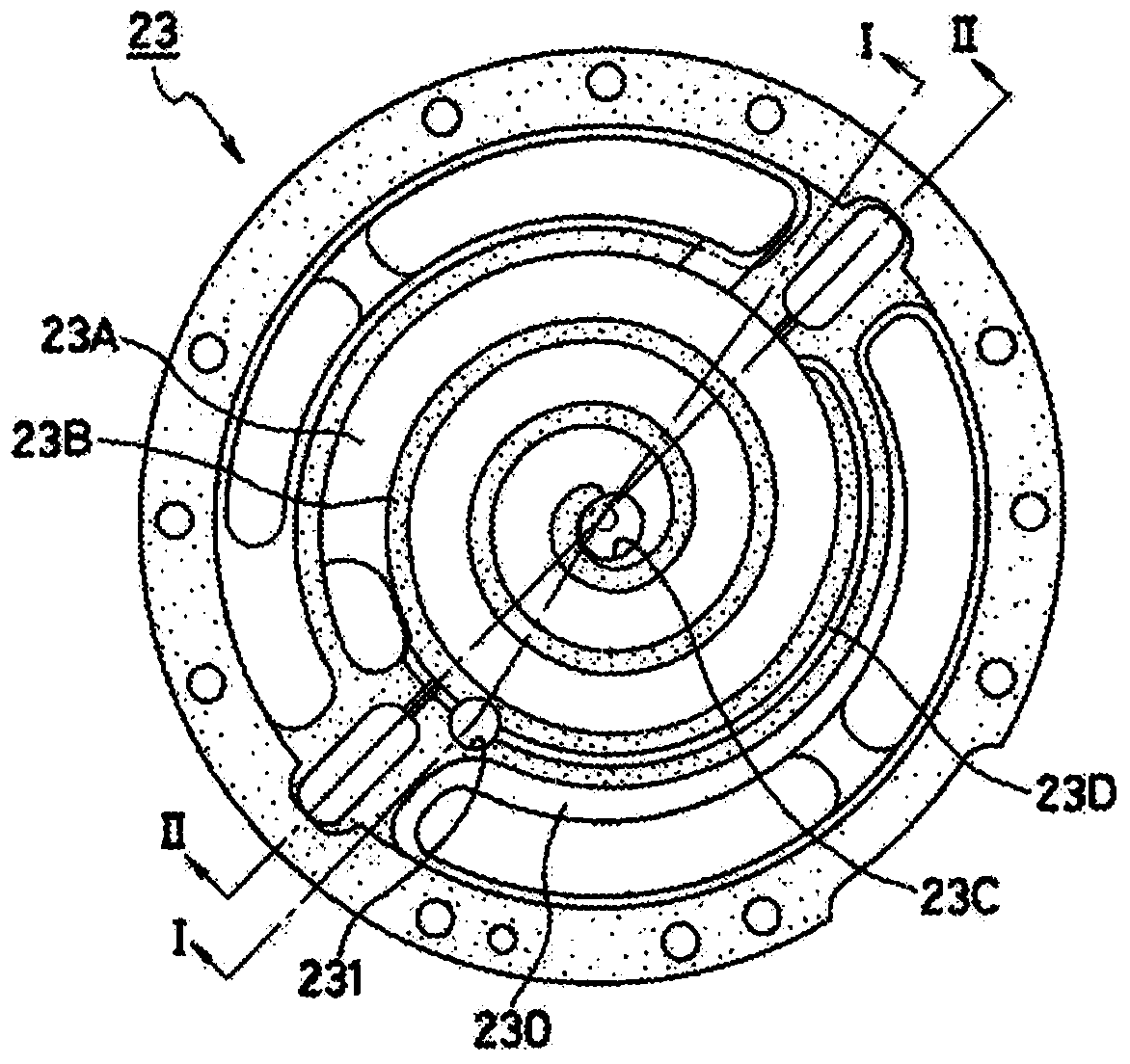

[0054] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

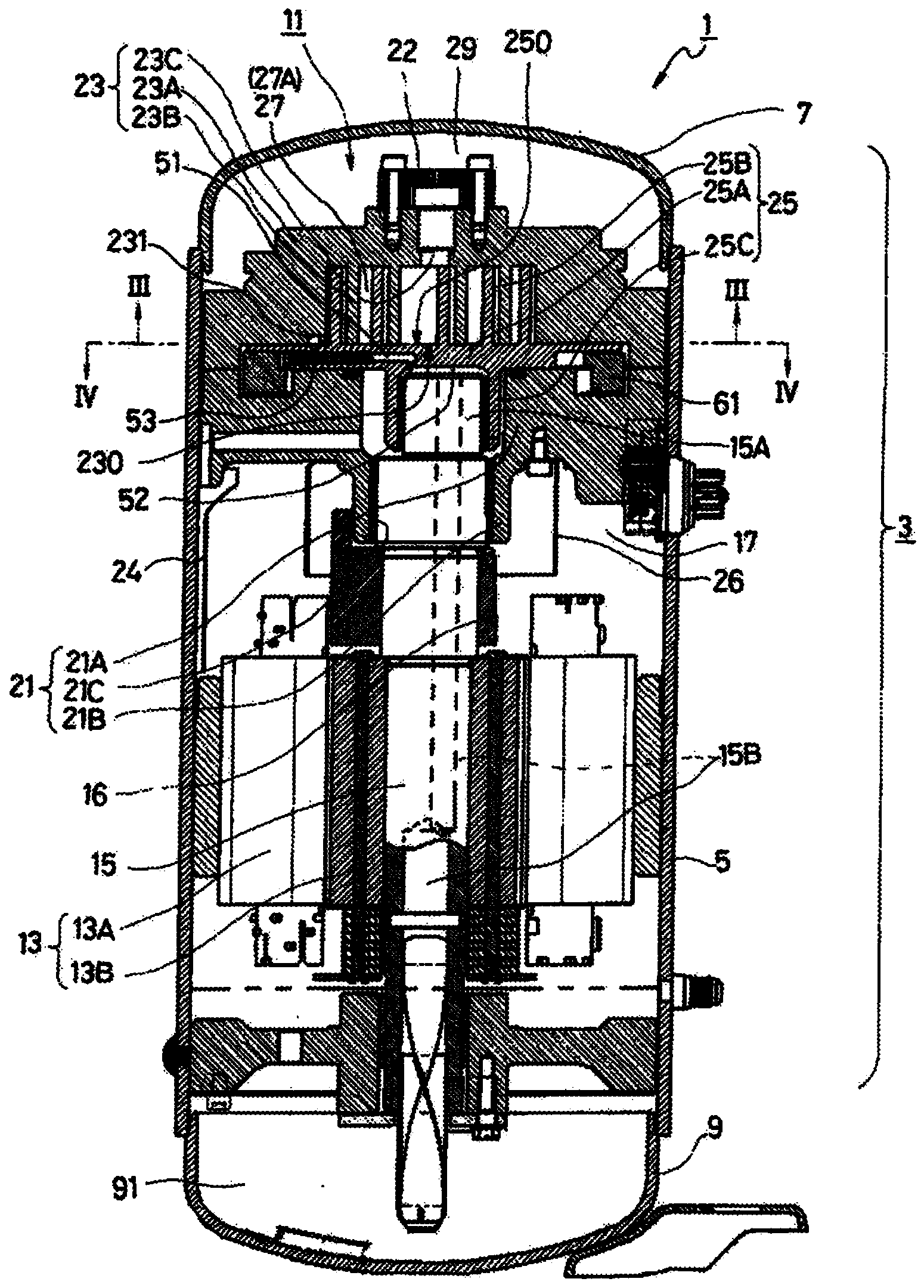

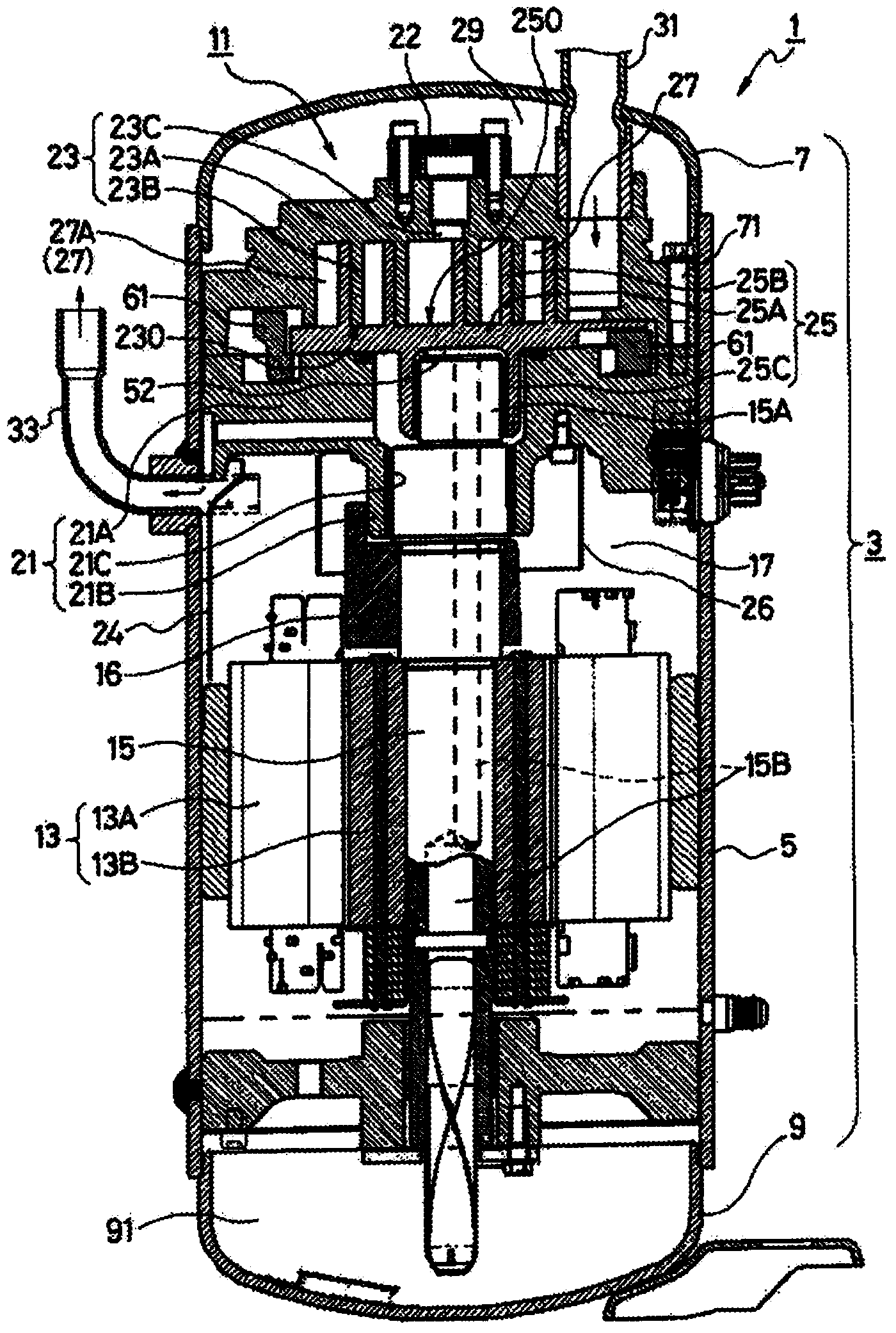

[0055] figure 1 It is a diagram showing an internal high-pressure scroll compressor 1 according to an embodiment of the present invention. The compressor 1 is connected to a refrigerant circuit not shown in the figure that circulates a refrigerant and performs refrigeration cycle operation, and is controlled by an inverter. to compress the refrigerant.

[0056] The compressor 1 has a vertically long cylindrical sealed dome-shaped casing 3 . The casing 3 is a pressure vessel composed of a casing main body 5, a bowl-shaped upper cover 7 and a bowl-shaped lower cover 9. The inside of the casing 3 becomes a cavity, and the casing main body 5 has a The cylindrical main body portion of the axis; the bowl-shaped upper cover 7 is airtightly welded and integrally joined to the upper end of the casing main body 5, and has an upwardly protruding convex surface; the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com