Fluid compressor

A technology of compressor and compression mechanism, which is applied in the field of air or other fluid compressors and refrigerant compressors, which can solve the problems of reducing the centrifugal effect, high price of volumetric pump parts, and inability to ensure oil supply, etc., and achieves low-cost structure, The effect of superior reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, several embodiments of the present invention will be described with reference to the drawings. The same symbols in the drawings of the respective embodiments represent the same objects or members corresponding to the objects.

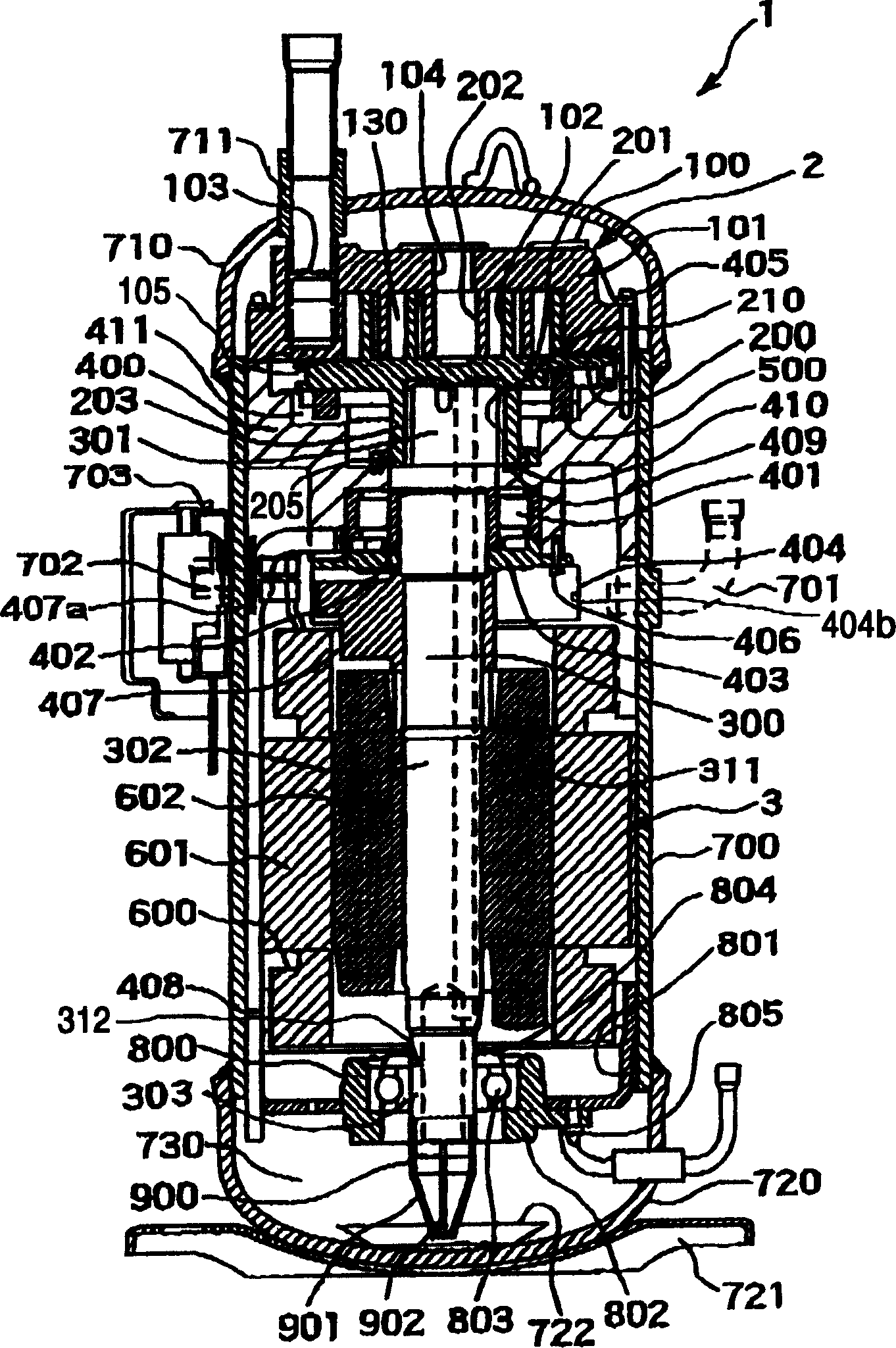

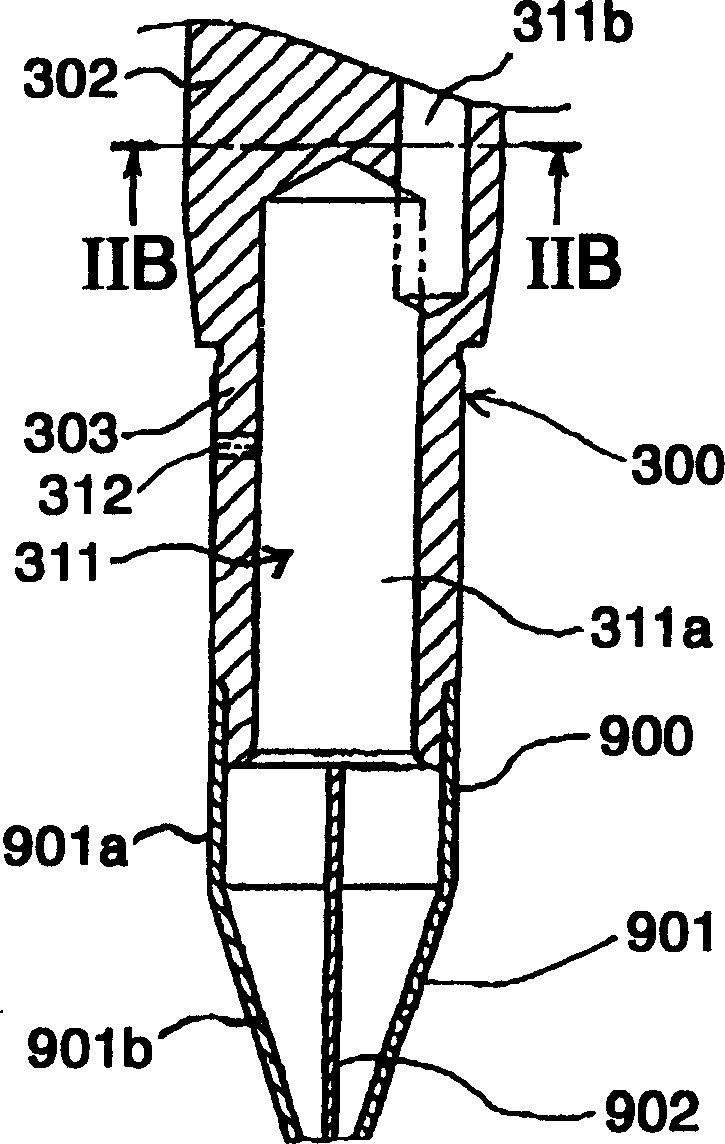

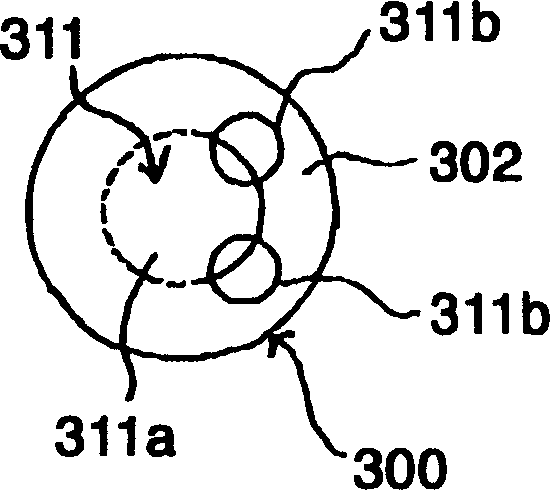

[0025] refer to figure 1 , Figure 2A and Figure 2B , the scroll compressor according to the first embodiment of the present invention will be described. figure 1 is a longitudinal sectional view of a scroll compressor according to a first embodiment of the present invention, Figure 2A yes figure 1 A longitudinal sectional view of the lower part of the rotating shaft and the pump part of the scroll compressor, Figure 2B yes Figure 2A The IIB-IIB sectional view.

[0026] The scroll compressor 1 has a structure in which the compression mechanism unit 2 and the drive unit 3 are accommodated in a sealed container 700 . In this embodiment, the compression mechanism unit 2 , the drive unit 3 , and the oil tank 703 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com