A Gradient Adaptive Diesel Engine Fuel Supply System

A technology of diesel engine and fuel supply system, applied in the direction of engine components, machine/engine, charging system, etc., can solve problems such as affecting vehicle safety, affecting vehicle function, engine stall, etc., to ensure normal supply and increase driving distance. , the effect of increasing oil storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

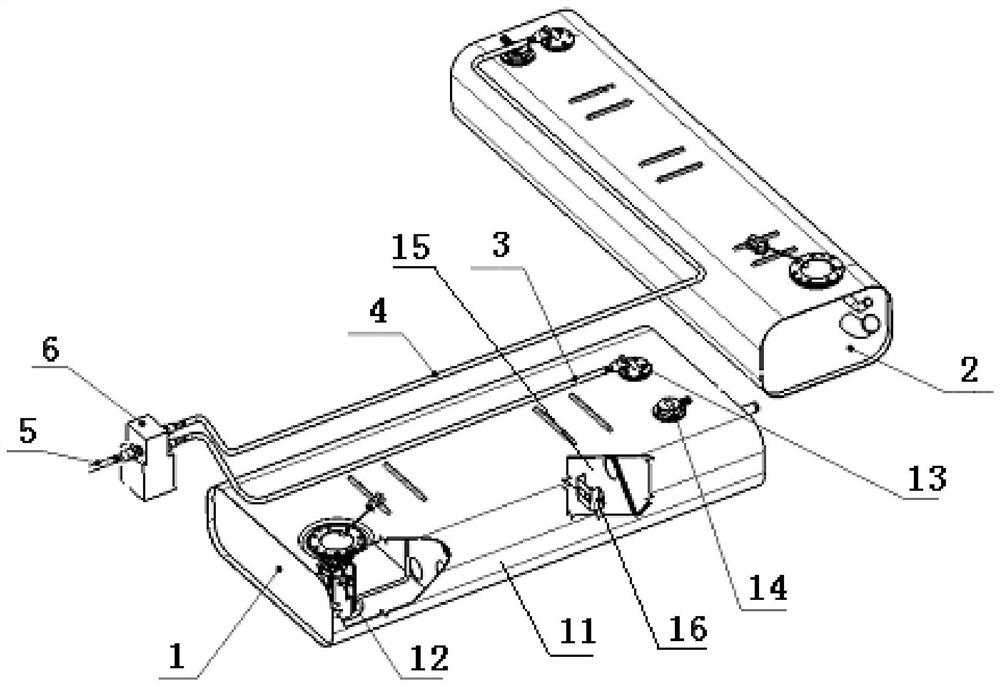

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

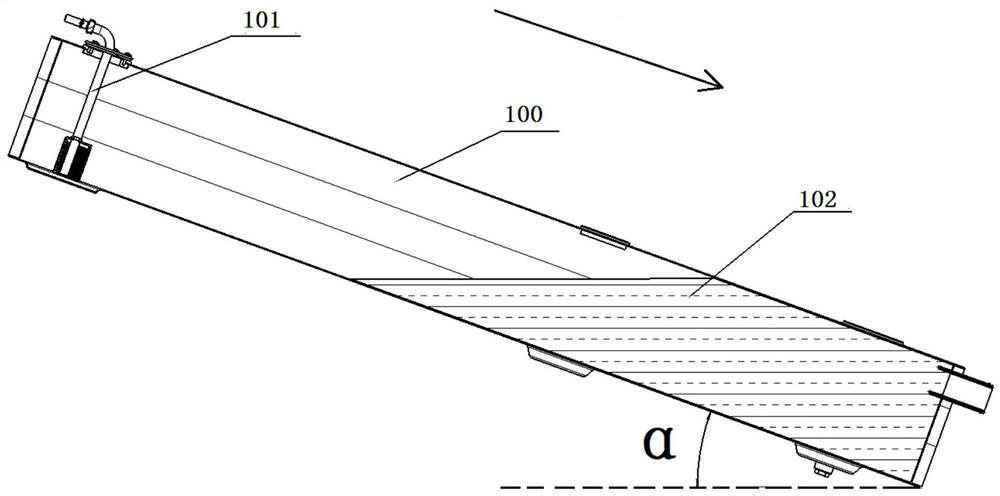

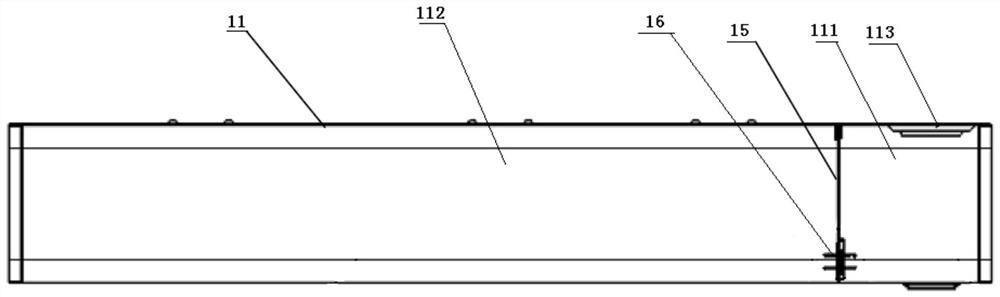

[0026] Such as figure 1 As shown, in order to ensure that the fuel 102 in the main fuel tank body 11 can be smoothly absorbed when the vehicle goes uphill, the oil suction pipe 13 is usually arranged behind the main fuel tank body 11 (with the forward direction of the vehicle as the front, figure 1 The direction of the middle arrow is the forward direction of the vehicle), so as to ensure that the fuel 102 can be sucked uphill.

[0027] When the car is on a slope with a slope of α, when going downhill, the fuel 102 flows to one side due to gravity, even if there is half a tank of fuel in the main fuel tank body 11 at this time, there is still no fuel available near the oil suction pipe 13, and the engine cannot absorb fuel. In extreme cases, it may cause the engine to stall, which will affect some functions of the vehicle and seriously affect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com