Patents

Literature

104results about How to "Increase oil storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

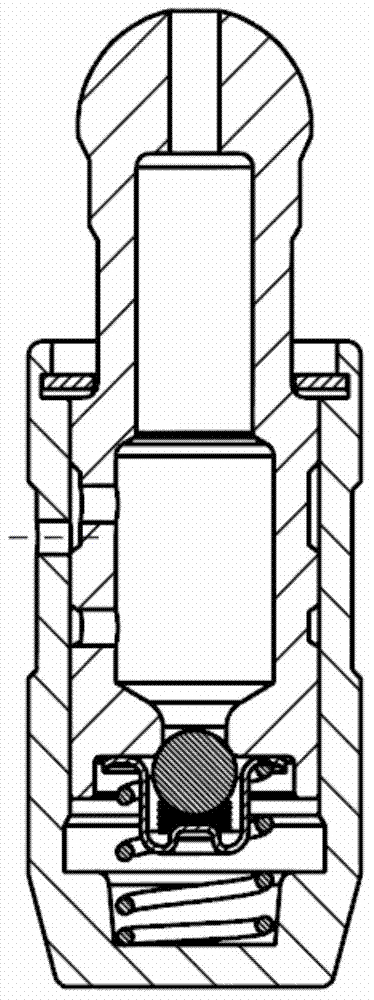

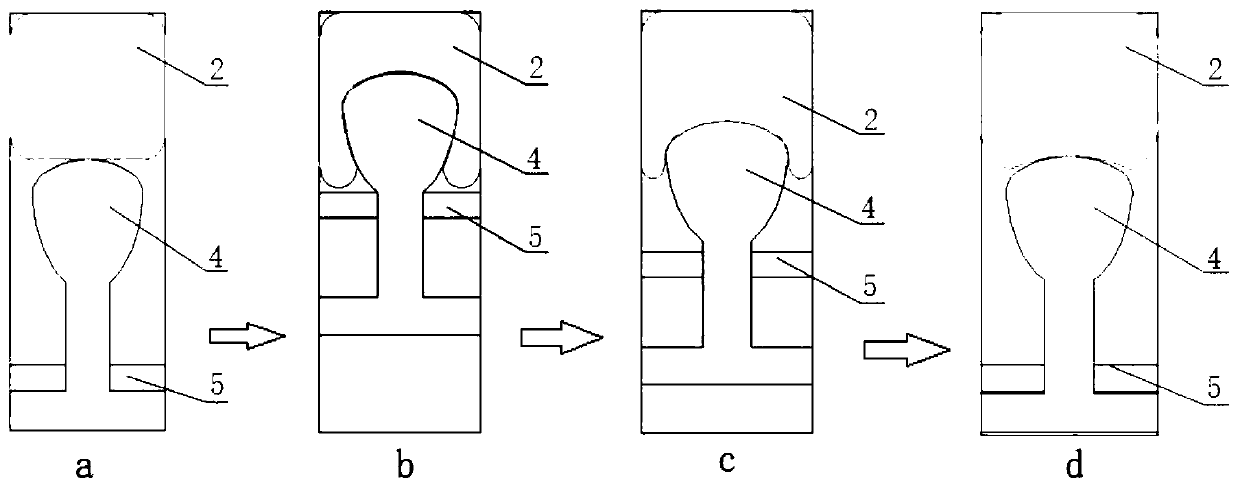

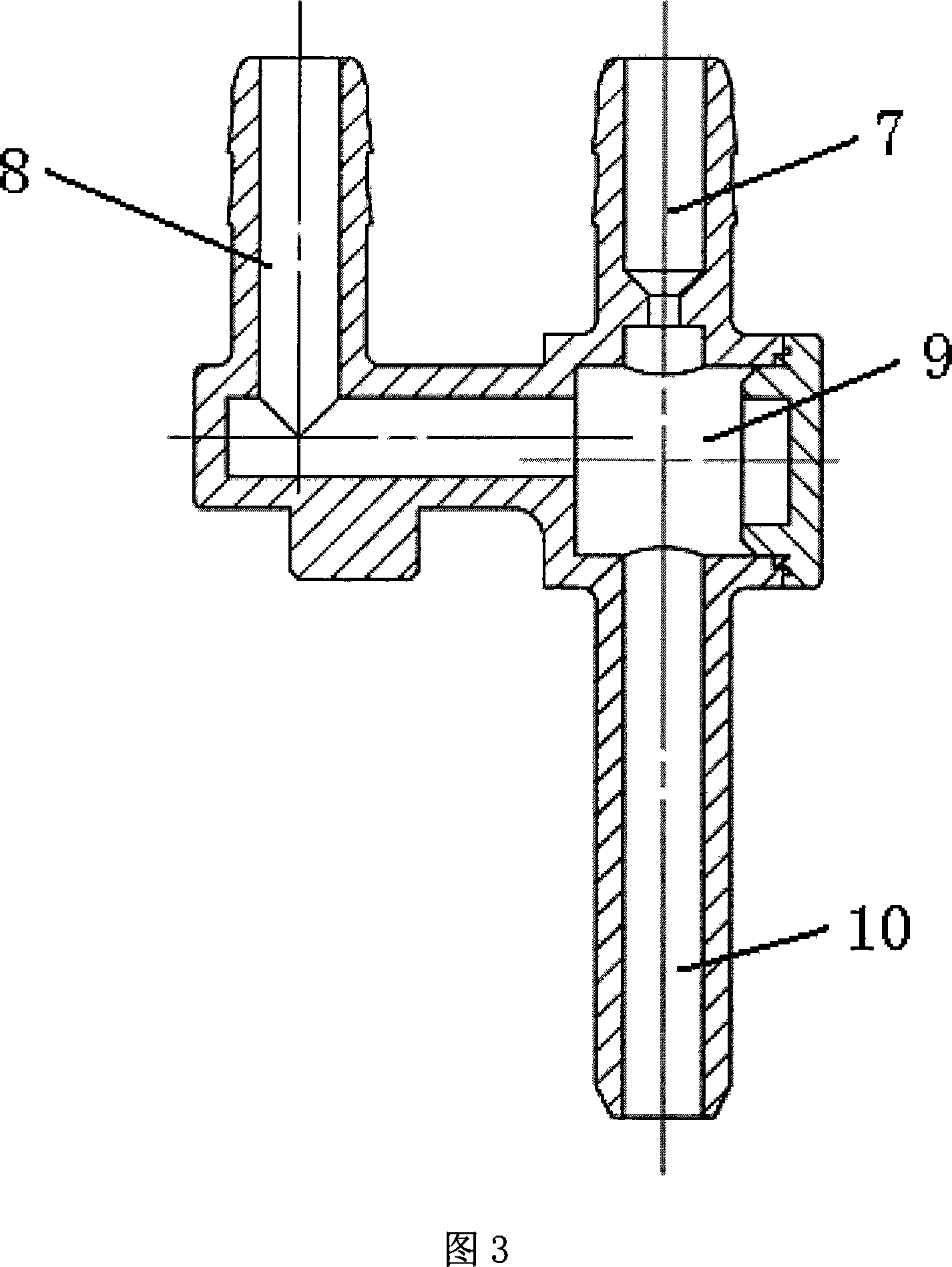

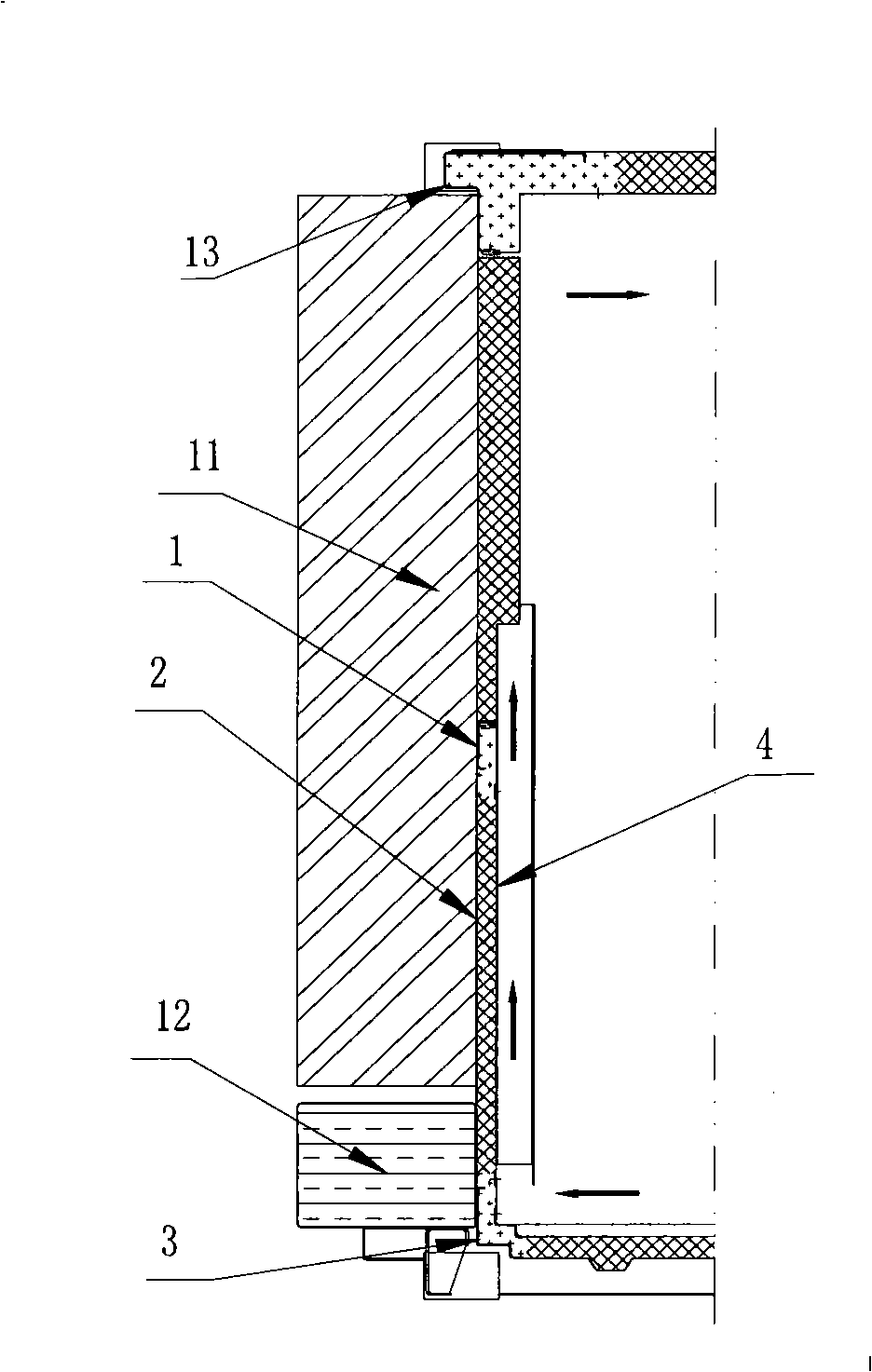

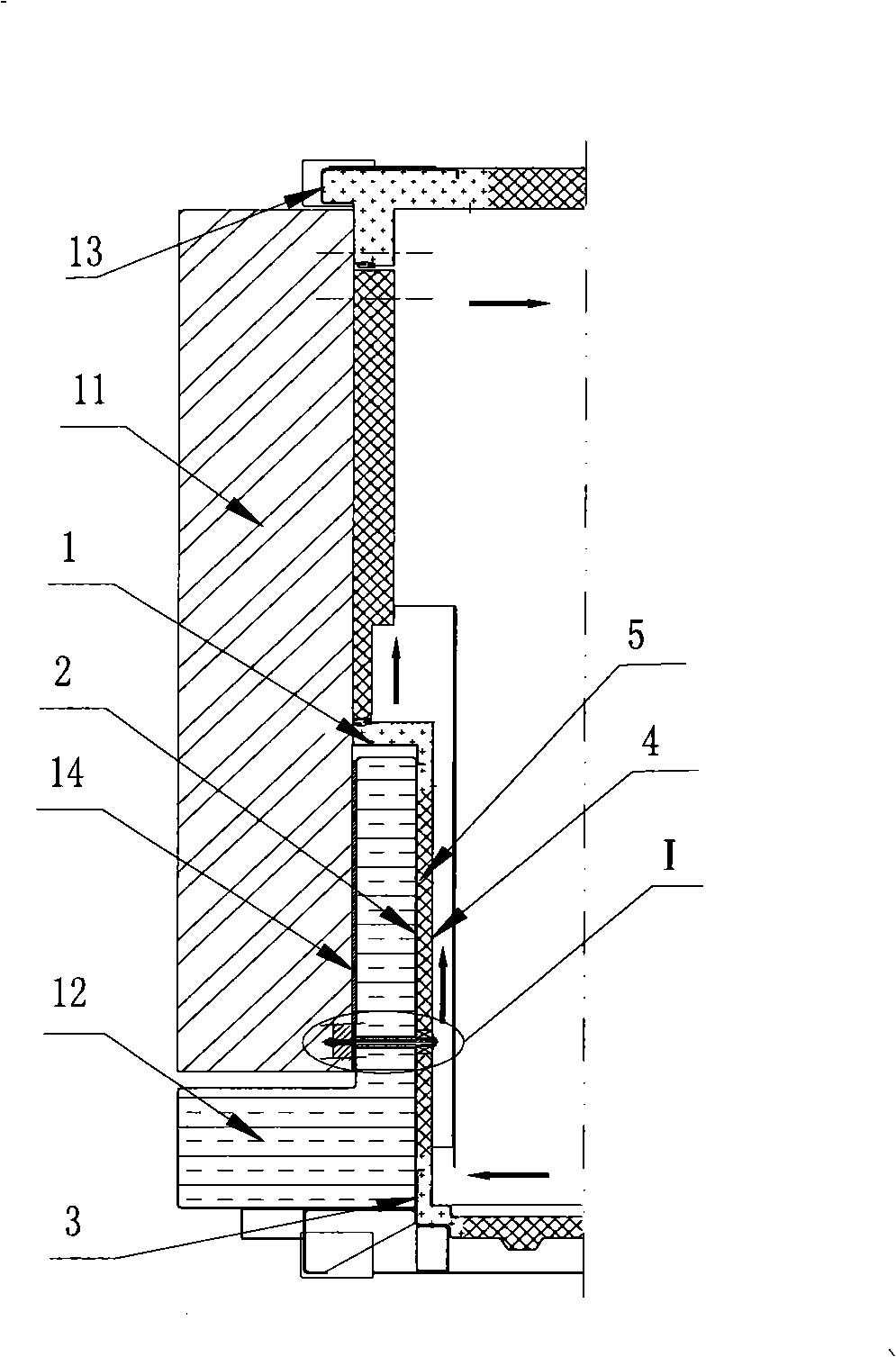

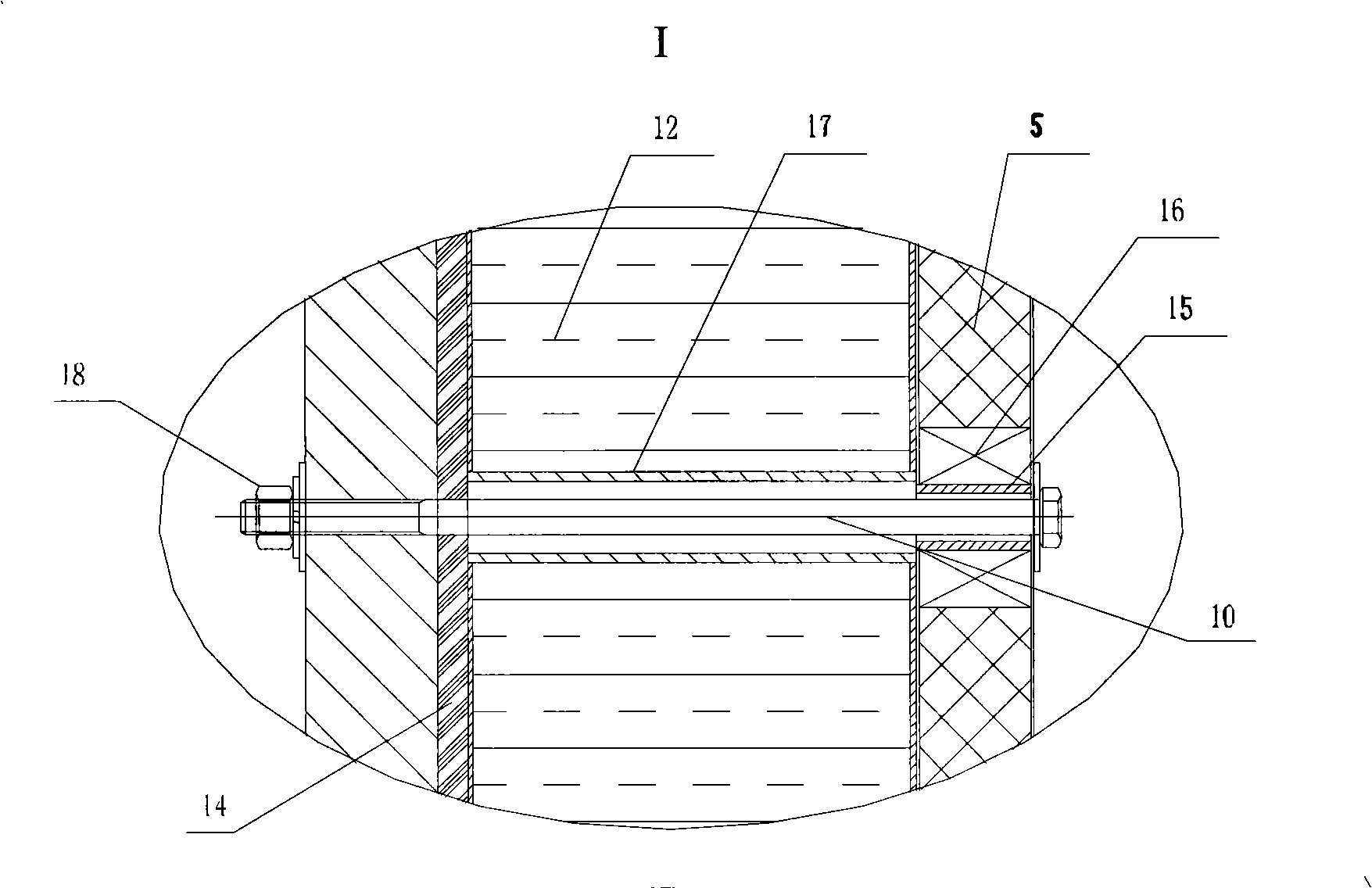

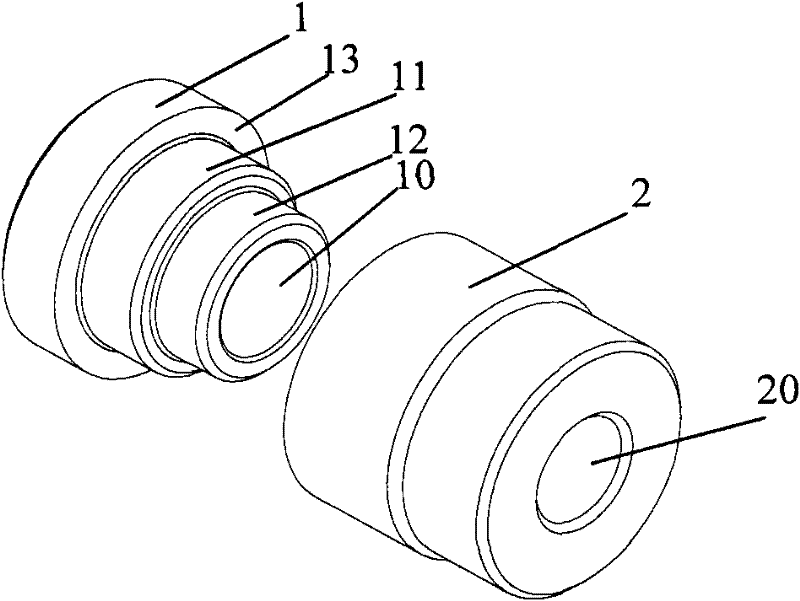

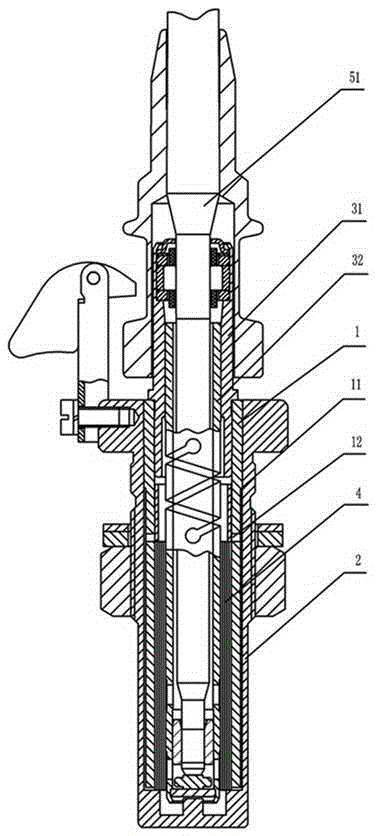

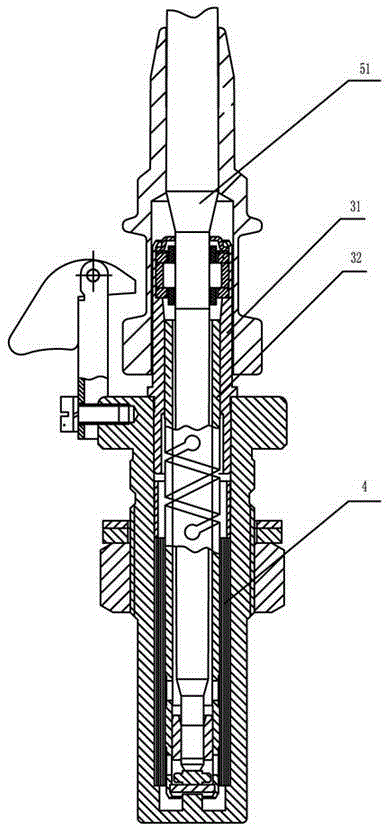

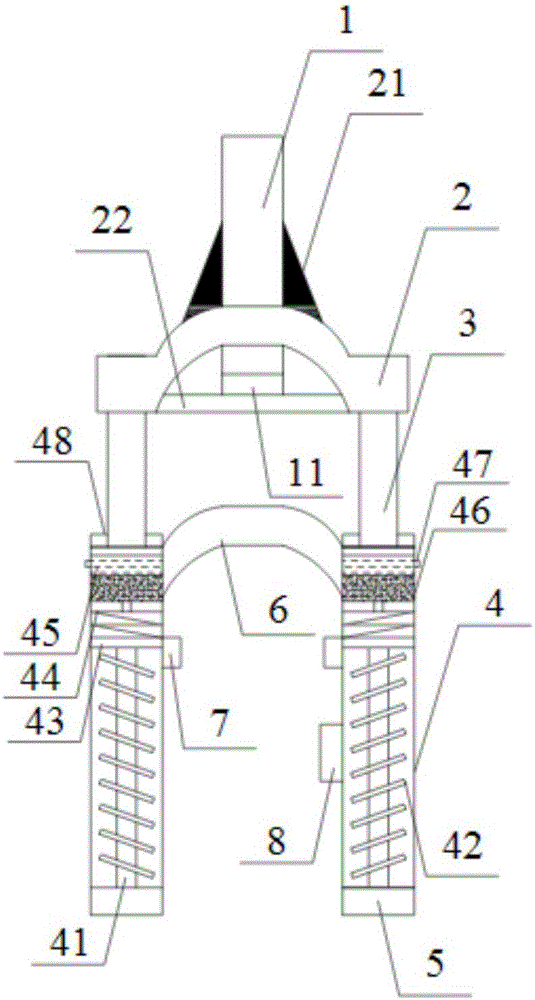

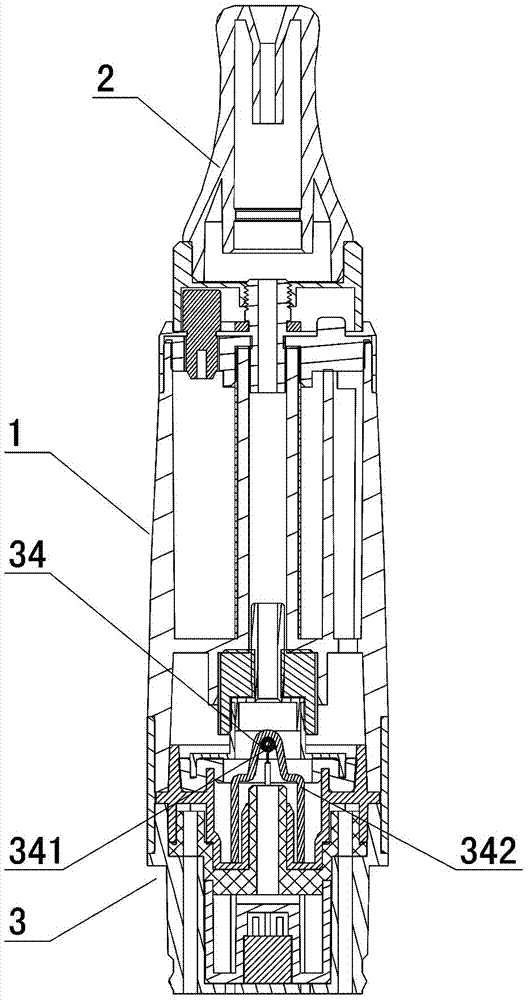

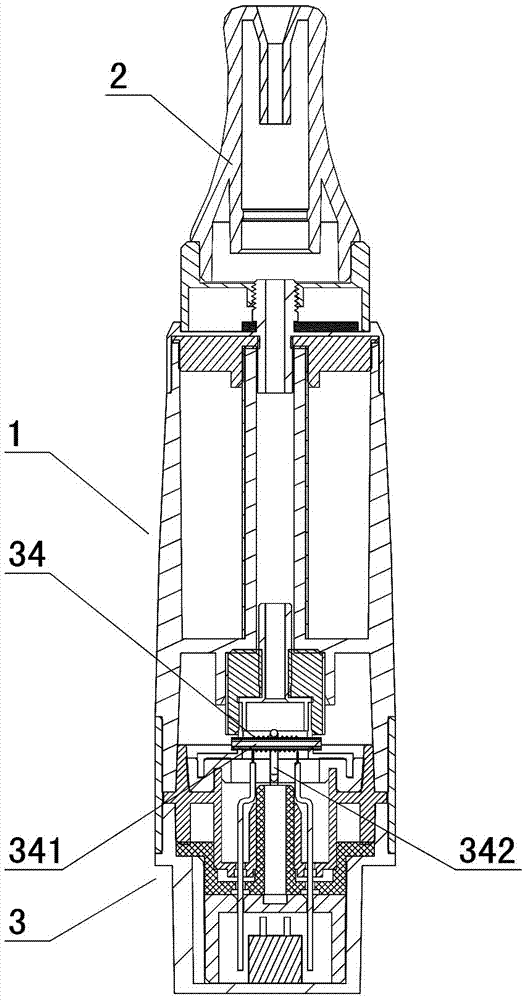

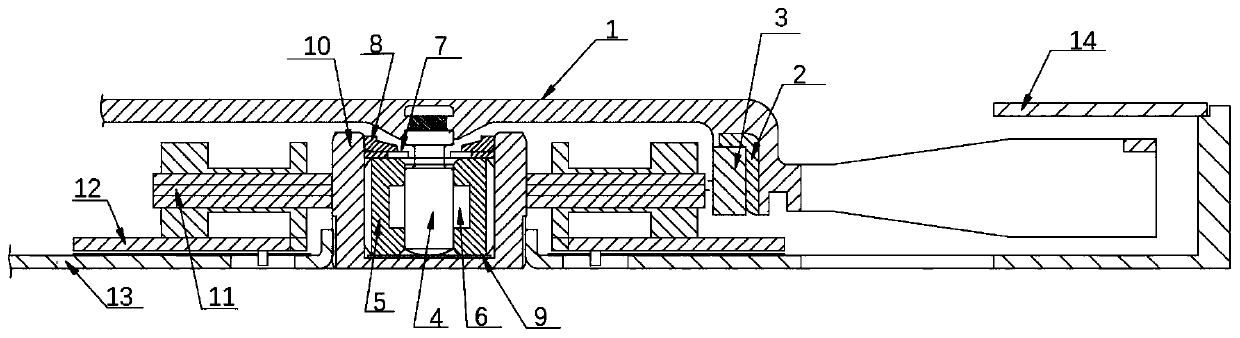

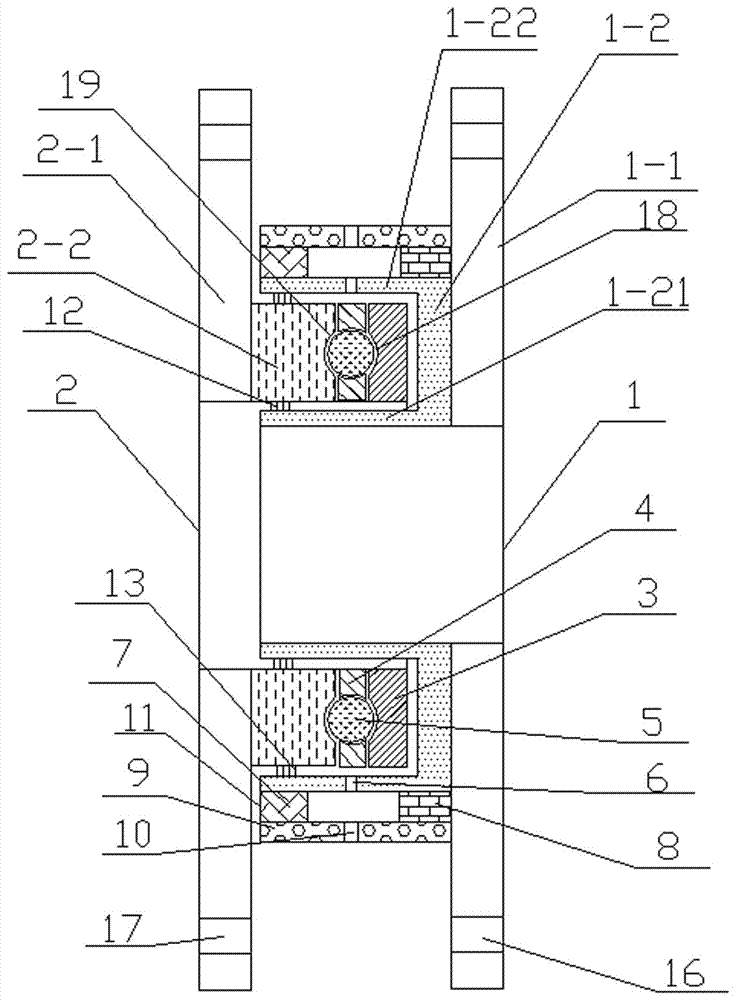

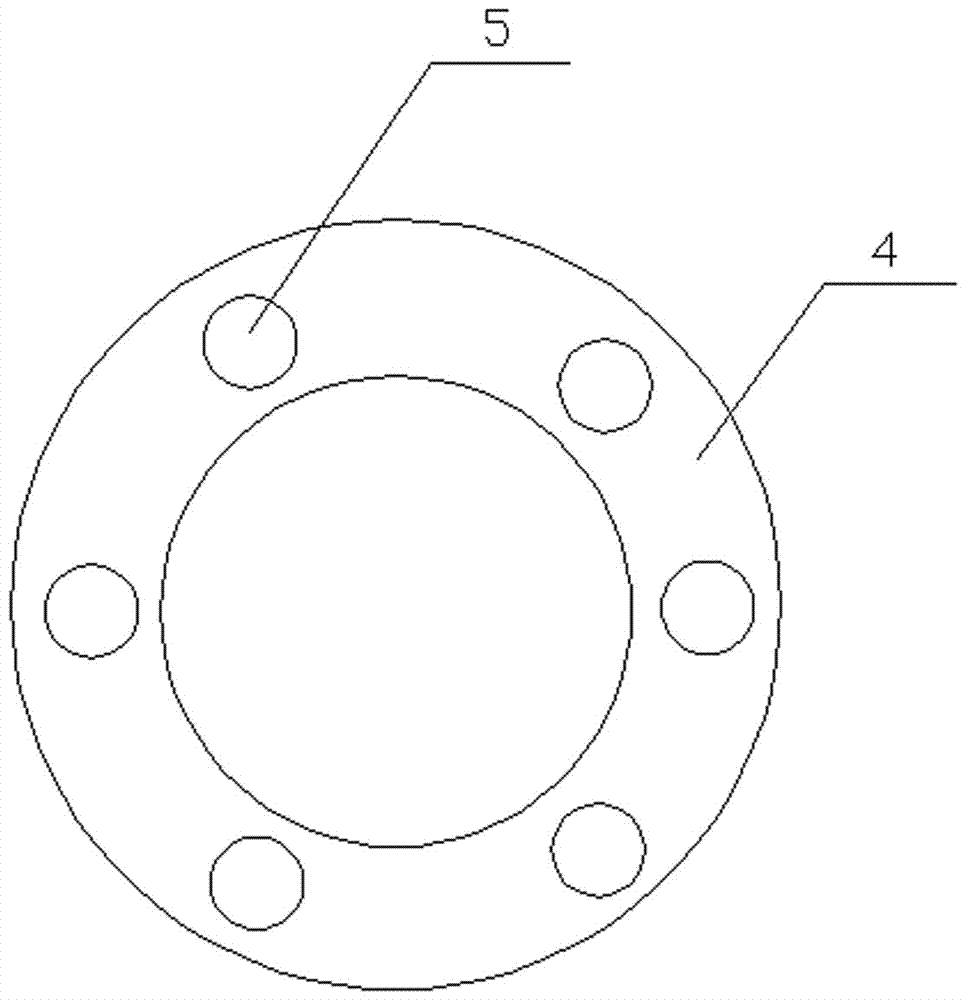

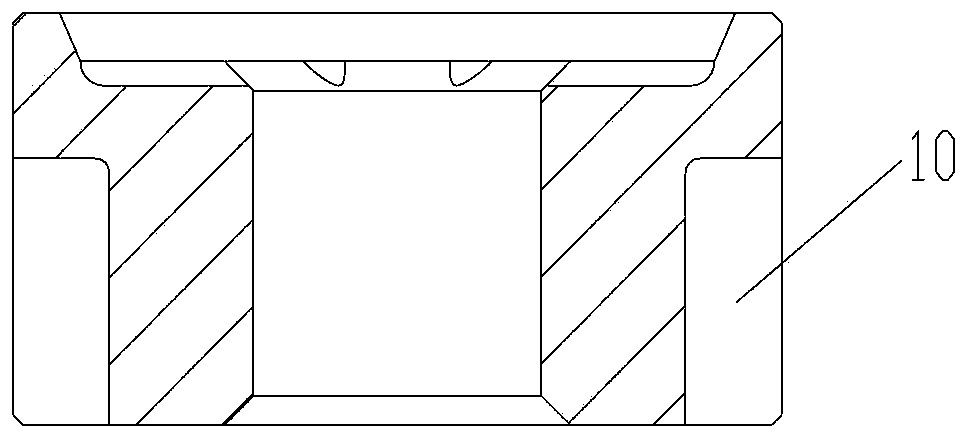

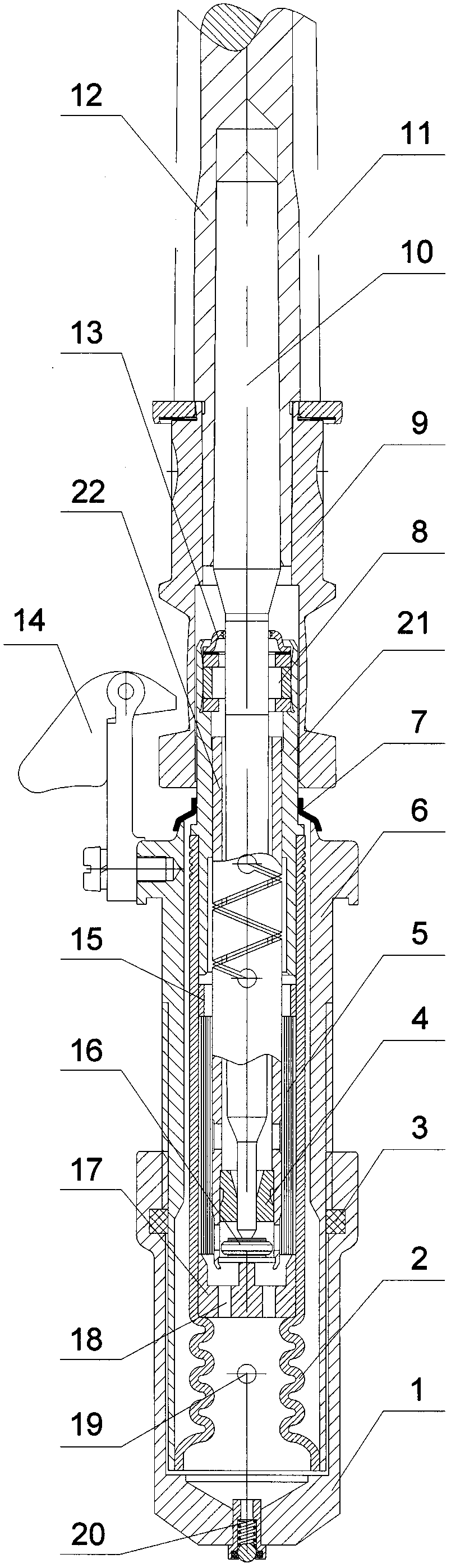

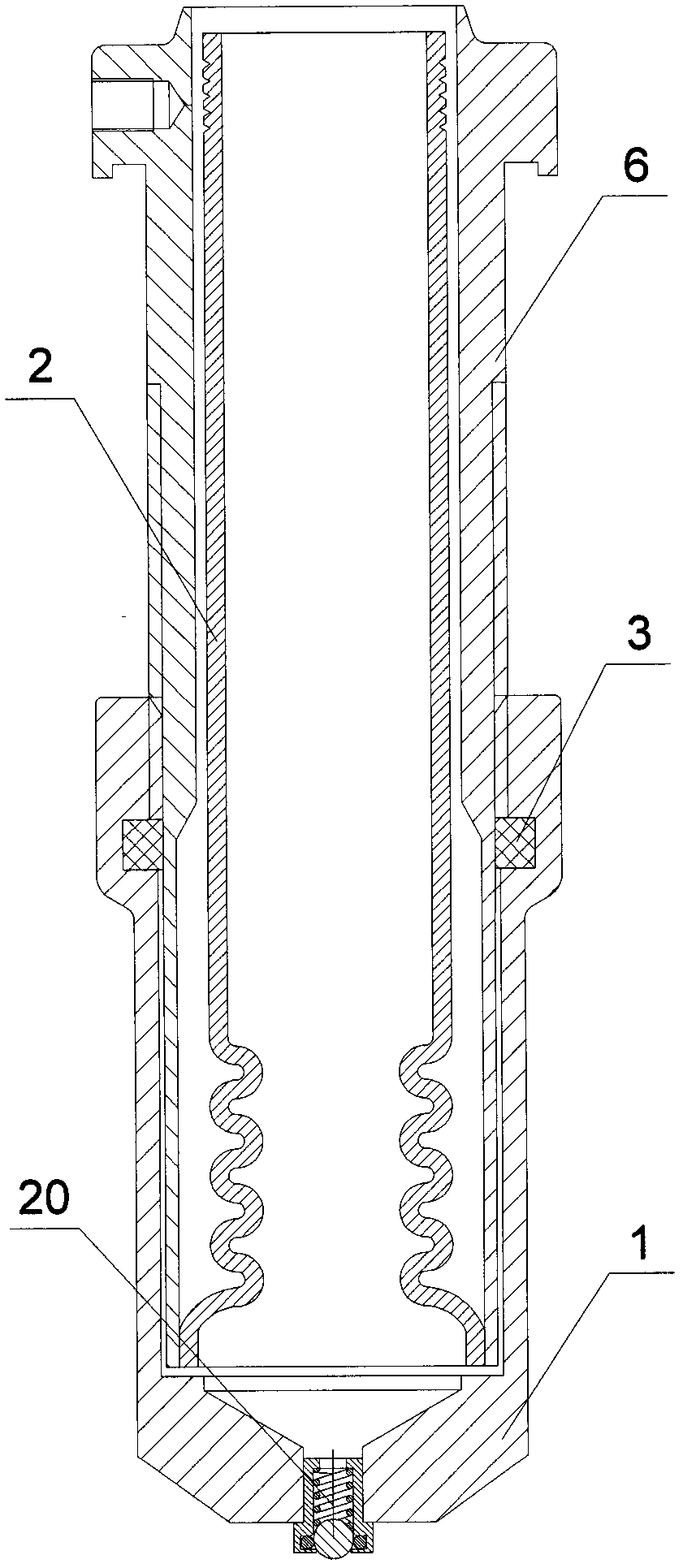

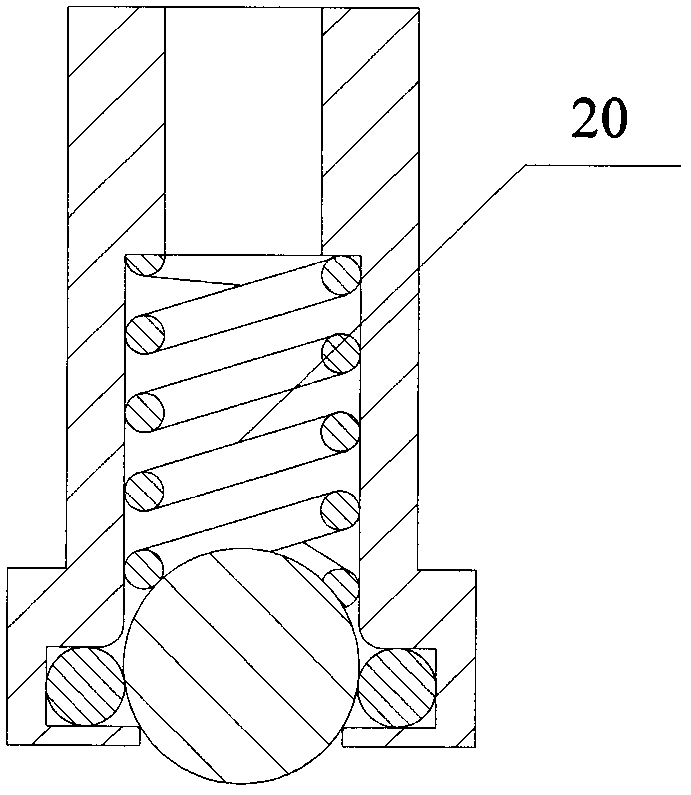

Columnar hydraulic tappet

ActiveCN103939162AThe overall structure is simple and reliableIncrease oil storagePump assembliesMachines/enginesCheck valveHydraulic tappet

The invention relates to a columnar hydraulic tappet which comprises a shell. A plunger is correspondingly installed in the shell. A high-pressure cavity for a hydraulic medium extends between a sealing base of the plunger and the lower side of the shell and can be sealed through a check valve which is opened towards the high-pressure cavity. An outer ring groove for hydraulic medium circulation is formed in the outer diameter of the shell, an inner ring groove for hydraulic medium circulation is formed in the radial inner side of the shell, and one or more shell oil holes are formed between the inner ring groove and the outer ring groove. The plunger is composed of a sealed hemispherical head portion, a rod portion and a body portion. The columnar hydraulic tappet is characterized in that an inward-concave neck portion is arranged between the head portion of the plunger and the rod portion of the plunger, and the wall thickness of the neck portion is 105% to 120% the wall thickness of the rest of the plunger. The columnar hydraulic tappet is simple and firm in structure, the design that the wall thickness of the low-strengthen area of the single-body thin-walled hollow plunger is increased is adopted, and therefore both the requirement for increasing the oil storage amount in the plunger and the requirement for improving fatigue strengthen are considered.

Owner:HANGZHOU XZB TECH

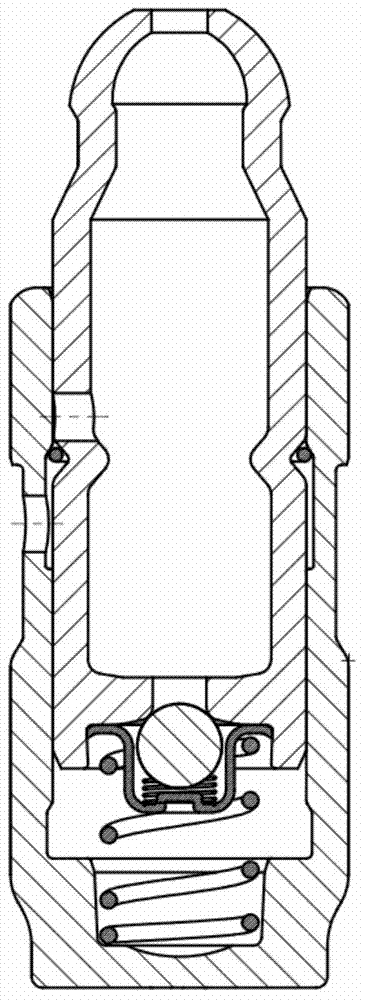

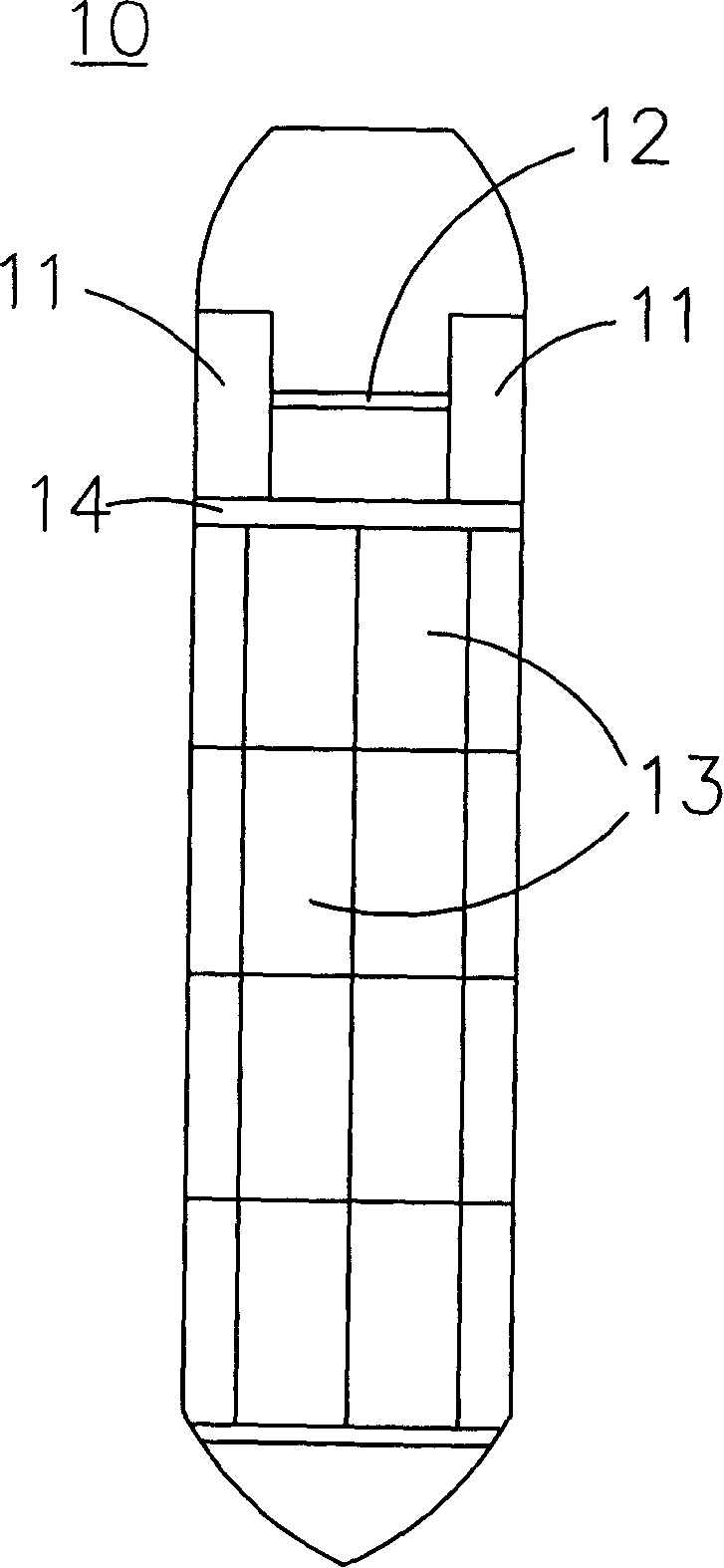

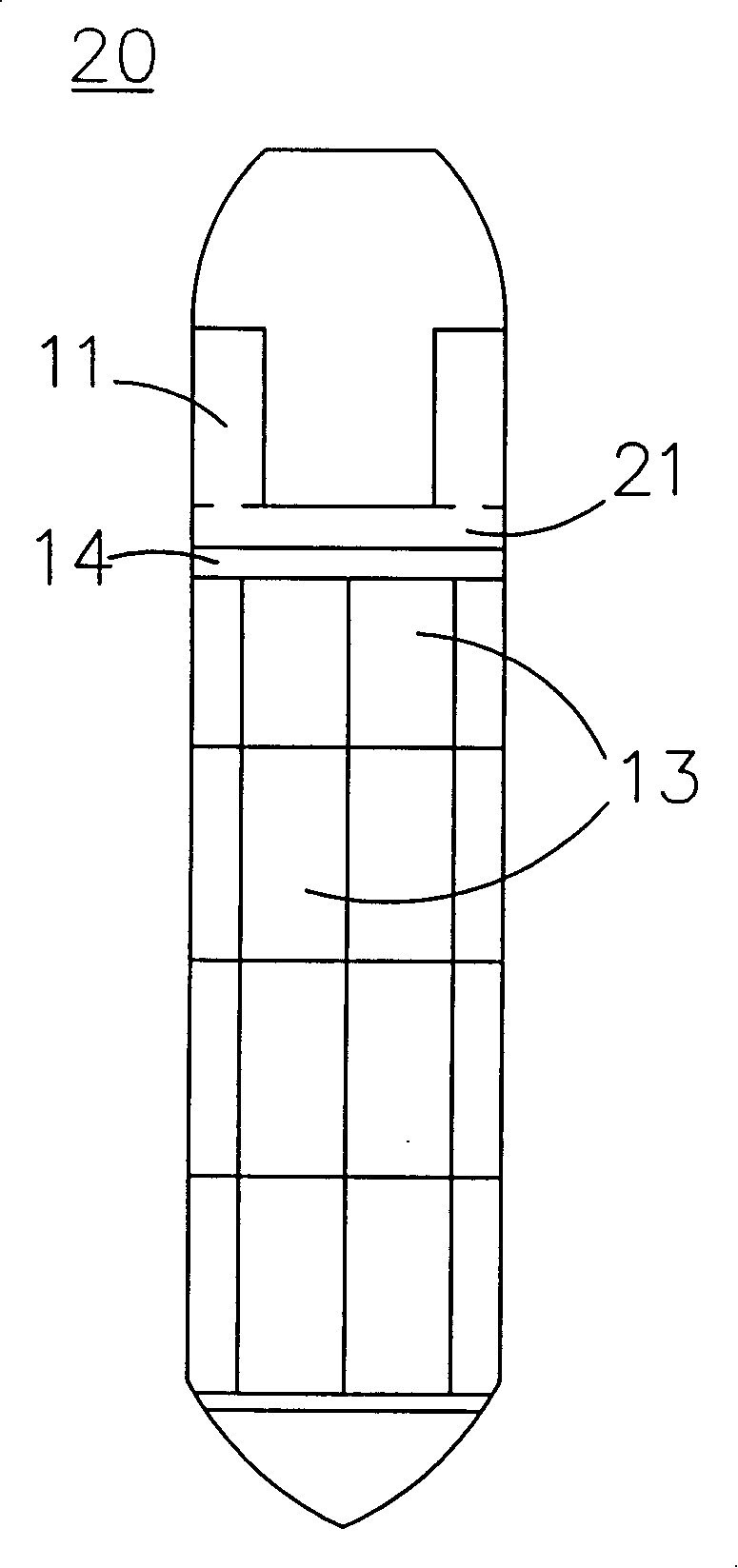

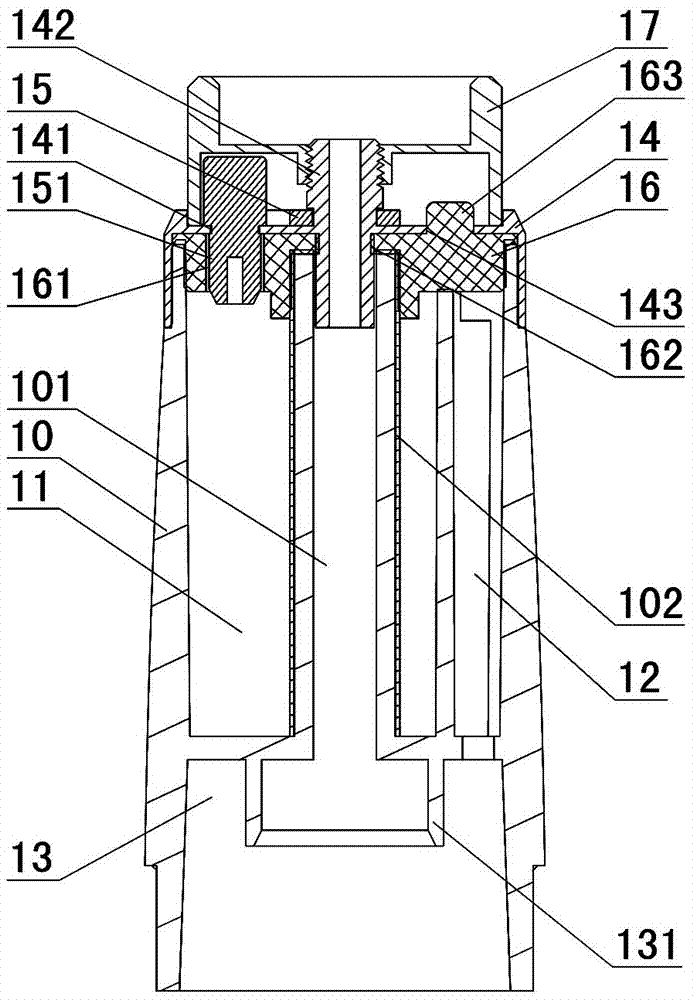

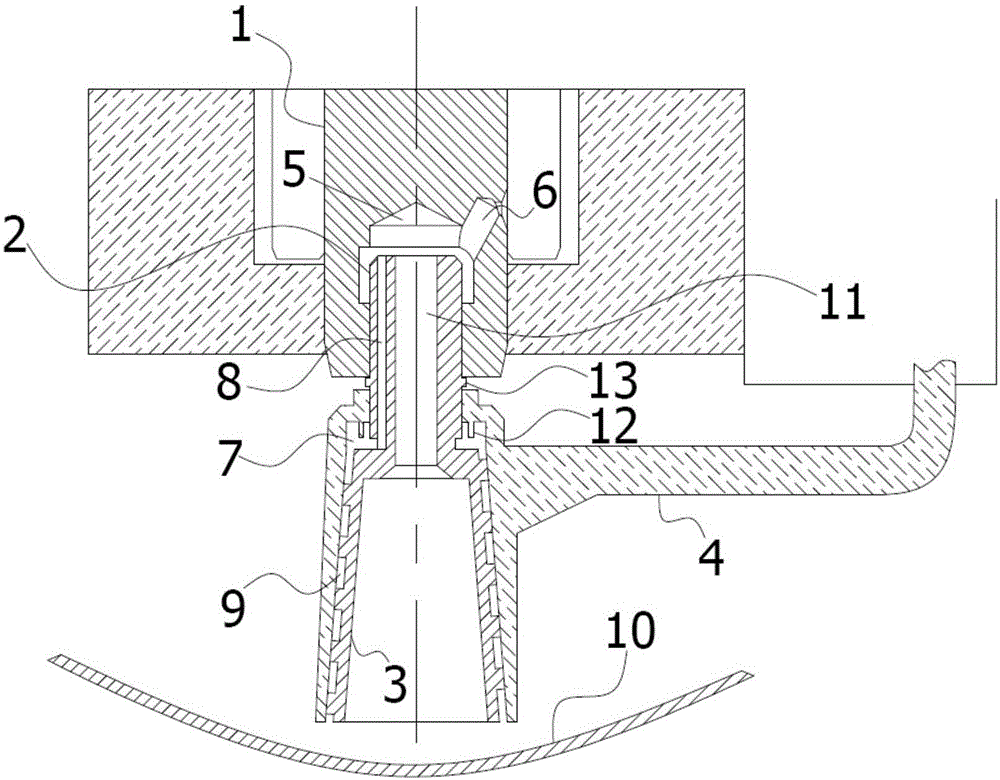

Electronic cigarette oil bottle with anti-leaking function and electronic cigarette atomizer

ActiveCN104068477AGuaranteed oil capacityIncrease oil storageTobacco devicesElectronic cigaretteBottle

The invention discloses an electronic cigarette oil bottle with an anti-leaking function and an electronic cigarette atomizer. The electronic cigarette oil bottle comprises a bottle provided with an airflow channel tube in the middle, wherein a big oil storing chamber and an oil adding channel are arranged inside the bottle; a small oil storing chamber is arranged on one side, used for mounting an atomizing chamber, of the bottle; the big oil storing chamber is communicated with the small oil storing chamber through the oil adding channel; the electronic cigarette atomizer comprises an electronic cigarette oil bottle, a cigarette holder and the atomizing chamber; one end of the electronic cigarette oil bottle is connected with the cigarette holder and the other end of the electronic cigarette oil bottle is connected with the atomizing chamber; the electronic cigarette oil bottle is the electronic cigarette oil bottle with the anti-leaking function. According to the invention, the electronic cigarette oil bottle provided with both the anti-leaking function and the electronic cigarette atomizer has the advantages of leakage prevention, big oil reserve, cleaning and sanitariness and convenience and comfort for utilization.

Owner:SHENZHEN MIST TECH DEV

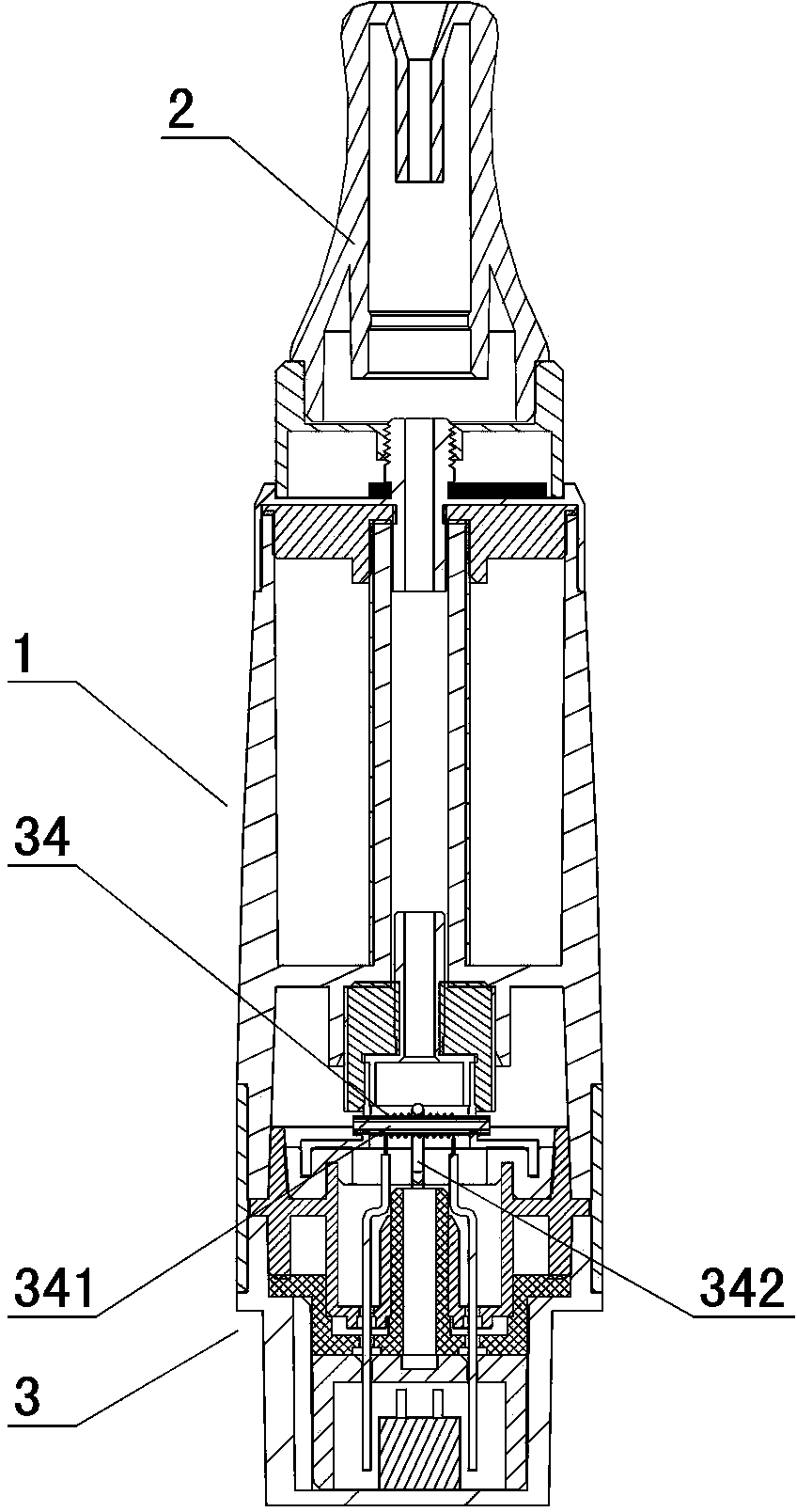

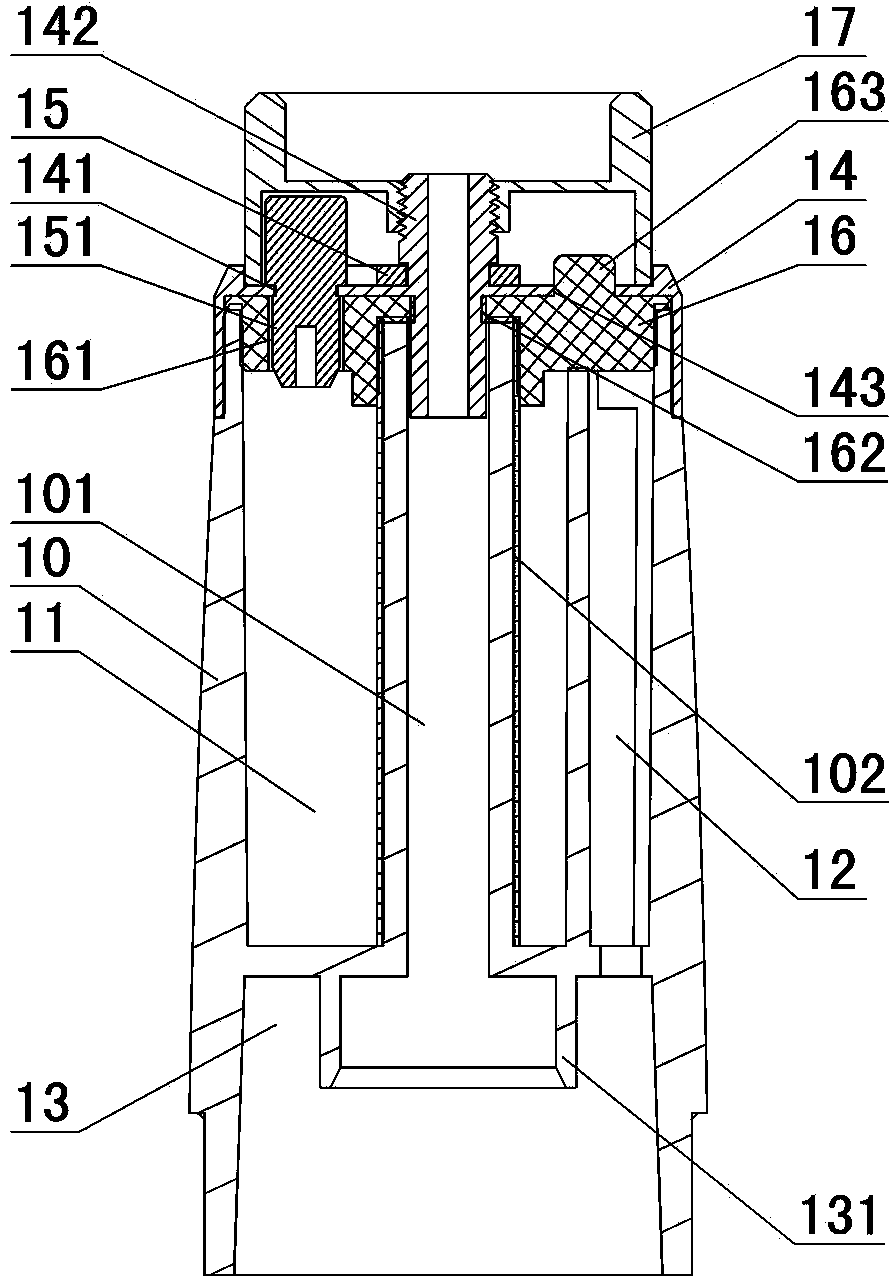

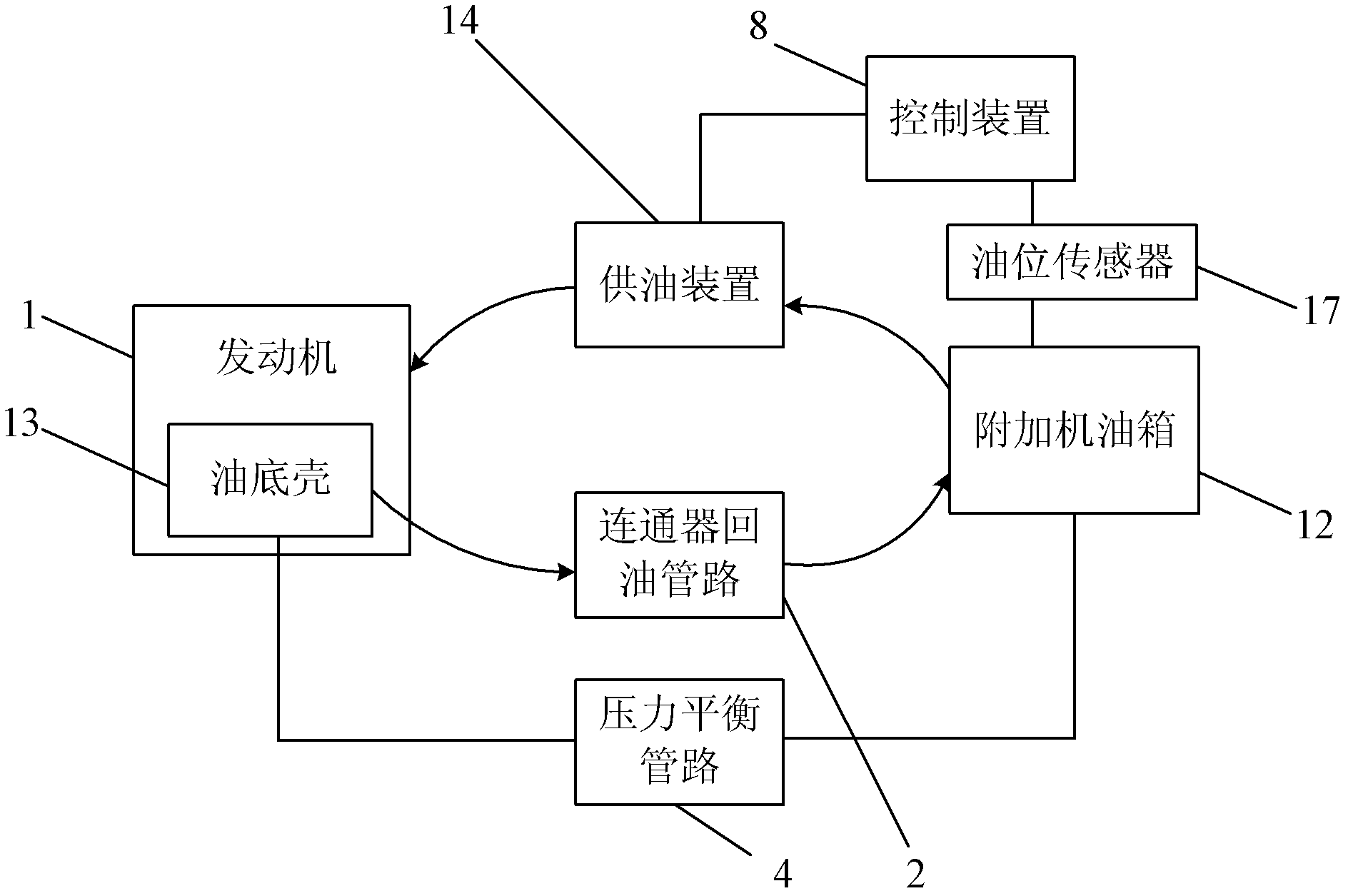

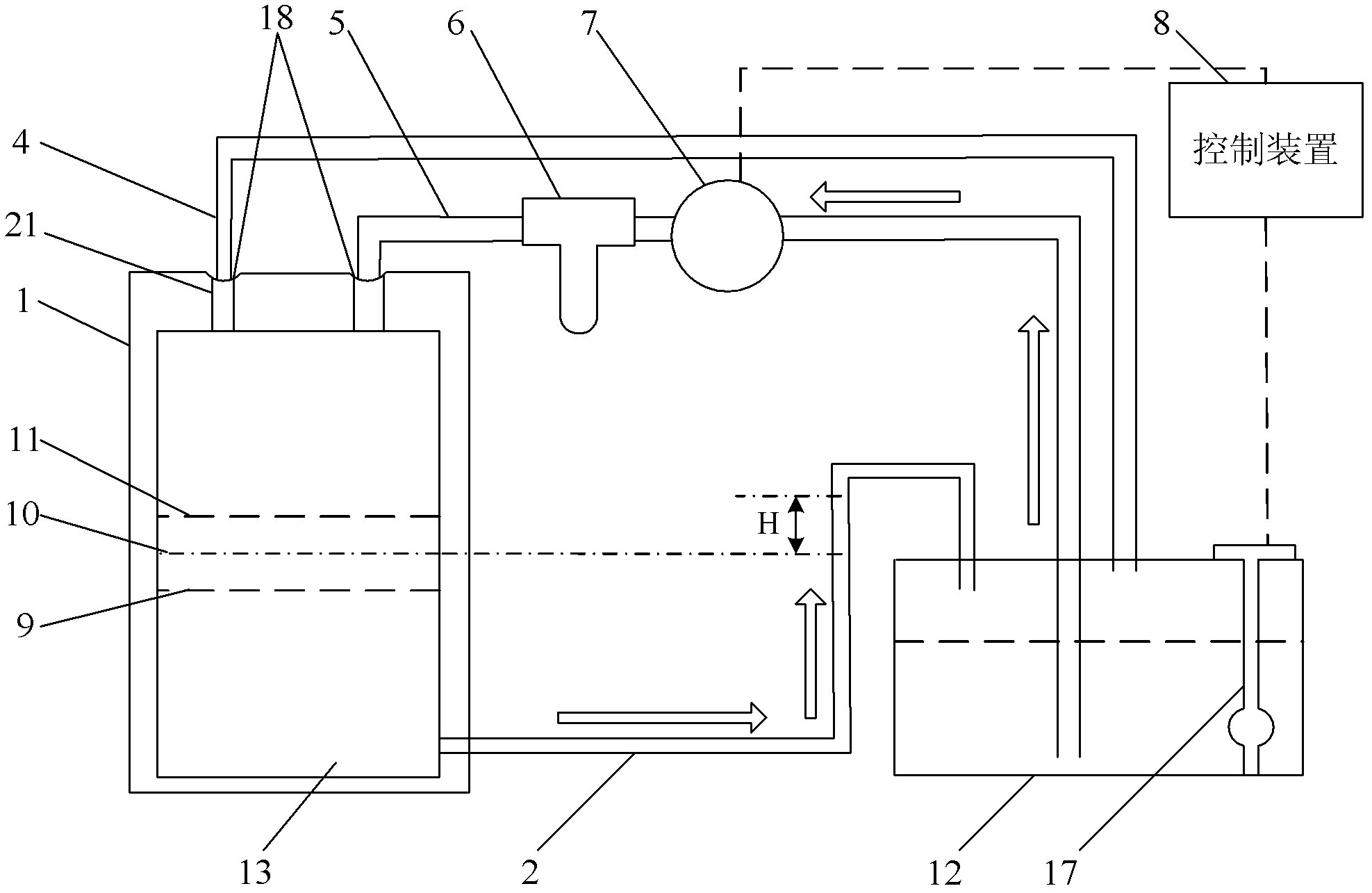

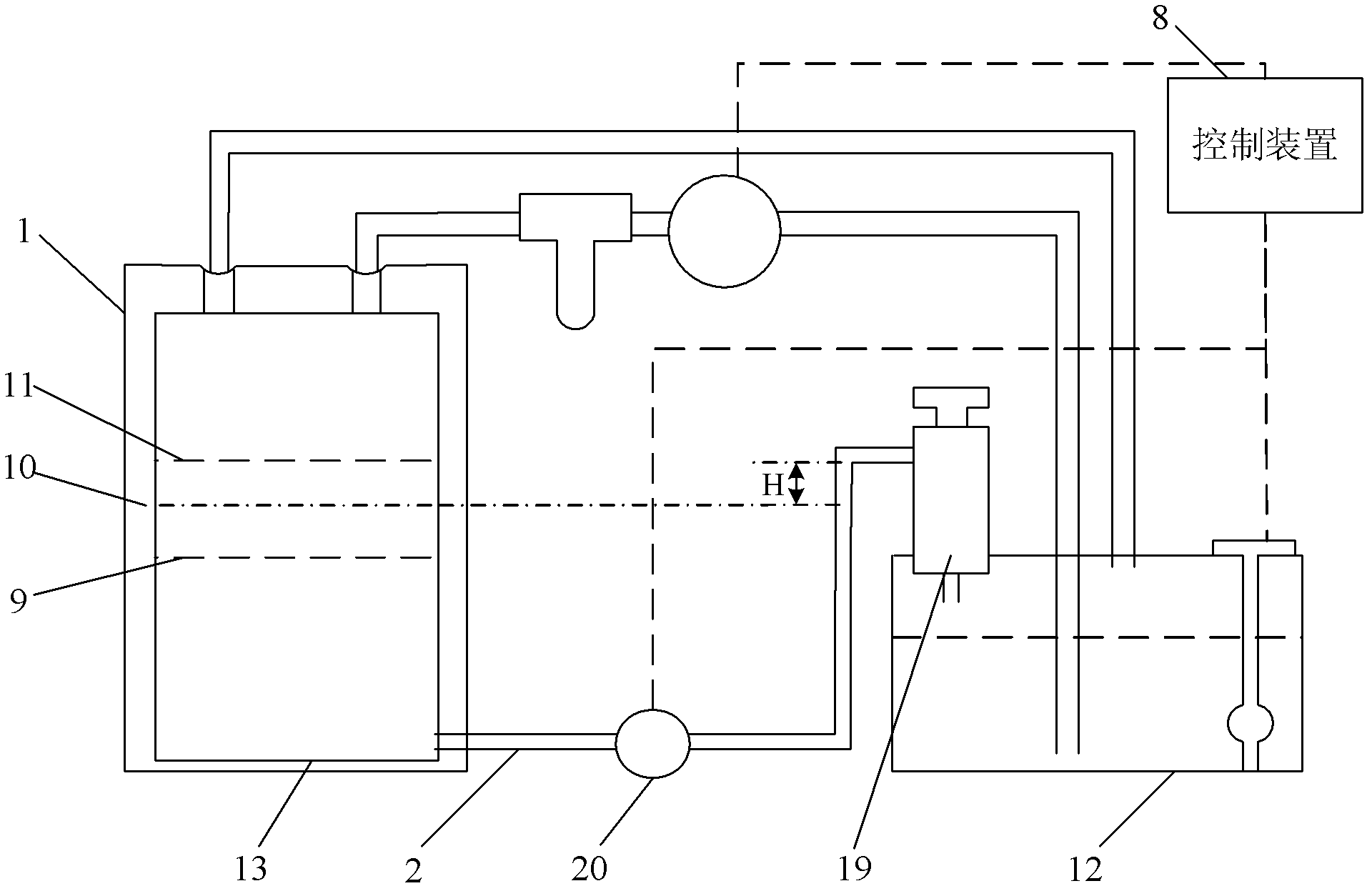

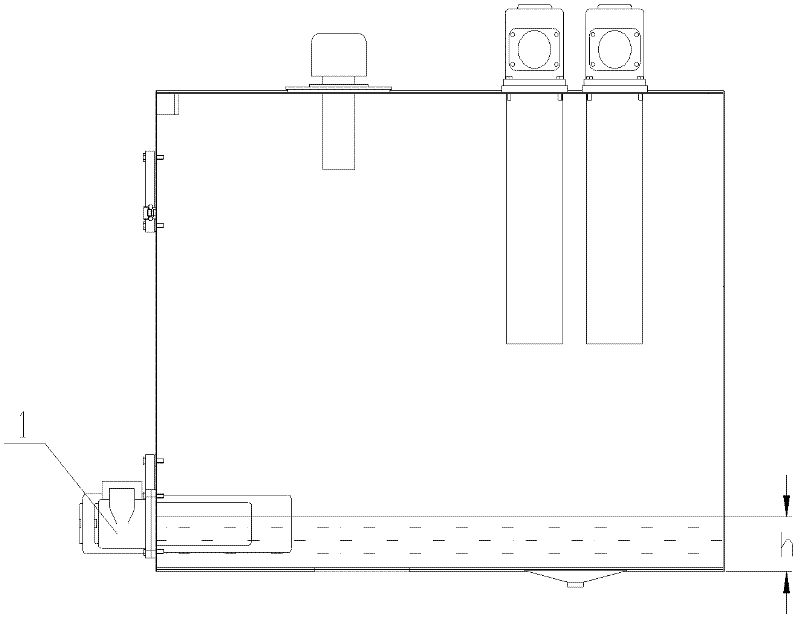

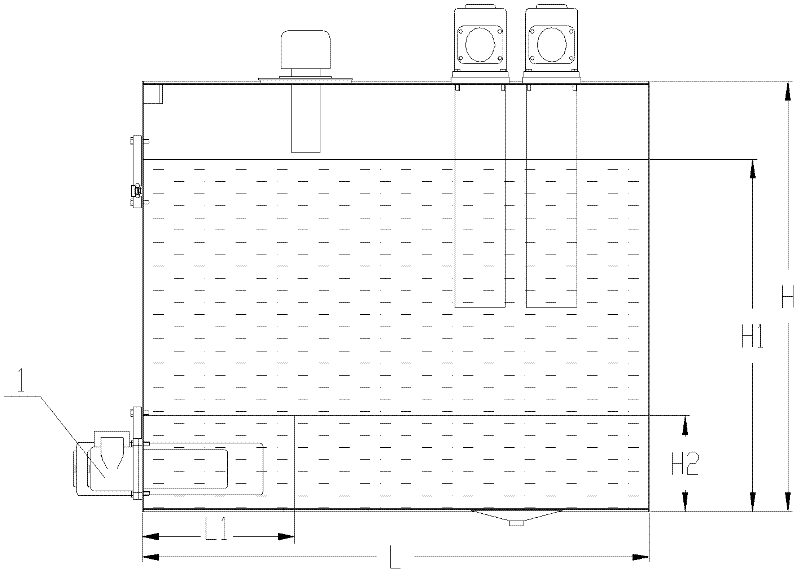

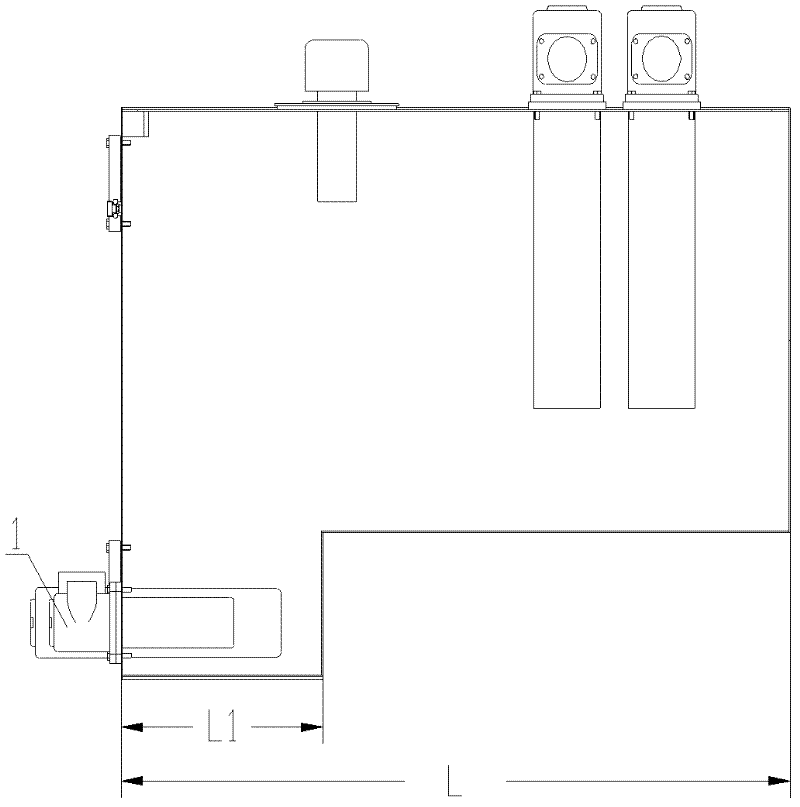

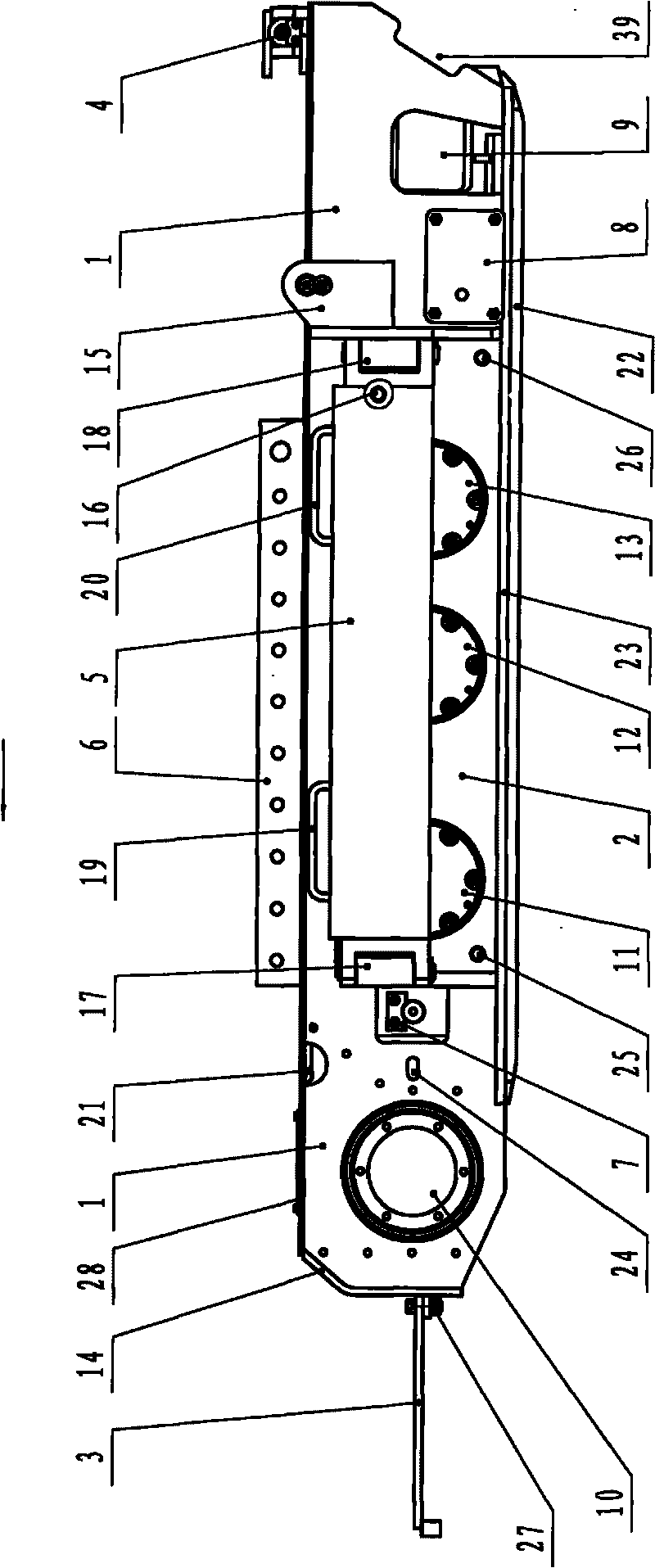

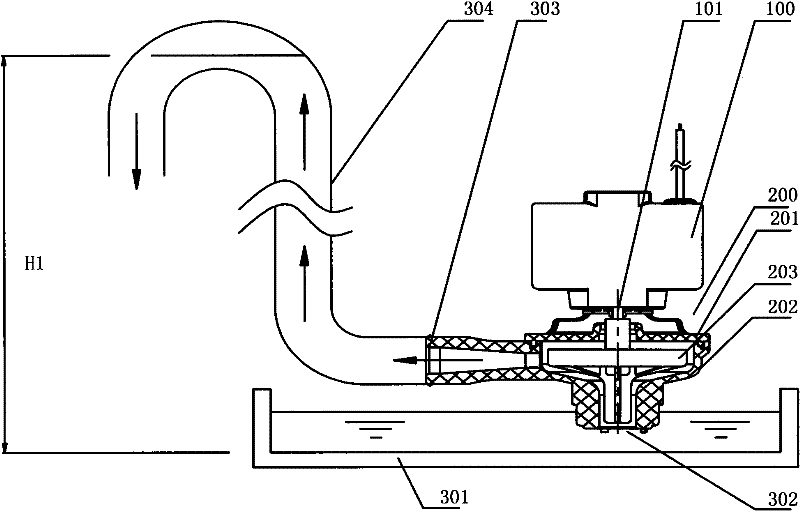

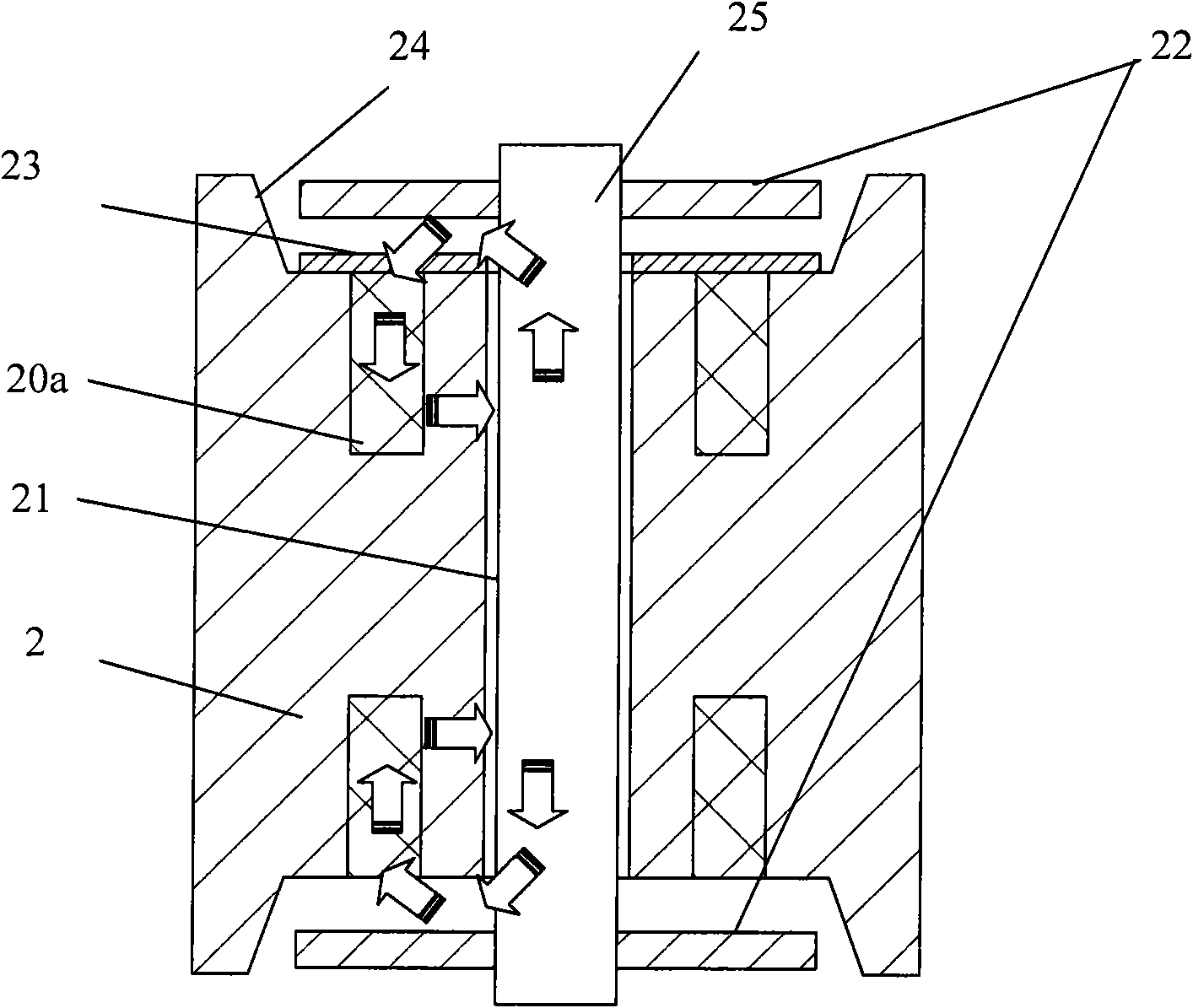

Automatic machine oil cleaning system, oil return pipeline of communicating vessel, and engine system

ActiveCN102536379AIncrease oil storageImprove cleanlinessLubricant conduit arrangementsLubricant mounting/connectionLubricationOil supply

The embodiment of the invention provides an automatic machine oil cleaning system, relates to the technical field of internal combustion engines lubrication, and is used for prolonging the replacing period of machine oil in an engine, reducing the cost of a machine oil cleaning system, and improving the reliability of the machine oil cleaning system. The automatic machine oil cleaning system comprises an auxiliary machine oil box, an oil supply device connected with the auxiliary machine oil box and the engine respectively, and an oil return pipeline of a communicating vessel, wherein two ends of the oil return pipeline are communicated with the bottom end of an oil pan and the top end of the auxiliary machine oil box respectively; the peak of the oil return pipeline is higher than the set machine oil level of the oil pan; the set machine oil level of the oil pan is lower than the accessible uppermost level and the accessible bottommost level of the engine; the height difference between the set machine oil level of the oil pan and the accessible uppermost level or the accessible bottommost level is set according to the pressure in the oil pan during the operation of the engine and the atmospheric pressure, so that when the machine oil level in the oil pan is higher than the set machine oil level, machine oil can flow back to the auxiliary machine oil box along the oil return pipeline.

Owner:HUAWEI TECH CO LTD

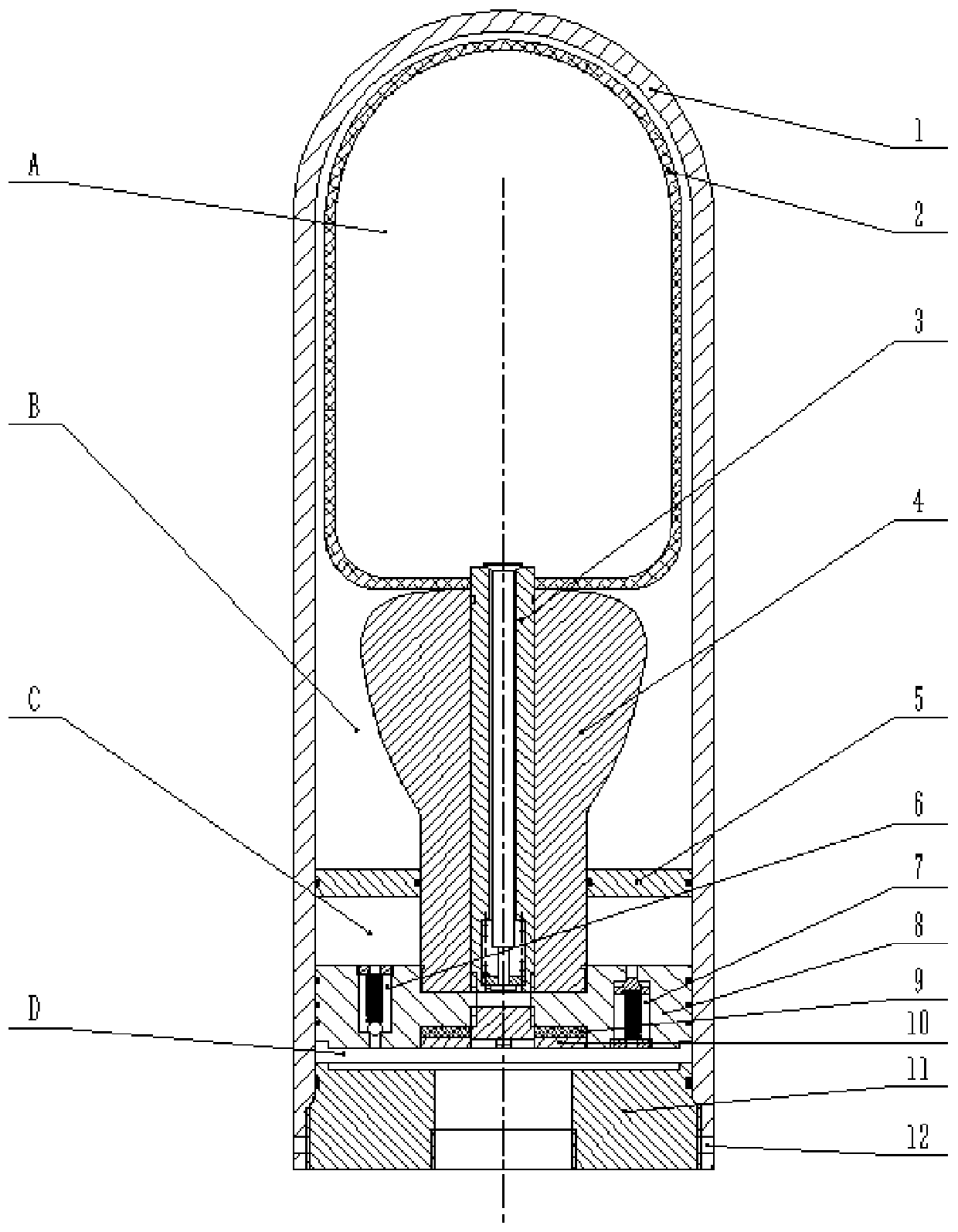

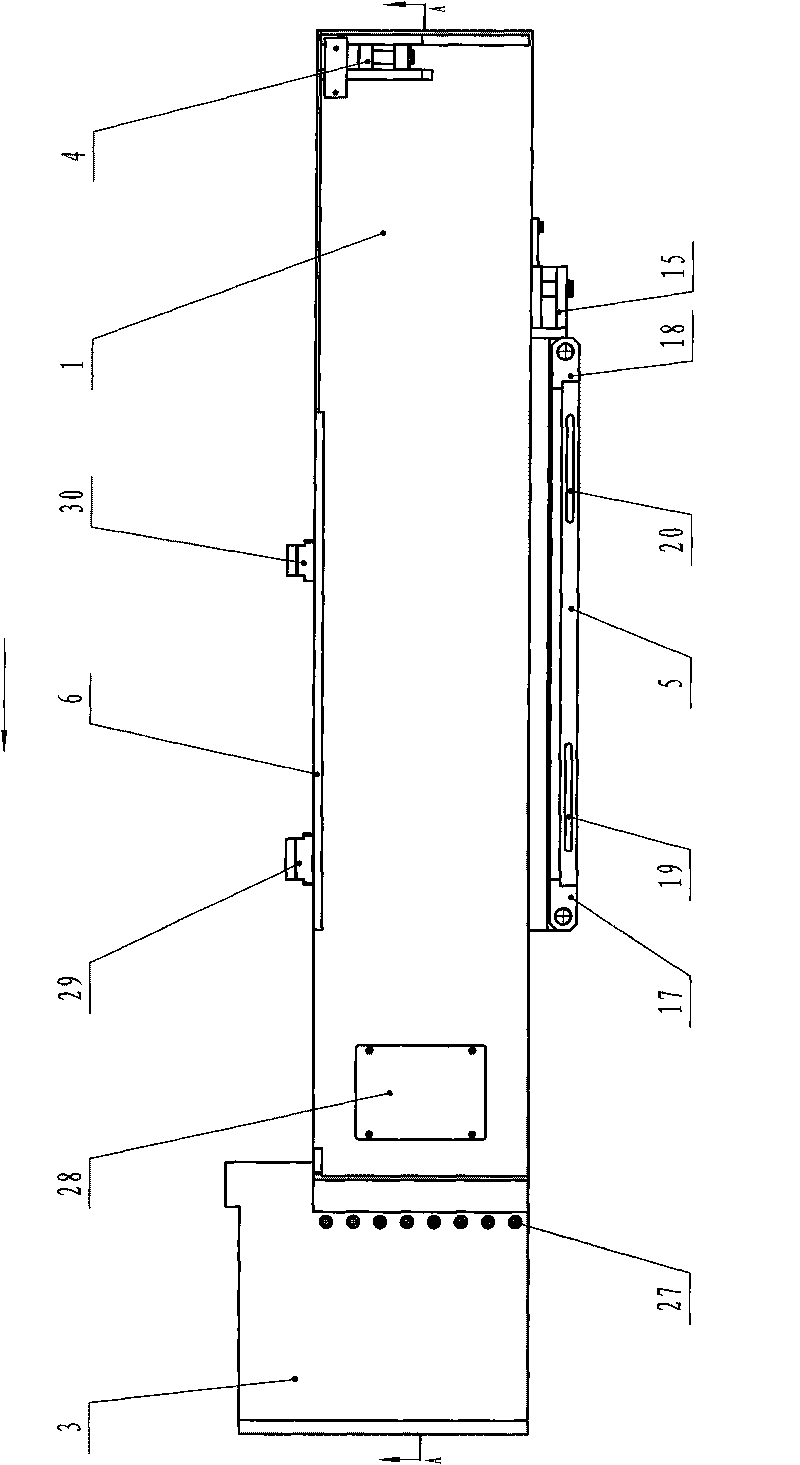

Large-volume leather bag type constant-pressure energy accumulator and application thereof

ActiveCN110374942AGuaranteed deformationRapid responseAccumulator installationsActuator accumulatorsPulp and paper industryPiston rod

The invention relates to a large-volume leather bag type constant-pressure energy accumulator and application thereof. The large-volume leather bag type constant-pressure energy accumulator comprisesa shell and further comprises a leather bag, a variable area piston, a floating piston, a piston and a flange which are arranged in the shell. The floating piston sleeves a piston rod of the variablearea piston. The bottom end of the piston rod of the variable area piston is connected with the piston, and a through hole is formed in the center axes of the variable area piston and the piston, an inflation valve is connected between the through hole and the leather bag, the bottom of the through hole is connected with a cover plate, the piston is provided with a one-way valve I and a one-way valve II, and the flange is connected with the inner wall of the bottom of the shell. The novel large-volume leather bag type constant-pressure energy accumulator has the advantages that leakage is notlikely to happen, the service life is long, inertia is small, the response is sensitive, and the applicable volume range is wide; and the novel large-volume leather bag type constant-pressure energy accumulator can be widely applicable to various hydraulic systems.

Owner:SHANDONG UNIV OF SCI & TECH

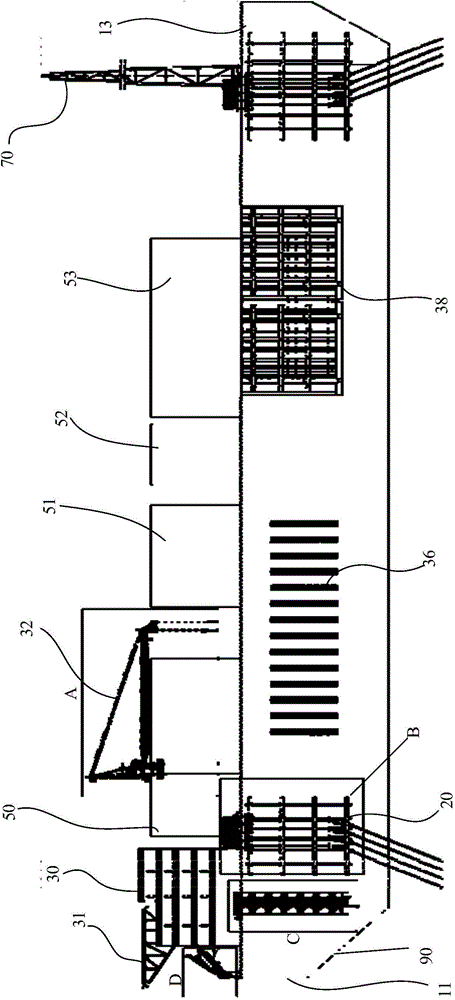

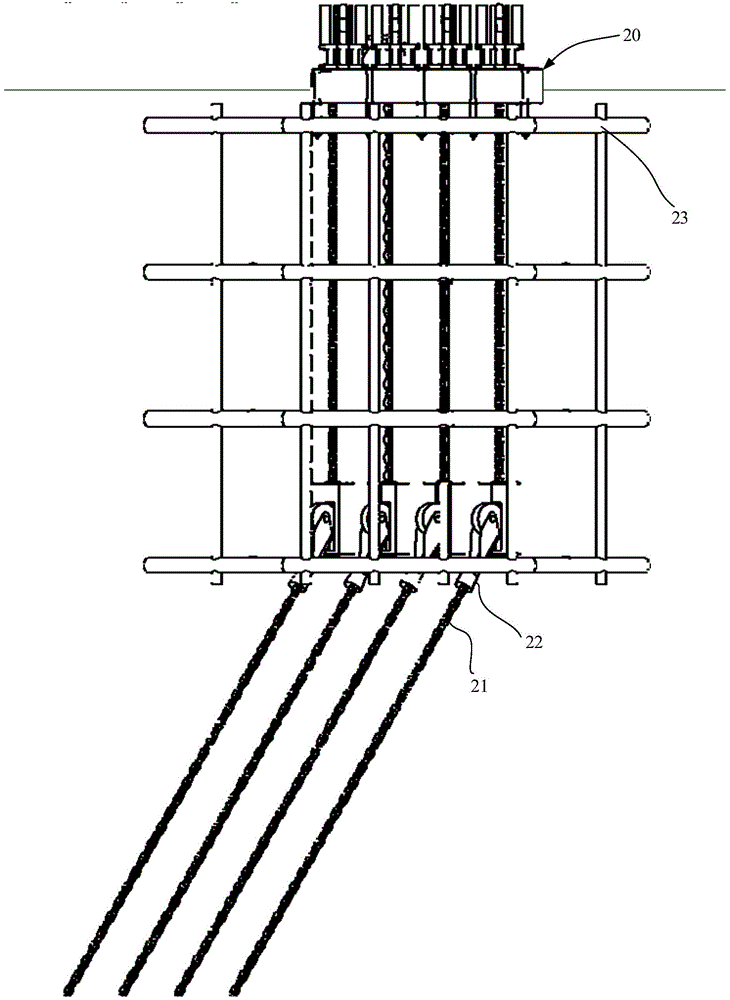

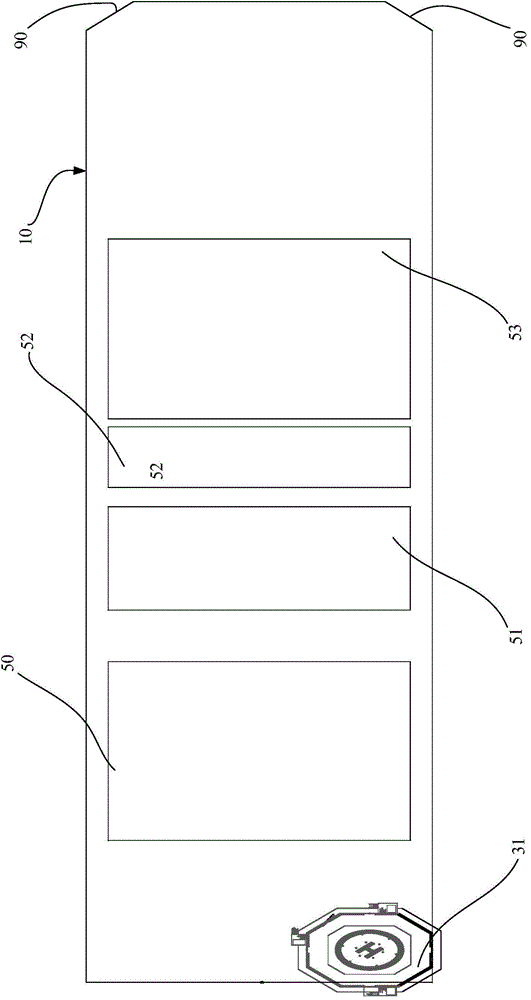

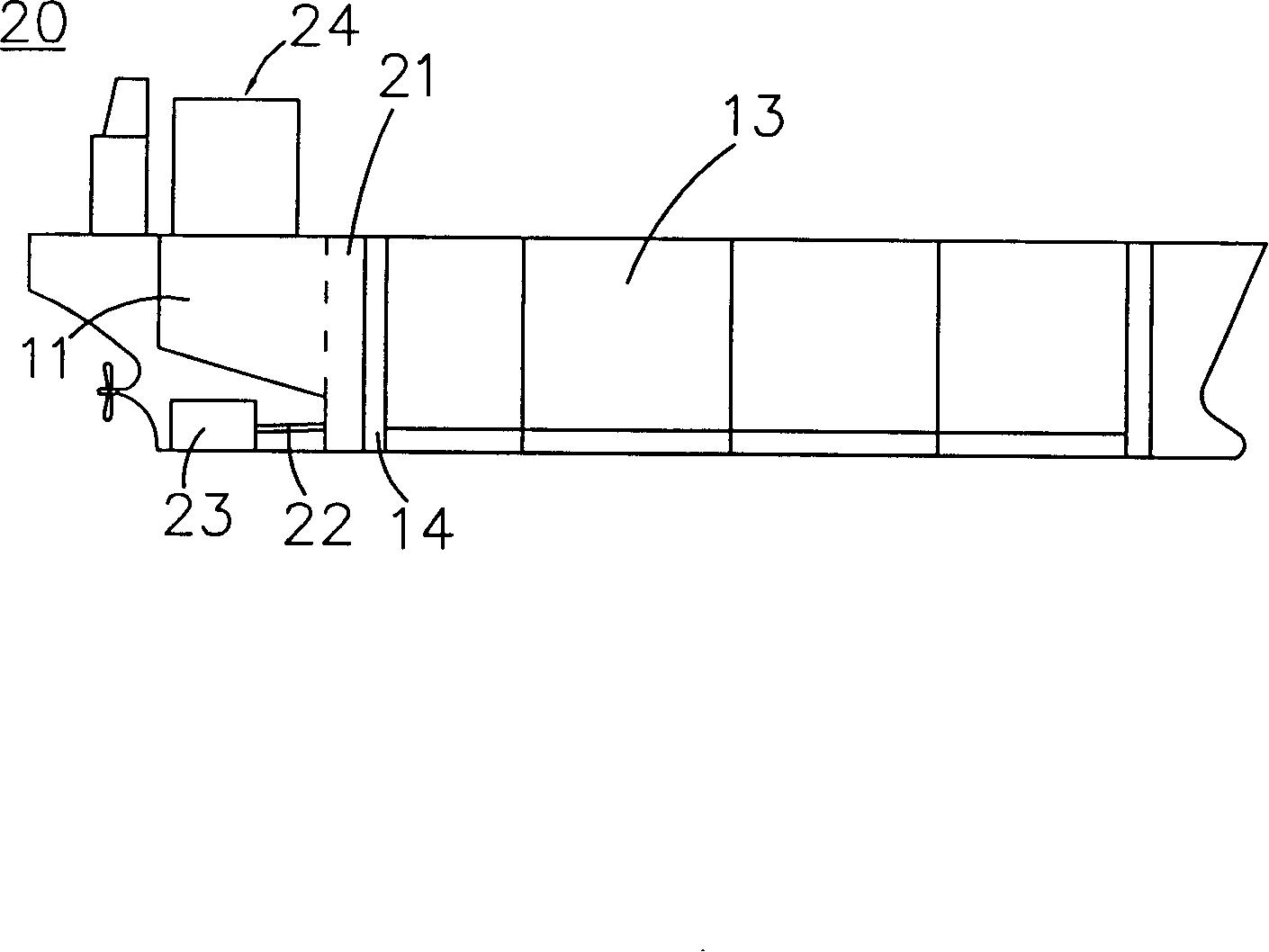

FPSO (Float Production Storage and Offloading) ship

InactiveCN104590497AGood ability to resist wind and wavesIncrease oil storageVessel superstructuresVessel mastsProcess systemsFlare

The invention discloses an FPSO ship. The total length of a ship body is 310m to 330m; the molded breadth is 60m to 65m; the moulded depth is 30m to 35m and the maximum draft is 20m to 25m; from a stern to the other stem of the ship body, the ship body sequentially comprises a living building, a main power station, a power distribution module, a heat station module, a process system module, an oil gas processing and metering module and a flare tower, wherein four mooring sites are symmetrically arranged at the left and right boards of the stern and the other stem of the FPSO ship in total; the left and right boards of the stern are respectively and symmetrically provided with a set of external oil transportation device. According to the FPSO ship, the principle dimension of the ship body meets the oil storage capacity of an oil hold of the FPSO ship and the demands of an upper part module, as well as that the functions implemented are adaptive to the ship type; furthermore, the layout of the stem, the middle part of the ship and the other stem meets the living and operating demands of personnel; in addition, by adopting the multi-site mooring, the maximum tension of a mooring line of the mooring system and the maximum operating response of the ship body can be controlled better; and the external oil transportation device can be set to prevent the danger of being impacted with the FPSO ship.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD +1

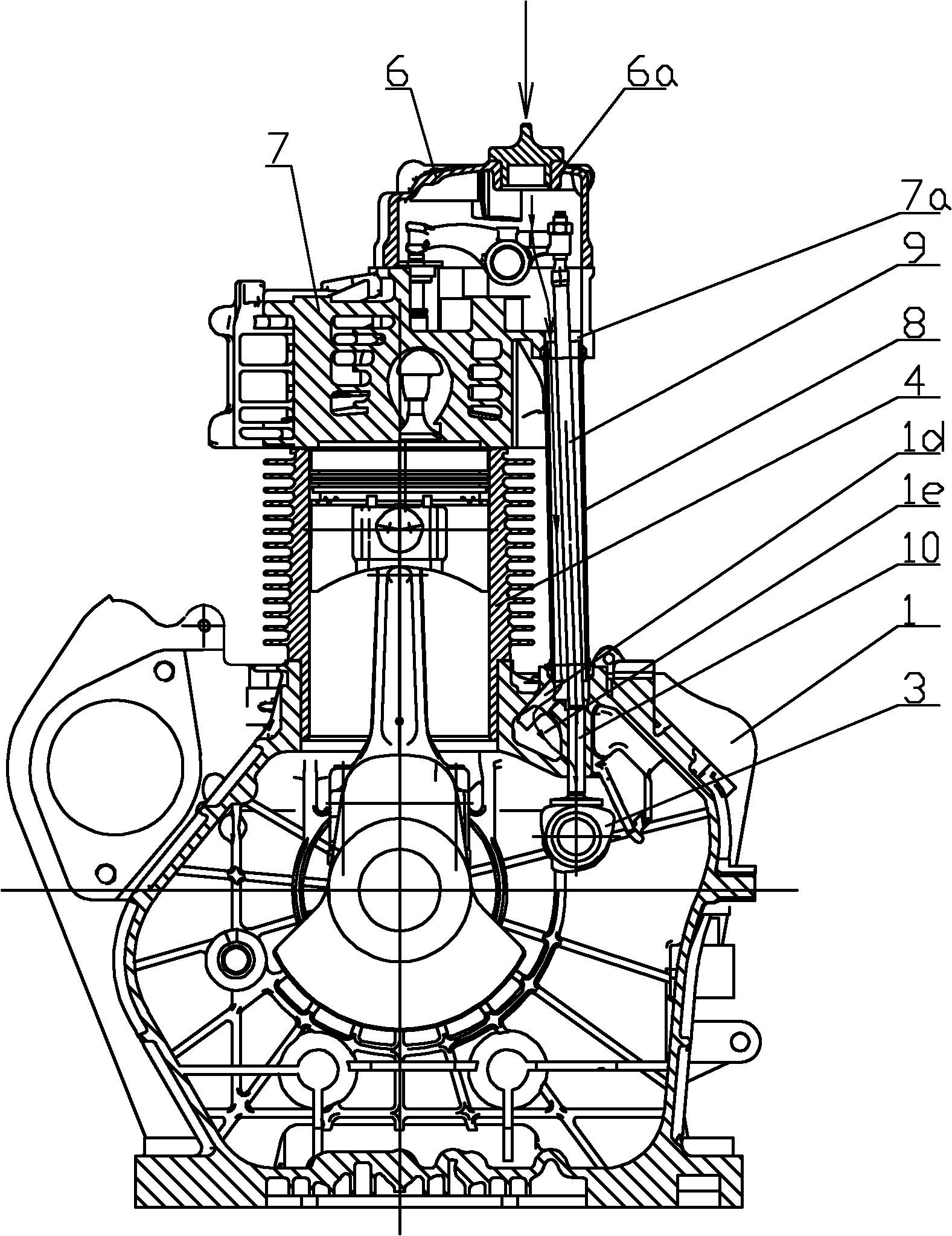

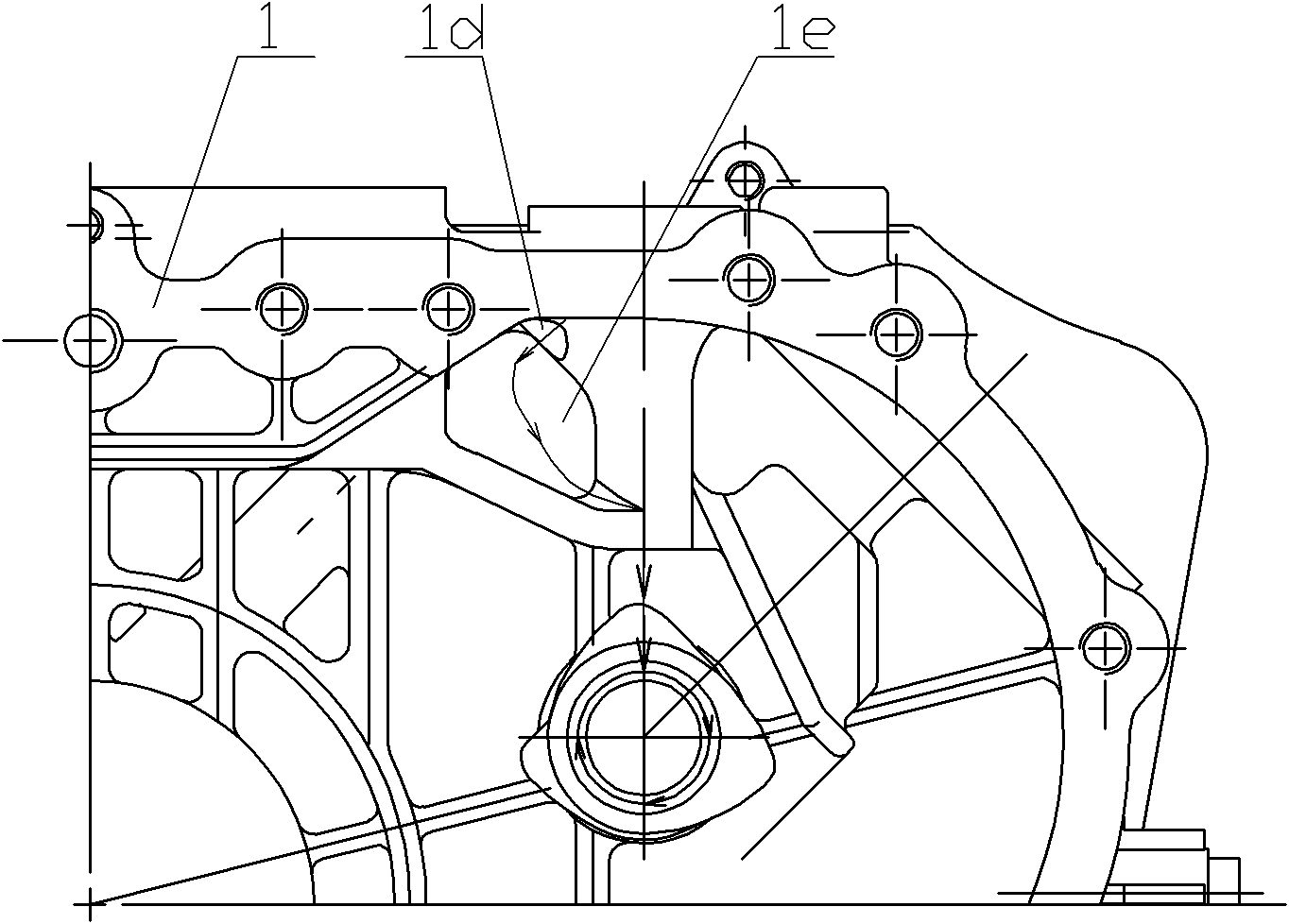

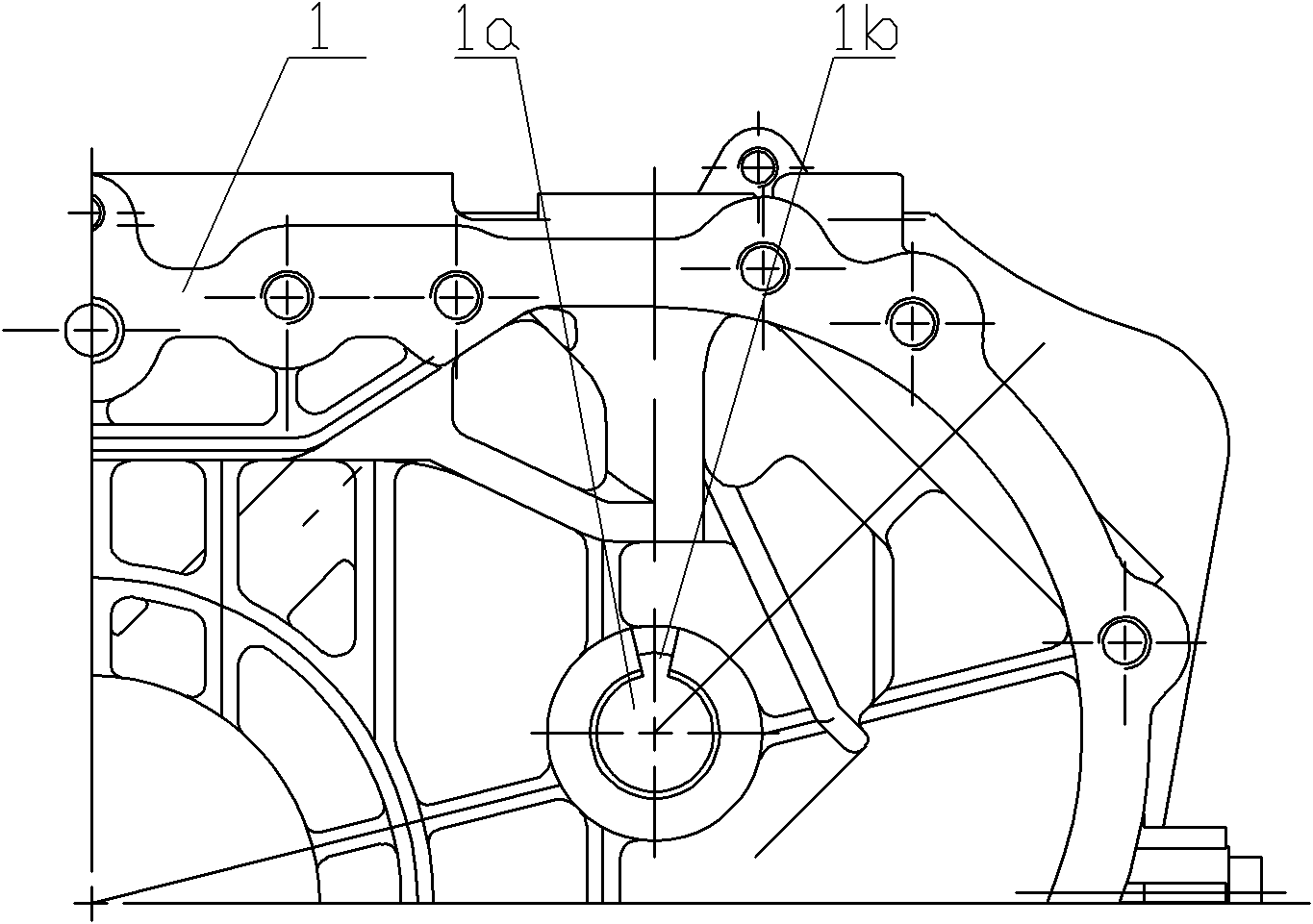

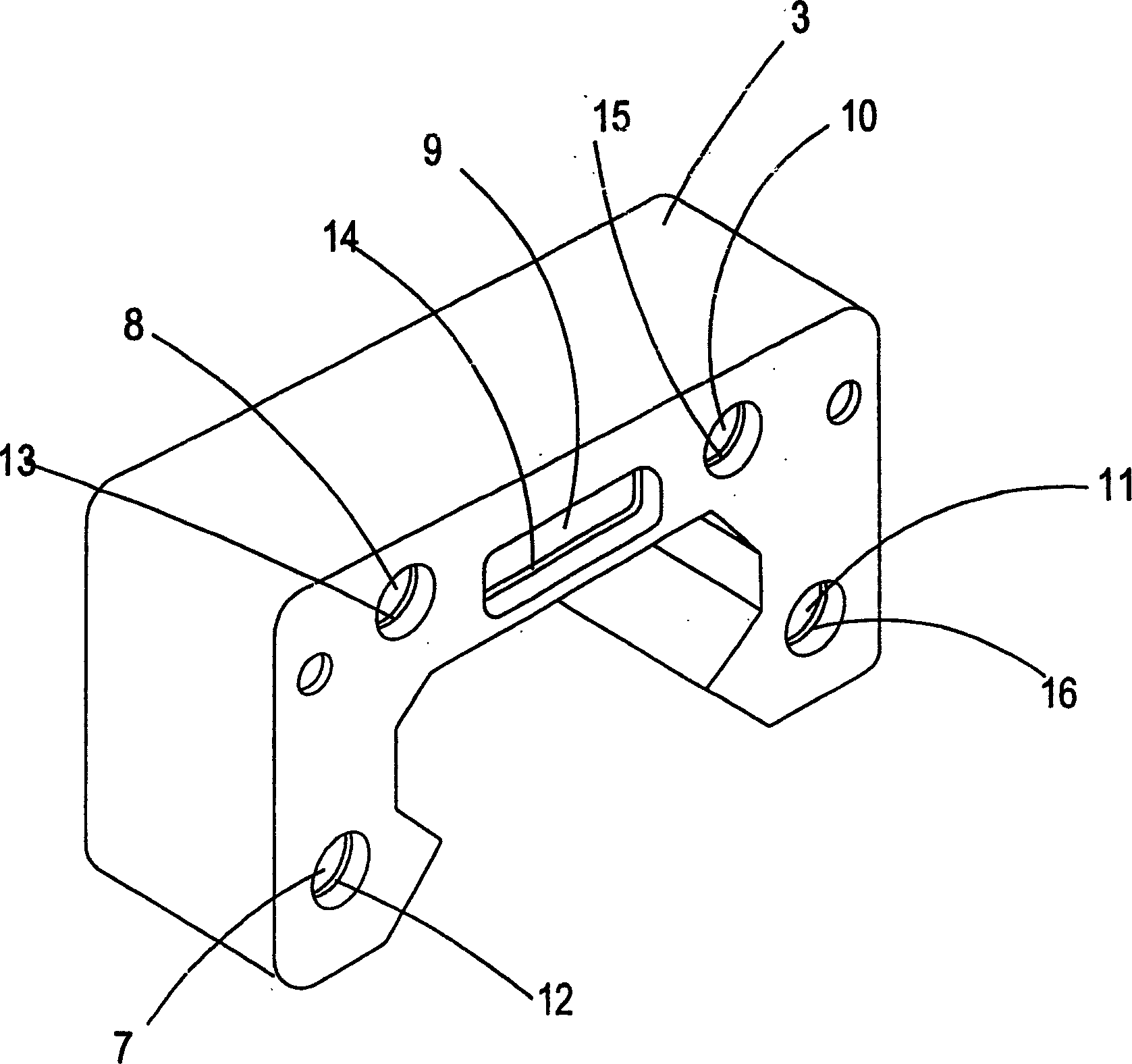

Installation of diesel engine camshaft and lubrication structure

ActiveCN101943038ALow costMeet the installationCasingsLubrication of auxillariesGear wheelCylinder head

The invention relates to installation of a diesel engine camshaft and a lubrication structure. The lubrication structure comprises an engine body, a crankcase cover, a camshaft, a cylinder block, a camshaft wheel gear, a cylinder head cover and a cylinder head, wherein the crankshaft is directly supported in a crankshaft supported hole corresponding to the engine body and the crank case cover by support shaft necks at two ends; the lubrication oil filler of the cylinder head cover is communicated with the lubrication oil inlet passage of the cylinder head; the lubrication oil inlet passage of the cylinder head is communicated with the lubrication oil inlet passage of the engine body by a push rod casing; and the support shaft necks at two ends of the crankshaft are lubricated by the lubrication oil in the crankcase introduced from the oil duct and the oil groove arranged in the supported hole. The invention not only meets the installation and lubrication requirements of the crankshaft, but also simplifies the installation of parts, reduces the cost, and has simple structure and reasonable configuration.

Owner:WUXI KIPOR POWER CO LTD

Fuel-feed system for motorcycle

The motorcycle oil supply system includes one oil tank and one fuel oil pump assembly. The fuel oil pump assembly outside the oil tank includes one primary filter, one electric pump, one fine filter and one pressure regulating valve connected successively to form one oil path. The fuel oil pump assembly has use and fixation not limited by the oil tank and occupies no volume inside the oil tank, so that the motorcycle oil supply system can lower the design and manufacture cost of motorcycle, shorten the design period, increase the volume of the oil tank and raise the range ability of the motorcycle.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

Oiltank structure

InactiveCN101161543AExempt from settingIncrease profitHull interior subdivisionHull double bottomsFuel tankEngineering

Owner:TAWWAN MARITIME TRANSPORTATION

Front frame of refrigerated container

ActiveCN101402413AIncrease volumeDoes not affect strengthLarge containersTank wagonsFuel tankStructural engineering

The invention discloses a front frame of a refrigerated container, which comprises a front end upper beam, a middle beam and a front end lower beam which are connected into a whole through a front wall outside plate and a front wall inside plate. An insulting layer is arranged between the front wall outside plate and the front wall inside plate; the upper part of the outside of the front wall outside plate is provided with a cooling machine, while the lower part is provided with an oil tank; the middle beam is a deformed beam bended inwardly; a cavity is formed between the middle beam and the lower part of the cooling machine as well as the front wall outside plate; and the upper part of the oil tank is arranged in the cavity. The front frame increases the oil tank capacity, saves cost and realizes nonrefuelling during the middle and long distance transportation on the premise of not changing the strength and the function of the container.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

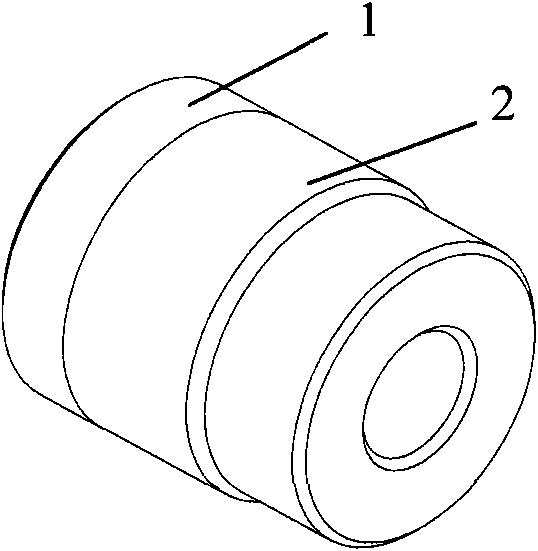

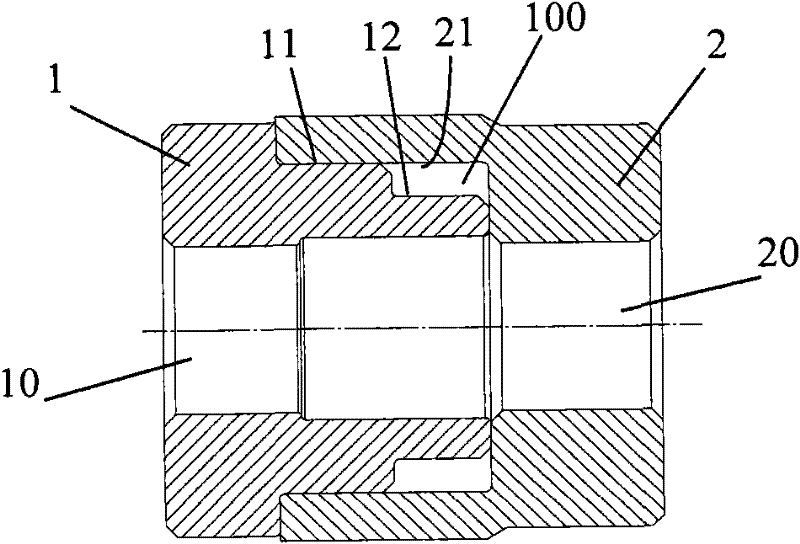

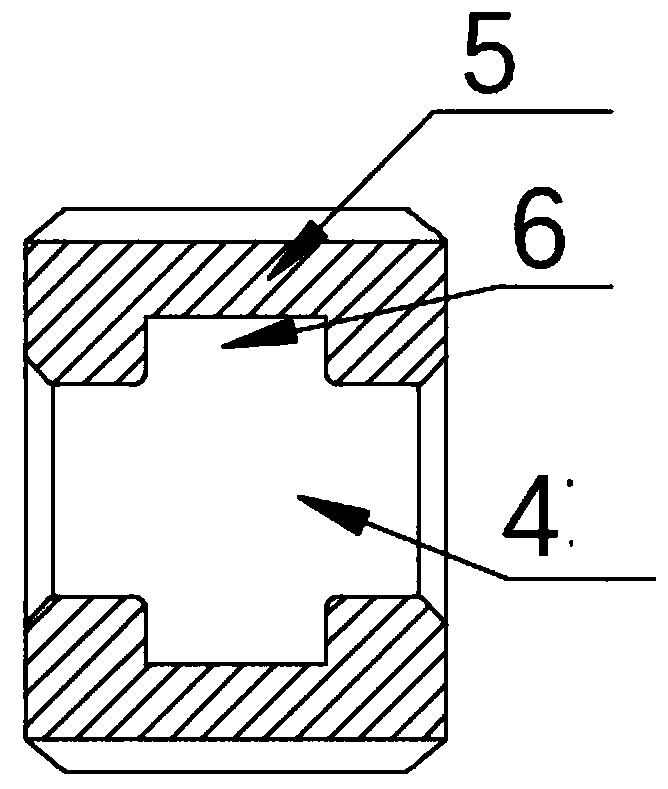

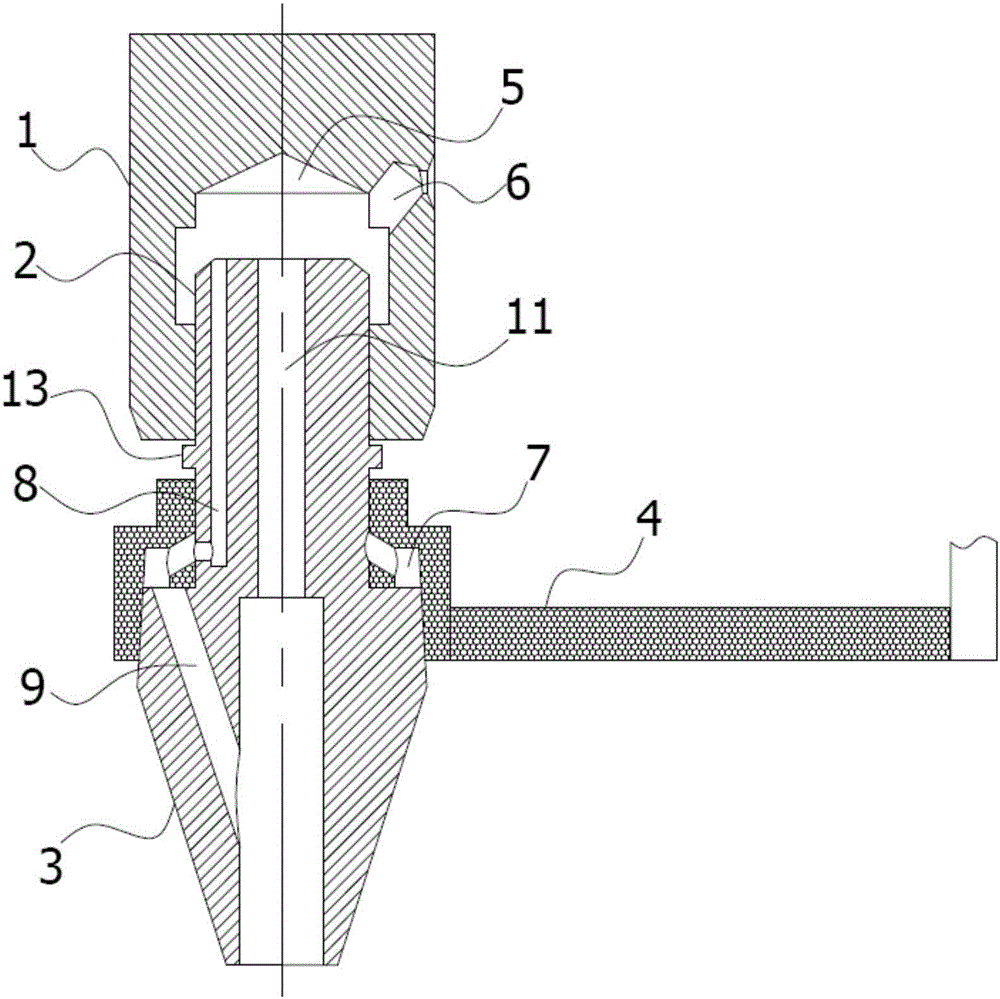

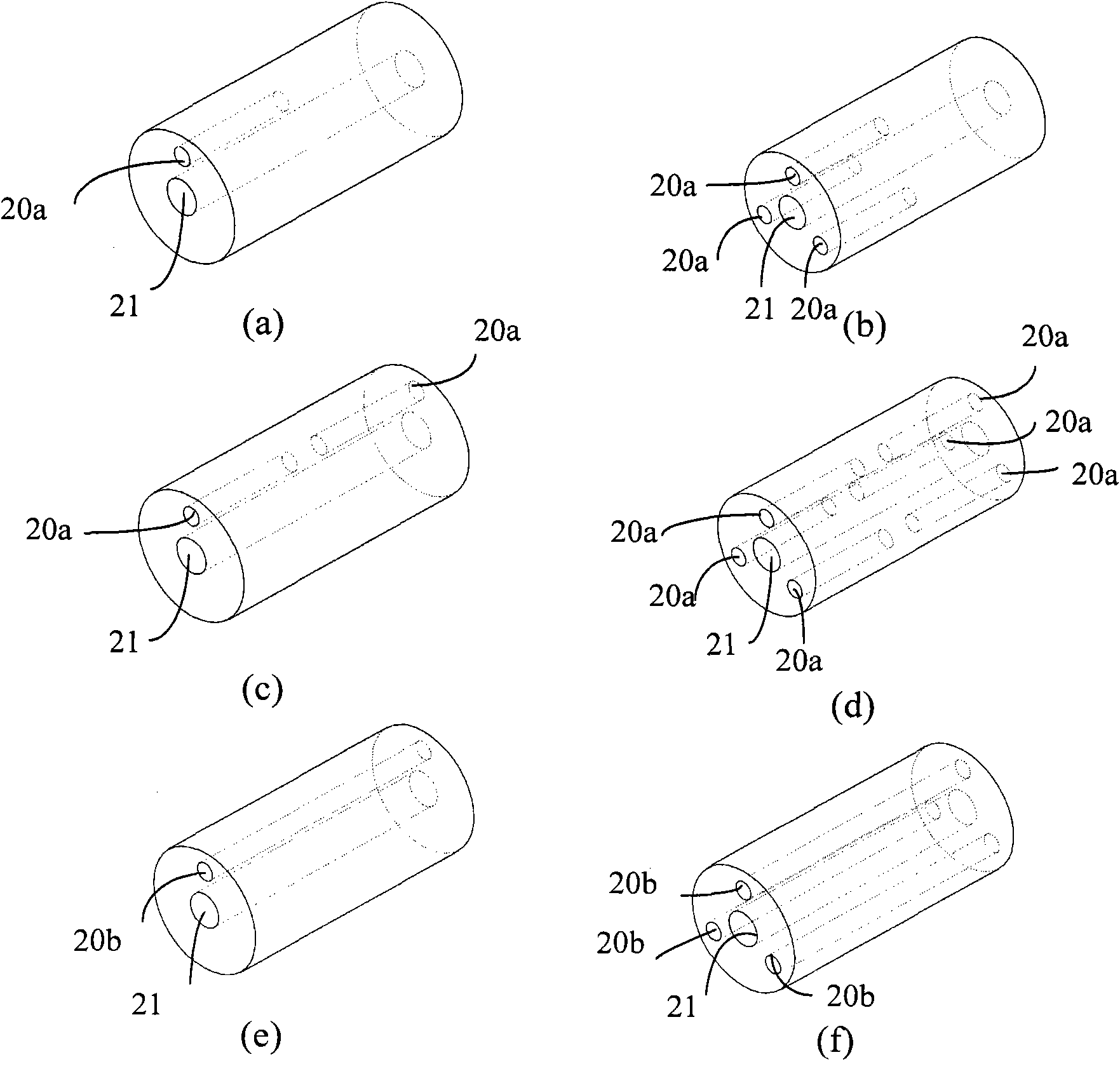

Motor, oil bearing and manufacturing method thereof

ActiveCN102480188AIncrease oil storageGood effectManufacturing dynamo-electric machinesSupports/enclosures/casingsButt jointOil storage

The invention relates to a motor, an oil bearing and a manufacturing method thereof. The oil bearing comprises at least two bearing sections, ends of each two corresponding bearing sections are in butt joint, an oil storage cavity is formed between each two butt joint surfaces of each two corresponding bearing sections, each two bearing sections in butt joint are sintered integrally, and accordingly oiliness of the bearing is greatly improved.

Owner:NEW SHICOH MOTOR CO LTD

Long-acting self-lubricating big oil cylinder

The invention discloses a long-cuting self-lubricating large oil barrel, it embeds a oil storing box at one side of the sliding base, the oil storing box is arranged with oil core, heavy ball and lubricating oil, by using the capillary phenomenon, the lubricating oil in the oil storing box are distributed into the oil containing cotton in the sliding base, the lubricating oil are coated onto the track when the oil containing cotton moves along the track; the ball moves on the track, realizes the long life lubrication; the end of the oil core is penetrated with a heavy ball, the oil core end can maintained at the lowest part in the oil storing box because of the weight of the heavy ball, the oil storing box can supply lubricating oil along with the assembling direction of the sliding base and the sliding tract.

Owner:ABBA LINEAR TECH

Radial double vibration absorption long oiling period high-speed energy-saving spindle

InactiveCN105401273AExtended refueling cycleReplenishing the circulatory systemTextiles and paperInterference fitIngot

The invention discloses a radial double vibration absorption long oiling period high-speed energy-saving spindle, comprising a pole disk and a spindle base. The spindle base is a radial double vibration absorption long oiling period spindle base, and comprises a spindle insert, a damper, and a radial double vibration absorption long oiling period spindle foot. The spindle insert comprises an upper bearing pedestal and an elastic pipe, and other elements. The upper part of the elastic pipe and the inner bore of the bearing pedestal are in interference fit. The damper is sleeved on the lower part of the elastic pipe. The spindle blade of the pole disk is inserted into the elastic pipe. The spindle pivot of the spindle blade contacts the element on the bottom of the elastic pipe. The radial double vibration absorption long oiling period spindle foot comprises a vibration damping sleeve and a spindle foot casing. The integrated vibration damping sleeve is in a cylindrical shape, one end of the vibration damping sleeve is provided with an annular projection. The spindle foot casing is in a blind hole shape. The vibration damping sleeve is sleeved in the hole of the spindle foot casing, and the projection and the blind hole of the spindle foot casing are in interference fit. The lower part of the bearing pedestal is pressed in the inner bore on the upper part of the bearing pedestal. The spindle is advantaged by absorbing radial acting forces twice, the radial acting forces being generated in high-speed running of the spindle, and increasing reserve fuel quantity in the spindle by one time.

Owner:HENGYANG TEXTILE MACHINERY MANUFACTORY

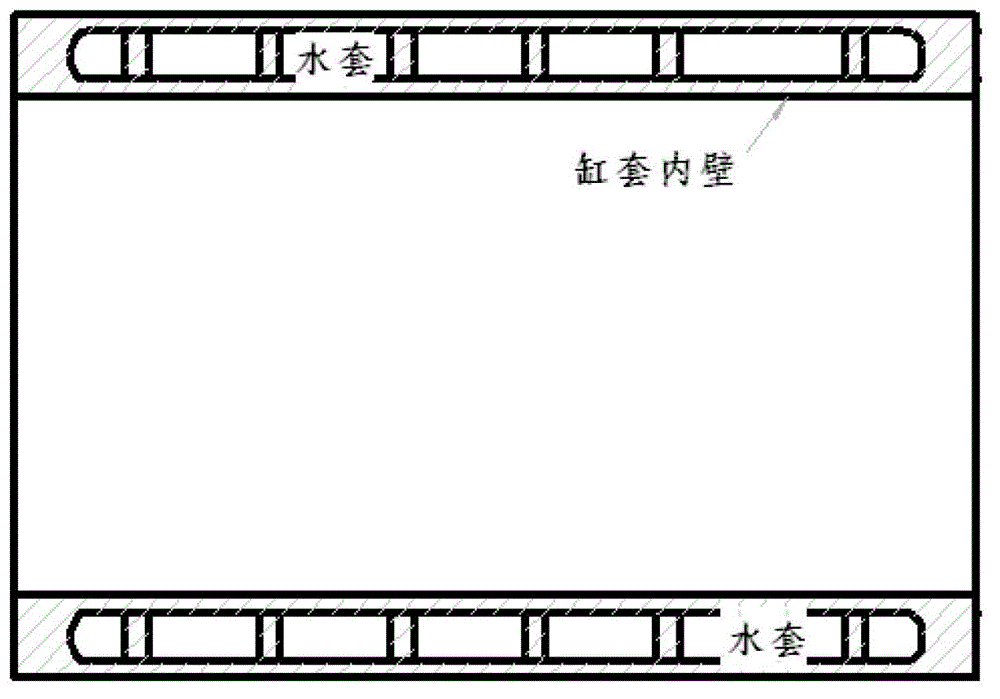

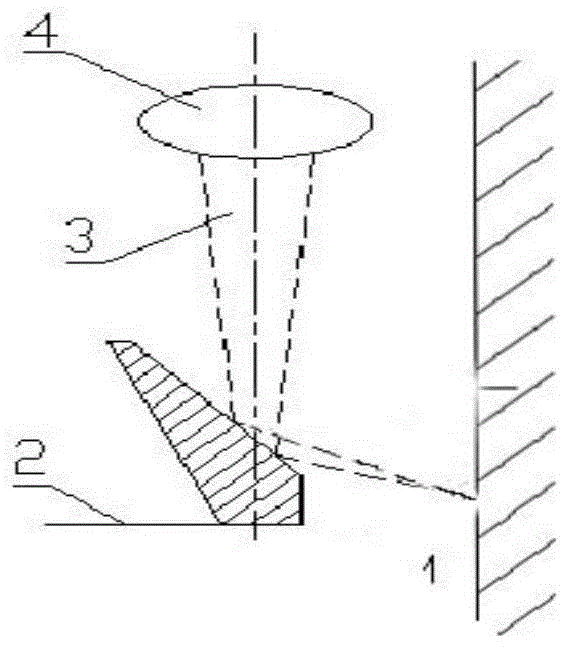

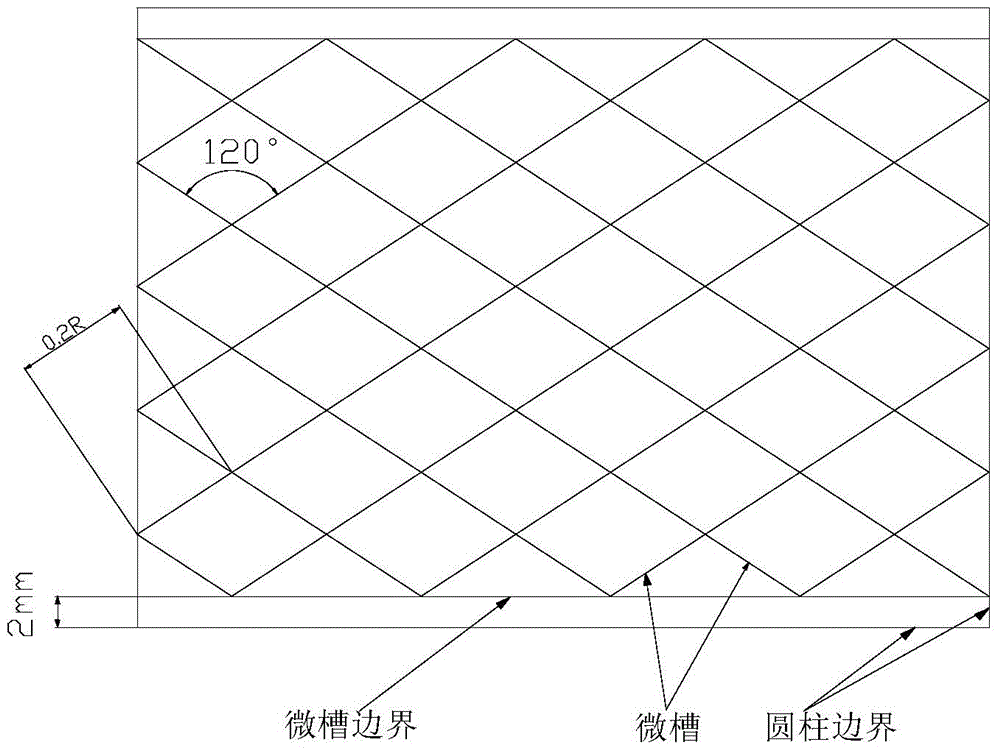

Cylinder sleeve inner wall oil circuit structure and production method thereof

ActiveCN102878289AIncrease oil storageImprove the lubrication effectCylindersLaser beam welding apparatusMicrometerLaser beams

A cylinder sleeve inner wall oil circuit structure comprises helical lines and micro-pits. Each helical line is 1-150 micrometers in depth, 1-100 micrometers in width, 10-100 in thread number and 1-20 micrometers in pitch. Each micro-pit is 3-100 micrometers in depth. A production method of the cylinder sleeve inner wall oil circuit structure includes: laser transmitted by a laser device passes through optical fibers to form laser beams, the laser beams are projected to a reflector and reflected to a cylinder sleeve inner wall through the reflector for itching the micro-pits and the helical lines. Spot and linear lubricant oil way structures in regular distribution are disposed on the surface of the cylinder sleeve inner wall. Wear resistance is doubled or tripled compared with the prior art, fuel consumption is reduced by 20-25%, cylinder abrasion is reduced from 5 micrometers to 2.5 micrometers, emission of hydrocarbon particles is reduced by 20-25%, and the service life of the cylinder sleeve is prolonged by 1.4 folds.

Owner:CSIC NO 12 RES INST

Bicycle front fork

InactiveCN105947079AGuaranteed stabilityImprove stabilityCycle springsSteering deviceEngineeringPiston

The invention relates to a bicycle front fork. The bicycle front fork comprises a vertical pipe, a fork shoulder, stroke pipes, outer pipes, fork feet and a fork bridge. The vertical pipe is connected with the fork shoulder. The stroke pipes comprise the left stroke pipe and the right stroke pipe and are installed at the two ends of the fork shoulder in a sleeving mode correspondingly. The lower ends of the stroke pipes are sleeved with the outer pipes. The fork feet are arranged under the outer pipes. The fork bridge is in bridge joint with the position between the outer pipes. A sealed oil storage chamber, a shock-proof spring, a gasket and a spring rod are sequentially arranged in each outer pipe from top to bottom. The periphery of each spring rod is provided with a negative-pressure spring. A piston is arranged between each sealed oil storage chamber and the corresponding shock-proof spring. Each sealed oil storage chamber is internally provided with an oil absorption sponge and is provided with an oil filling port. The bicycle front fork is good in stability, shockproof effect and damping effect and capable of meeting using requirements.

Owner:天津市嘉德宇通科技发展有限公司

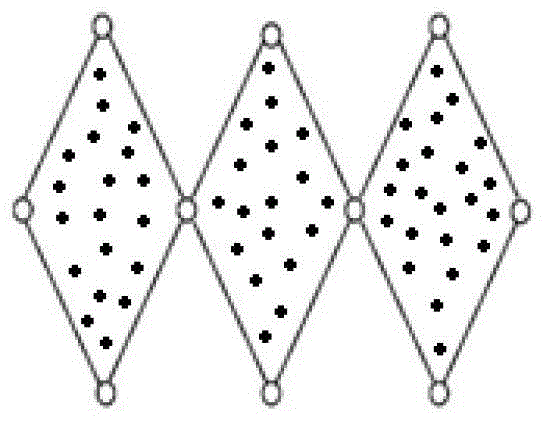

Cylinder inner wall network oil storage structure manufacturing method

ActiveCN104455407AImprove wear resistanceIncrease oil storageCylindersMetallic material coating processesSurface finishLaser etching

A cylinder inner wall network oil storage structure manufacturing method comprises the steps of firstly preparing an alloying-like solution, performing preparation of an alloying solution, pre-preparing an alloying-like coating, adopting an immersion preset mode to immerse all cylindrical workpieces into the alloying solution, lifting out the cylindrical workpieces and then clamping the cylindrical workpieces on a chuck to perform rotation, enabling the laser surfaces of cylinder inner walls to be alloying, then performing network texturing laser etching and finally adopting fluid polishing finishing to conduct streamline finishing on the laser texturing surfaces. The problem of boundary texturing of an oil storage channel is solved, the problem that the roughness of the inner surface of a cylinder sleeve is improved due to modification is solved, and the surface smoothness reaches Ra 0.8 after fluid polishing. By means of the cylinder inner wall network oil storage structure manufacturing method, the problem that the abrasion resisting performance of the inner walls of the cylindrical workpieces is poor, the inner wall lubricating condition of the cylindrical workpieces is improved, and the service life of the cylindrical workpieces is prolonged.

Owner:CSIC NO 12 RES INST

Oil tank and crane with same

The invention discloses an oil tank, wherein the oil tank is provided with a main tank body, an oil pumping filter and a first auxiliary tank body, wherein the oil pumping filter is communicated with the main tank body; the first auxiliary tank body is arranged outside the main tank body and is communicated with the main tank body; the oil pumping filter is installed on the first auxiliary tank body; and the position of the first auxiliary tank body is lower than the lowest oil level of the liquid oil in the main tank body. The oil tank provided by the invention has the beneficial effects that the oil pumping filter installed on the first auxiliary tank body is enabled to be always immersed in the liquid oil, thereby ensuring that an oil pump always can pump oil and further effectively avoiding the phenomenon that all oil is pump up by the oil pump; and simultaneously, the first auxiliary tank body which is independent of the main tank body can be arranged flexibly according to the idle space on engineering machinery, the space on engineering machinery is utilized fully, and the more reasonable arrangement of the oil tank on engineering machinery is realized.

Owner:XUZHOU HEAVY MASCH CO LTD

Electronic cigarette oil bottle and atomizer with anti-leakage function

ActiveCN104068477BGuaranteed oil capacityIncrease oil storageMedical devicesTobacco devicesElectronic cigaretteBottle

The invention discloses an electronic smoke oil bottle and an atomizer with the function of preventing oil leakage. The electronic smoke oil bottle includes a bottle body with an airflow passage tube in the middle, and a large oil storage chamber and a refueling channel are arranged in the bottle body. A small oil storage chamber is provided on the side of the bottle body for installing the atomization chamber, and the large oil storage chamber communicates with the small oil storage chamber through a refueling channel; One end of the electronic cigarette oil bottle is connected to the mouthpiece, and the other end is connected to the atomization chamber. The electronic cigarette oil bottle is the aforementioned electronic cigarette oil bottle with the function of preventing oil leakage. The invention has the advantages of no oil leakage, large oil storage capacity, clean and hygienic, convenient and comfortable use.

Owner:SHENZHEN MIST TECH DEV

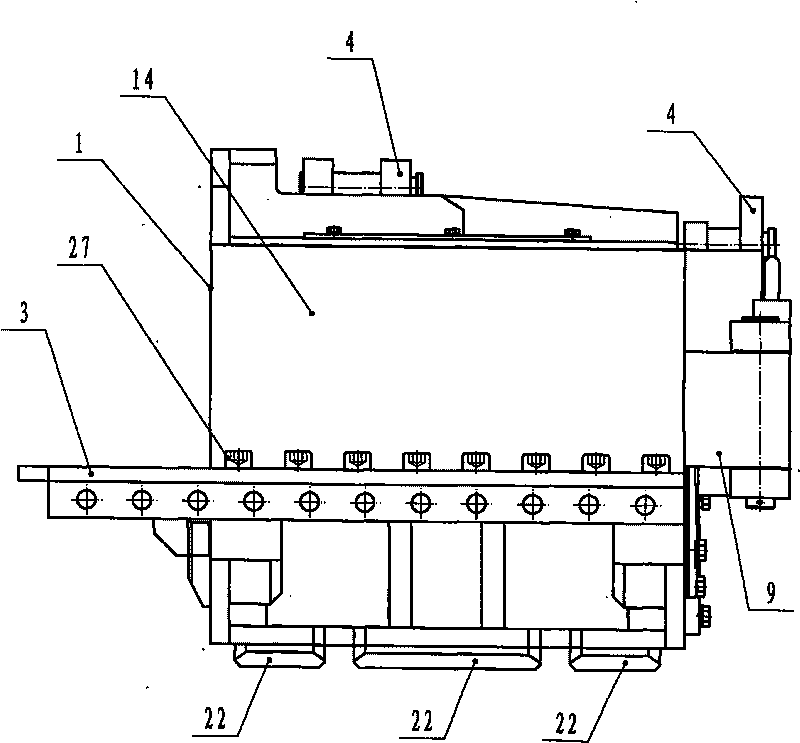

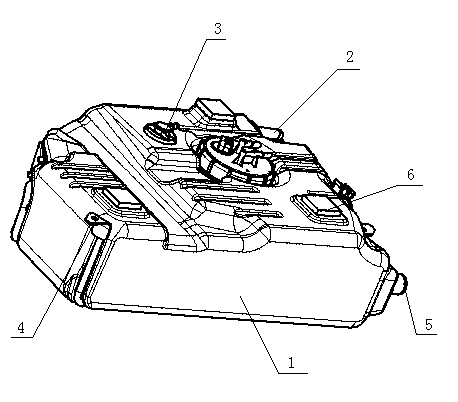

Oil tank-containing track frame of continuous miner

InactiveCN101704388AImprove structural performanceCompact structureUnderstructuresEndless track vehiclesFuel tankReducer

The invention relates to an oil tank-containing track frame of a continuous miner, and the main structure is composed of a track frame, an oil tank, a supporting plate, an installation seat, a reducer hole, a track support groove, an oil tank cover, an oil tank pipeline component, an up-down anti-friction plate, an oil tank vertical guard plate, an oil tank bottom, a top guard plate, an oil tank top plate, a bottom plate, a guiding seat, a connecting seat and a top lateral plate. Oil storage tanks are additionally arranged in a left track frame and a right track frame, structural totally-closed protection is preformed on the oil storage tanks to lead the oil tanks to store and transport oil safely in the running process of the track frame without influence of jolty running, therefore, the oil tank-containing track frame has the advantages of advanced and reasonable design, compact structure, good protection, safety, stabilization and reliability, makes full use of the inner space of the track frame, enlarges oil storage amount of the continuous miner, prolongs digging work time, improves work efficiency, and is an ideal oil tank-containing track frame. In addition, the design can be used in other similar equipment.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

Special-shaped bearing and special-shaped bearing structure

PendingCN111577647AReduce friction noiseImprove the protective effectPump componentsPumpsFriction reductionEngineering

The invention discloses a special-shaped bearing and a special-shaped bearing structure. The special-shaped bearing comprises a fan blade, the bottom of the fan blade is fixedly connected with a motorshell, the outer wall of the motor shell is fixedly connected with a magnet, the interior of the fan blade is fixedly connected with a shaft core, the outer wall of the shaft core is movably connected with the special-shaped bearing, the interior of the special-shaped bearing is provided with an oil storage groove, and the top of the special-shaped bearing is fixedly connected with a buckle ring;and the top of the buckle ring is fixedly connected with a positioning ring, the bottom of the special-shaped bearing is fixedly connected with a wear plate, the bottom of the wear plate is fixedly connected with a copper middle tube, one side of the copper middle tube is fixedly connected with a shooting stator, the bottom of the shooting stator is fixedly connected with a PCB board, the bottomof the PCB board is fixedly connected with a base, and the top of the base is fixedly connected with an upper cover. According to the special-shaped bearing and the special-shaped bearing structure, the oil storage inside the bearing is increased, the lubrication time is improved, the contact area between the bearing and the shaft core is reduced, the friction is reduced, the service life of the fan is prolonged, and the sound quality of a fan is improved.

Owner:江苏嘉之瑞电子科技有限公司

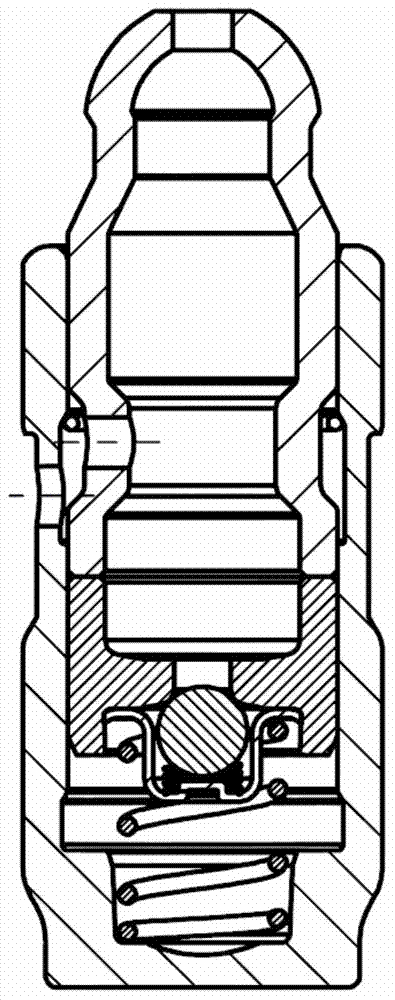

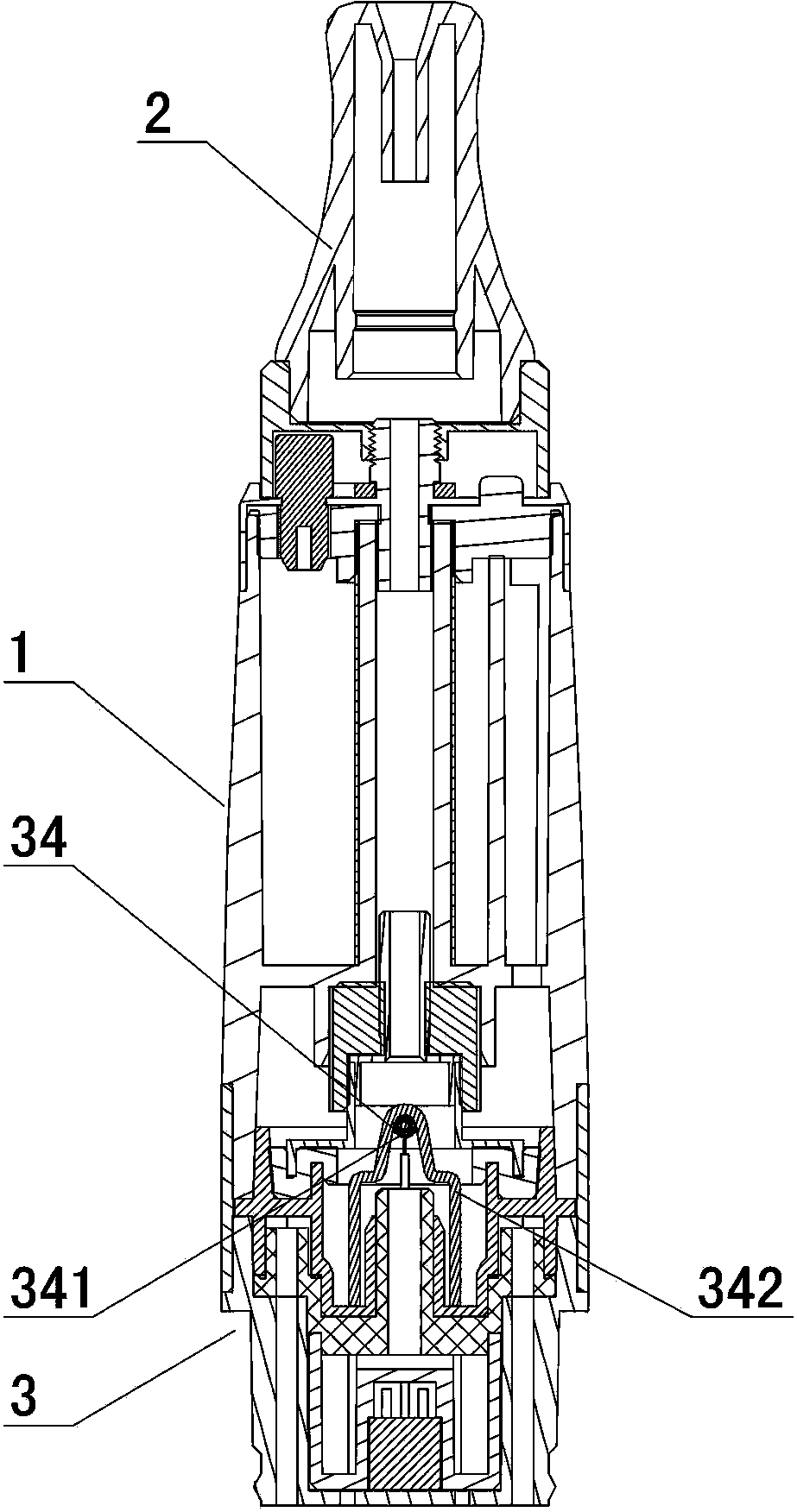

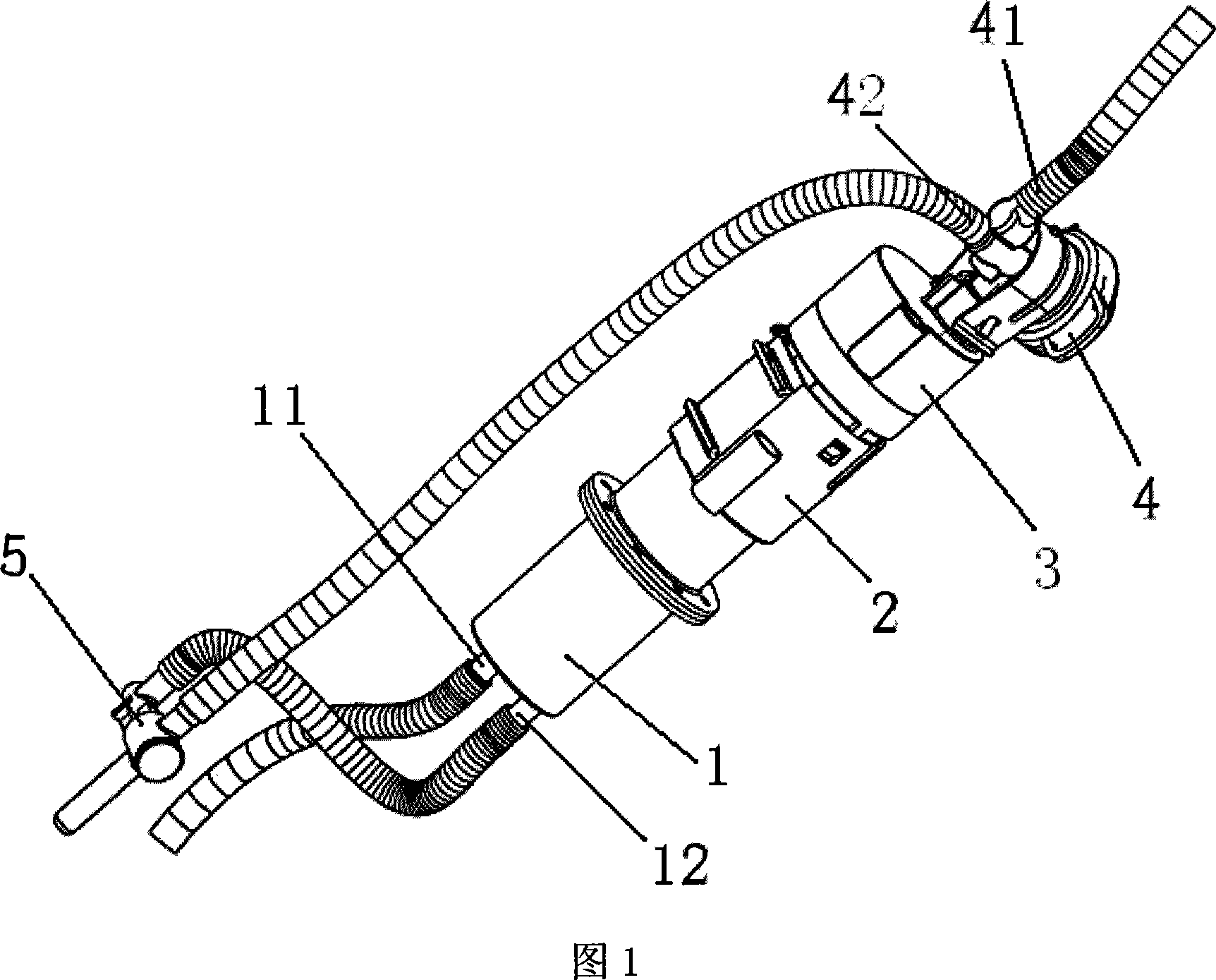

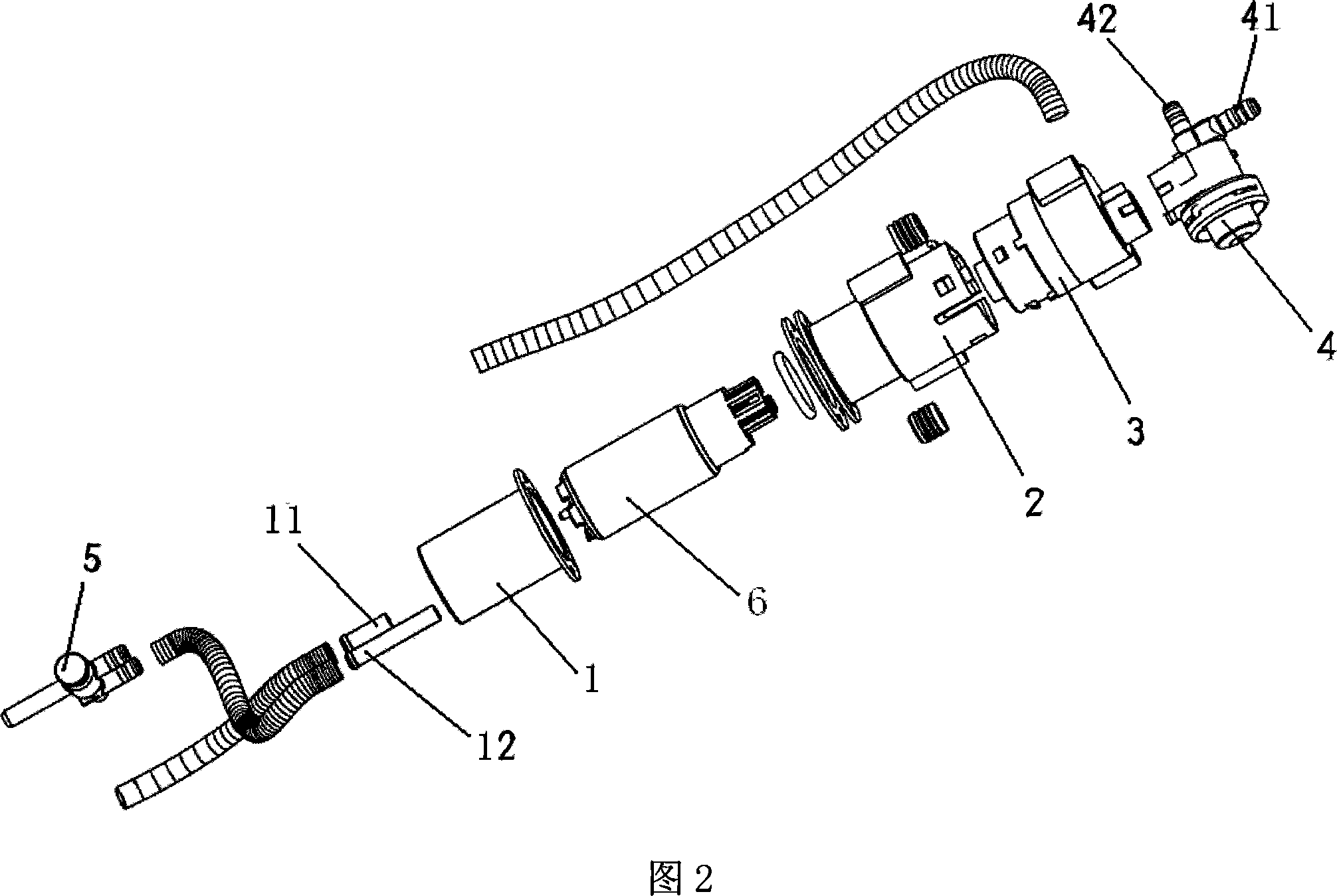

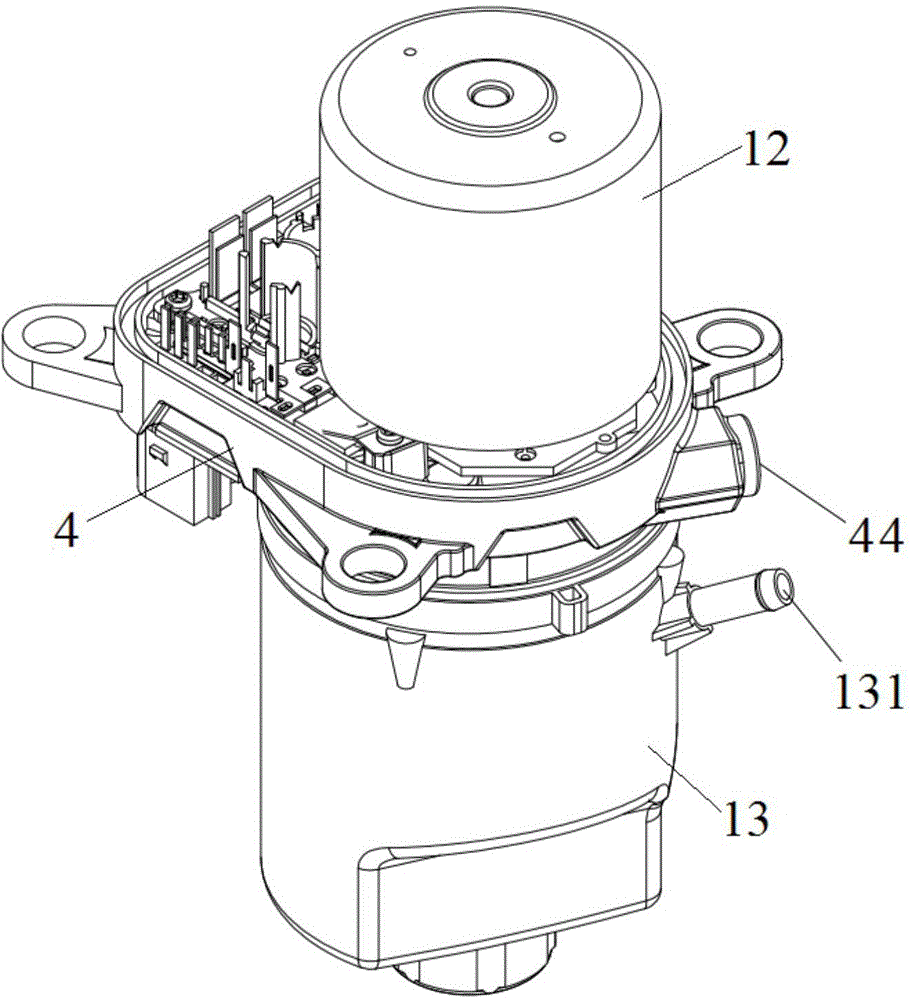

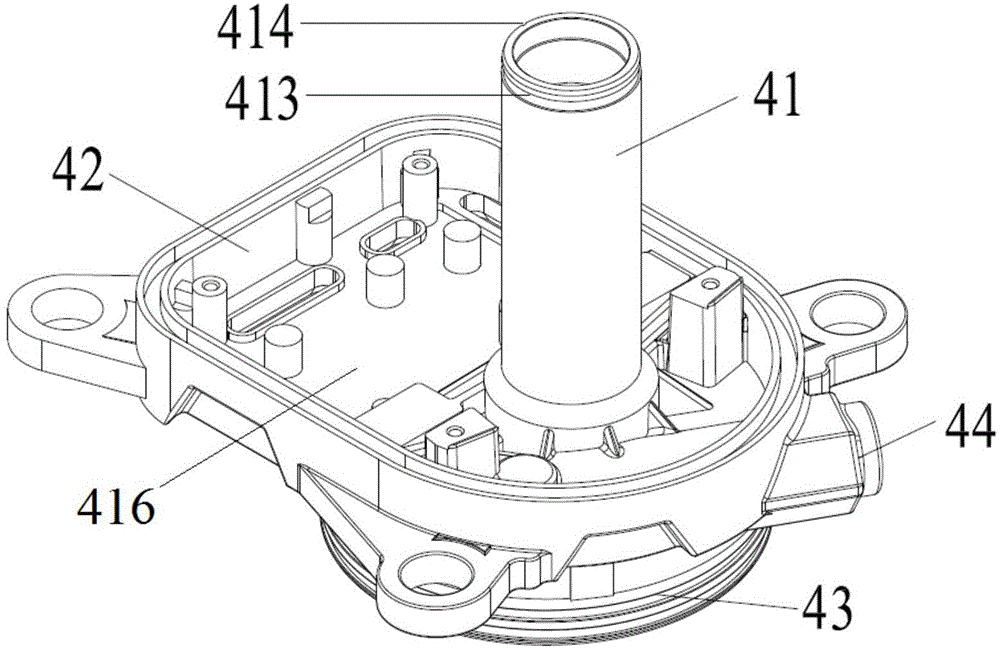

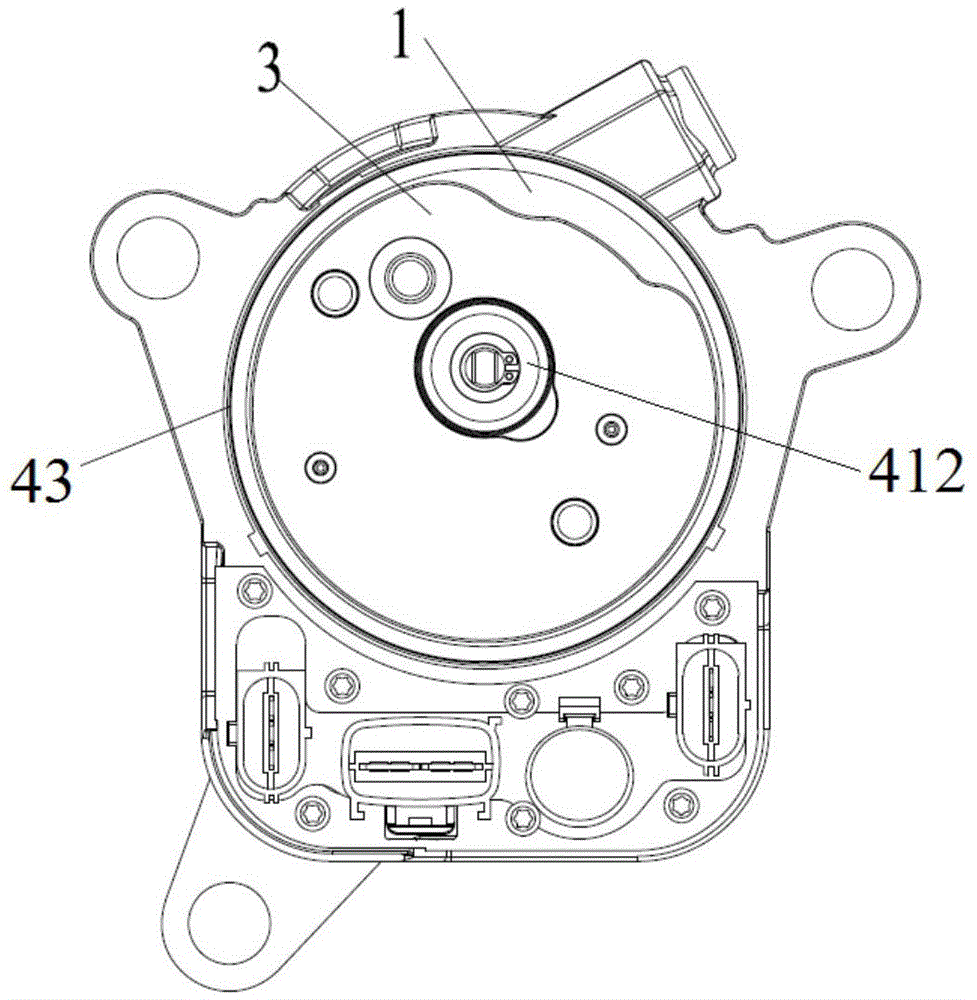

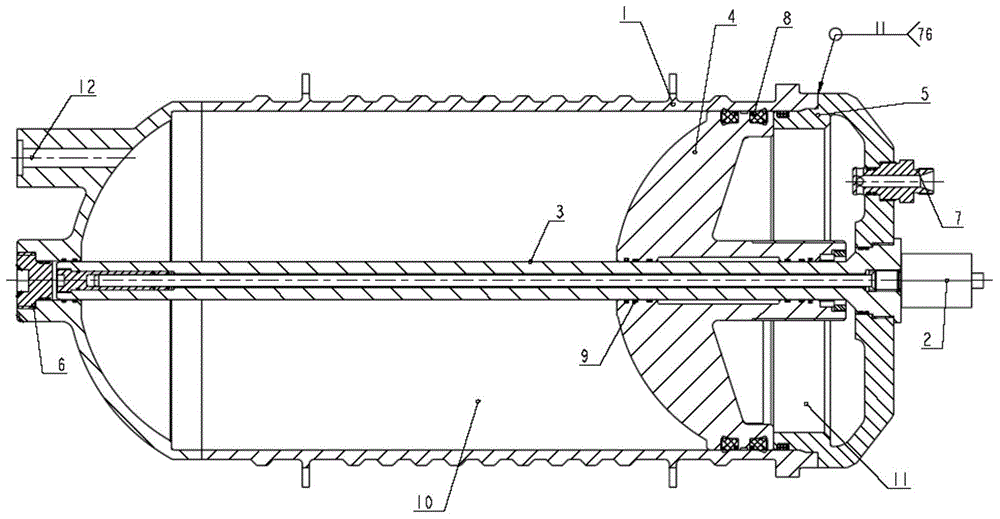

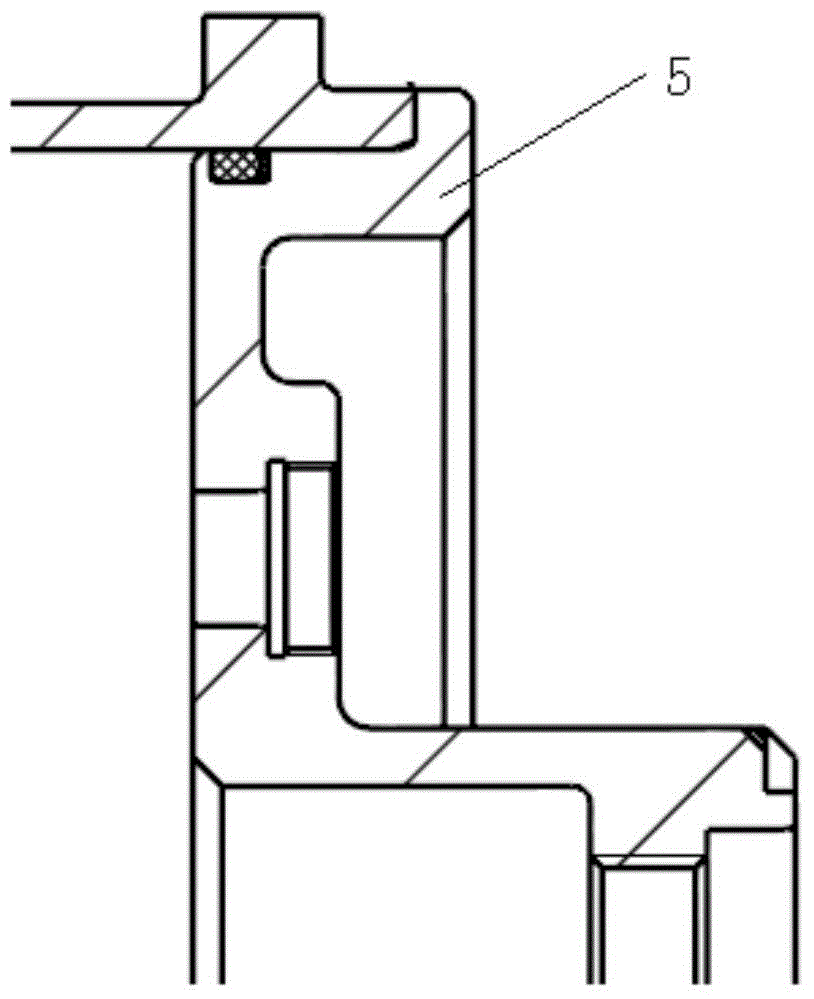

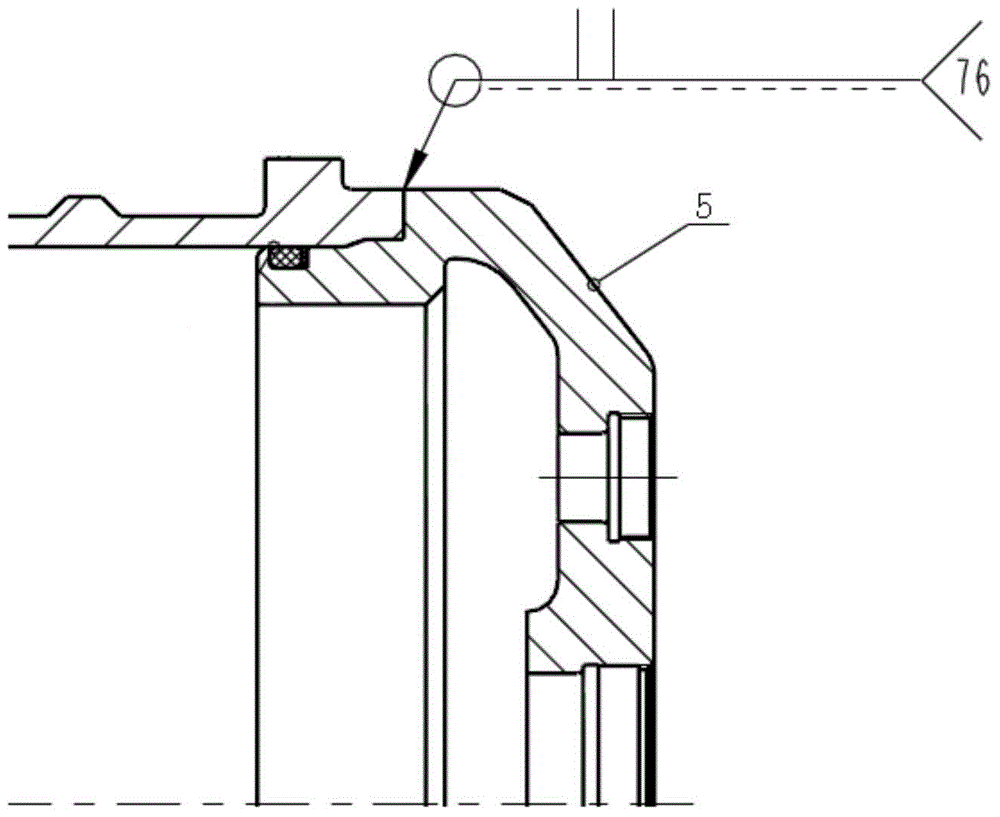

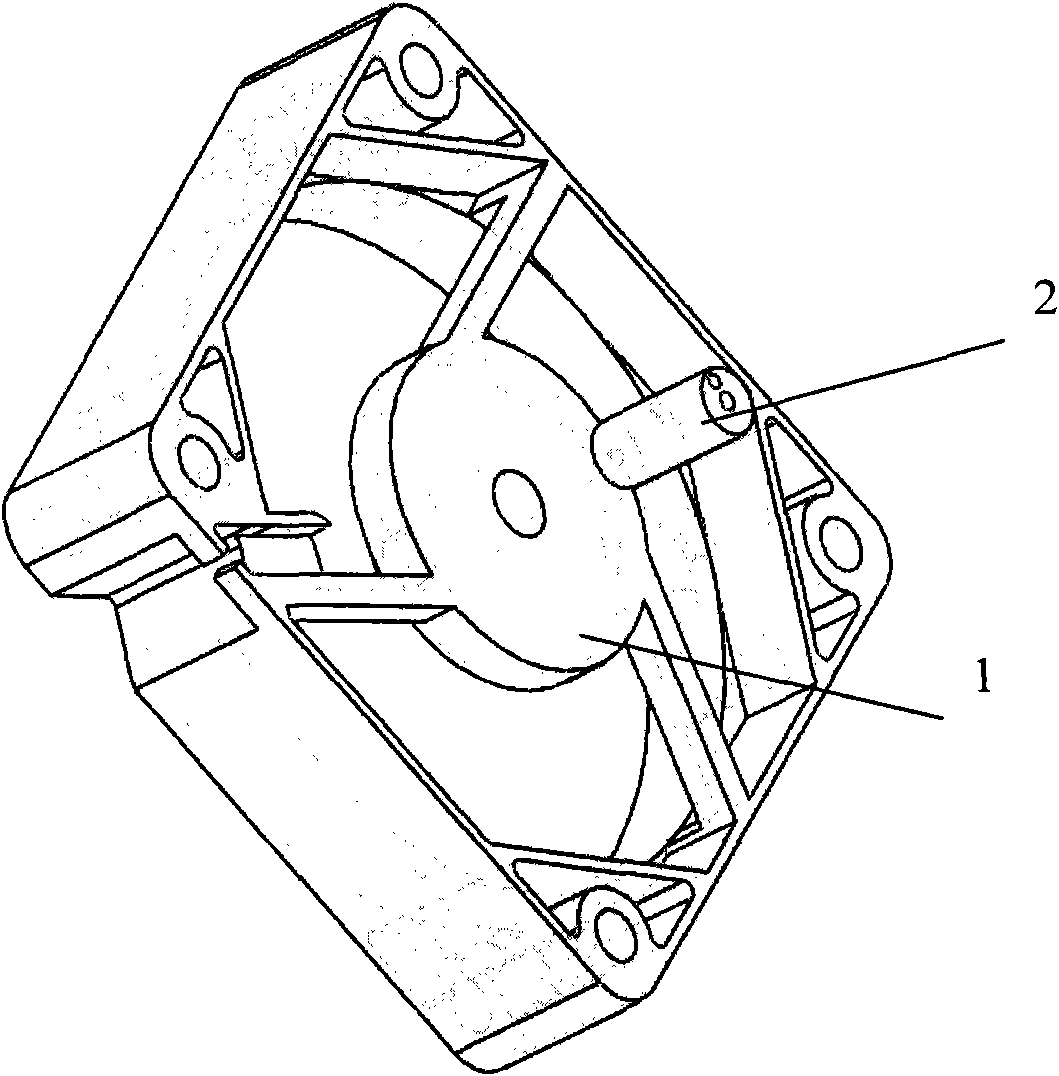

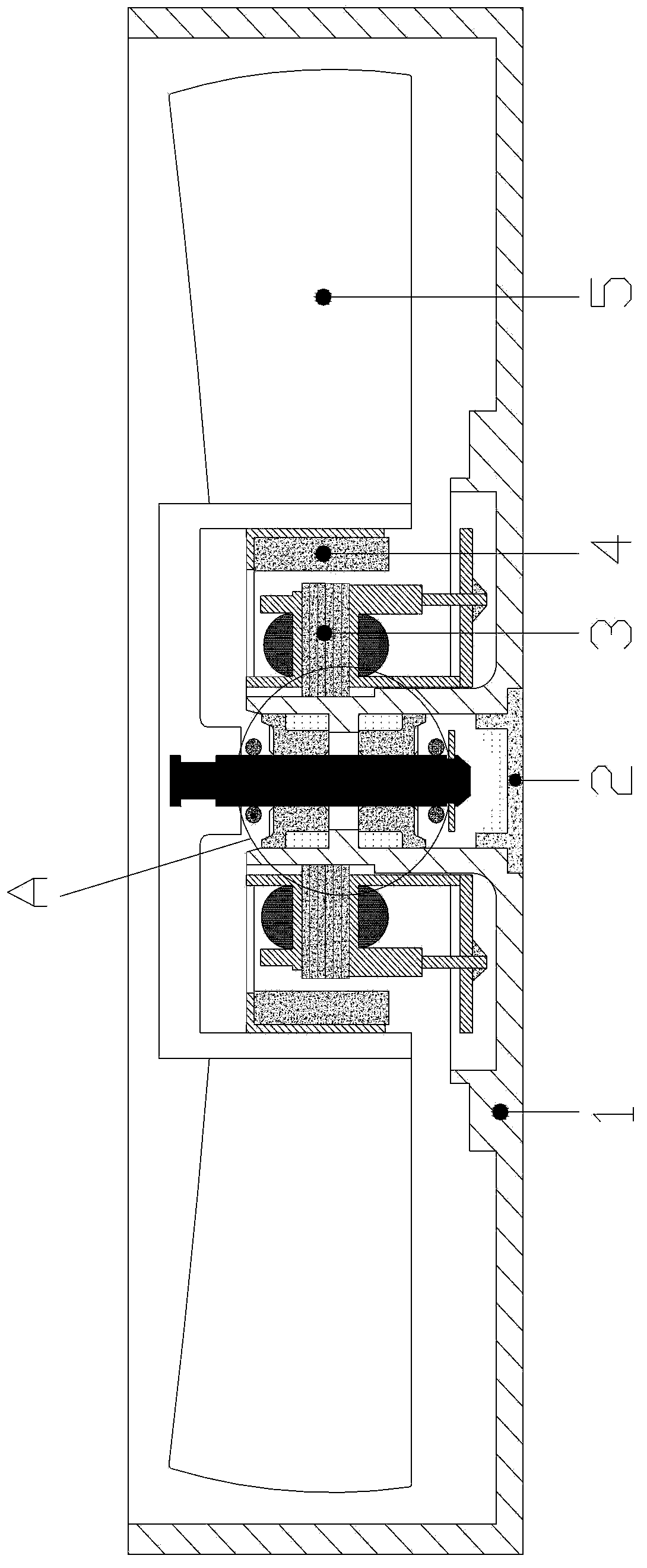

Electric hydraulic power steering pump assembly

The invention discloses an electric hydraulic power steering pump assembly. The electric hydraulic power steering pump assembly comprises a motor, a controller and a driving support. The driving support comprises a copper conductor and an outer insulation sleeve wrapping the copper conductor. The copper conductor is provided with first copper sheets connected with a motor stator of the motor and second copper sheets connected with the controller. The first copper sheets and the second copper sheets stretch out of the outer insulation sleeve. According to the electric hydraulic power steering pump assembly, the driving support connected with the motor stator and the controller is arranged, so that a traditional wiring harness is replaced, the driving support is used for connecting the motor and the controller, the driving support is composed of the copper conductor with good conductivity and the outer insulation sleeve, the advantages of being not prone to ageing and not prone to short circuit are achieved, and the connecting reliability and safety of the motor and the controller are guaranteed.

Owner:WUHU DEFU STEERING SYST

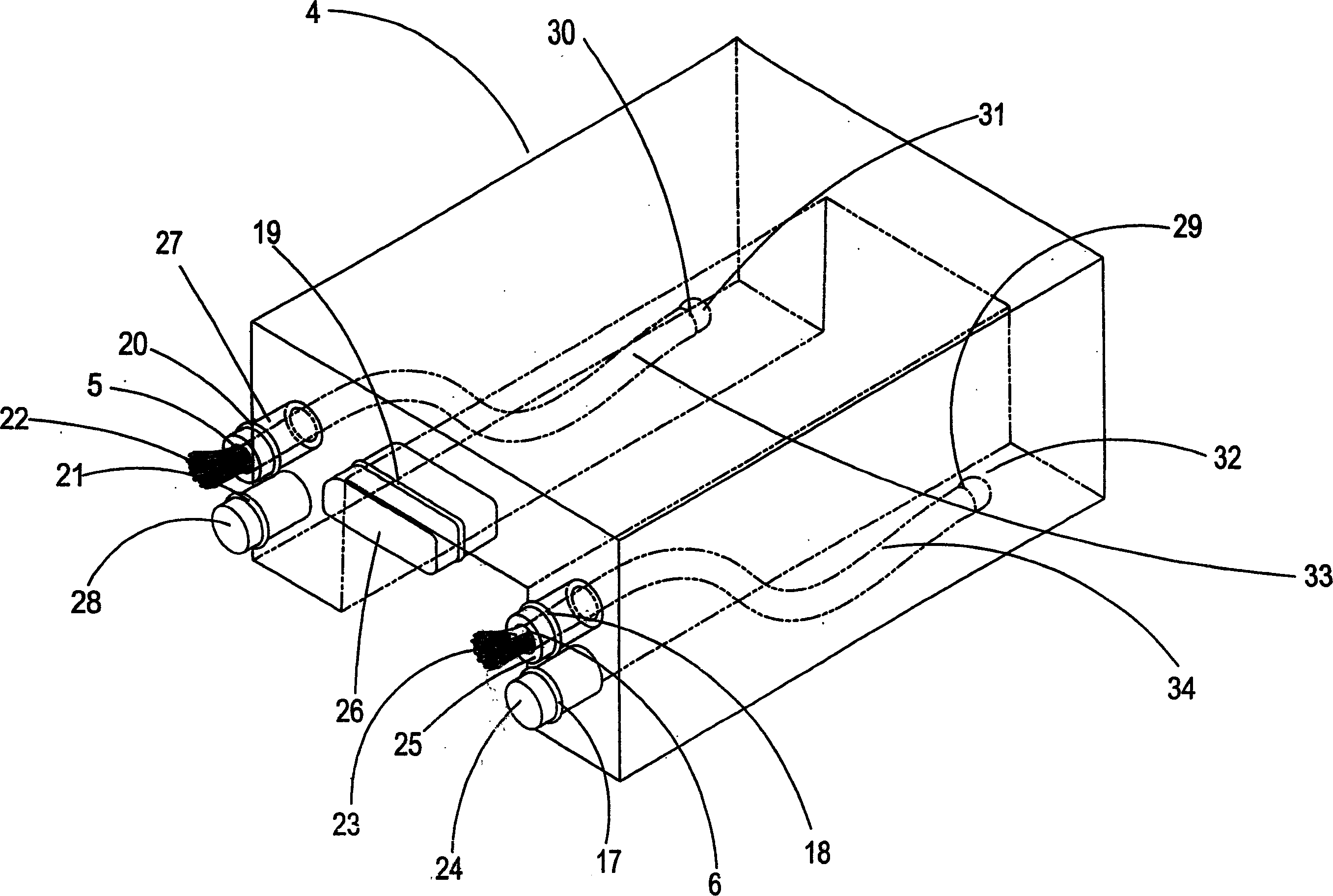

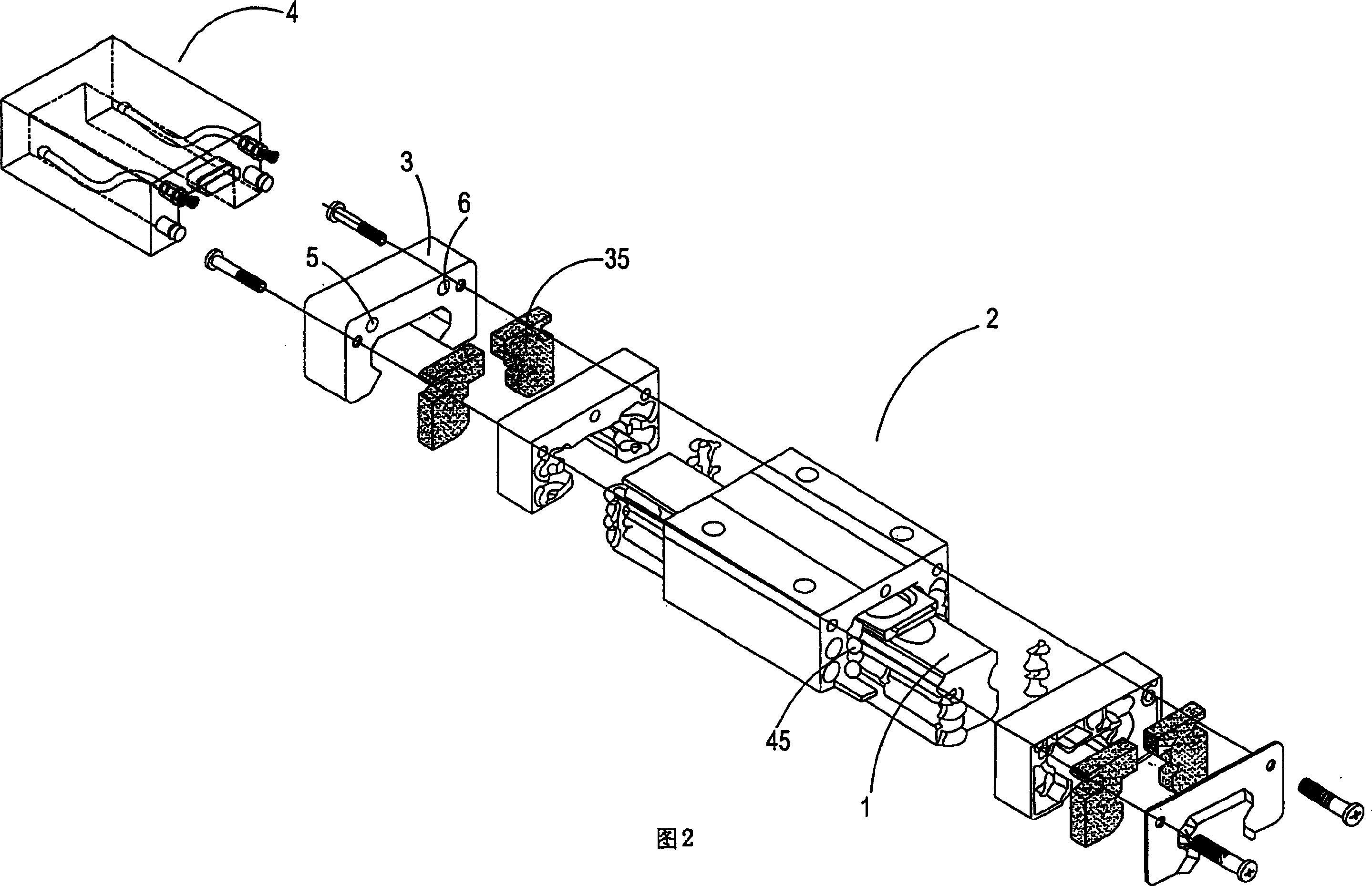

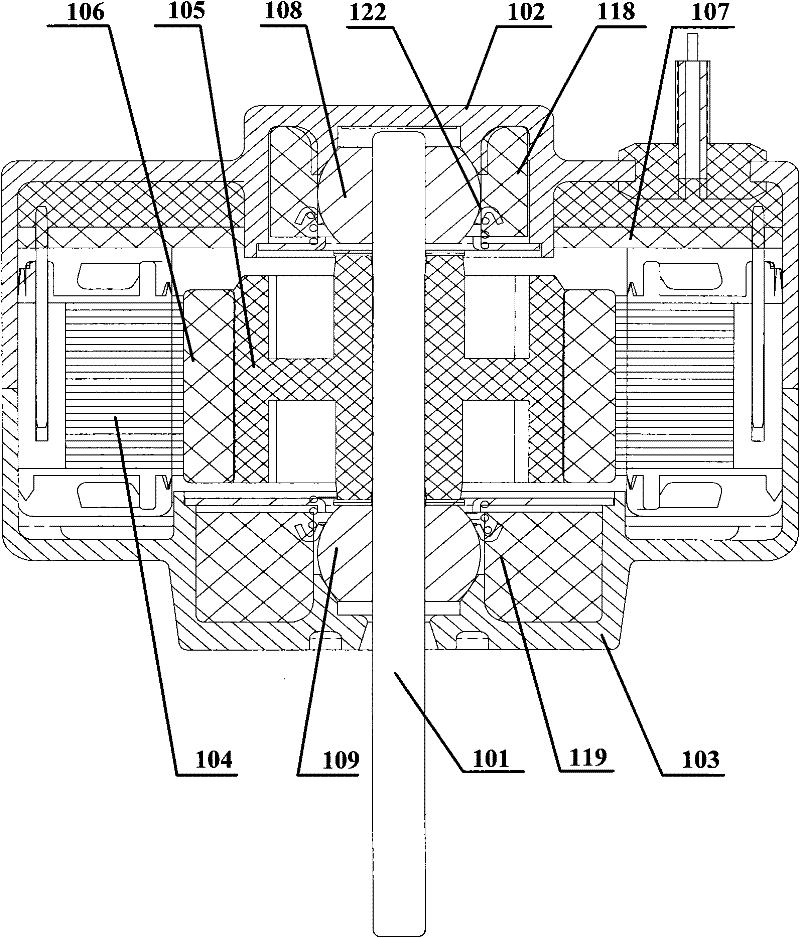

Direct current brushless motor and draining pump

ActiveCN102347677AExtend your lifeIncrease oil storageMechanical energy handlingPump installationsBrushless motorsEngineering

The invention discloses a direct current brushless motor and a draining pump. The direct current brushless motor comprises an upper end cover, a lower end cover, motor shafts, an upper bearing, a lower bearing, a stator assembly and a rotor assembly; the motor shafts respectively penetrate through shaft outputting holes of the upper end cover and the lower end cover through the upper bearing and the lower bearing; a side wall extending upward is formed on the upper surface of the upper end cover to form an upper bearing chamber; and an upward bearing surface is formed at the shaft outputting hole of the upper end cover; the upper bearing is arranged in the upper bearing chamber and is located on the bearing surface; the top surface of the upper bearing chamber is provided with an upper pressing cover, the upper pressing cover is connected with the side wall of the upper end cover to press and fix the upper bearing. According to the direct current brushless motor and the draining pump provided by the invention, the upper bearing of the motor is arranged on the upper side of the upper end cover, so that the oil reserve of the lubricant can be increased, leakage and seepage of the lubricant during long-term operation can be prevented, and the service life of the motor can be effectively prolonged. The upper bearing is moved from the internal side of the end cover to the external side, therefore, the space for a drive circuit board provided by the internal part of the motor can be enlarged, thereby enlarging the board distribution area of the circuit board.

Owner:ZHEJIANG SANHUA COMMERCIAL REFRIGERATION CO LTD

Oil pump of compressor and variable frequency compressor

ActiveCN106286226AAvoid load increaseAvoid installationPositive displacement pump componentsPositive-displacement liquid enginesCrankshaftOil storage

The invention provides an oil pump of a compressor and a variable frequency compressor. The oil pump comprises a crankshaft, a mandrel and a pump sleeve; the mandrel includes an upper mandrel and a lower mandrel; a groove hole is formed in the lower end surface of the crankshaft; a throttling hole is formed in the side wall of the crankshaft; the pump sleeve is formed with an annular cavity at the connecting part of the upper mandrel and the lower mandrel; an upper oil conveying hole is formed in the side wall of the upper mandrel; a lower oil conveying hole is formed in the lower mandrel; and when the mandrel rotates, lubricating oil can enter a space of the outer side wall of the crankshaft by passing through the lower oil conveying hole, the annular cavity, the upper oil conveying hole, the groove hole and the throttling hole in sequence from an oil pool. The variable frequency compressor is provided with the oil pump. In the oil pump of the compressor and the variable frequency compressor, the mandrel in the oil pump rotates, and the pump sleeve dose not rotate, but moves in the axis direction of the mandrel, so that the oil pumping capacity control of the compressor is realized; and the oil pump has such advantages as simple structure, convenience for installation, lower needed oil storage quantity and lower noise and system influence.

Owner:黄石东贝压缩机有限公司

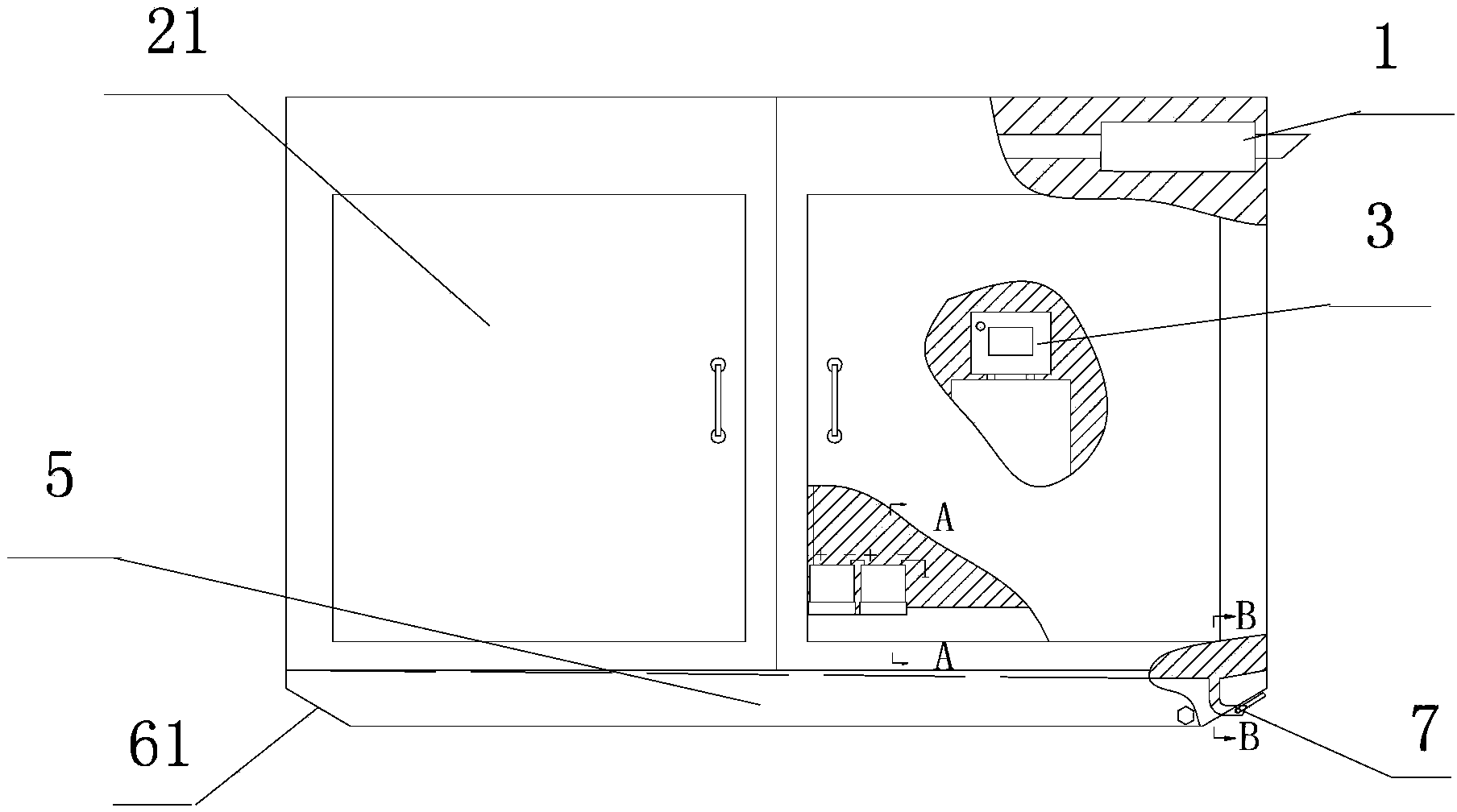

Novel generating set

InactiveCN103912373AEffective rain protectionEasy to operate and transportMachine framesMachines/enginesFuel tankEngineering

The invention provides a novel generating set and relates to the improvement of a generating set structure. The novel generating set comprises a case, a generating set, a silencer, a control cabinet, a storage battery, an oil tank, a water tank, a base plate, a side door and a door frame; the generating set, the control cabinet, the storage battery and the water tank are arranged in the case, the base plate is located at the bottom of the case, and the side door is located at one side or both sides of the case and rotatably connected with the door frame; the silencer is located at one side of the water tank in a position slightly close to the top, the control cabinet is located on the generating set, the storage battery is mounted on a generating set base, and the storage battery is fixed on a storage battery rack. The novel generating set has the advantage that the silencer is arranged at one side of the water tank in the position slightly close to the top and thus can be effectively protected against rain. In addition, the control cabinet is placed on the generating set and thus convenient to operate and transport. Meanwhile, the storage battery is stored on the storage battery rack which is fixed to the generating set base, and in addition, an anti-theft device is mounted to prevent the storage battery from being stolen.

Owner:YANGZHOU FEIHONG ELECTRIC MATERIAL

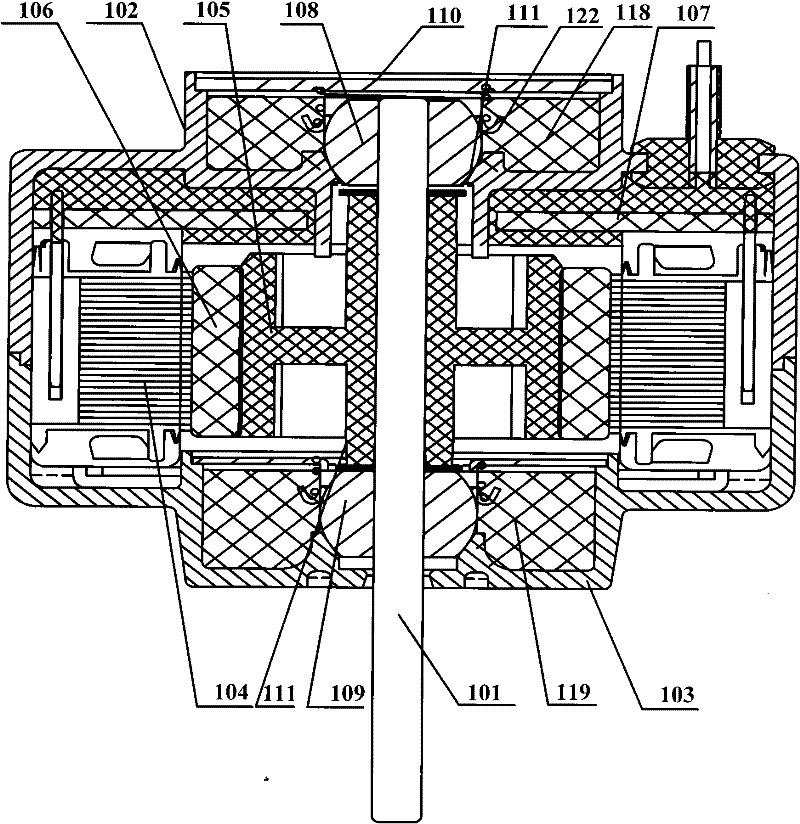

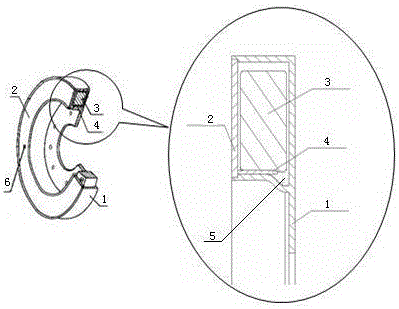

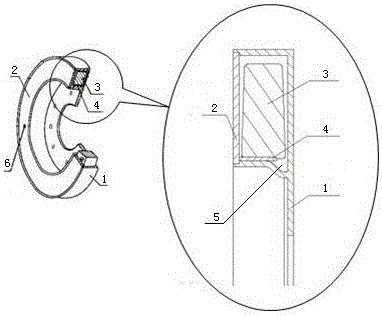

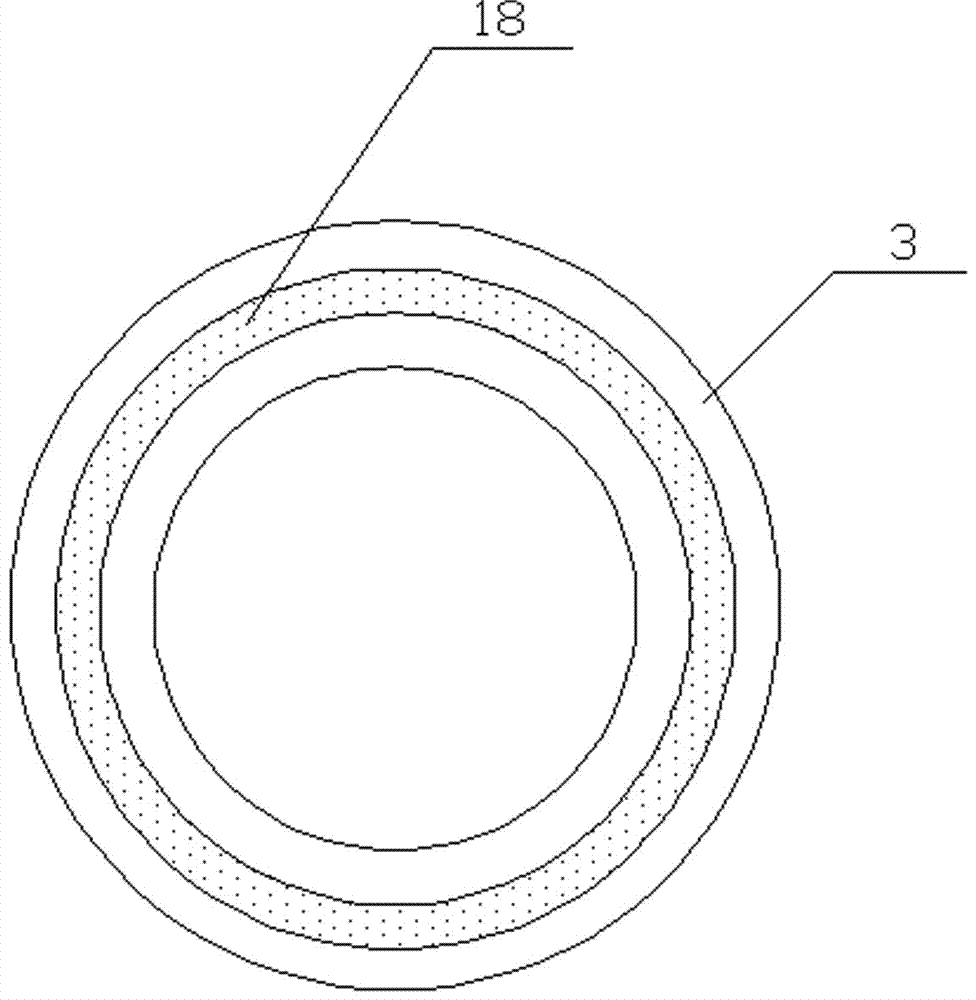

A silicone oil torsional vibration damper

ActiveCN104019175BIncrease axial clearanceImprove convenienceSpringsLiquid based dampersEngineeringTorsional vibration

The invention relates to a silicone oil torsional vibration damper, and belongs to the technical field of engine vibration reduction. The silicone oil torsional vibration damper comprises a shell and a side cover matched with the shell. An annular groove is formed in one end face of the shell. The side cover covers an opening of the annular groove to form a sealed inner cavity. An inertia ring is arranged in the sealed inner cavity through a bush in a sliding and sleeved mode. The gap between the shell and the inertia ring is filled with silicone oil. As innovation points, the thickness of the inner ring of the inertia ring is larger than the thickness of the outer ring of the inertial ring, the fracture of the inertia ring is in a trapezoid shape, and the axial clearance between the end face of the inertia ring and the inner wall of the sealed inner cavity is in a wedge shape; thus, the rigidity and the damping of a shock absorber are improved under the same condition, the axial clearance between the inertia ring and the shell is enlarged on the premise that the reliability of the shock absorber and the compactness of the spatial arrangement of the shock absorber are ensured, the shock absorber can adapt to a higher axial acceleration, the shock absorption performance of the shock absorber is improved, and the service life of the shock absorber is prolonged.

Owner:DONGFENG COMML VEHICLE CO LTD

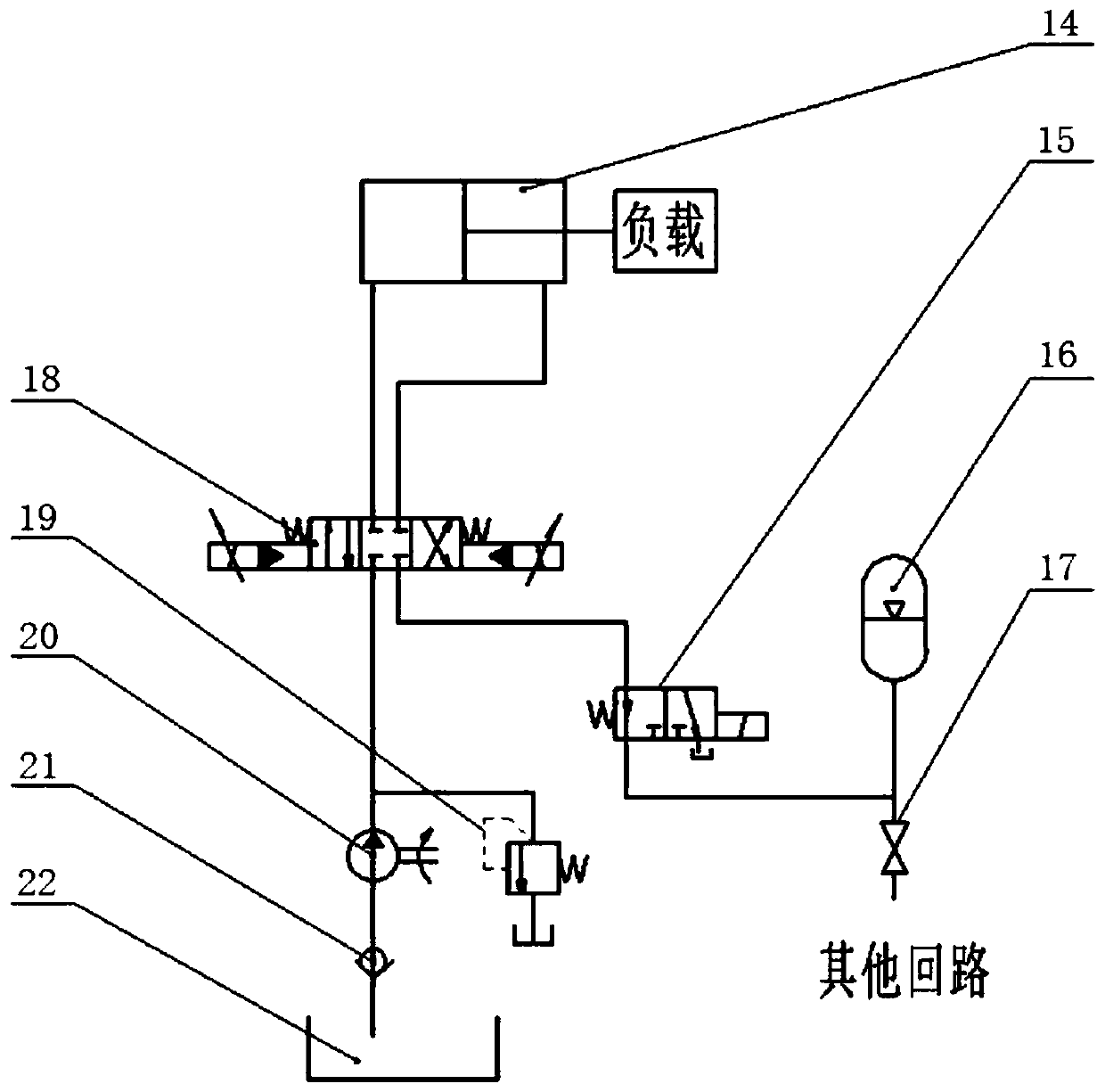

High-pressure thin-wall large-diameter extrusion oil tank

InactiveCN105041760AStrong adaptability to deformationCompensation for seal failurePiston ringsFluid-pressure actuatorsFailure causesHigh pressure

The invention discloses a high-pressure thin-wall large-diameter extrusion oil tank which comprises an oil tank cylinder, a supporting mandrel, a piston and an end cover. One end of the oil tank cylinder of a cylindrical structure is connected with the end cover. The supporting mandrel is arranged on the central axis of the oil tank cylinder. A displacement sensor is installed in an inner cavity of the supporting mandrel and used for measuring the oil storage amount in the oil tank. The supporting mandrel is sleeved with the piston in a sealed manner. The oil tank cylinder is divided into an oil cavity and a gas cavity through the piston. The piston is provided with two Y-shaped sealing rings for isolating oil from gas and matched with the inner wall of the oil tank cylinder. The end cover is a cover body protruding outwards and is welded to the oil tank cylinder in a stepped manner. Double guidance is set for the inner ring and the outer rings of the piston so that the oil storage amount of the oil tank can be increased. Due to the fact that the outer rings of the piston are the Y-shaped rings, the capacity of the piston adapting to deformation of the cylinder is high, the sealing manner is adopted for effectively compensating for seal failure caused by deformation of the cylinder, and the oil tank has the good sealing effect when working under the conditions of high vibration and high impact magnitude.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

Oil bearing

InactiveCN102457129APrevent leakagePrevent from being evaporatedSupports/enclosures/casingsOil storageGasket

The invention relates to an oil bearing. The oil bearing is characterized in that reserve fuel quantity is enhanced, and oil keeping time is longer, and at least one side end of the oil bearing is at least provided with an oil storage concave part; a port of the oil storage concave part retracts to the most relative to the most outside of the side end of the bearing, and the side end is provided with an oil undertaking wall; the oil undertaking wall is positioned on the periphery of a port of an oil storage hole, and an oil circulation gasket is fixed on a spindle connected with the oil bearing; and the oil circulation gasket is positioned in a distributing region of the oil in the oil storage hole, and the port of the oil storage hole is sealed by a cover part.

Owner:SHANGHAI SHICOH ELECTRONICS CO LTD

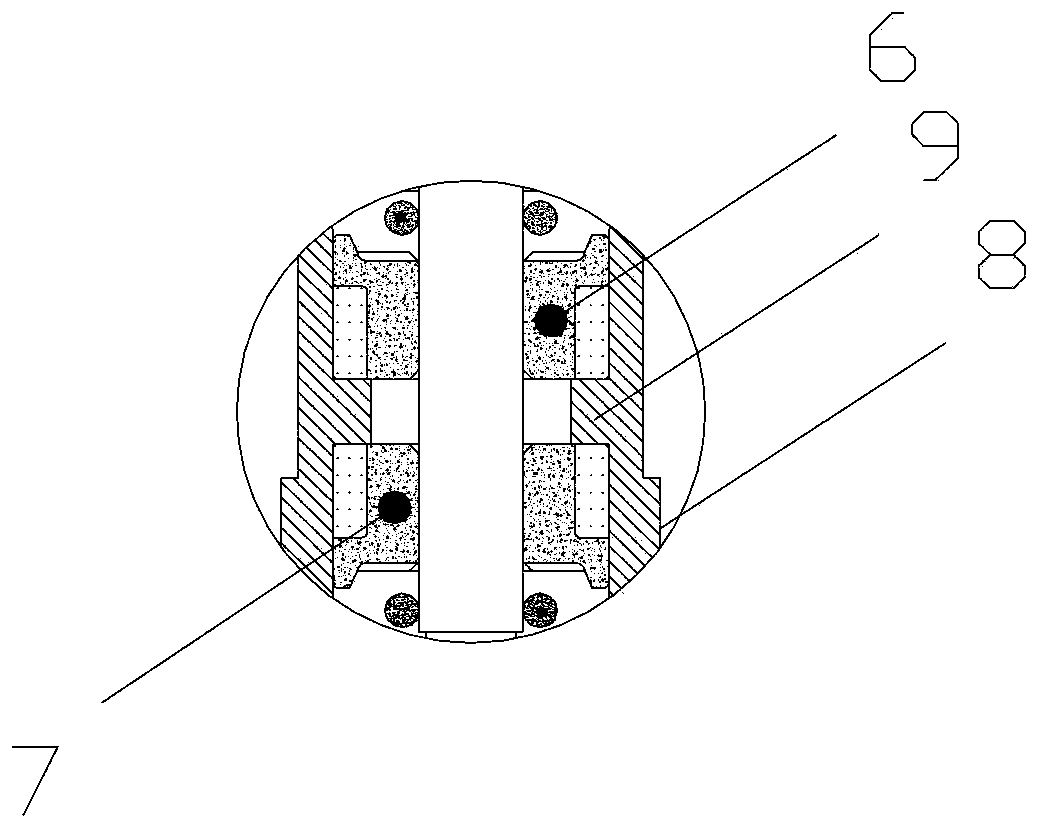

Thrust ball bearing with good sealing performance and application thereof

ActiveCN107956793AAdjustable axial clearanceWon't leakMechanical machines/dredgersShaftsBall bearingEngineering

The invention discloses a thrust ball bearing with the good sealing performance and an application thereof. The thrust ball bearing comprises a flange-shaped base and a flange-shaped shaft ring, wherein the flange-shaped base comprises a base flange plate and a base flange tube, and the flange-shaped shaft ring comprises a shaft ring flange plate and a shaft ring flange tube; the base flange tubeis provided with a groove, and the groove is used for dividing the base flange tube into a base flange inner tube and a base flange outer tube, and a bearing base is installed at the bottom part of the groove; two ends of retainer rolling bodies are arranged in a bearing base rolling way and a shaft ring flange tube end surface rolling way respectively; oil permeation holes are formed in the baseflange outer tube, a left reinforcing rib and a right reinforcing rib are arranged on the base flange outer tube, and an outer sleeve is arranged on the outer periphery of the base flange outer tube;and a cavity formed among the outer wall of the base flange outer tube, the inner wall of the outer sleeve, an end plate and the inner wall of the base flange plate is an oil storage cavity. The invention further discloses the application of the thrust ball bearing on an excavator. According to the thrust ball bearing with the good sealing performance and the application thereof, the oil storage cavity is adopted, so that the oil storage capacity is increased, the lubricating effect is good, the sealing performance is good, and maintenance is not needed in years.

Owner:吴银辉

Fan provided with oil bearing

InactiveCN103573685AIncrease oil storage spaceIncrease oil storagePump componentsPumpsEngineeringRing mode

The invention provides a fan provided with an oil bearing. The fan provided with the oil bearing comprises a casing, the oil bearing, a sealing oil cover, a stator and a rotator which can rotate relative to the stator; the casing comprises a shaft seat; the stator is sleeved to the periphery of the shaft seat; the oil bearing is accommodated inside the shaft seat; the sealing oil cover is arranged at the bottom of the oil bearing; lubricating fluid inside the oil bearing is sealed inside the shaft base; the rotator comprises a hub, fan blades and a rotating shaft which is arranged inside the oil bearing and can rotate relative to the oil bearing; the hub is arranged on the periphery of the stator; the fan blades are arranged on the periphery of the hub in a ring mode; the rotating shaft vertically extends towards the shaft base from the hub center; a plurality of sinking grooves are formed in the bottom of the outer circumference of the oil bearing. The fan provided with the oil bearing has the advantages of prolonging the service life due to the facts that part of spare lubricating oil is stored inside the sinking grooves which are formed in the bottom of the outer circumference of the oil bearing and the spare lubricating oil is automatically supplied when immersion oil precipitation inside the oil bearing is deficient.

Owner:平湖市建盟电子有限公司

Grease stain resistance separation-type high-speed energy-saving spinning spindle

ActiveCN109338532AEffective absorptionImprove quality and efficiencyTextiles and paperEconomic benefitsEngineering

The invention discloses a grease stain resistance separation-type high-speed energy-saving spinning spindle. The grease stain resistance separation-type high-speed energy-saving spinning spindle is characterized by comprising a spindle bolster base, an inner spindle bolster tube, a sealing ring, an outer spindle bolster tube, an inner and outer spindle bolster tube sealing cover, a support block,a through hole, an outer spindle bolster oil valve and a spindle bottom oil valve; the inner spindle bolster tube, the outer spindle bolster tube and the spindle bolster base are each an independent body and form a spindle bolster together, wherein the lower end of the inner spindle bolster tube tightly cooperates with the outer spindle bolster tube, the portion between the inner spindle bolster tube and the outer spindle bolster tube is filled with damping oil, oil filling operation is completed by the outer spindle bolster oil valve, and the upper end of the inner spindle bolster tube and the upper end of the outer spindle bolster tube are sealed by the inner and outer spindle bolster tube sealing cover. The grease stain resistance separation-type high-speed energy-saving spinning spindle has the advantages that due to the separation-type spindle bolster, the washing and oil filling problems of spinning spindles are effectively solved; due to the inner spindle bolster tube, oil storage space is enlarged, the oil change period of the spindle is prolonged, the high-speed vibration absorption and energy saving function of a dual vibration absorption system is significant, and not only can actual engineering requirements in the textile spinning be met to fill a technical gap, but also great social and economic benefits can be generated.

Owner:TIANJIN POLYTECHNIC UNIV

Fuel tank

InactiveCN103832270AIncrease oil storageIncrease productivityFuel supplyAutomotive engineeringCorrosion

The invention provides a fuel tank which comprises a fuel tank body, an oiling port and a ventilation port. The oiling port is formed in the sidewall of the fuel tank body, the ventilation port is formed in the top of the fuel tank body, and the top of the fuel tank body is further provided with a multifunctional valve and a buffer layer which is used for reducing influences of external force. The fuel tank is a six-layer coextrusion plastic fuel tank made of polyethylene, nylon and binding agents. The fuel tank is molded at a time, integration is achieved, and therefore the production efficiency is improved. The infiltration capacity of the fuel tank is lower than 0.2g / 24h, so the fuel tank is friendly to environment and capable of saving energy. The fuel tank is light in weight, large in shape freedom degree and capable of utilizing the effective space inside a car to the maximum degree, so the oil storage capacity of the fuel tank of the car is greatly improved; the fuel tank is high in safety and reliability and resistant to impact, corrosion and rusting, sparks will not be generated to cause explosion in the friction or collision process, the fuel tank can generate springback automatically and will not deform permanently, and the service life is long.

Owner:JIANGSU DONGFANG AUTOMOTIVE ORNAMENTS GENERAL FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com