Columnar hydraulic tappet

一种液压挺柱、柱状的技术,应用在柱状式液压挺柱领域,能够解决应力疲劳、应力集中等问题,达到增加疲劳强度、加工容易、产品重量增加的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

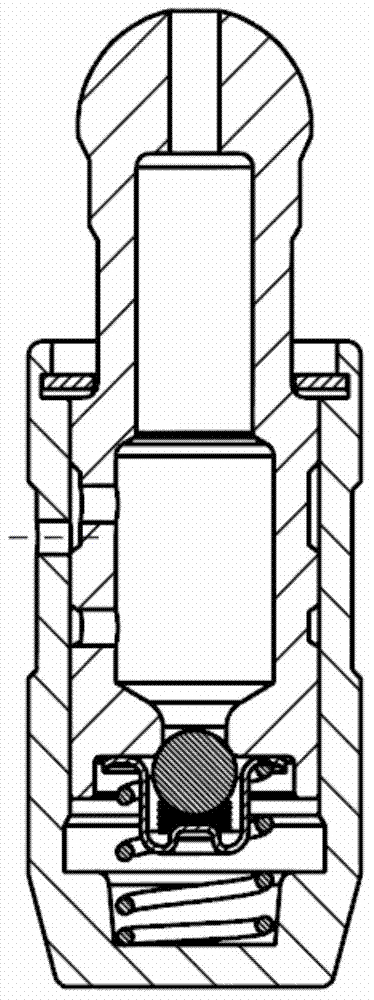

[0056] like Figure 4 Shown is a hydraulic tappet for a valve train of an internal combustion engine, the hydraulic tappet has a cylindrical housing (2), and an axially slidable plunger (1) is assembled inside the housing. On the lower face of the plunger (1) and the lower side of the housing (2) there is a high-pressure chamber (10) for hydraulic medium, which can be controlled by a check valve (3) located at the lower end of the plunger (1). closed. There is an outer ring groove (13) on the outer diameter of the shell (2) for the circulation of the hydraulic medium, and an inner ring groove (8) for the circulation of the hydraulic medium on the radial inner side of the shell. One or more oil holes (7) for connection.

[0057] The outer diameter of the plunger has a concave wide ring groove (5), and there are one or more oil holes (6) on the concave wide ring groove (5), and the inner ring groove (8) of the housing and the plunger The inner concave wide ring grooves (5) co...

Embodiment 2

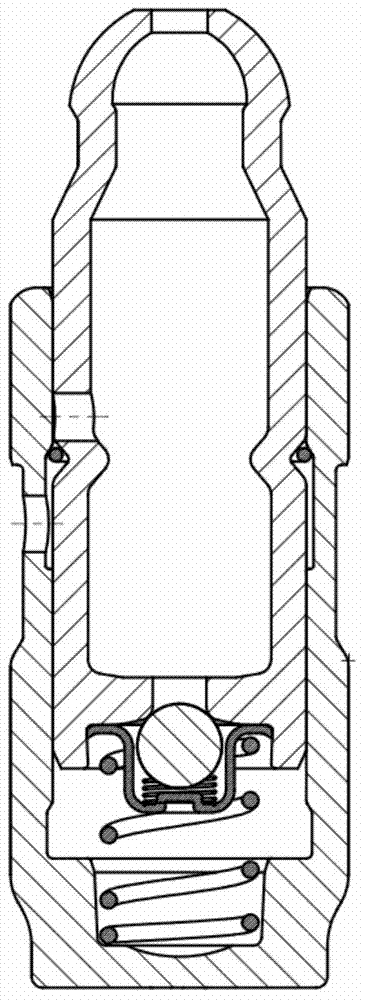

[0064] The difference from Example 1 is that, if Figure 5 As shown, there is a smooth neck (4B) between the head (11) and the stem of the plunger.

Embodiment 3

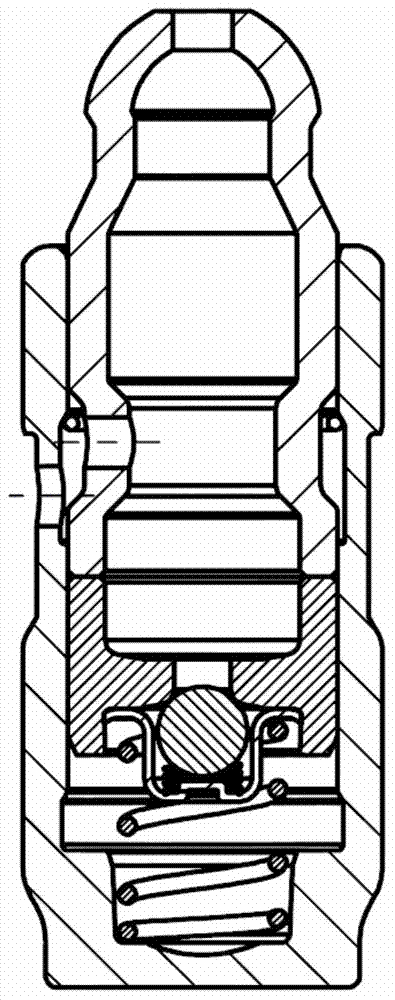

[0066] The difference from Example 1 is that, if Image 6 As shown, the positioning surface (15) of the plunger is a combination of a conical surface and an arc surface, the radius r of the arc portion is 0.3-0.8mm, and the cone angle α of the conical surface portion is 5°-15°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com