Patents

Literature

158results about How to "Enough security" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

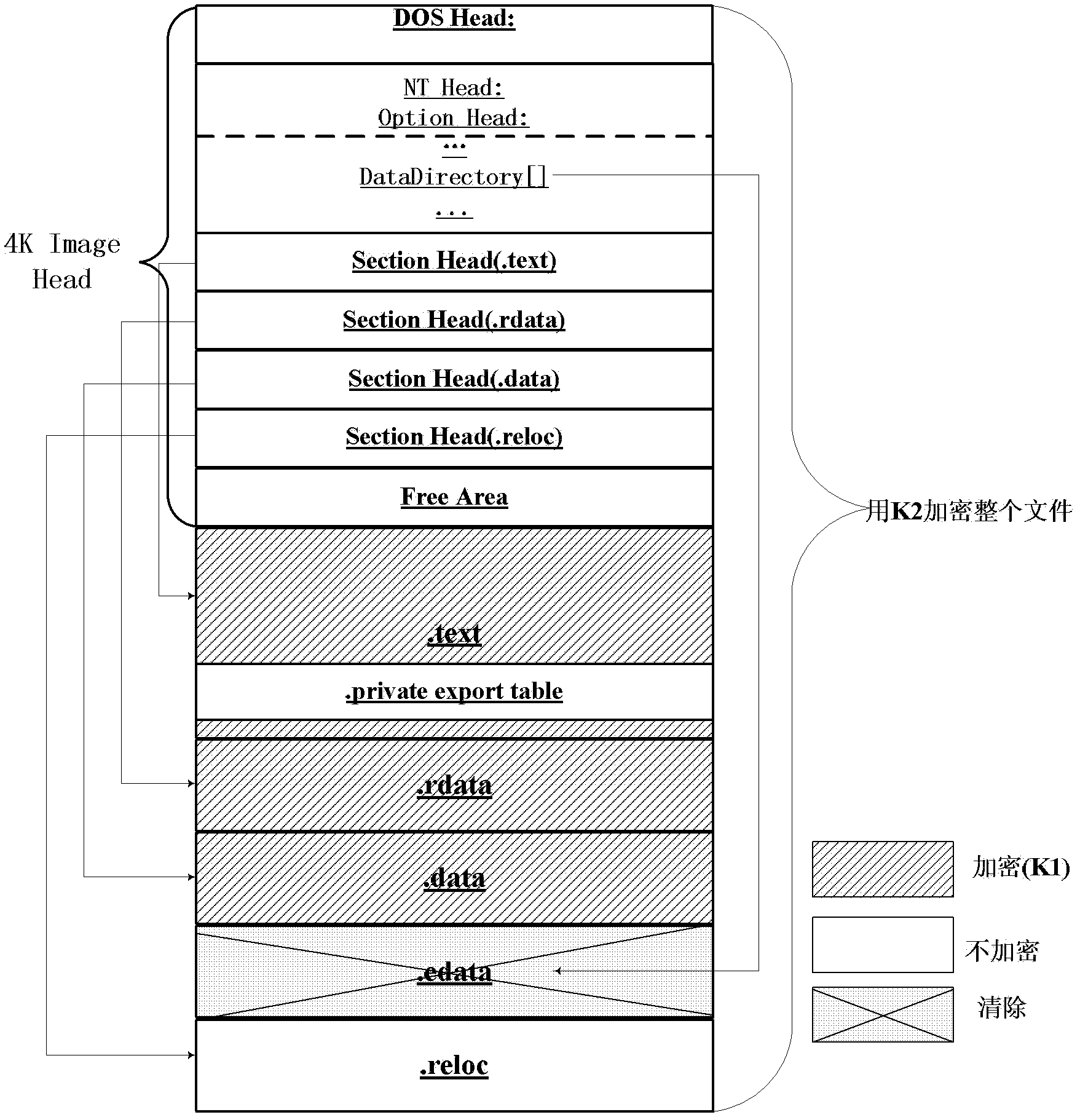

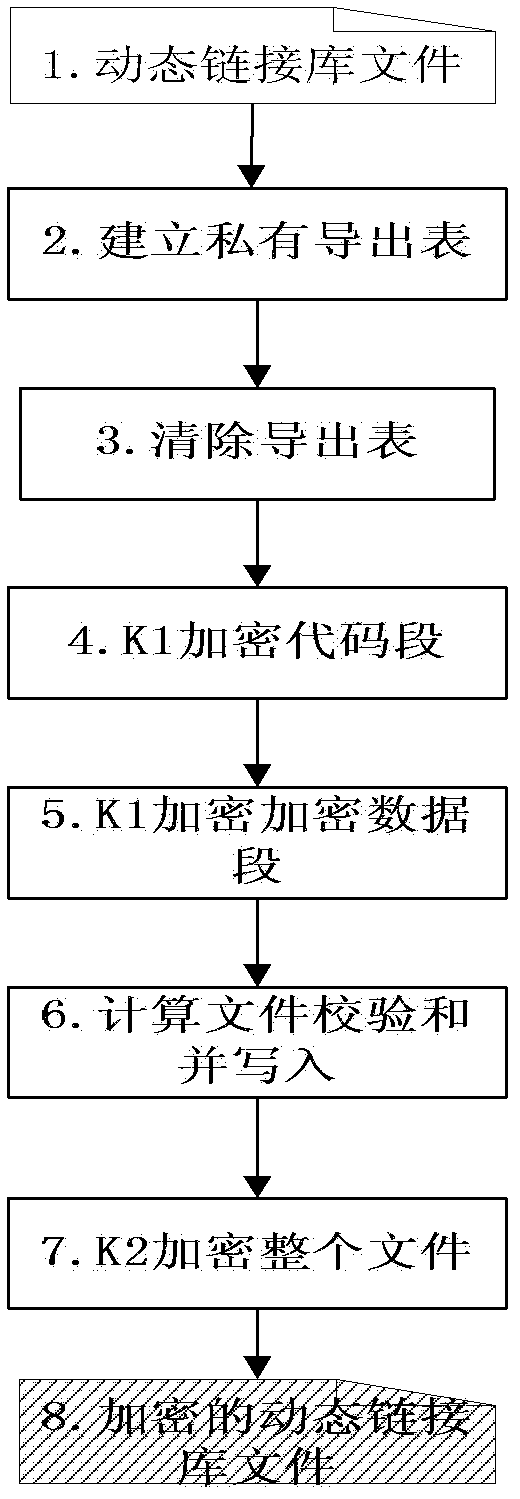

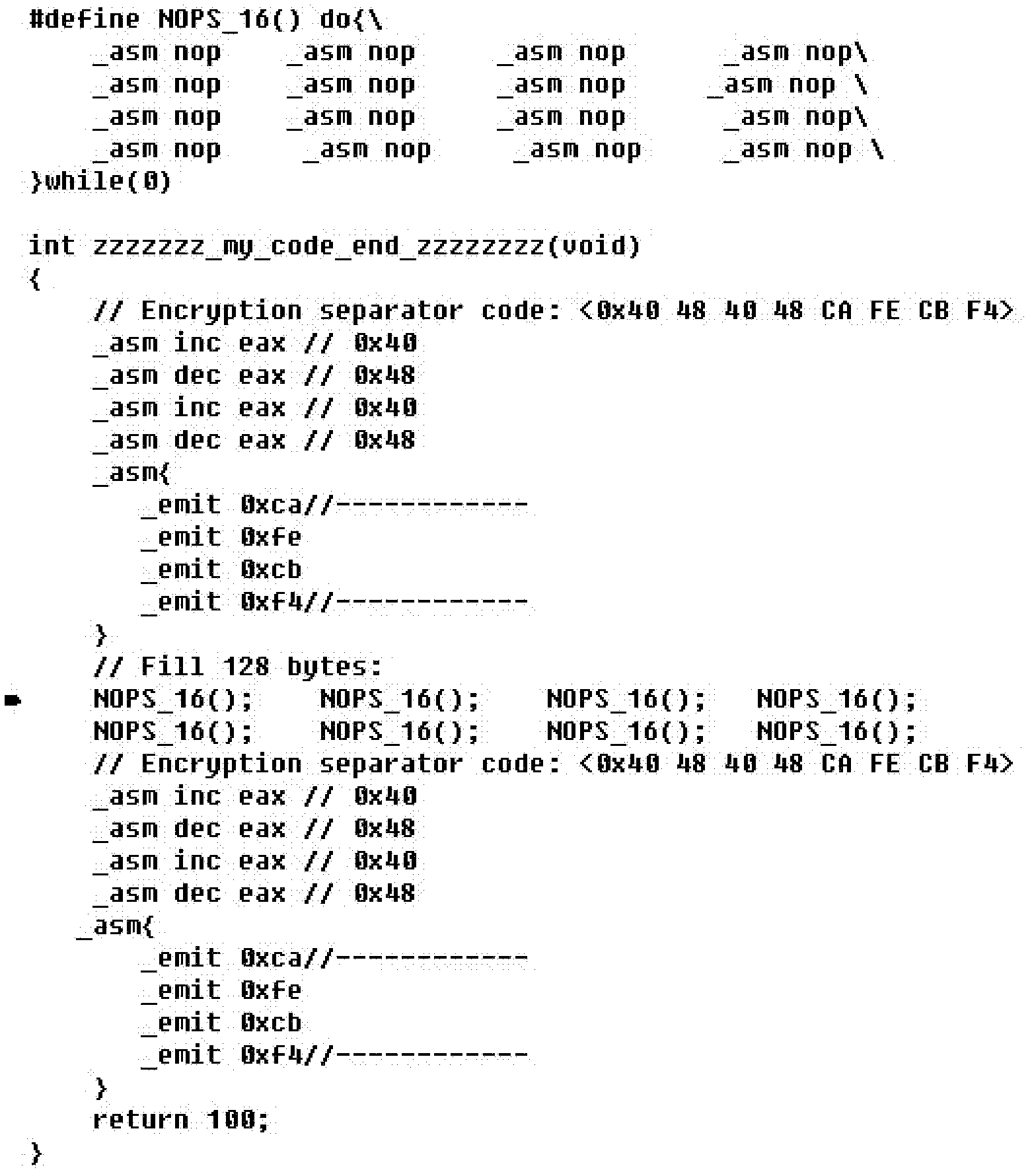

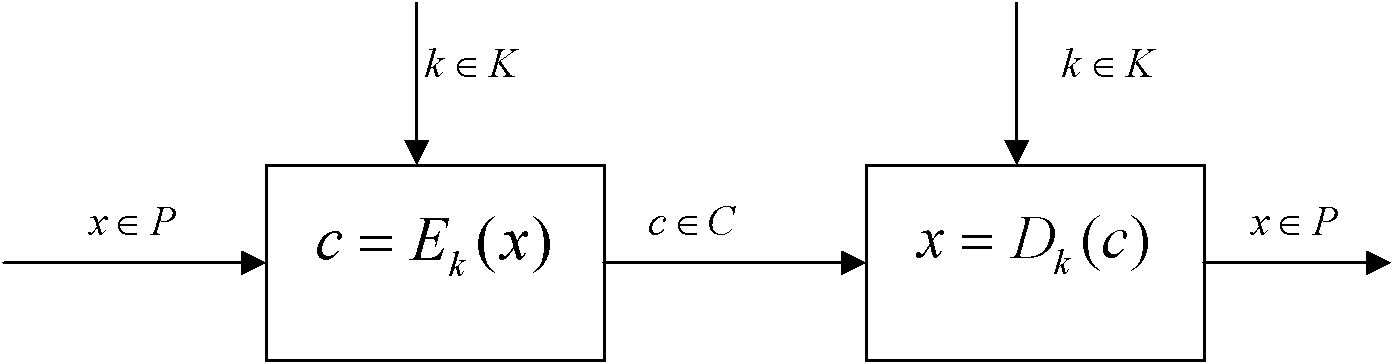

Section double encryption and safe loading method of Windows dynamic link library

ActiveCN102938036APrevent illegal debugging tracesEnough securityComputer security arrangementsProgram loading/initiatingData segmentApplication software

The invention discloses a section double encryption and safe loading method of a Windows dynamic link library and aims at solving the technical problems that dynamic link libraries in prior art are prone to be tracked and debugged, privately loaded by application programs and statically disassembled. The method includes the following steps of analyzing a Windows dynamic link library file structure, establishing a private dynamic link library derived table, clearing away the derived table of the dynamic link library, respectively subjecting a code segment and a data segment of a dynamic link library file to encryption by an encryption key of an assigned encryption algorithm; subjecting the whole dynamic link library file to encryption by another encryption key of the assigned encryption algorithm; and outputting an interface function from the private dynamic link library derived table to an application program during loading.

Owner:优地网络有限公司

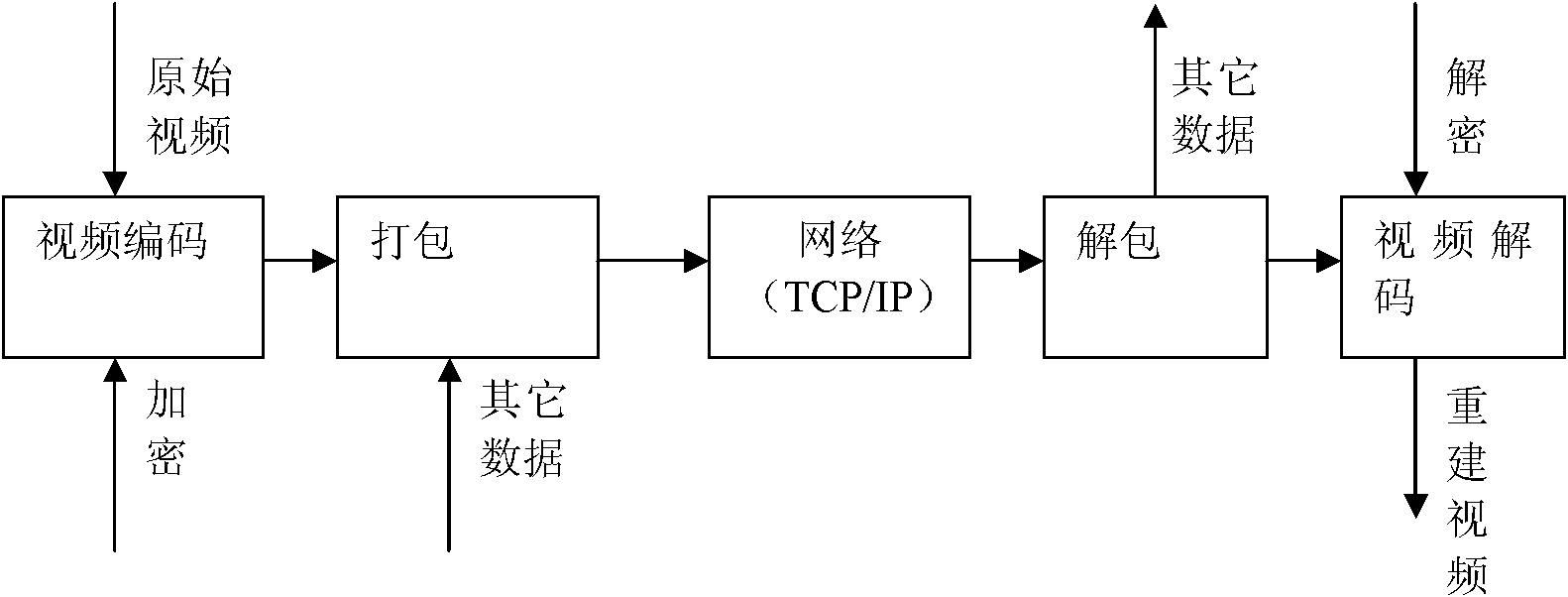

Chaos and hyperchaos based two-level video streaming media encryption method

InactiveCN102123026AImprove securityPromote perfectionSelective content distributionSecuring communicationStreaming dataNetworked Transport of RTCM via Internet Protocol

The invention provides a chaos and hyperchaos based two-level video streaming media encryption method, which comprises the step of providing a chaos and hyperchaos based two-level video streaming media encryption algorithm. The method is combined with a video compression standard H.263 in network transmission; the first-level encryption is such that video streaming data is encrypted with a discrete cosine transform (DCT) based selective encryption algorithm in a video compression process; and the second-level encryption is performed after the video compression, and comprises the following two parts of: scrambling the video streaming data based on discrete Baker mapping, and confusing scrambled data based on hyperchaos mapping. As the multilevel encryption is adopted, and a hyperchaos system has a strong encryption performance, a video streaming media encryption system adopting the method can be used for effectively resisting malicious attacks and professional decryption; and moreover, the encryption method has a significant application value in the field of the safety of transmission information of network streaming media.

Owner:NANKAI UNIV

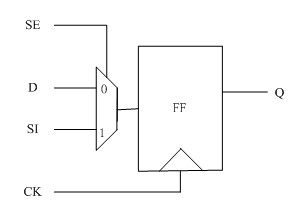

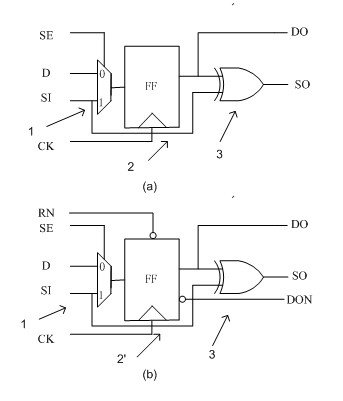

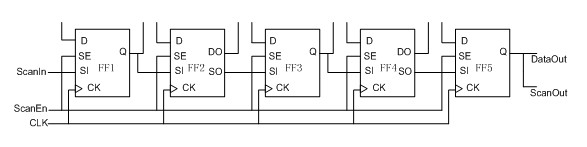

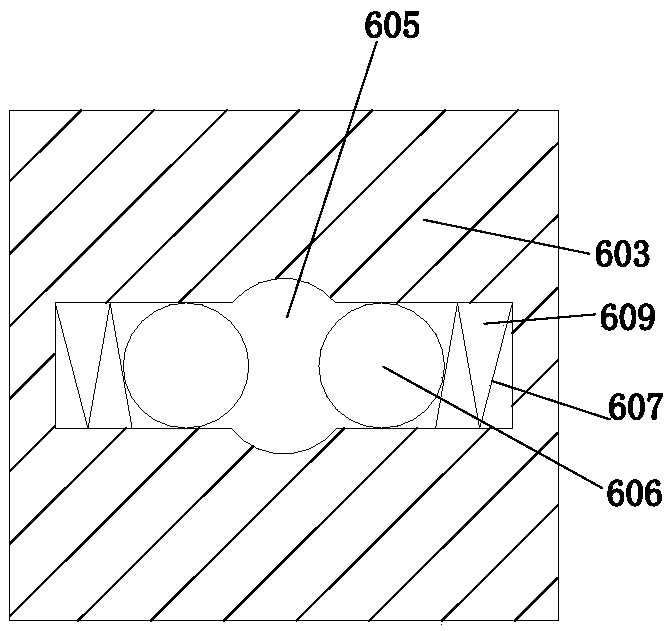

Safety scanning register, safety scan chain and scanning method of safety scan chain

InactiveCN102495360AProtection securityEnough securityElectrical testingMultiplexerProcessor register

The invention discloses a safety scanning register, a safety scan chain and a scanning method of the safety scan chain and belongs to the field of measurability design of an integrated circuit. The safety scanning register consists of a D trigger, an XOR gate and an alternative multiplexer. A data input end of the D trigger is connected with an output end of the alternative multiplexer. An output end of the D trigger is connected with a first input end of the XOR gate. A second input end of the XOR gate is connected with a second data input end of the alternative multiplexer. The safety scan chain disclosed by the invention comprises conventional scanning registers and the safety scanning registers. All the registers are cascaded. The number and the positions of the registers are determined according to a certain rule. The safety scan chain disclosed by the invention can resist the reset attack. Sufficient safety can be obtained by small area cost. The safety scan chain has high practicality.

Owner:ZHEJIANG UNIV

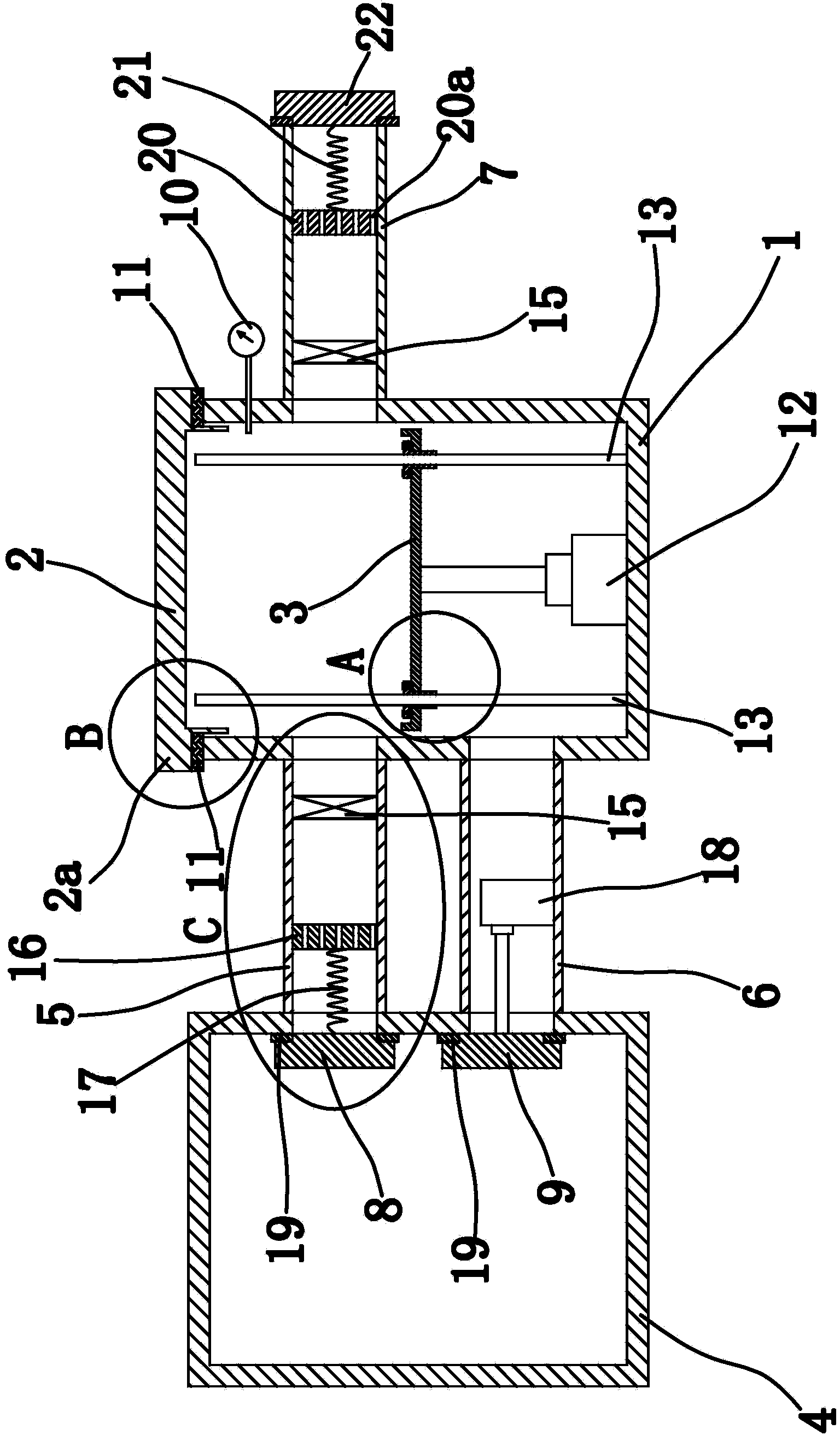

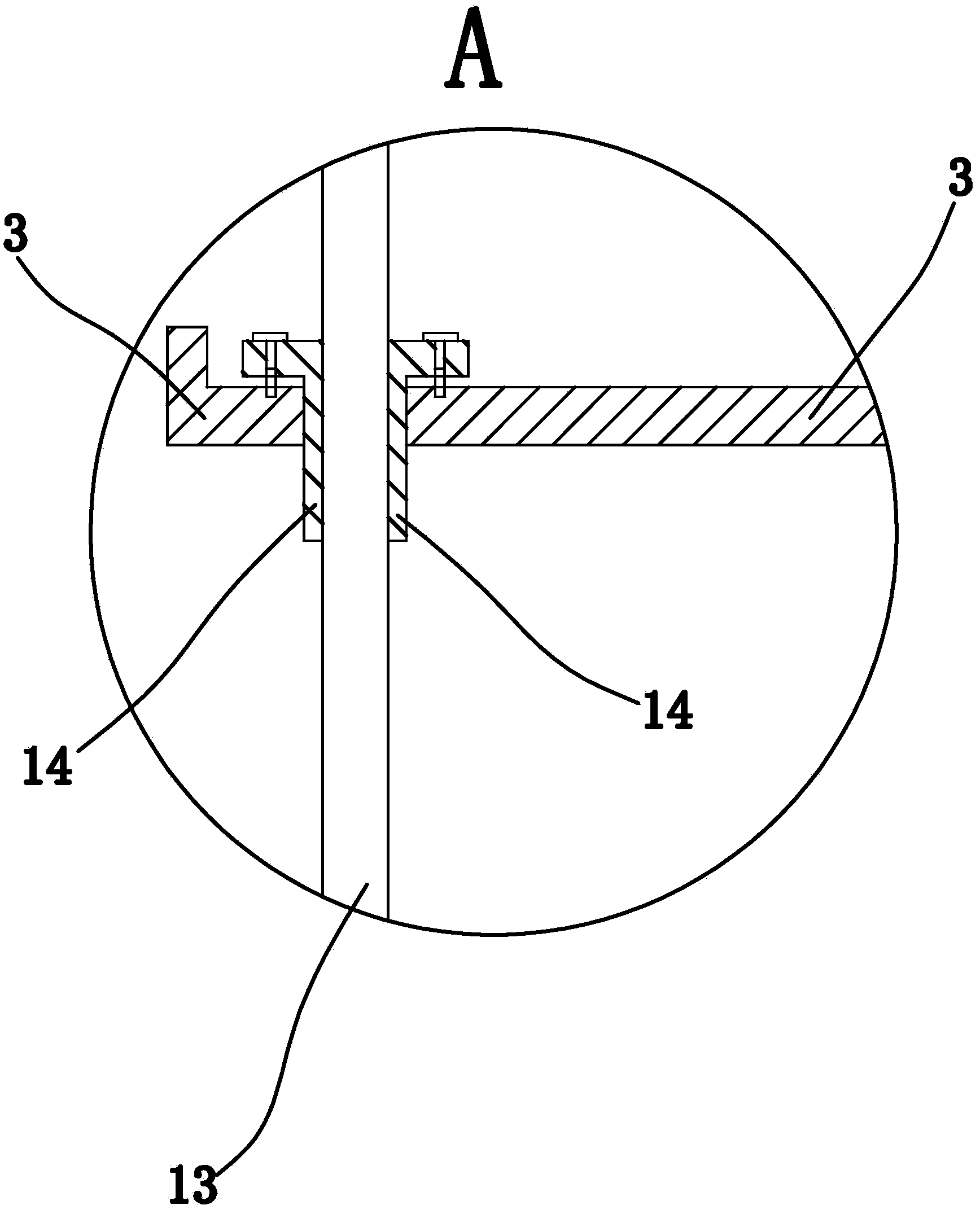

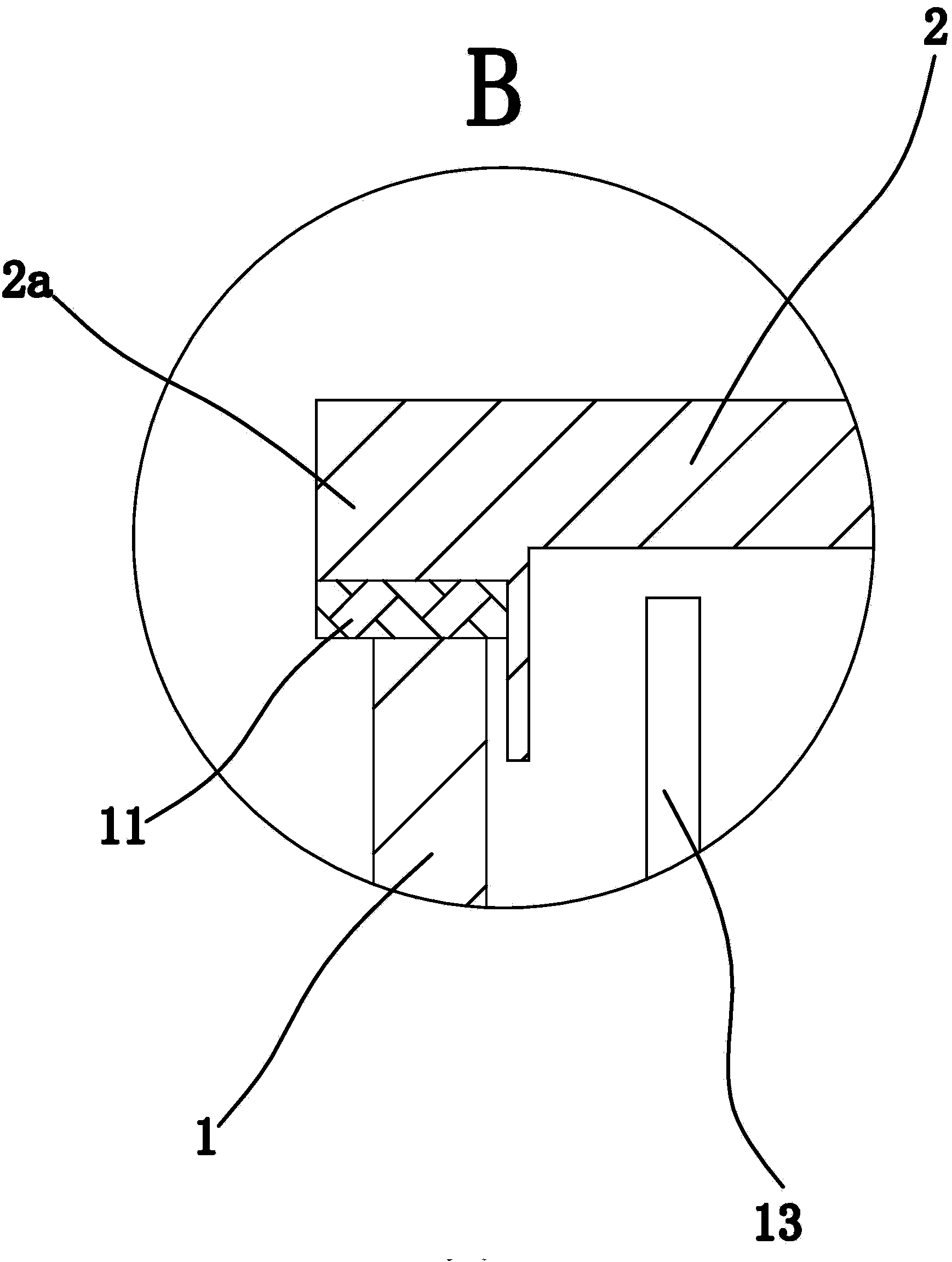

Biogas digester

ActiveCN104293655AReduce leakageReduce lossesGas production bioreactorsWaste based fuelSlagEngineering

The invention provides a biogas digester which is used for solving the problem that waste of biogas is easily caused in the slag removal process in the conventional biogas digester. The biogas digester comprises a gas storage tank and a digester body in which a fermentation disc is arranged, wherein the top of the digester body is connected with a sealing cover; a lifting device which can drive the fermentation disc to translate up and down is arranged at the bottom of the fermentation disc; a gas inlet pipe and a gas outlet pipe are arranged between the gas storage tank and the digester body; a gas suction piece I is arranged in the gas inlet pipe; a sealing plate I and a sealing plate II are arranged in the gas storage tank; an elastic piece through which the sealing plate I has the tendency of sealing the gas inlet pipe is connected to the sealing plate I; a cylinder I through which the sealing plate II seals or opens the gas outlet pipe is connected to the sealing plate II; an exhaust pipe and a pressure gage are connected to the digester body; a gas suction piece II is arranged in the exhaust pipe; a sealing plate III is arranged at the end face of the exhaust pipe; and a spring I through which the sealing plate III has the tendency of sealing the exhaust pipe is arranged between the gas suction piece II and the sealing plate III. The biogas digester disclosed by the invention has the advantages that waste of biogas is avoided during slag removal.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

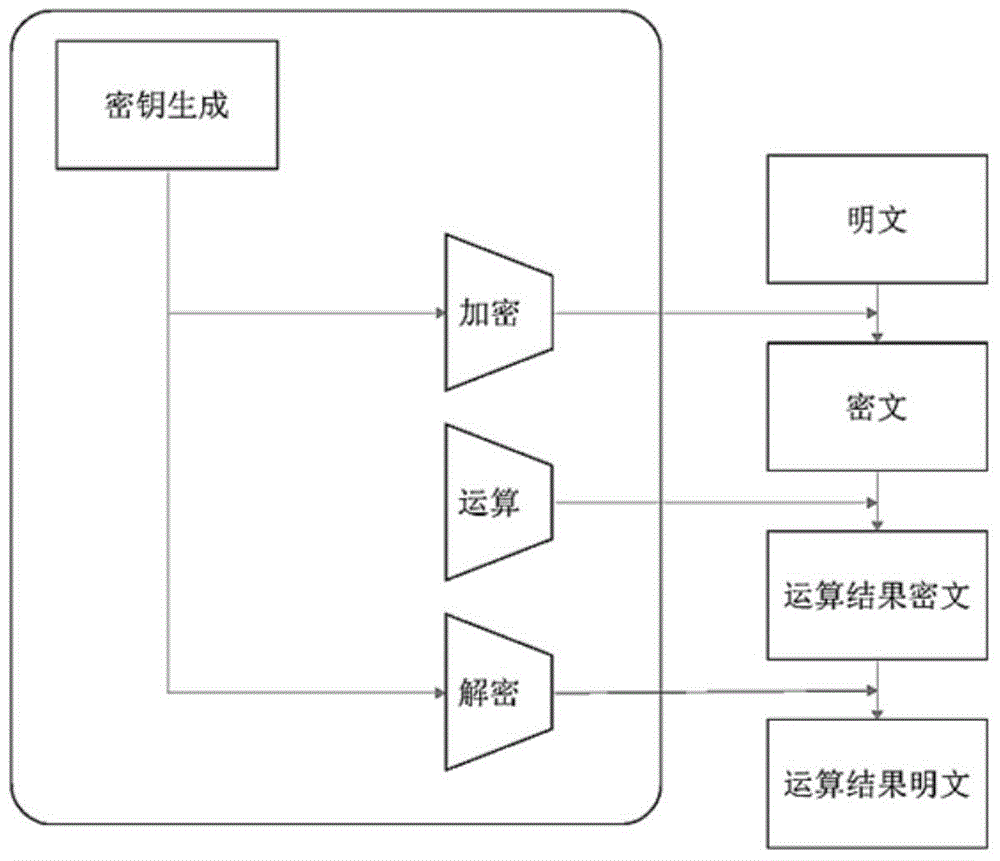

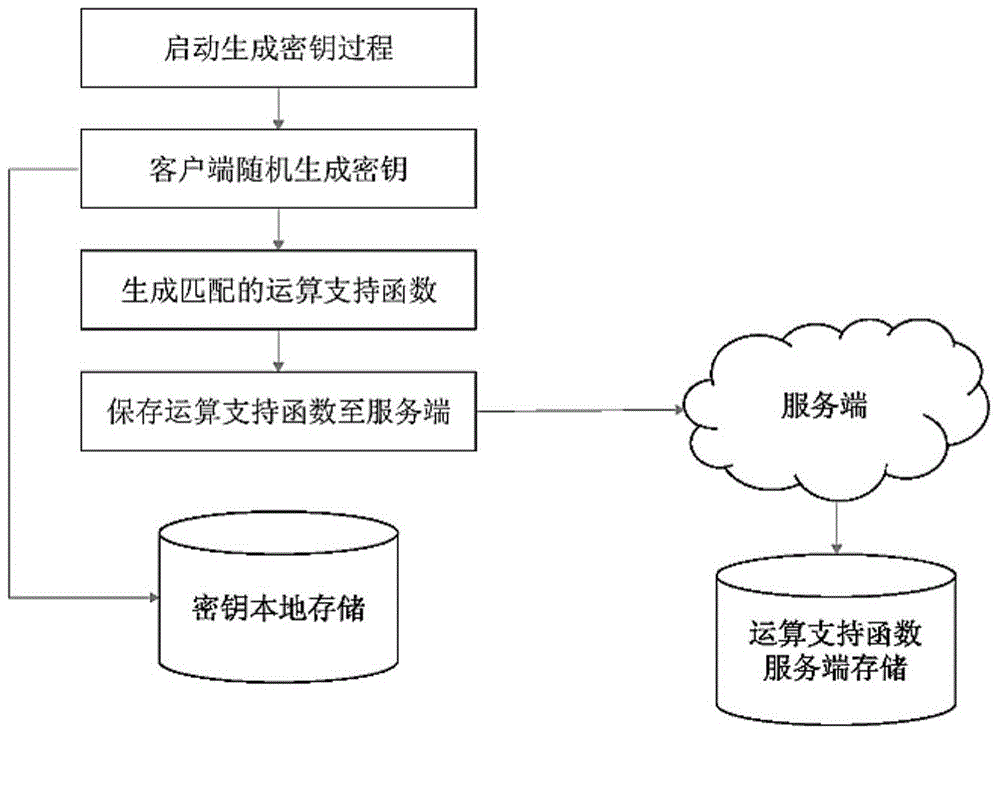

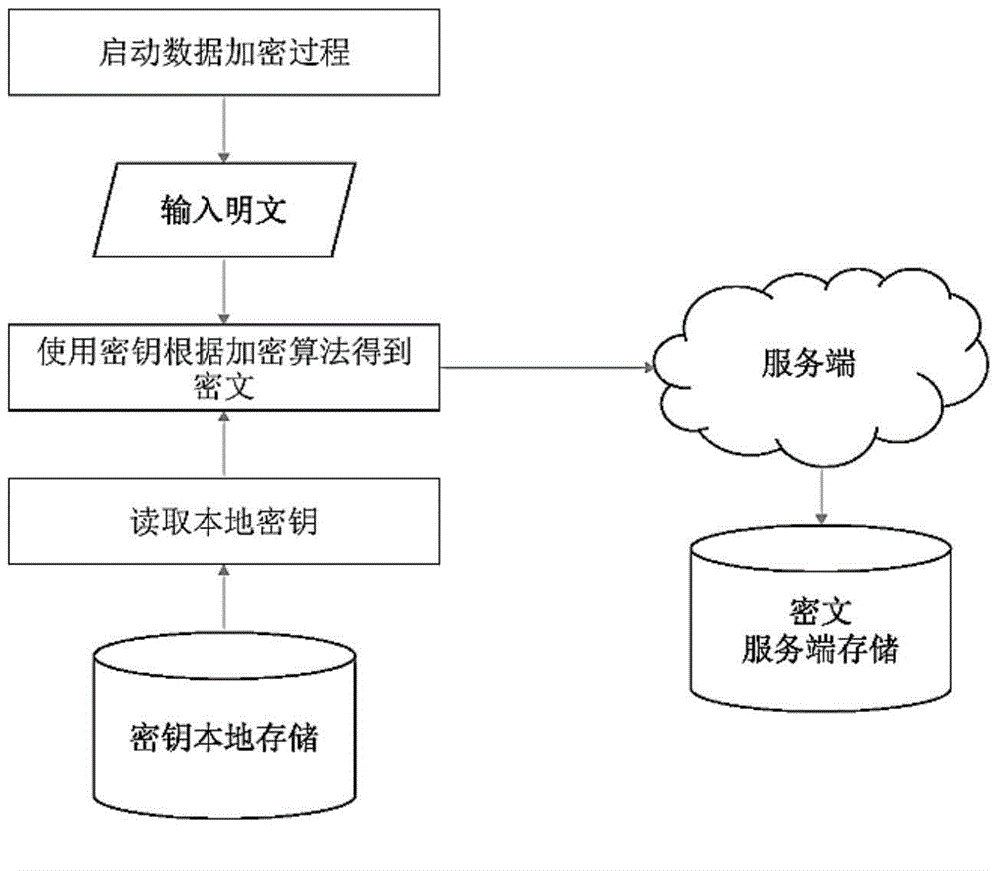

Coefficient mapping transformation-based polynomial complete homomorphic encryption method and system

ActiveCN106160995ASmall expansion speedEnough securityCoding/ciphering apparatusCommunication with homomorphic encryptionPlaintextCiphertext

The invention relates to a coefficient mapping transformation-based polynomial complete homomorphic encryption method and a system. According to the method, a plaintext is expressed as a polynomial of a specified mapping function, wherein the polynomial is composed of a set of random values, two sets of random coefficient factors and a random constant, and the expression of the specified mapping function and one set of random coefficient factors are adopted as a key; the other set of random coefficient factors, one set of random independent variables of the mapping function, and the random constant are adopted as a ciphertext which can be subjected to homomorphic operation; three kinds of different mapping is carried out on the key part of the function, and numerical value fitting is carried out, so that an operation support function family composed of three sub-functions is obtained; and after operation support function family-based ciphertext homomorphic operation is carried out at a different place, the method returns to a local place, and encryption is carried out through the key. With the coefficient mapping transformation-based polynomial complete homomorphic encryption method and the system of the invention adopted, true value of data is only visible to a data owner possessing the key, and the data present as a ciphertext at a data storage side, a data transmission pipeline and a data operation side which cannot guarantee the security of the data, and therefore, a secure data storage and operation environment can be ensured.

Owner:郑珂威

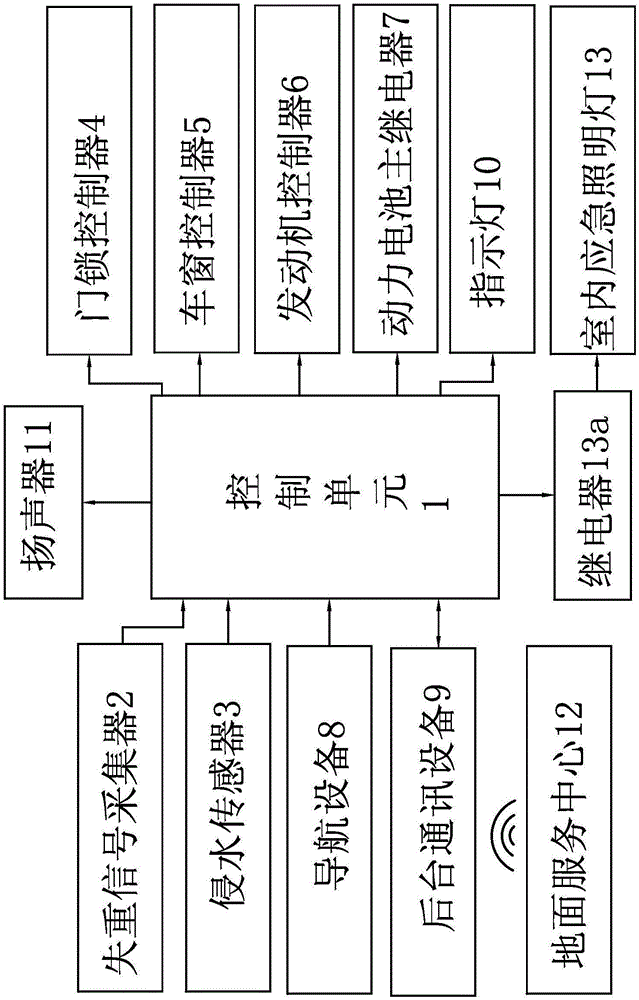

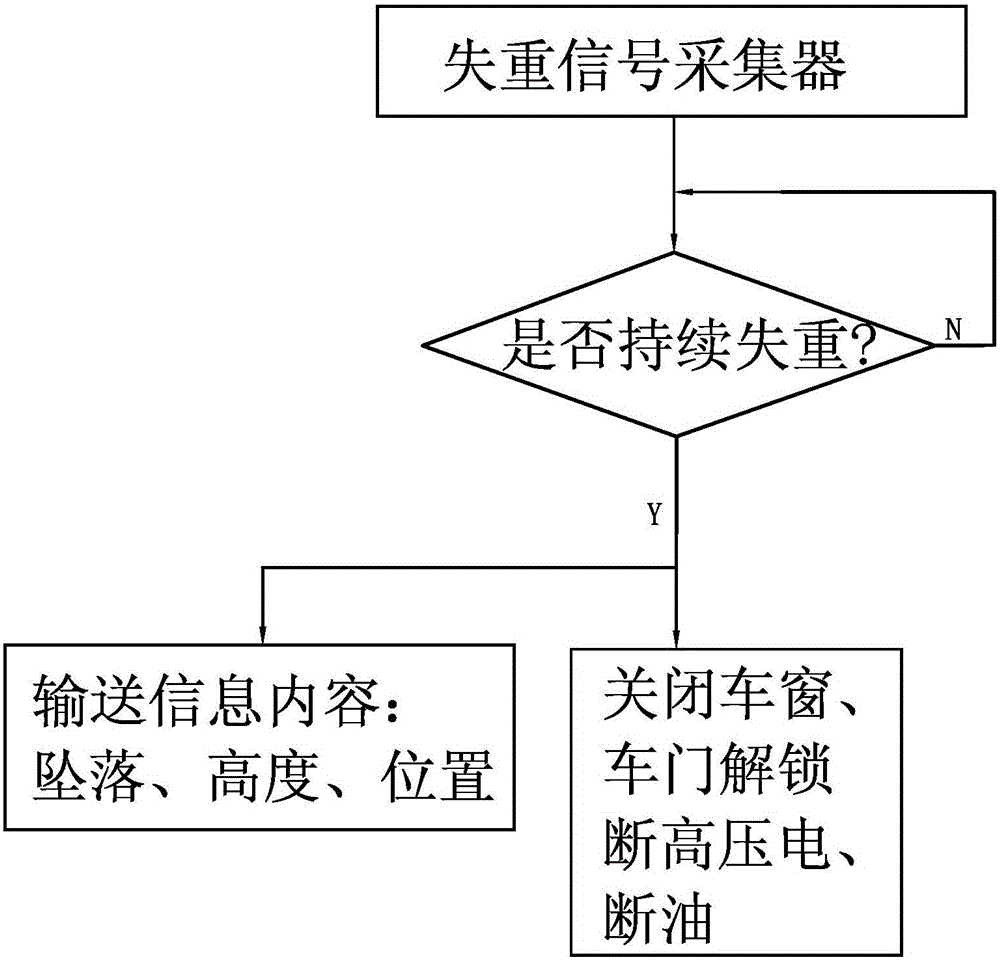

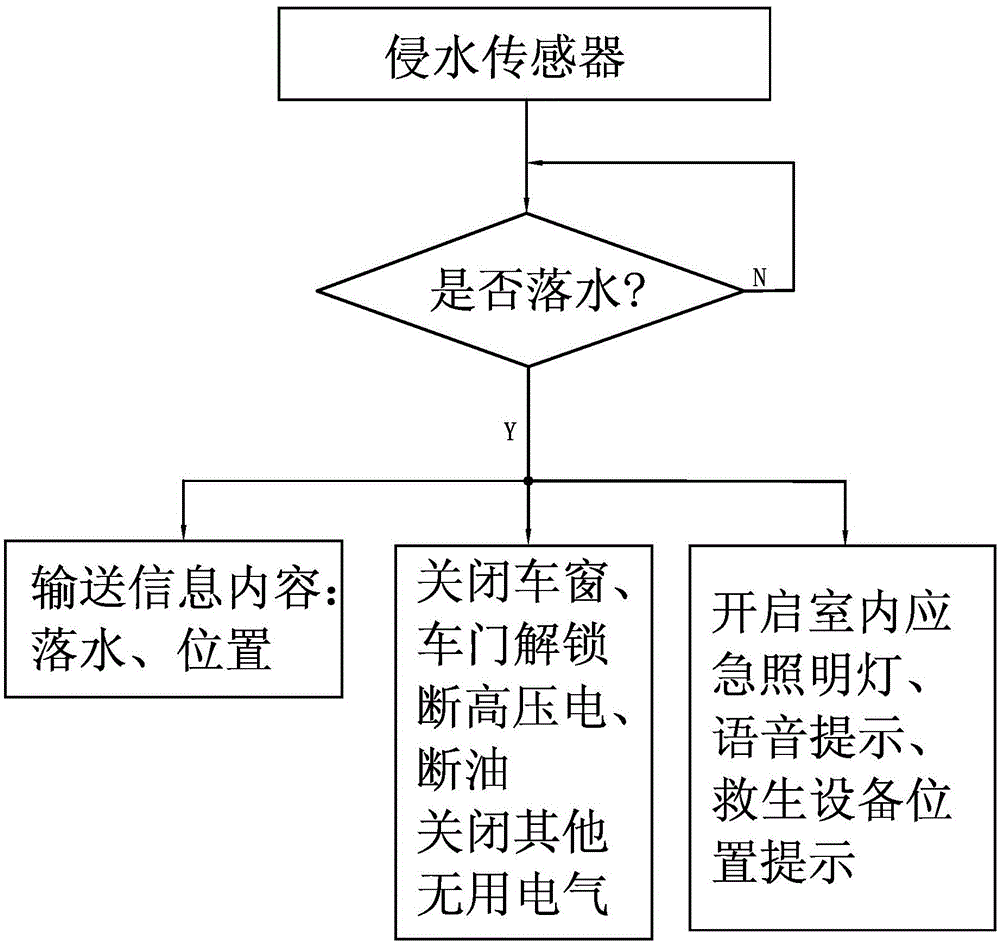

High-altitude falling and drowning safety guaranteeing system for automobile and control method thereof

ActiveCN105015470AIncrease chance of escapeAvoid situations such as throwing out the windowPedestrian/occupant safety arrangementSignalling/lighting devicesControl signalFall accident

The invention provides a high-altitude falling and drowning safety guaranteeing system for an automobile and a control method thereof, which belongs to the technical field of automobiles. A problem of the prior art that the safety is not high is solved. The high-altitude falling and drowning safety guaranteeing system for the automobile comprises a control unit, an immersion sensor, a weightlessness signal sensor, a door lock controller, an automobile window controller and an engine controller, wherein the immersion sensor and the weightlessness signal sensor are connected with an input end of the control unit; and the door lock controller, the automobile window controller and the engine controller are connected with an output end of the control unit. The high-altitude falling and drowning safety guaranteeing control method for the automobile comprises the following steps of exerting the control unit to receive signals transmitted by the weightlessness signal sensor and the immersion sensor and to analyze and judge the received signals; and exerting the control unit to send a control signal to control automobile window closing, automobile door unlocking and engine fuel cutoff when a high-altitude falling accident or a drowning accident is judged. The high-altitude falling and drowning safety guaranteeing system for the automobile and the control method thereof, provided by the invention, is advantaged in that safety measures such as automobile door unlocking, fuel cutoff and so on are automatically executed for passengers on the automobile to escape in case of high-altitude falling and drowning.

Owner:宁波吉润汽车部件有限公司 +2

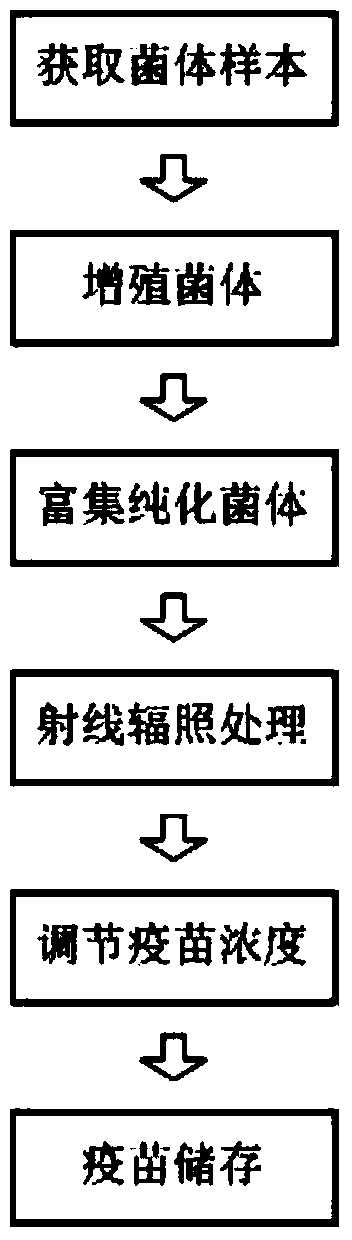

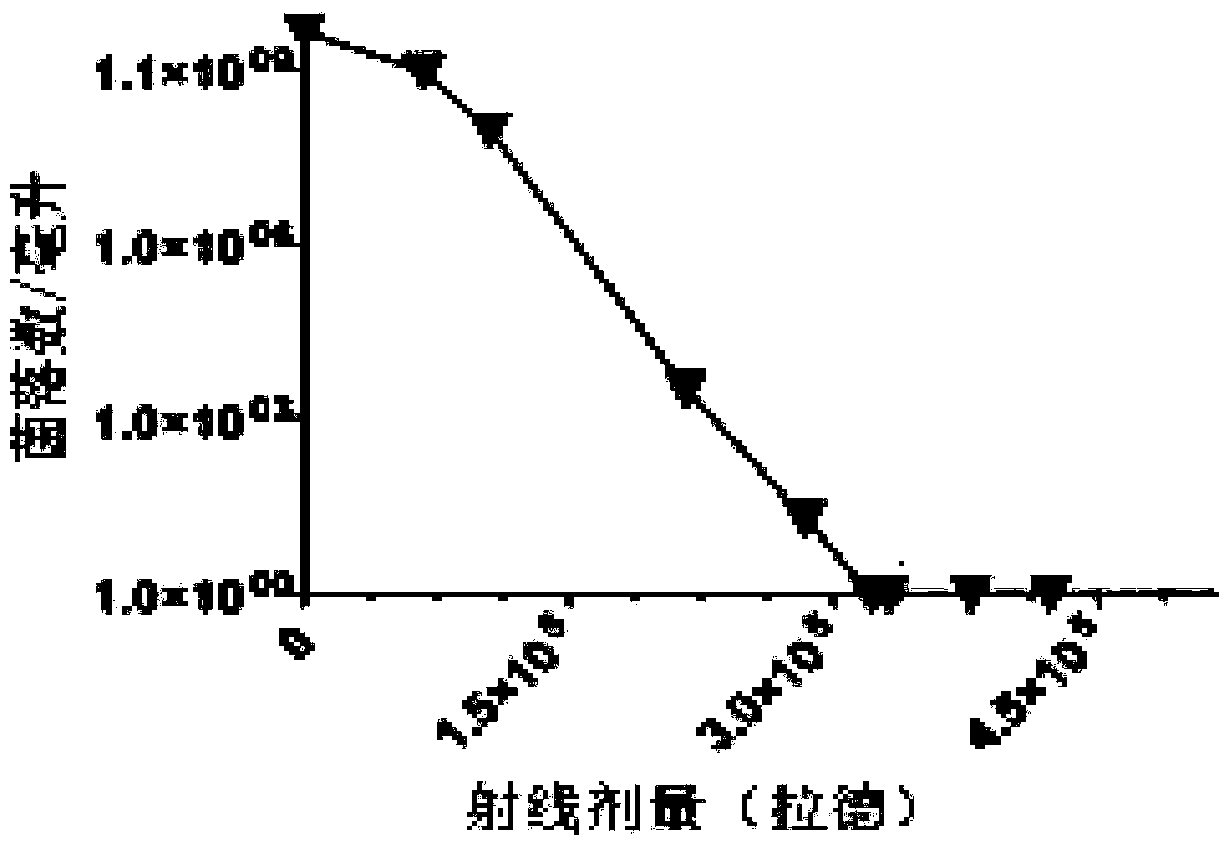

Pseudomonas aeruginosa vaccine and preparation method thereof

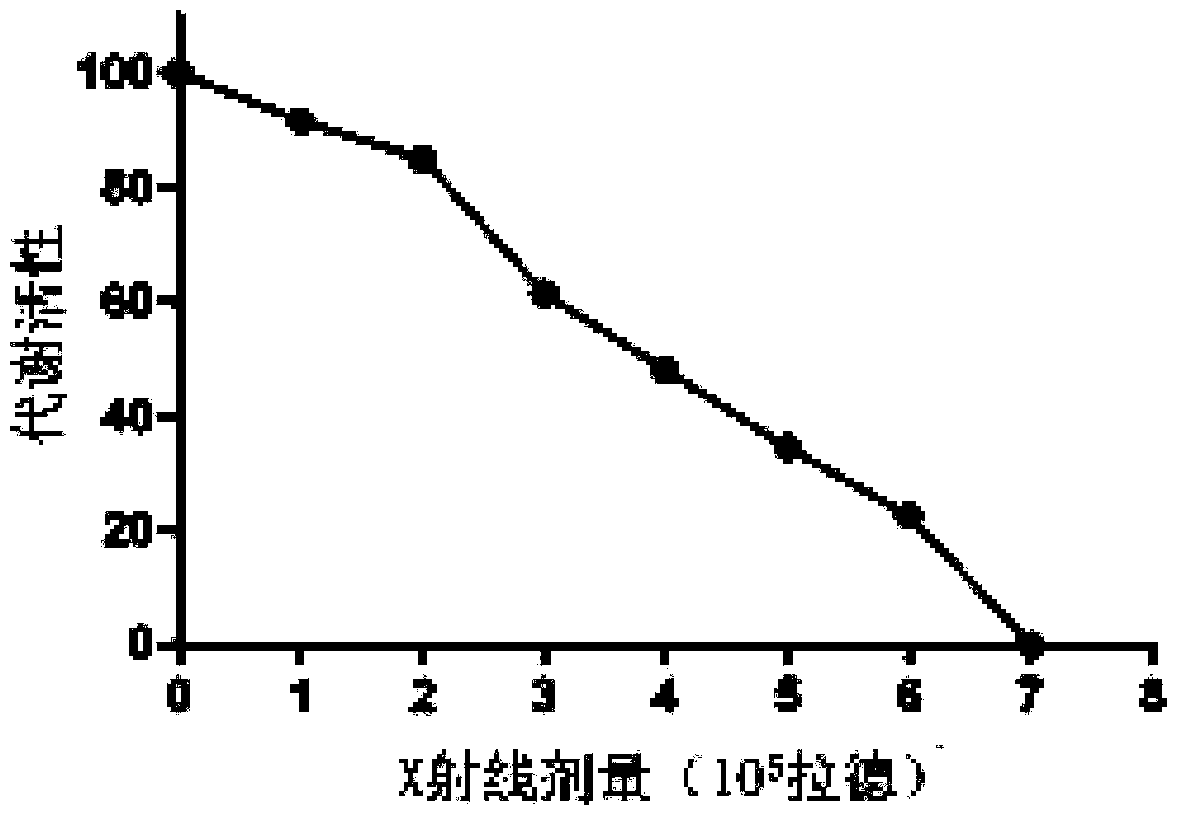

ActiveCN104189898ARetain metabolic activityPreserve immunogenicityAntibacterial agentsElectrical/wave energy microorganism treatmentBacteroidesDisease

The invention relates to the technical field of biology and specifically relates to a pseudomonas aeruginosa vaccine and a preparation method thereof. The pseudomonas aeruginosa vaccine is used for solving the technical problem that the existing pseudomonas aeruginosa vaccine at the development and clinical test stages are low in protective efficacy, high in toxicity to organisms and incapable of meeting the requirements of clinical immunology due to failure in curing infection. The technical scheme adopted to solve the technical problem is as follows: a preparation method of a novel vaccine is provided. The preparation method comprises the steps of firstly obtaining pseudomonas aeruginosa bacteria and then irradiating the bacteria by use of rays to obtain the pseudomonas aeruginosa vaccine. The pseudomonas aeruginosa vaccine is used for either preventing diseases or treating diseases, and has good application prospect.

Owner:SICHUAN UNIV

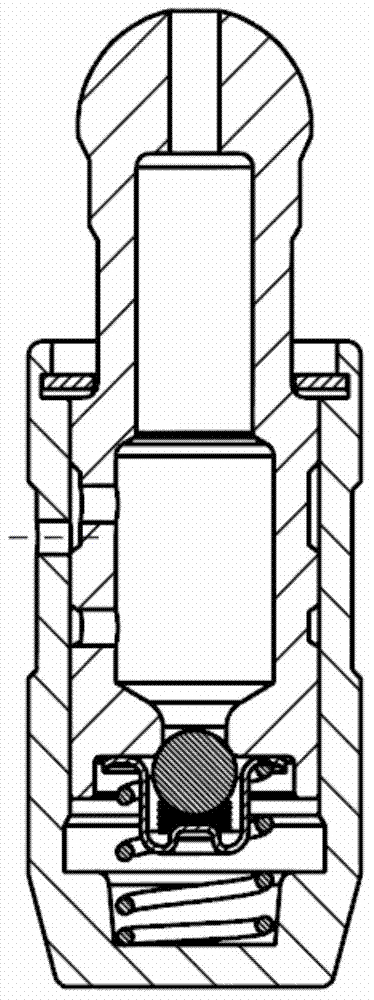

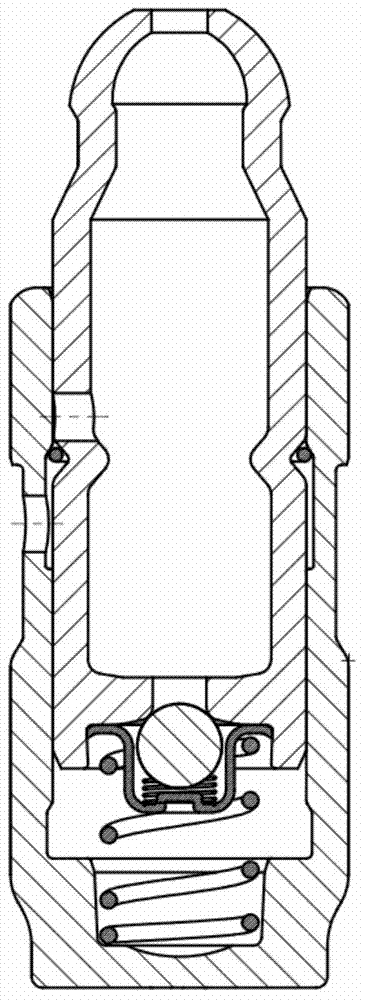

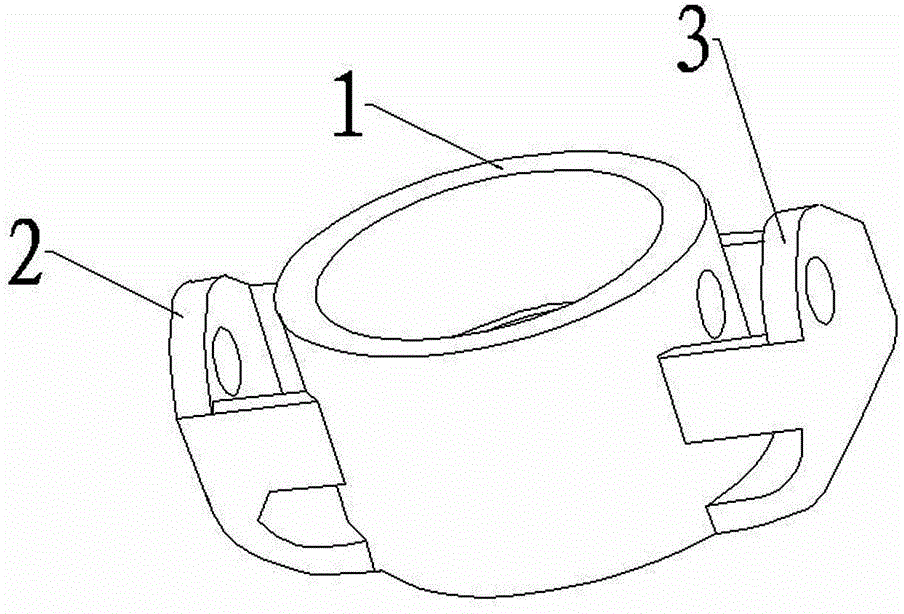

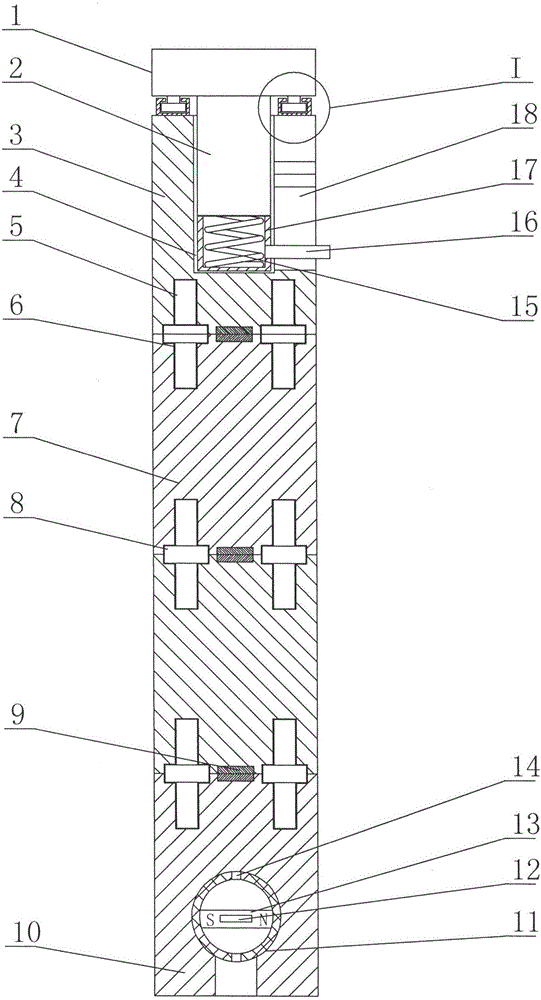

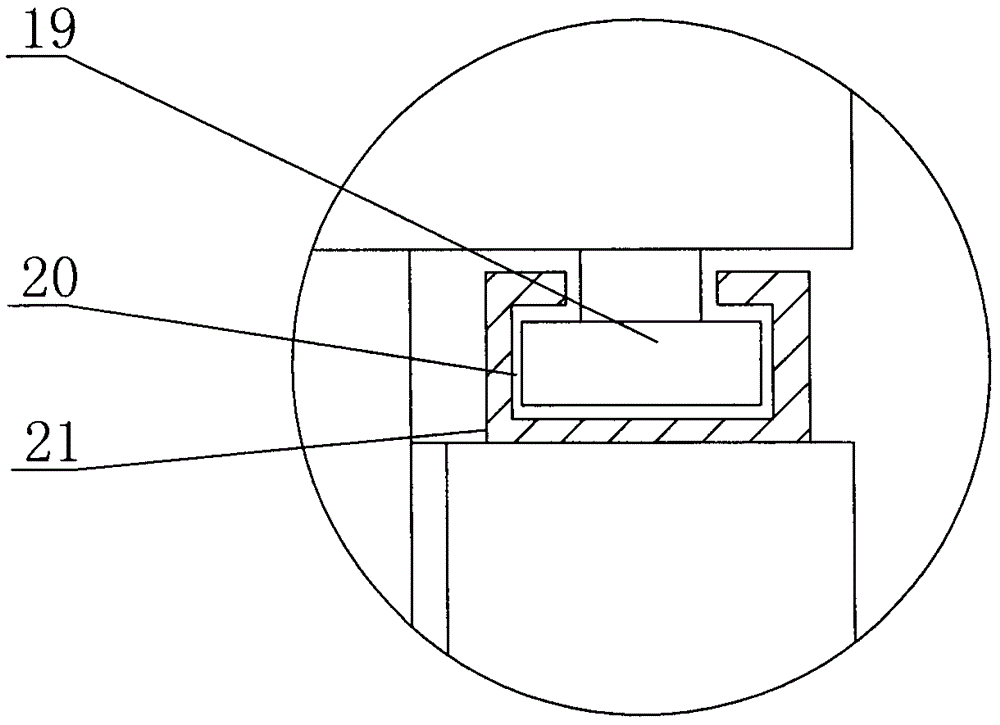

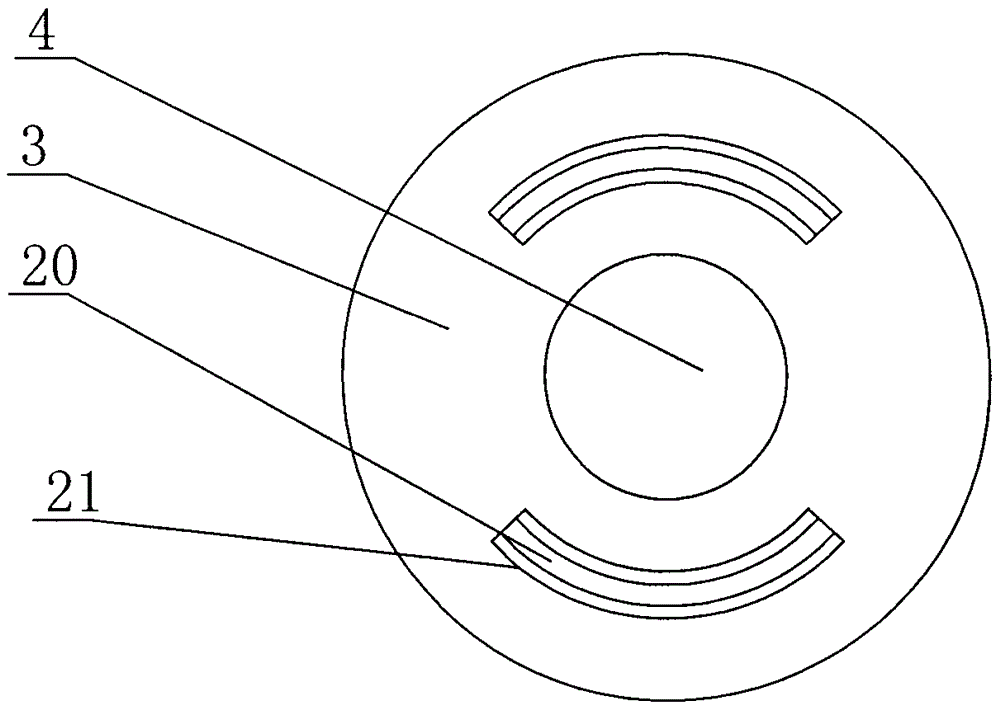

Columnar hydraulic tappet

ActiveCN103939162AThe overall structure is simple and reliableIncrease oil storagePump assembliesMachines/enginesCheck valveHydraulic tappet

The invention relates to a columnar hydraulic tappet which comprises a shell. A plunger is correspondingly installed in the shell. A high-pressure cavity for a hydraulic medium extends between a sealing base of the plunger and the lower side of the shell and can be sealed through a check valve which is opened towards the high-pressure cavity. An outer ring groove for hydraulic medium circulation is formed in the outer diameter of the shell, an inner ring groove for hydraulic medium circulation is formed in the radial inner side of the shell, and one or more shell oil holes are formed between the inner ring groove and the outer ring groove. The plunger is composed of a sealed hemispherical head portion, a rod portion and a body portion. The columnar hydraulic tappet is characterized in that an inward-concave neck portion is arranged between the head portion of the plunger and the rod portion of the plunger, and the wall thickness of the neck portion is 105% to 120% the wall thickness of the rest of the plunger. The columnar hydraulic tappet is simple and firm in structure, the design that the wall thickness of the low-strengthen area of the single-body thin-walled hollow plunger is increased is adopted, and therefore both the requirement for increasing the oil storage amount in the plunger and the requirement for improving fatigue strengthen are considered.

Owner:HANGZHOU XZB TECH

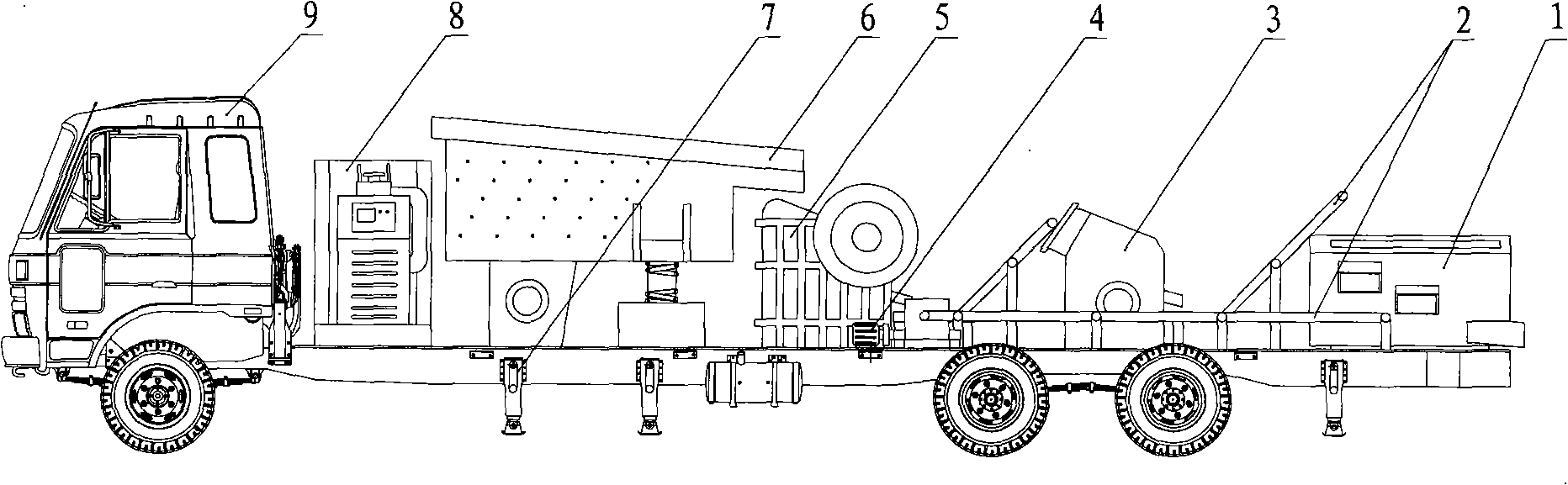

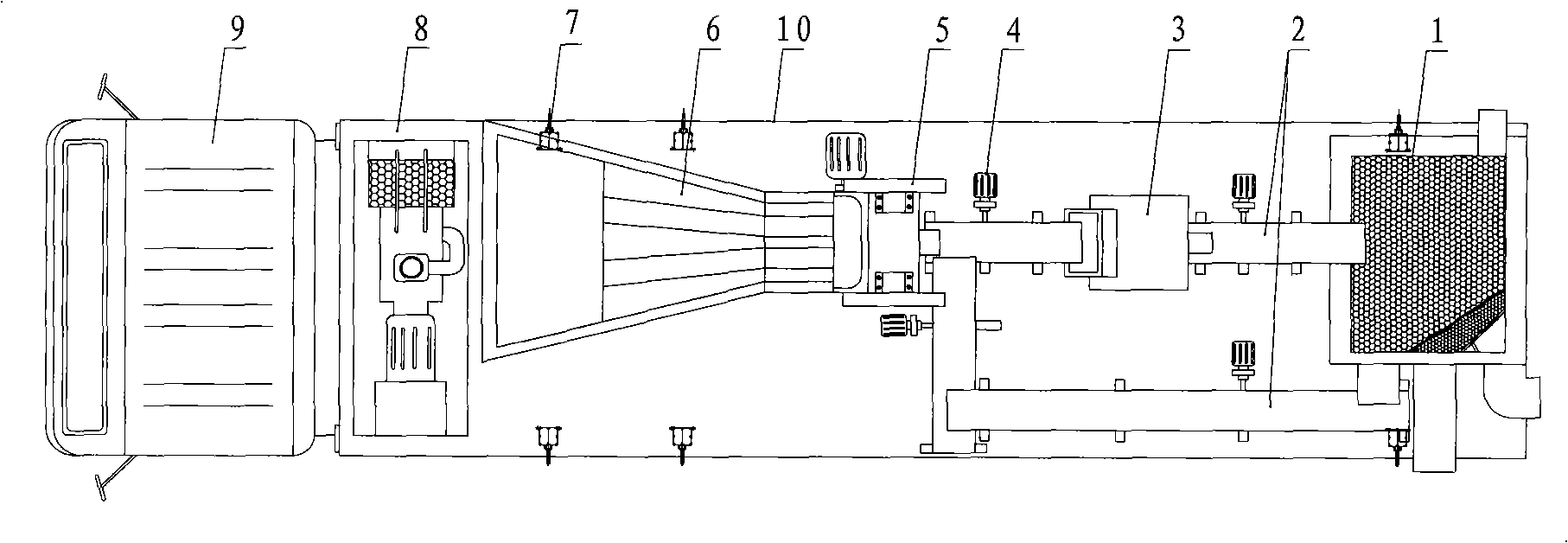

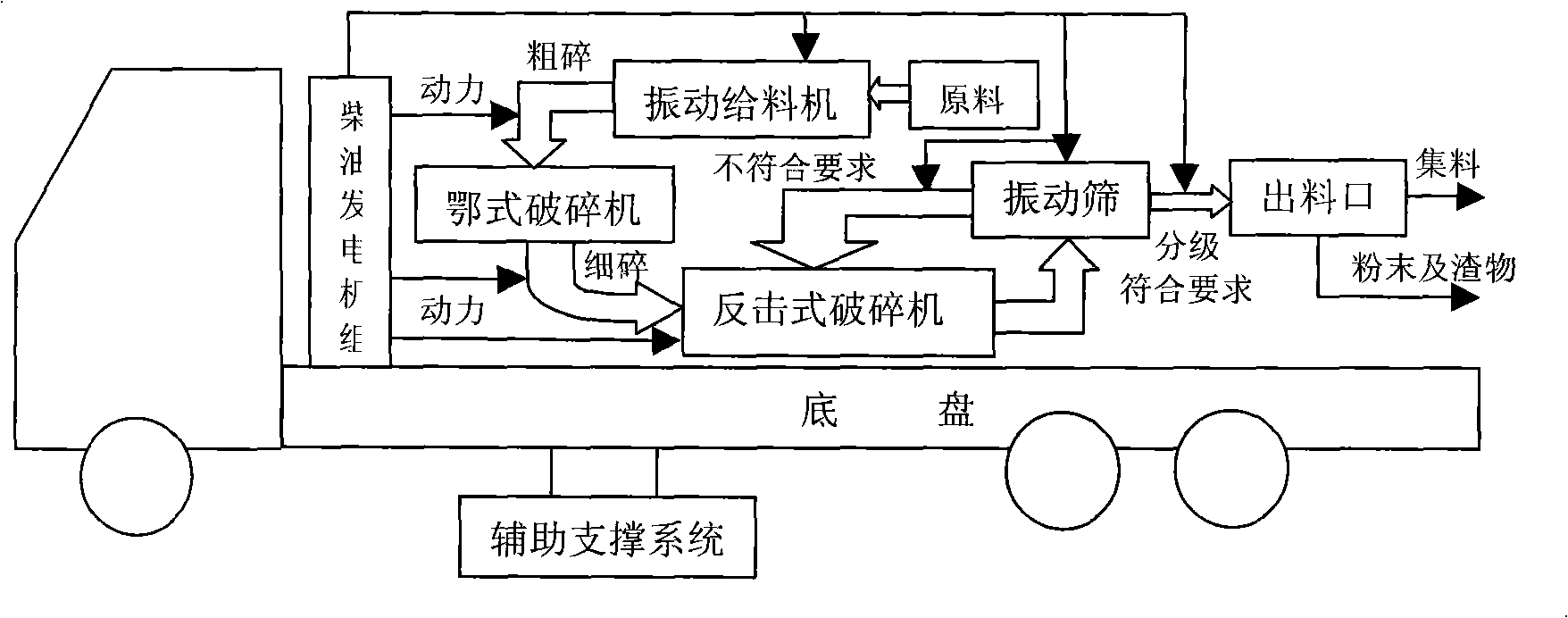

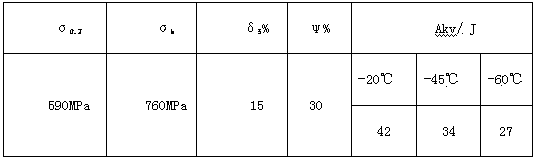

Concrete block regeneration aggregate processing vehicle

The invention provides a concrete block regeneration aggregating processing car, belonging to a special purpose engineering car. The concrete block regeneration aggregating processing car comprises a car body and has a structure that a device used in the concrete mixing waste material processing production is integrally arranged on a frame (10) of a chassis according to the production line in the stone fabrication plant, the power of the processing system is provided by a diesel fuel electric generating set (8); and the production flow line comprises loading, vibrating feeding, jaw smashing, counterattack smashing, vibrating sieving and discharging. The concrete block regeneration aggregating processing car can process the concrete road surface mixing waste material on the spot in the process of paving or overhauling the concrete road and is applied to the building of the road, has good flexibility, high production efficiency, high degree of production automation and low operation cost, can adapt to various working environments and meet various requirements, saves energy resources and protects the environment.

Owner:WUHAN UNIV OF TECH

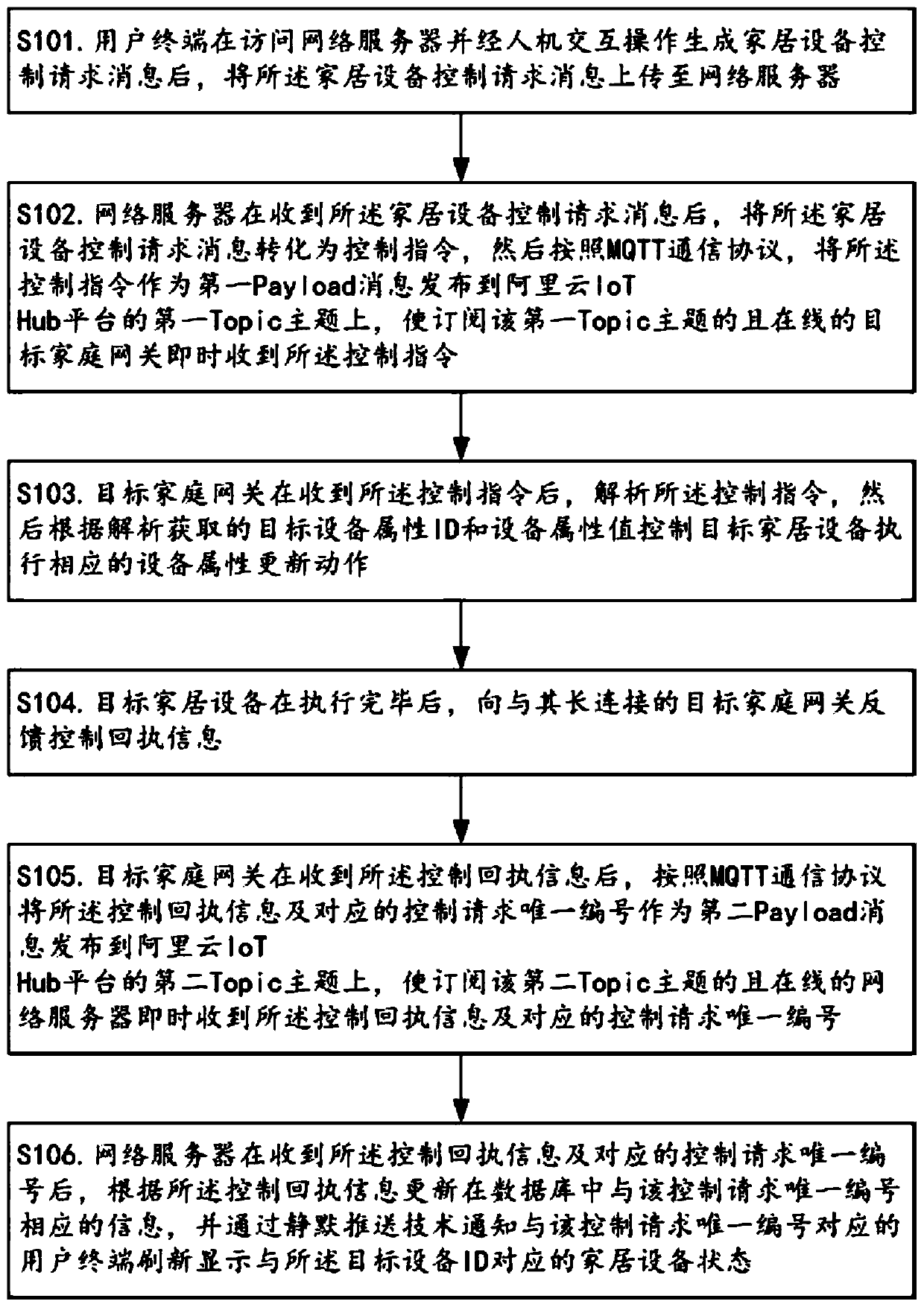

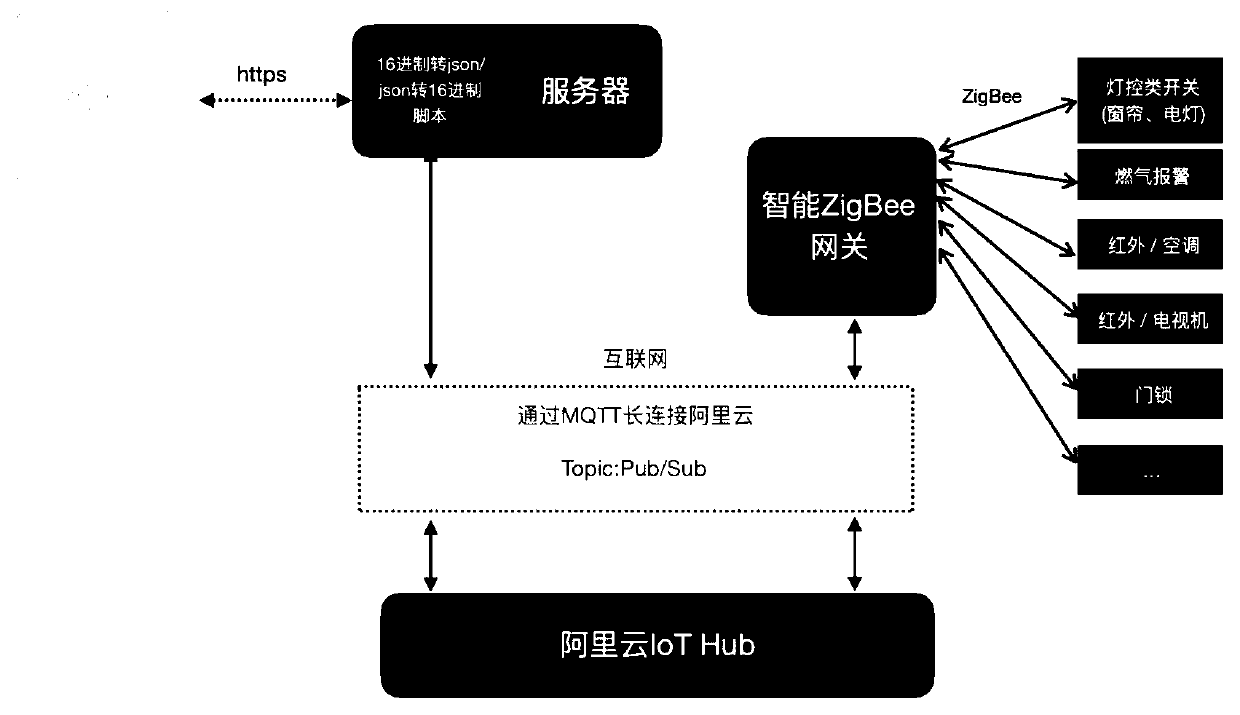

Smart home Internet of Things communication method based on AliCloud IoT Hub platform

ActiveCN110912789AMeet timeliness needsTimeliness demand guaranteeIndividual entry/exit registersSecurity arrangementTelecommunicationsInformation transmission

The invention relates to the technical field of smart home and discloses a smart home Internet of Things communication method based on an AliCloud IoT Hub platform. On one hand, subscription message transmission between a network server and a home gateway is realized on an AliCloud IoT Hub platform by adopting an MQTT communication protocol. The timeliness of information transmission can be guaranteed by using the communication characteristics of the MQTT communication protocol, so that after a user terminal sends out the control request, target household equipment can execute and respond mostquickly, the receipt receiving time is shortened to the greatest extent, the use state of the household equipment can be updated quickly, and the timeliness requirement of a user is met; and on the other hand, the home gateway only needs to subscribe to one publish theme and one subscribe theme to complete the operation of a plurality of devices in the room, so that the purposes of economy, practicability and easiness in popularization can be achieved. In addition, the invention has the characteristics of gateway activation automation, convenience in equipment addition, easiness in multi-house management and the like, can provide a simple operation interface, and is convenient to operate.

Owner:无锡青起长升智能科技有限公司

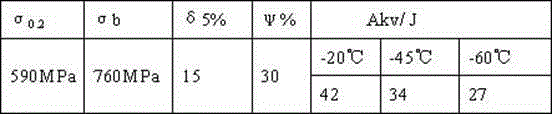

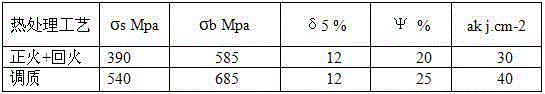

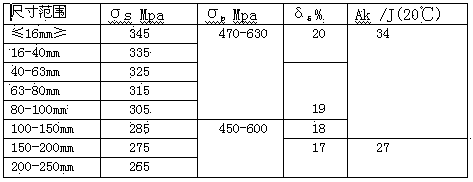

Manufacture technique of tap shells for polar drill rigs

The invention discloses a manufacture technique of tap shells for polar drill rigs. The manufacture technique incudes: (1) for forging, performing forging via upsetting, punching, broaching and forming to guarantee a forging fiber flow line under the conditions that heating temperature is 1270-1310 DEG C, initial forging temperature is 1100-1250 DEG C and terminal temperature is not lower than 850 DEG C, performing annealing after forging under the condition that the heating temperature is 880+ / -20 DEG C, and performing furnace cooling to enable tapping temperature not higher than 300 DEG C; (2) for heat treatment, normalizing at temperature of 880-900 DEG C prior to air cooling, quenching at temperature of 840-860 DEG C prior to oil cooling or cooling with a PAG quenching medium, tempering at temperature of 580+ / -40 DEG C prior to air cooling, performing subcritical quenching at temperature of 790+ / -10 DEG C prior to oil cooling or cooling with the PAG quenching medium, and tempering at temperature of 520-600 DEG C prior to air cooling; (3) for non-destructive inspection, finishing prior to machining a product according to size, and performing ultrasonic inspection and magnetic particle inspection, wherein the qualified level conforms to API Specification 8C standards. Compared with the prior art, the manufacture technique has the advantages that the tap shells manufactured with the technique have high strength to guarantee enough safety factor, adapt to polar regions (at the temperature of minus 60 DEG C) and meet the requirement on enough low temperature impact toughness so as to resist to the low-temperature environment of the polar regions.

Owner:RG PETRO MACHINERY GROUP

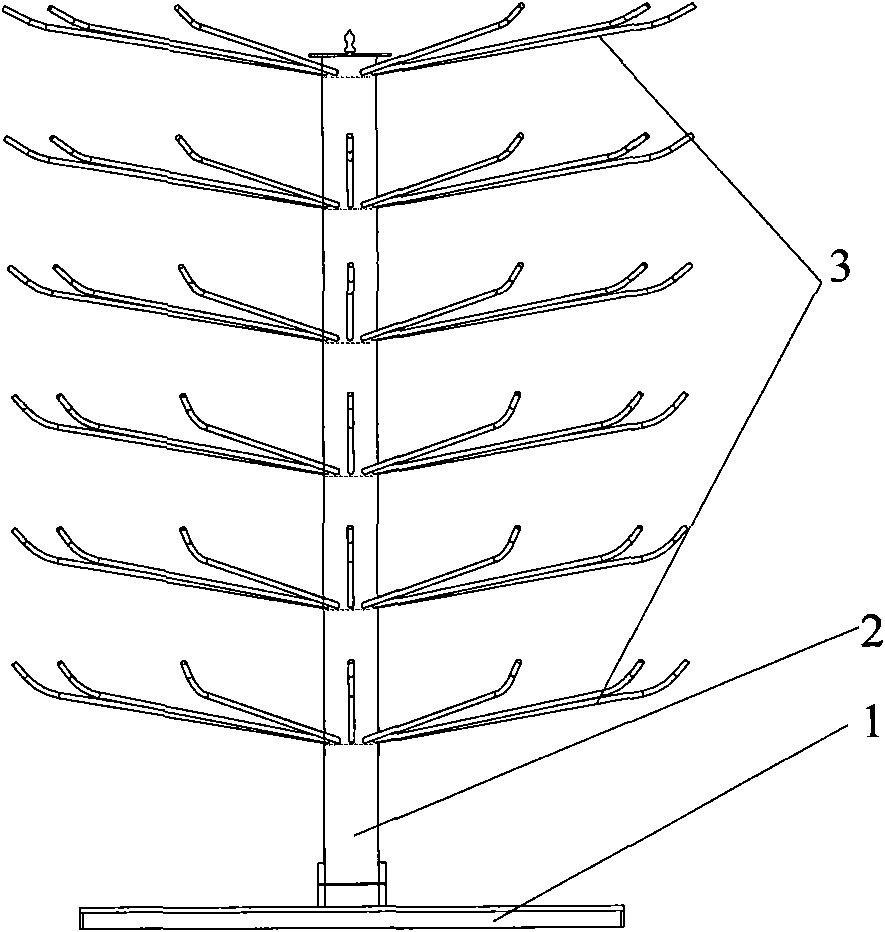

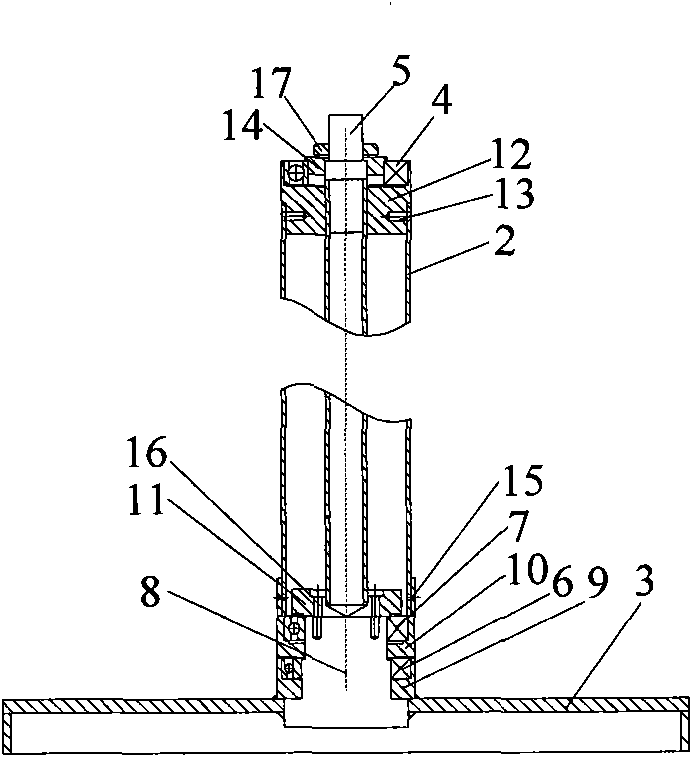

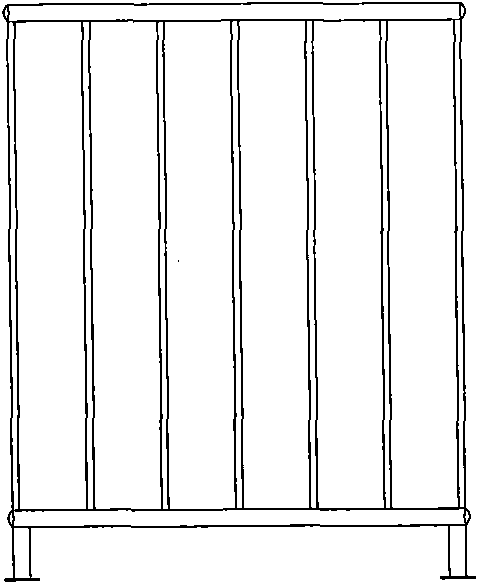

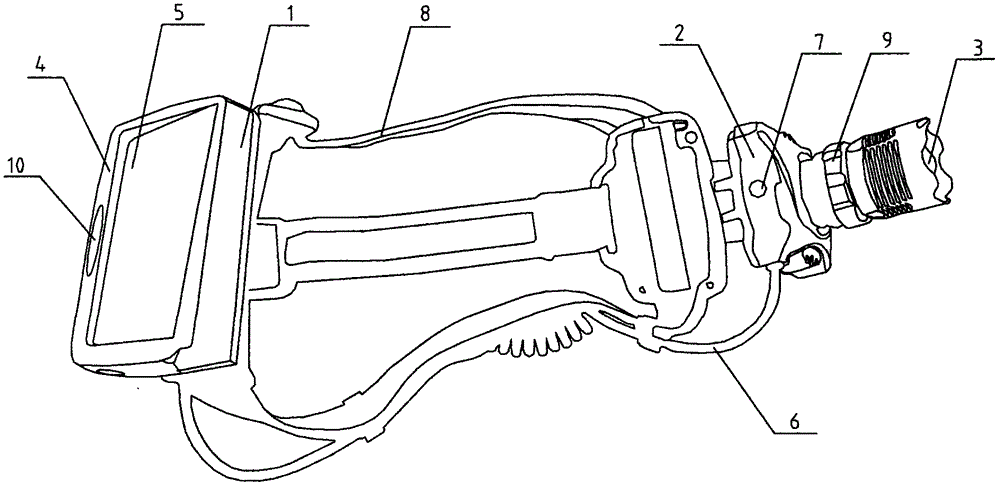

Assistive device tool for placing working tools

The invention discloses an assistive device for placing working tools, comprising a base and a column spinner, wherein the column spinner is provided with a plurality of hanging arms for hanging the working tools. The assistive device is characterized in that the base is fixedly provided with a mandrel movably sheathed in the column spinner, and the column spinner can rotate relative to the base. The six layer of hanging arms for hanging the working tools are formed, wherein drilled holes on each layer are welded with twelve hanging arms. Because of the adoption of the design of the annular tree structure, more working tools are contained in a limited space. A movable swiveling mechanism is adopted, and employees easily classify the working tools and conveniently fetch the working tools when various types of vehicle are produced in a paint production line, thereby avoiding false and neglected assembly for employees. In addition, a safety guard rail is adopted, so that no potential safety hazard exists in the use process and enough safety is ensured. The assistive device is made of common materials and has the advantages of simple manufacture process, good durability and lower cost.

Owner:CHERY AUTOMOBILE CO LTD

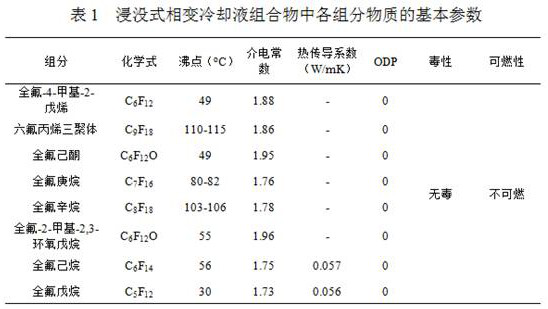

Immersed liquid phase change cooling medium and application thereof in cooling system of electronic equipment

InactiveCN111726971AImprove data transfer performanceHigh electrical insulationCooling/ventilation/heating modificationsEpoxyMeth-

The invention discloses an immersed liquid phase change cooling medium and application thereof in a cooling system of electronic equipment, wherein the cooling medium is a mixture formed by mixing one, two or three of perfluoro-4-methyl-2-pentene, a hexafluoropropylene tripolymer, perfluorohexanone, perfluoroheptane, perfluorooctane, perfluoro-2-methyl-2, 3-epoxy pentane, perfluorohexane and perfluoropentane. The immersed phase change cooling medium provided by the invention has the characteristics of high electrical insulation property, low viscosity, relatively low boiling point, high gasification latent heat, good compatibility and stability, incombustibility, combustion inhibition, low global warming potential (GWP), zero ozone depletion potential (ODP) and the like.

Owner:ZHEJIANG UNIV OF TECH

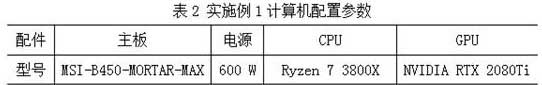

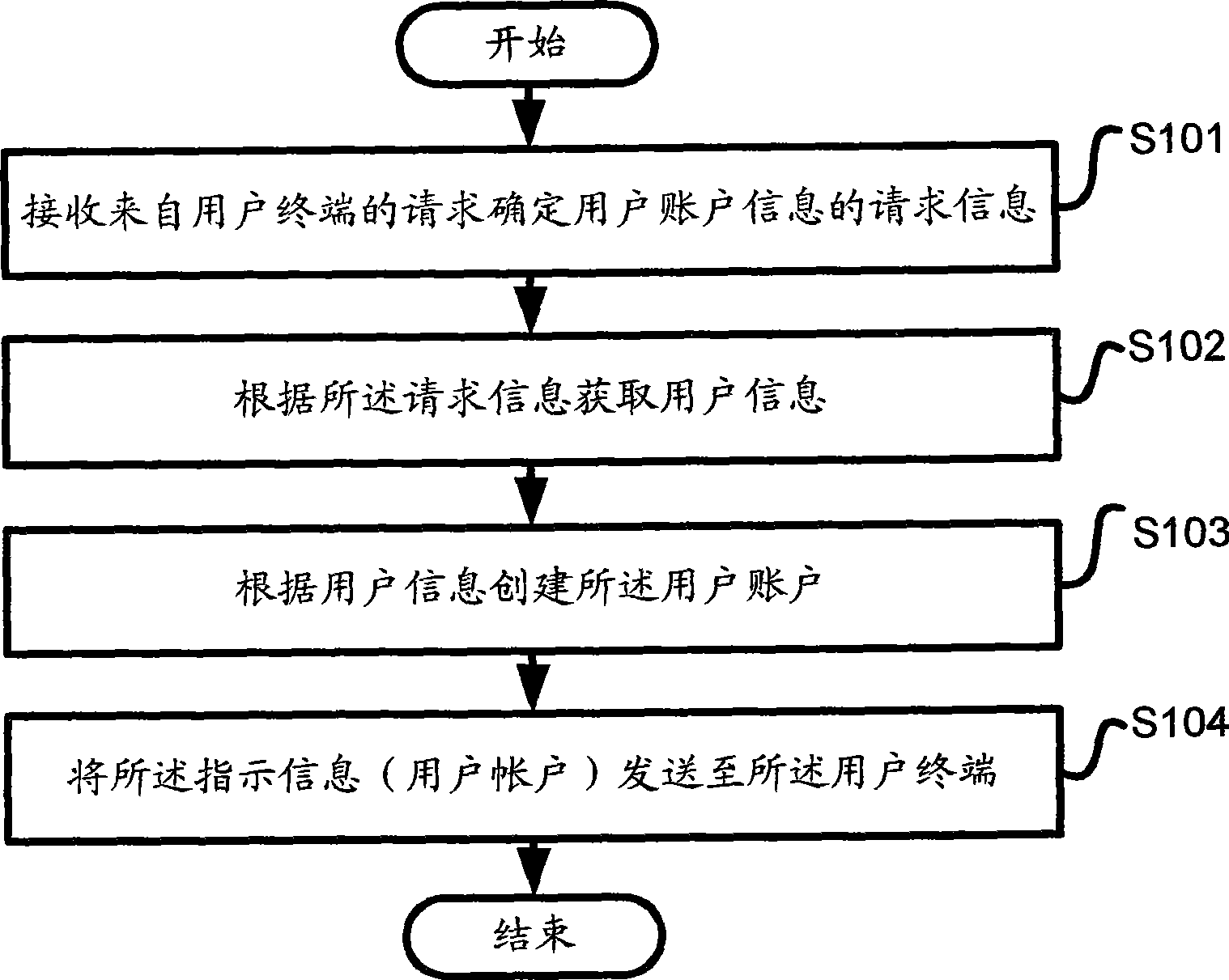

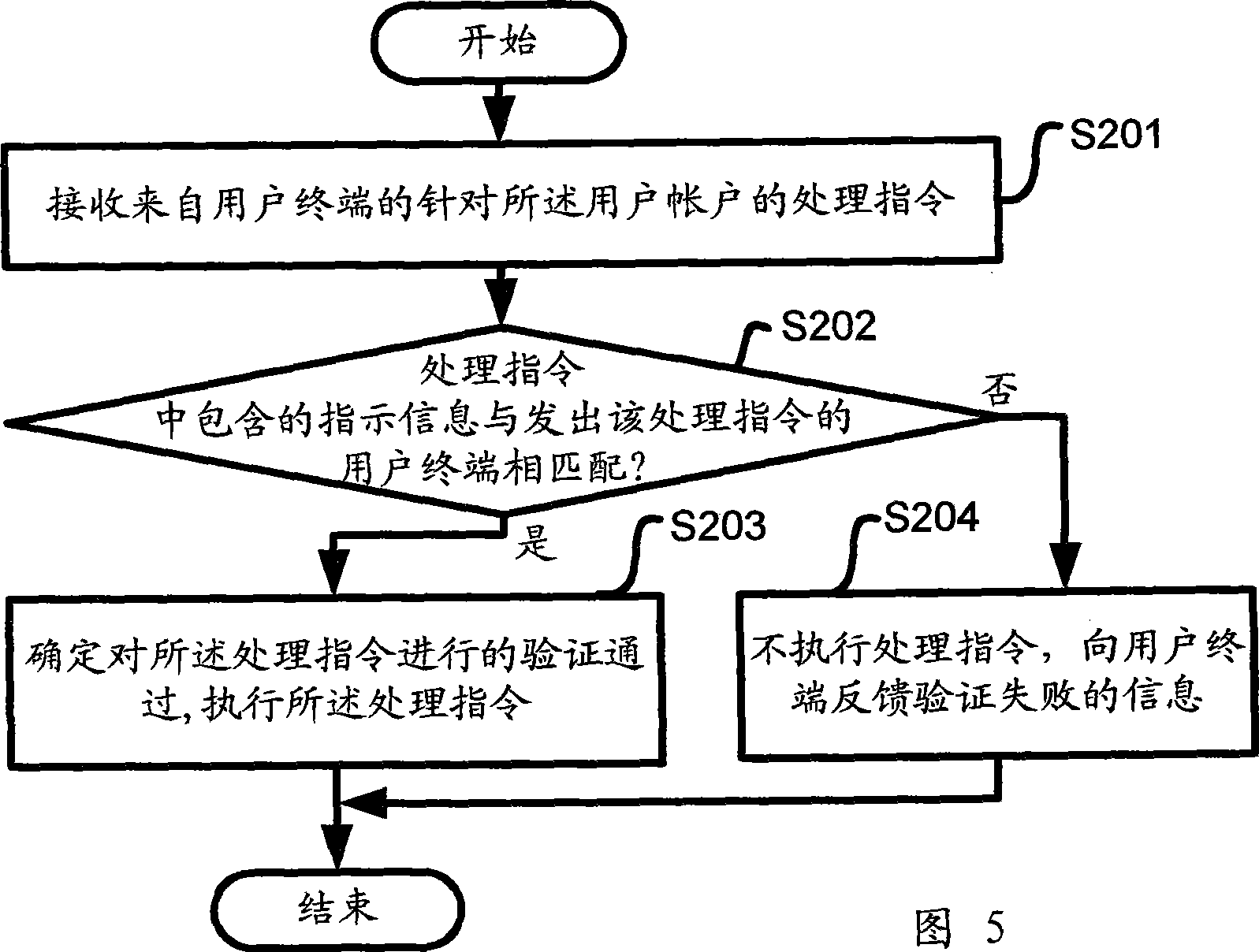

Control system for establishing and using user account by user terminal and method thereof

InactiveCN101447037AFlexible usageEnough securityPayment architectureResourcesControl systemComputer terminal

The invention provides a control method for confirming user account information by a user terminal, wherein, the method comprises the steps as follows: a. user account indication information is confirmed according to user information; and b. the indication information is sent to the user terminal. The indication information can be identification information associated with the user account, and the step a. comprises the step of confirming the identification information according to the user information and also comprises the step of setting the associated relation of the identification information and the user account. The invention also provides a control system for confirming the user account information by the user terminal, an auxiliary control method for disposing the user account by the user terminal, an auxiliary control system for using the user account by the user terminal and a control apparatus used for confirming the user account information in an assisting way and / or carrying out auxiliary disposal towards the user account in the user terminal. The invention can confirm the user account and dispose the user account in an assisting way by the user terminal, and has flexible form and enough safety.

Owner:陈静

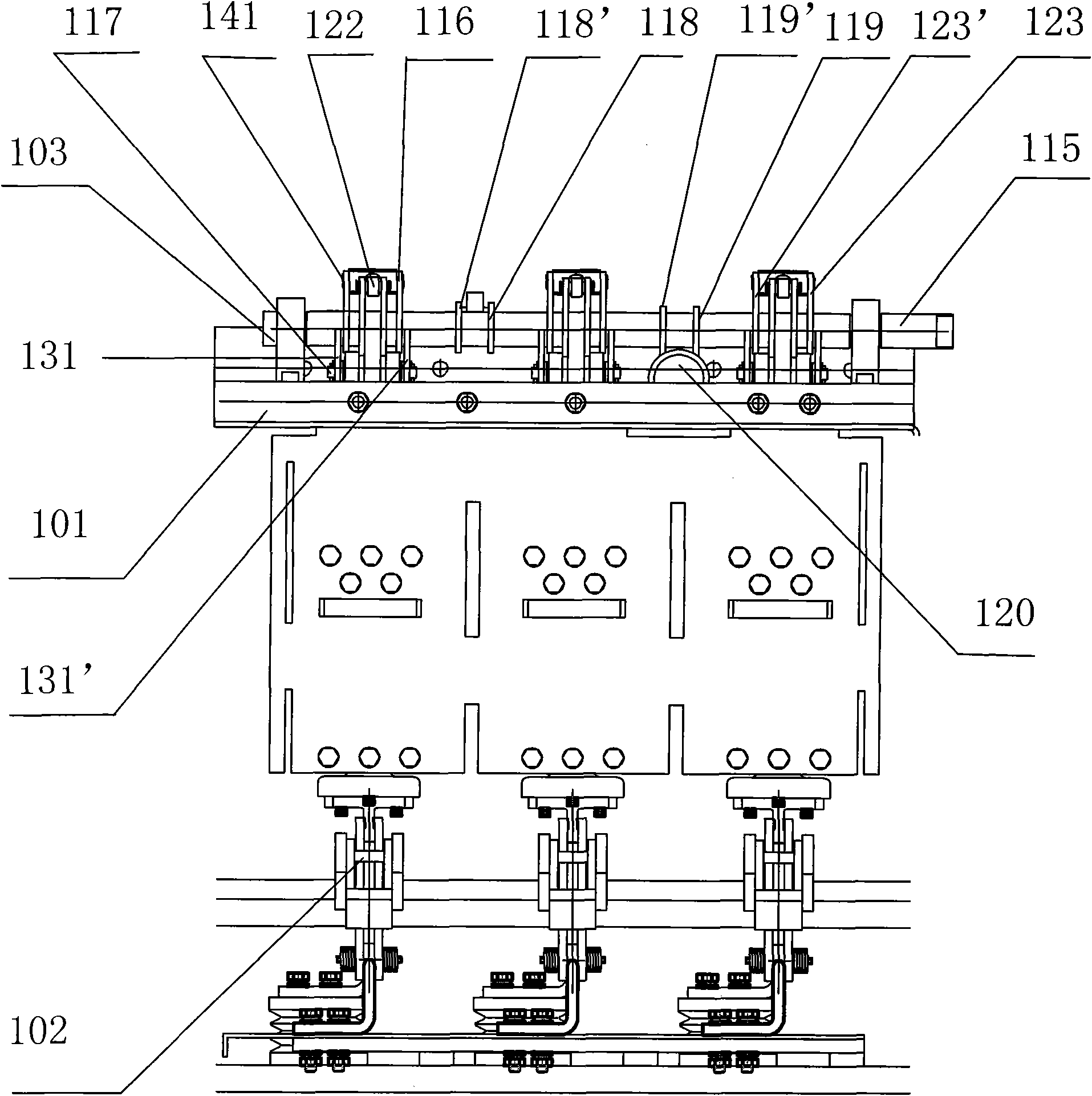

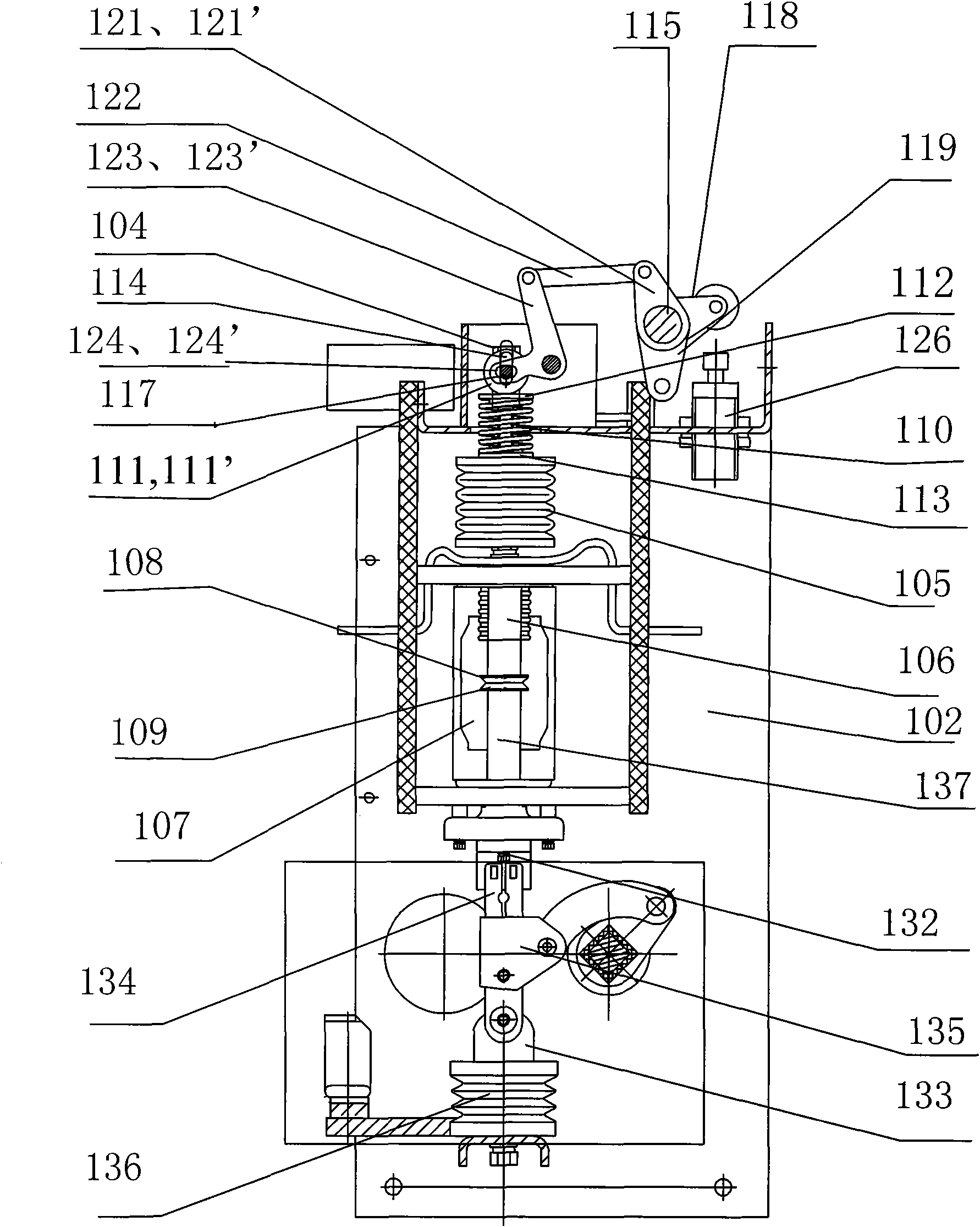

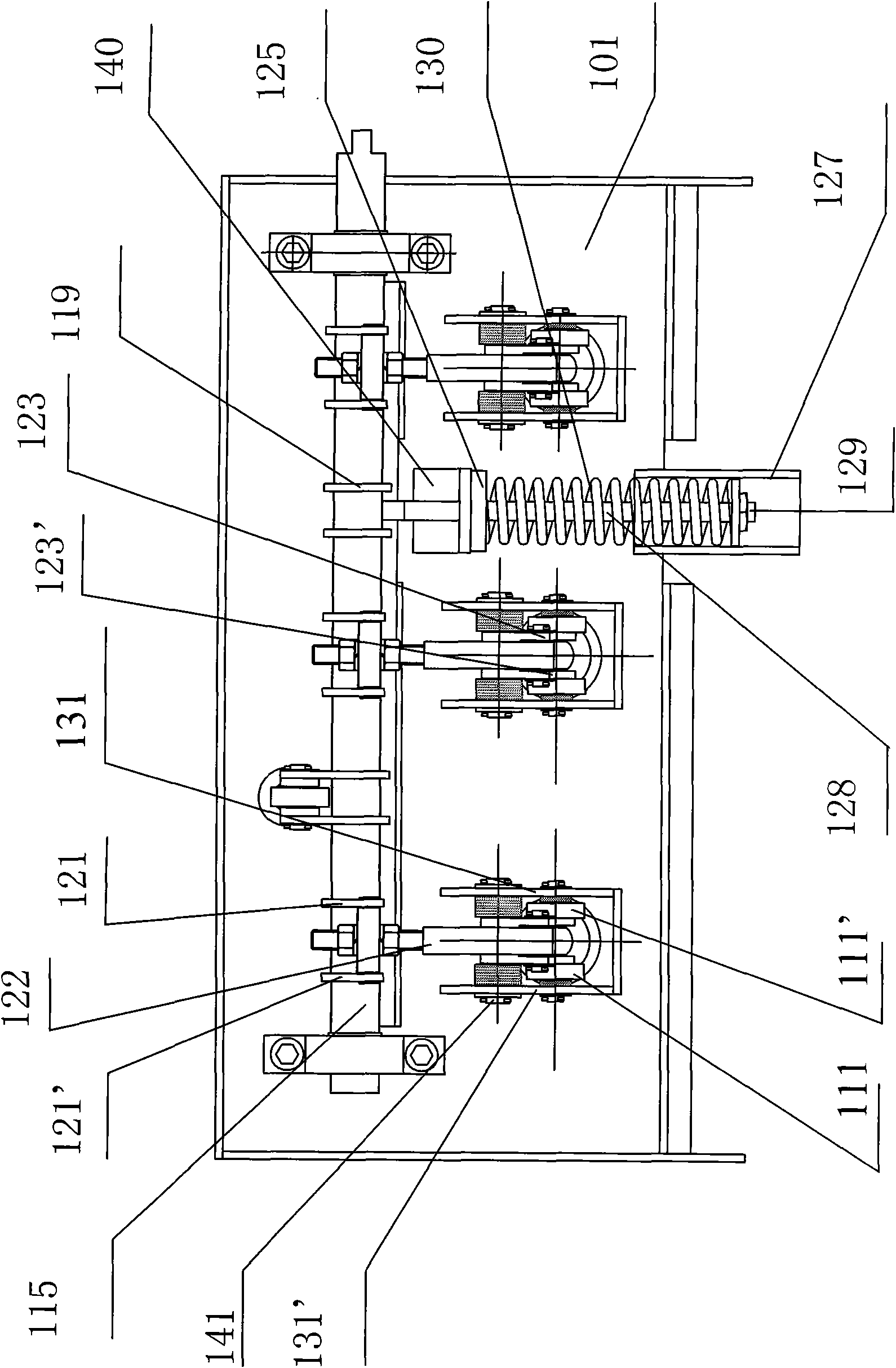

Electric switch provided with separate arc-extinguishing device

ActiveCN101645368ASimple structureReduce volumeHigh-tension/heavy-dress switchesAir-break switchesElectricityDrive shaft

The invention discloses an electric switch provided with a separate arc-extinguishing device. The technical problem to be solved by the invention is to provide an electric switch provided with a separate arc-extinguishing device, having the advantages of simple structure, small size and stable performance. The electric switch provided with the separate arc-extinguishing device comprises a base, acircuit breaker and a connecting rod assembling mechanism. By arranging the unique connecting rod assembling mechanism, the rotating force applied on a transmission shaft can be converted into the vertical force on a pull rod. Therefore, the electric switch of the invention has the characteristics of simple structure, small size and high connection reliability of each part.

Owner:BEIJING SOJO ELECTRIC

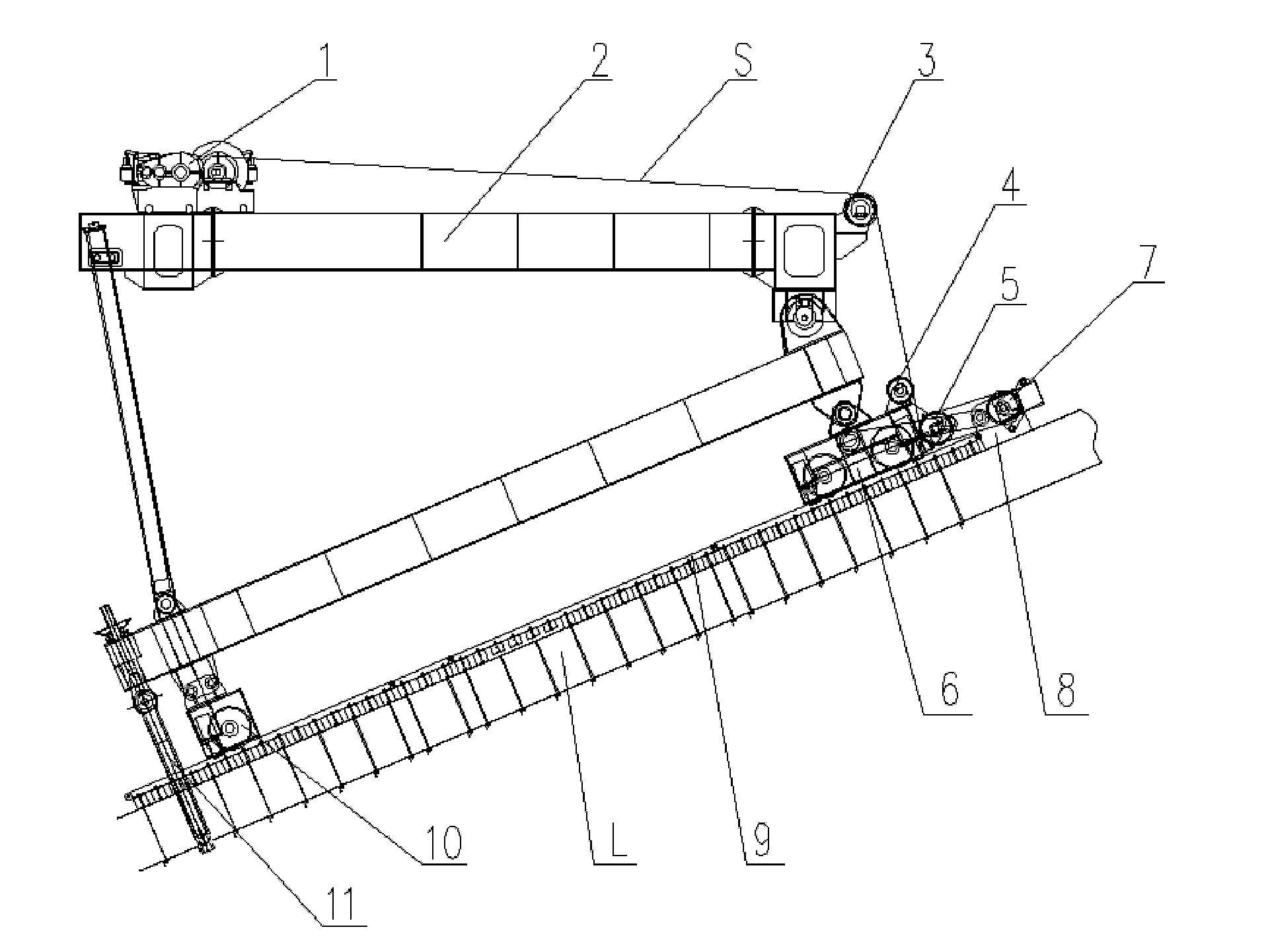

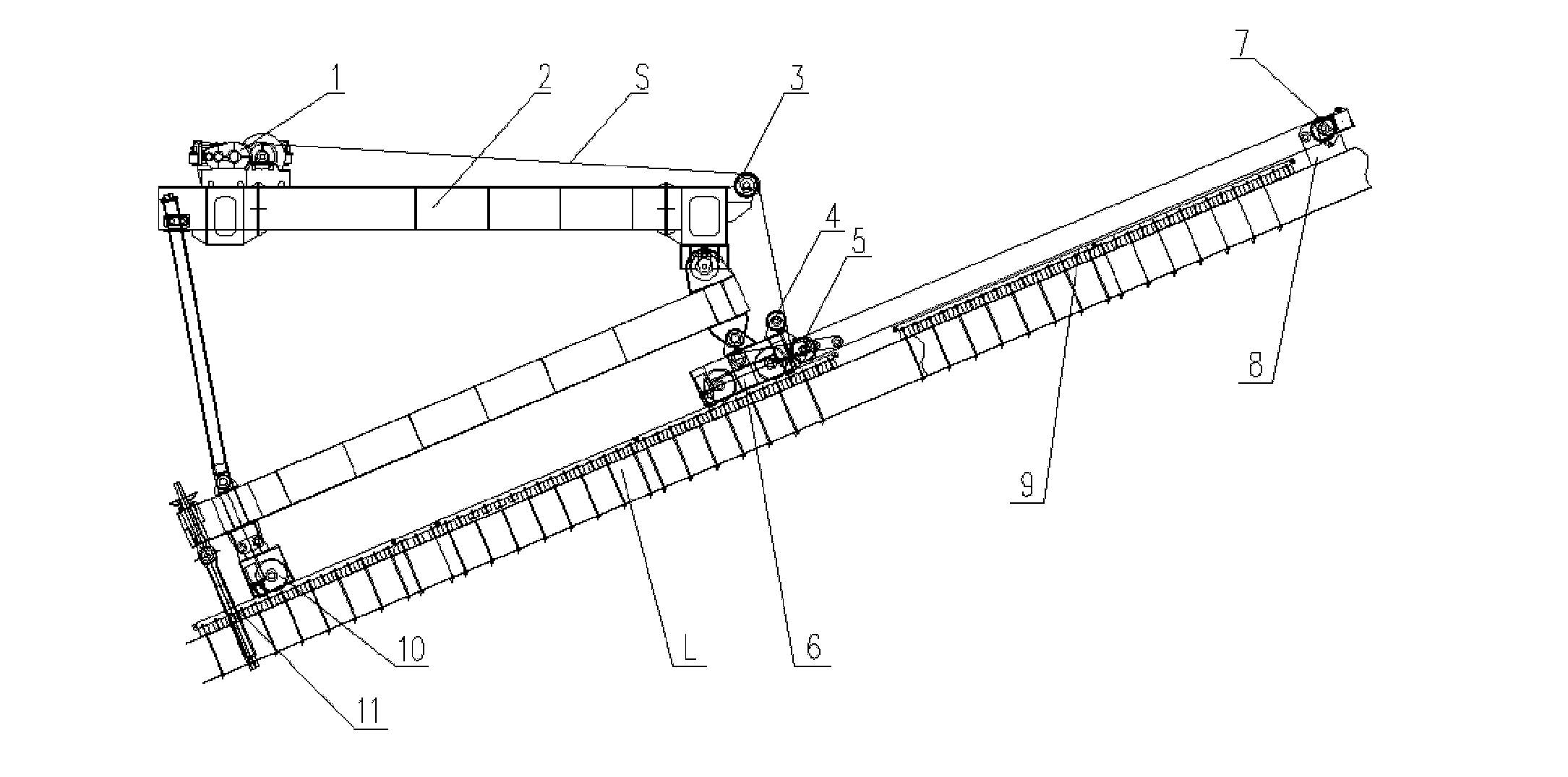

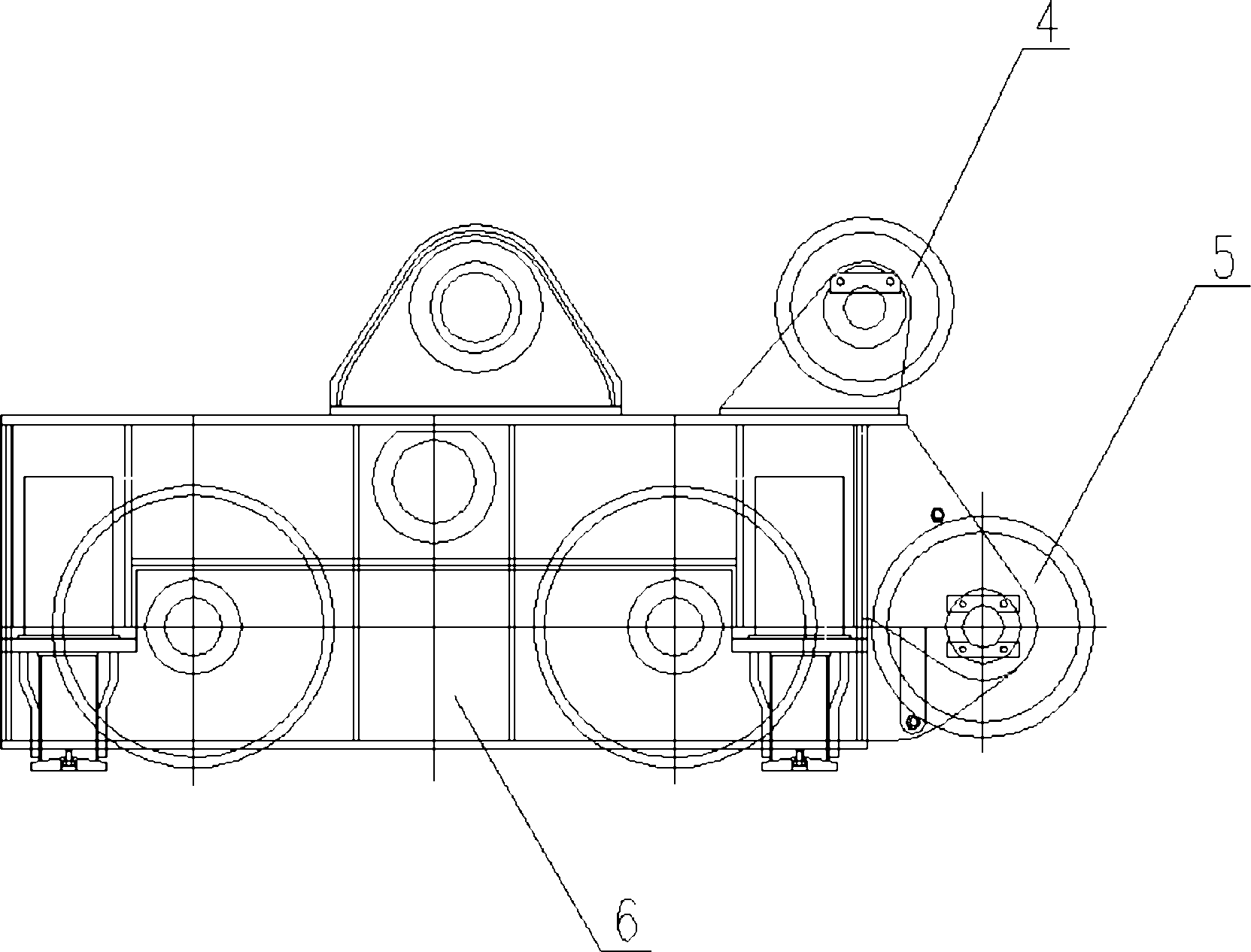

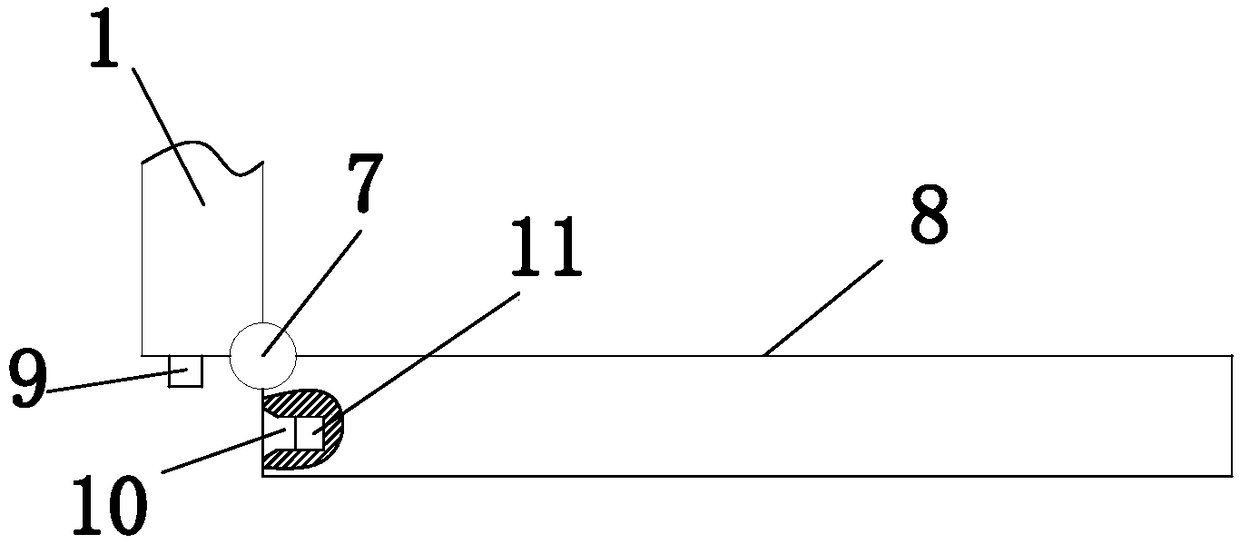

Traction running mechanism for climbing girder crane

InactiveCN102616651APrevent slippingOvercoming Nodal Slope VariationsBridge erection/assemblyWinding mechanismsLow speedPull force

The invention discloses a traction running mechanism for a climbing girder crane, which comprises the field of cranes. Traction hoisting machines comprise two low-speed hoisting machines which are fixed on an upper chassis of the crane in a bilateral symmetry manner ; two hoisting cable-pulley groups are symmetrically connected between the two traction hoisting machines of the upper chassis and corresponding front anchoring mechanisms; the pulling force of the traction hoisting machines is used for providing traction power and overcoming the downwards-sliding power caused by deadweight to pull the whole mechanism to move ahead; the design of the hoisting cable-pulley groups guarantees the stable movement direction of hoisting cables and provides sufficient safety factor assurance; a block brake is arranged at the output shaft end of a motor of the traction running mechanism; meanwhile, a disc brake is arranged on a winding drum wallboard; when the traction hoisting machine rotates, the tensile force of the hoisting cables can prevent the crane from sliding from a ramp; and when the traction hoisting machine is braked, the block brake and the disc brake can be started to realize double safety brake, so that the downwards-sliding of the crane caused by the counter revolution of the hoisting machine is effectively prevented, and the safety requirement is guaranteed.

Owner:WUHAN BRIDGE HEAVY INDS GROUP

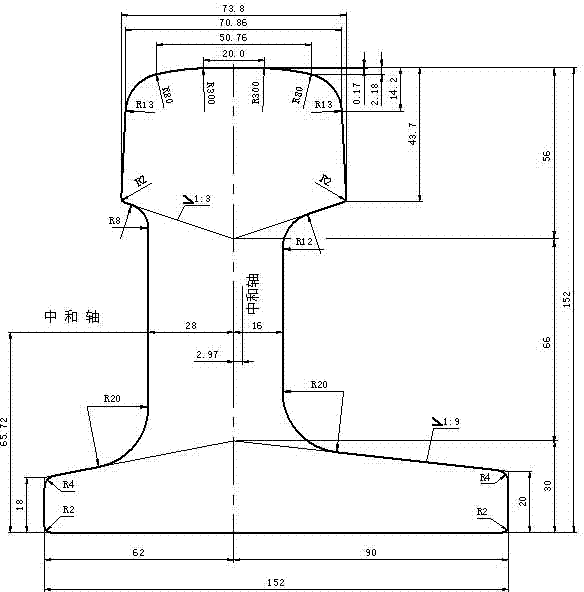

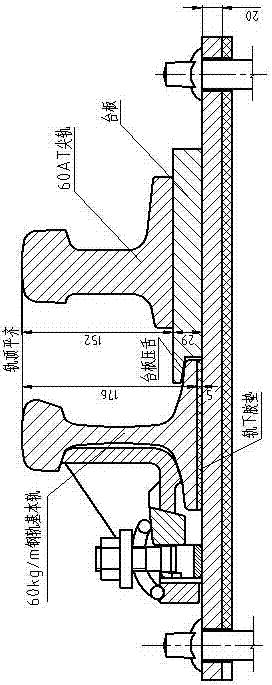

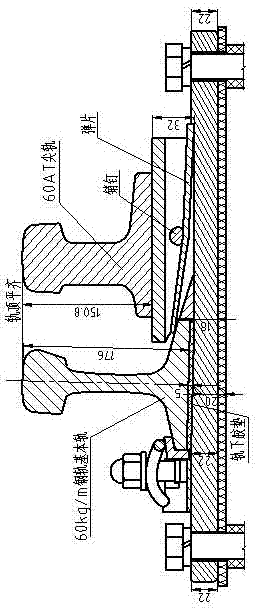

Urban rail transit switch rail and manufacture process thereof

The invention relates to an urban rail transit switch rail and a manufacture process thereof. Switching force of the switch rail can be reduced, even fewer switches are required, purchase cost of switch equipment is lowered, a slide plate fitted to the switch rail is provided with wedged regulation spring fasteners, stability and safety of the switch rail are enhanced, and amount of daily maintenance for switches by maintainers can be reduced effectively. The urban rail transit switch rail is made of a 60D40 steel rail. The urban rail transit switch rail has the advantages that the switch rail is made of the 60D40 steel rail, switching force of the switch rail is reduced, and the slide plate convenient to fit to the switch rail is provided with the elastic fasteners with high fastening force; the 60D40 steel rail has small rail height, thin waist and narrow bottom, low horizontal and vertical inertial torque and the like, space condition is provided for the design of switches, the train shaft with the switch rail for urban rail transit is lighter than train shafts for passenger special lines, and safety is sufficient.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

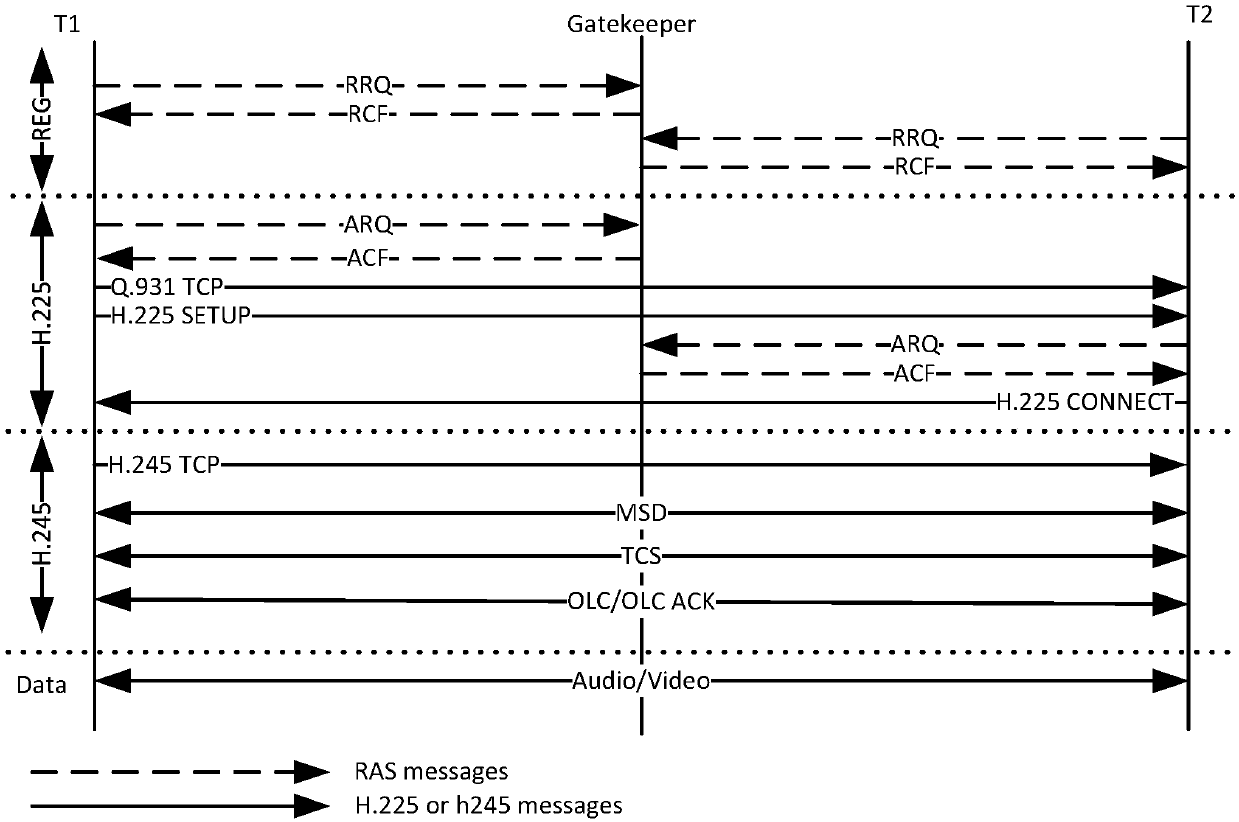

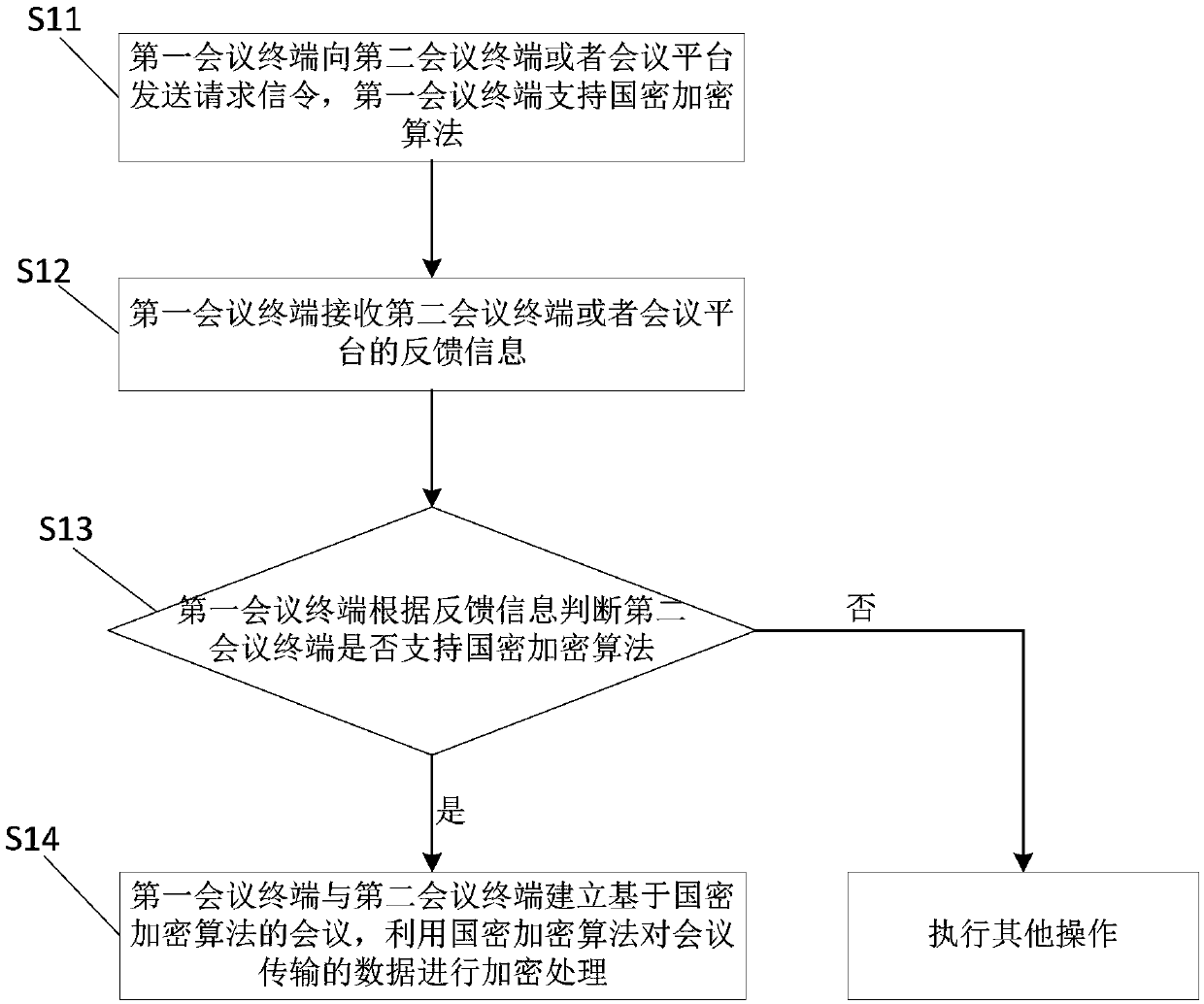

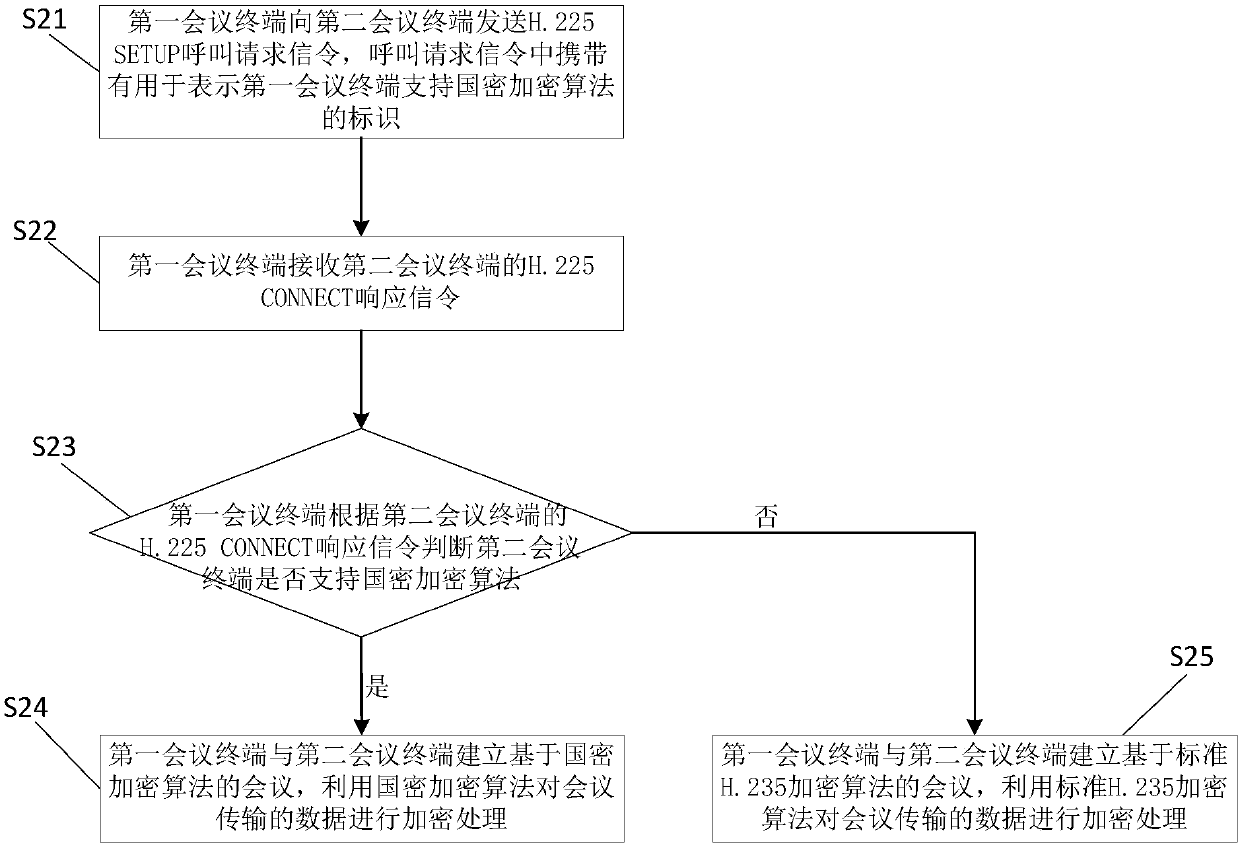

Video conference calling method and video conference calling device

ActiveCN107872462AImprove securityEnough securityMultiple keys/algorithms usageTelevision conference systemsInternational standardPassword

The invention relates to the field of video conference technologies, and discloses a video conference calling method and a video conference calling device. The video conference calling method includestransmitting request signals to second conference terminals or conference platforms by the aid of first conference terminals which support domestic password encryption algorithms; receiving feedbackinformation of the second conference terminals or the conference platforms by the aid of the first conference terminals; judging whether the second conference terminals support the domestic password encryption algorithms or not by the aid of the first conference terminals according to the feedback information; setting up conferences on the basis of the domestic password encryption algorithms by the aid of the first conference terminals and the second conference terminals when the fact that the second conference terminals support the domestic password encryption algorithms is determined, and carrying out encryption processing on data by the aid of the domestic password encryption algorithms. The data are transmitted in the conferences. The video conference calling method and the video conference calling device have the advantages that the domestic password encryption algorithms are applied to data transmission procedures in the video conferences on the premise that two ends support thedomestic password encryption algorithms, accordingly, the safety of data transmission in the video conferences can be sufficiently guaranteed, and the video conference calling method and the video conference calling device are favorable for promoting integration of national standards and international standards.

Owner:SUZHOU KEDA TECH

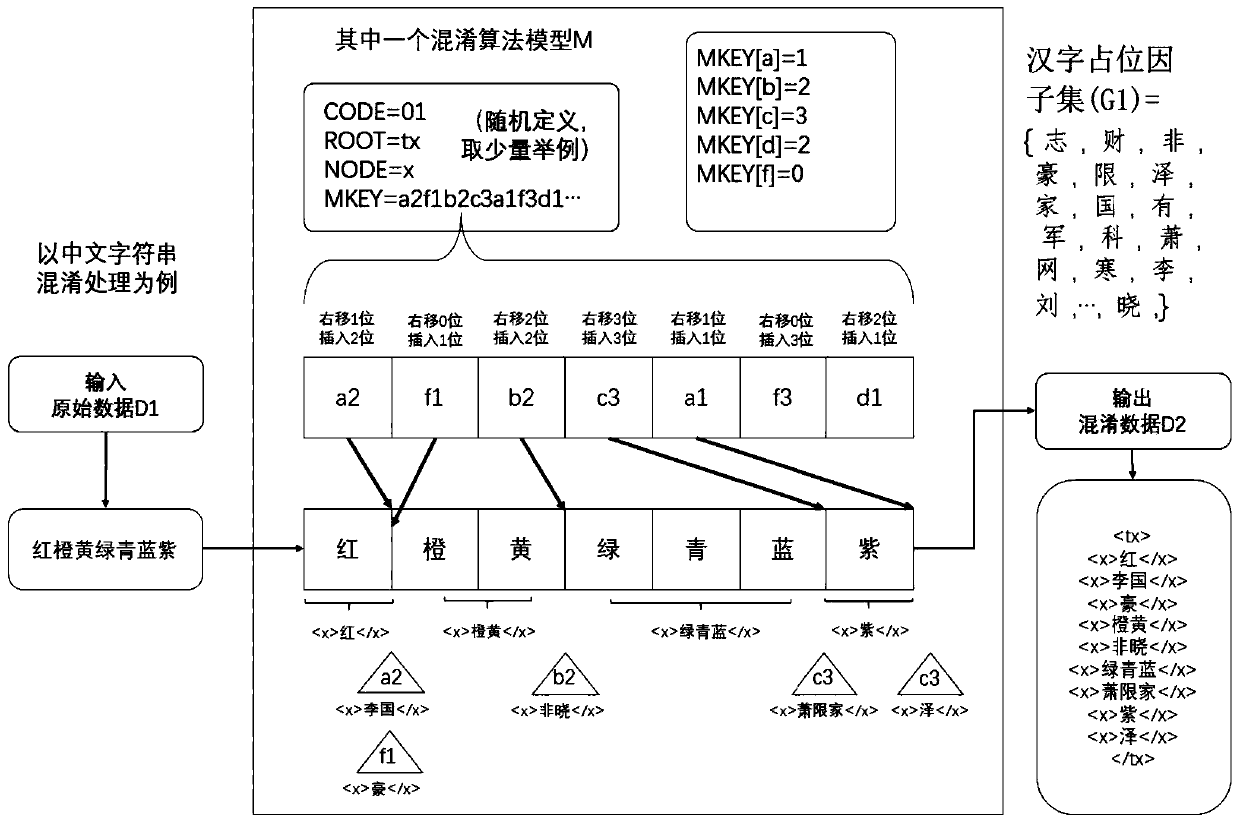

Webpage data anti-crawling encryption method

InactiveCN111291397AEnough securityWeb data indexingDigital data protectionOriginal dataTheoretical computer science

The invention discloses a webpage data anti-crawling encryption method, which comprises the following encryption steps: when a webpage data access request is received, correspondingly obtaining a confusion algorithm model from an algorithm library according to a feature identifier or a random identifier of the access request; performing obfuscation processing on each original data segment in the webpage data of the access request by utilizing the obtained obfuscation algorithm model so as to obtain obfuscated data; and encrypting the unique identification code of the obfuscation algorithm model and the obfuscation data to obtain encrypted data. According to the webpage data anti-crawling encryption method, confusion processing can be carried out on original webpage data by utilizing the confusion algorithm model, a corresponding program for restoring confusion processing is arranged at a client of a normal user, only disordered data can be obtained when crawling is carried out, and therefore it is guaranteed that the original webpage data is crawled in time and cannot be normally displayed.

Owner:成都神殿科技有限责任公司

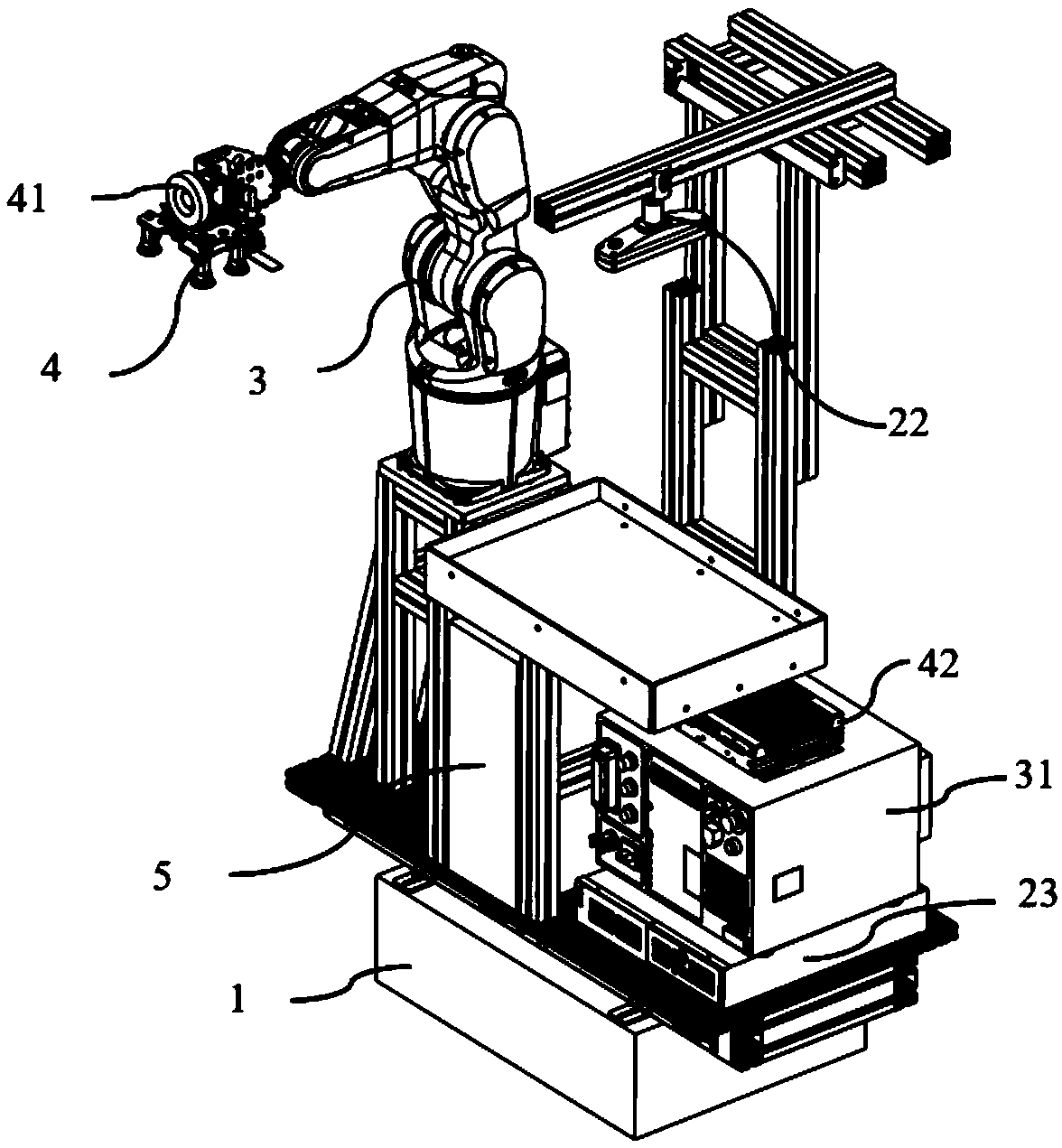

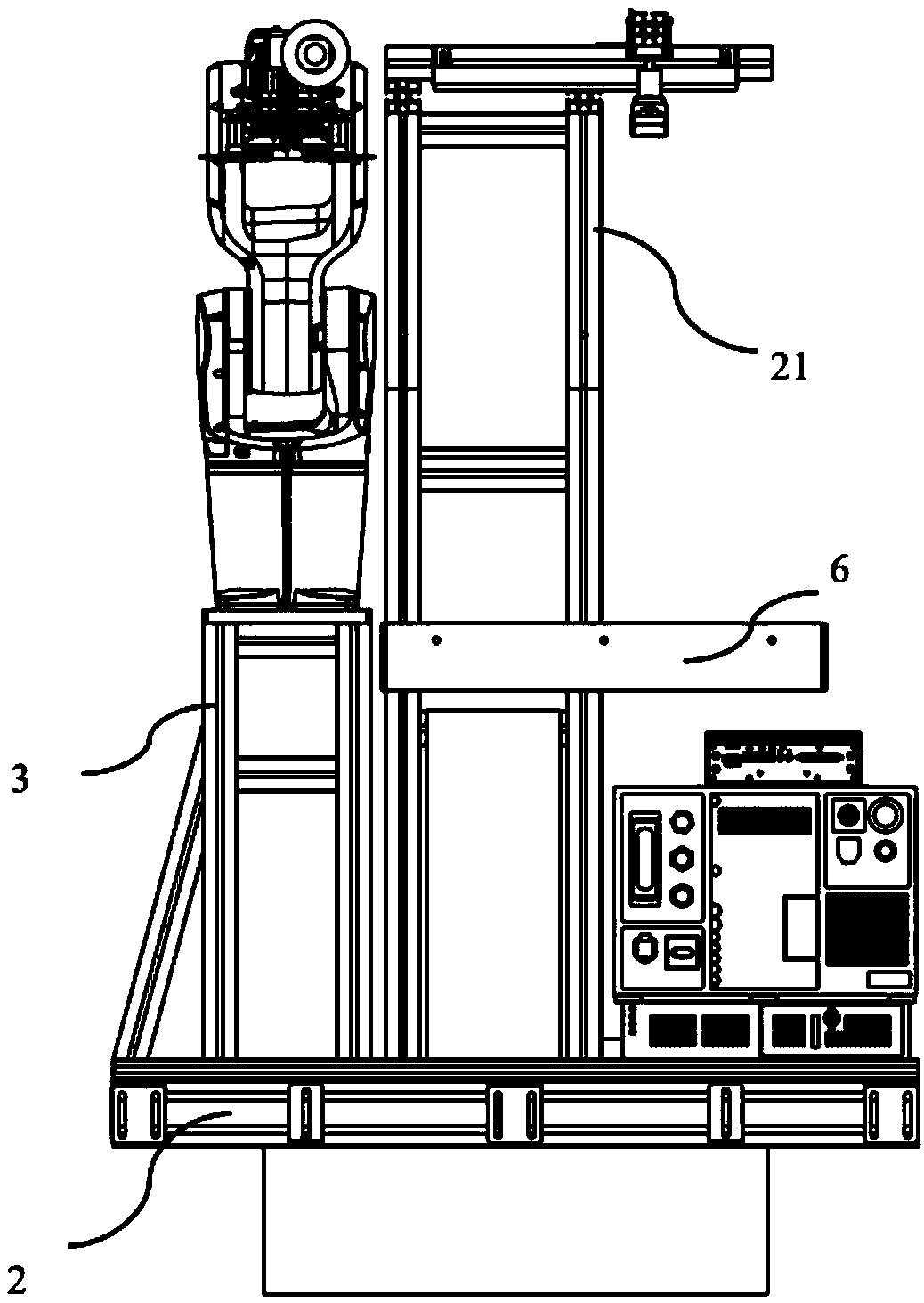

Robot for picking and delivering goods in unmanned supermarket and automatic loading method

PendingCN109677826AReduce labor intensityReduce management costsStorage devicesConveyor partsAir compressorControl theory

The invention provides a robot for picking and delivering goods in an unmanned supermarket and an automatic loading method, relate to the field of the unmanned supermarket; the robot comprise a powersupply, an autonomous navigation trolley, a base arranged on the autonomous navigation trolley and a robot arranged on the base; a robot controller for controlling the robot is arranged on the base; the base is provide with a bracket, one end, away from the base, of the bracket is provided with a visual camera; one end, away from the base, of the robot is provide with a grabbing device; an intelligent camera is arranged on the grabbing device; the base is provided with an air compressor for controlling the opening and closing of the grabbing device, a visual camera controller for controlling the visual camera and an intelligent camera controller for controlling the intelligent camera; the base is provided with a placing frame for placing goods; the beneficial effects are as follows: the robot can automatically mount and dismount various goods, improve working efficiency, reduce the management cost of the unmanned supermarket and meet the needs of the unmanned supermarket.

Owner:SHANGHAI SAGE INTELLIGENT TECH CO LTD

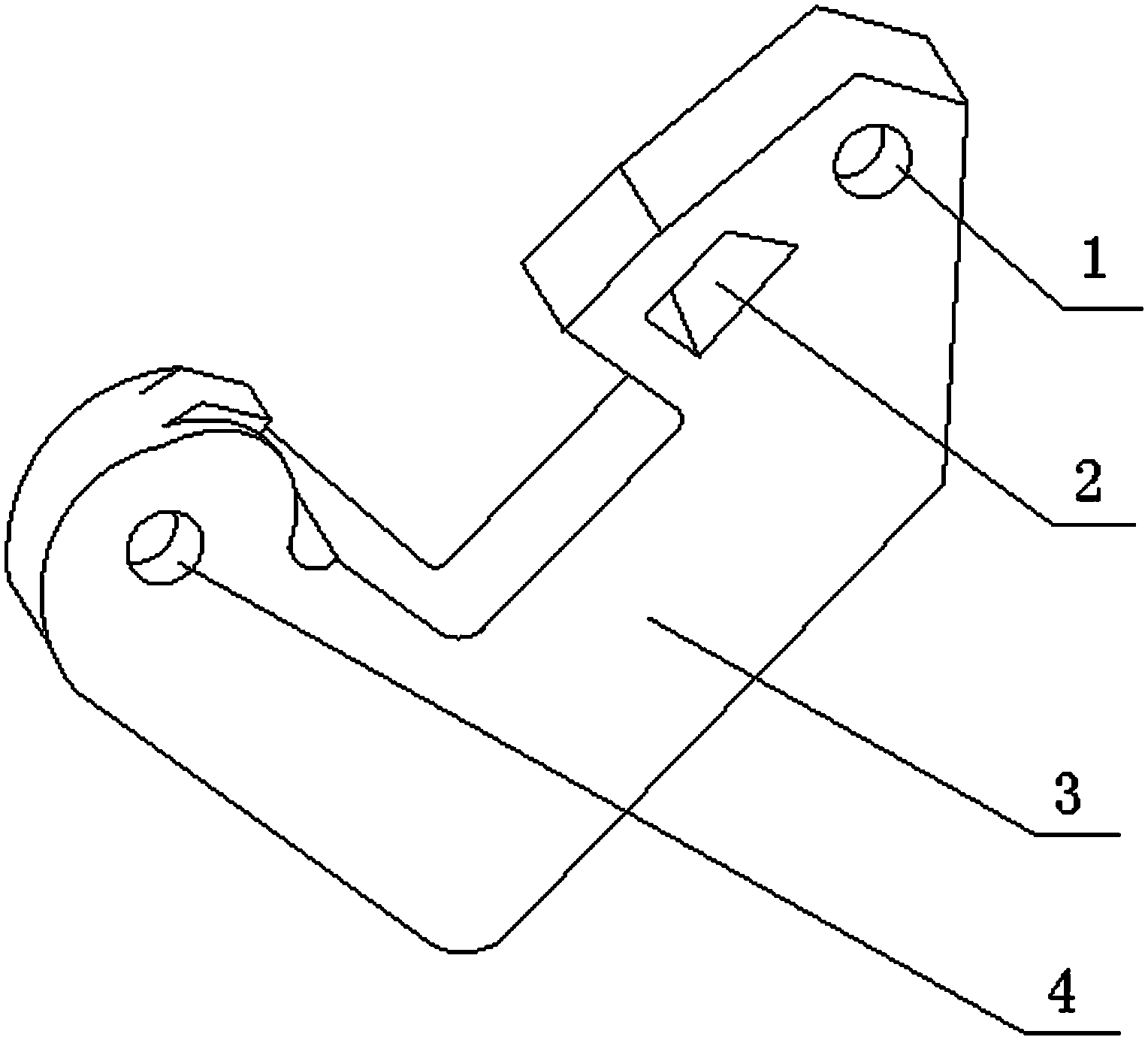

Manufacturing method of hook body of large hook for polar region drilling machine

ActiveCN103978342AAvoid shockAvoid this shortcoming of non-destructive testing failureDrilling rodsFurnace typesPetroleumMechanical property

The invention provides a manufacturing method of a hook body of a large hook for a polar region drilling machine. The manufacturing method adopts the process steps of design and blanking, forging, rough machining, heat treatment and finish machining, and the hook body is processed according to requirements of GB / T19190 and APISpec8C. The forging hook body processed by the manufacturing method adopts the integral forging design, the conventional material 35CrMoA and normalizing, tempering and subcritical quenching processes are adopted, and the intensity, the impact power in the polar low-temperature environment (-60 DEG C) and other mechanical properties of the hook body are ensured. The hook body of the large hook processed by the manufacturing method is applicable to petroleum drilling machines and workover rigs in polar low-temperature environment (-60 DEG C), the safety factor is guaranteed, and sufficient low-temperature impact toughness and polar low-temperature environment resistance performance is realized.

Owner:RG PETRO MACHINERY GROUP

Large freight vehicle tail anti-impact device

The invention discloses a large freight vehicle tail anti-impact device which comprises a front face impact board. An oblique board is arranged at the upper end of the front face impact board. A height adjusting mechanism fixed to the tail end of a vehicle girder is arranged on the inner side of the oblique board. A connecting frame is arranged on the inner wall face of the front face impact board. A limiting buffering mechanism located on the two sides of the tail of the vehicle girder is hinged to the two ends of the connecting frame and located on the inner side of the height adjusting mechanism. The limiting buffering mechanism comprises two bases fixed to the vehicle girder. A horizontal guide rod is arranged between the two bases and sleeved with a horizontal sliding seat. The horizontal sliding seat is hinged to the connecting frame. A buffer spring is further arranged on the side face of the horizontal sliding seat, wherein the horizontal guide rod is sleeved with the buffer spring. The large freight vehicle tail anti-impact device has the beneficial effects that the safety protection performance can be improved.

Owner:聊城市汉拯信息科技有限公司

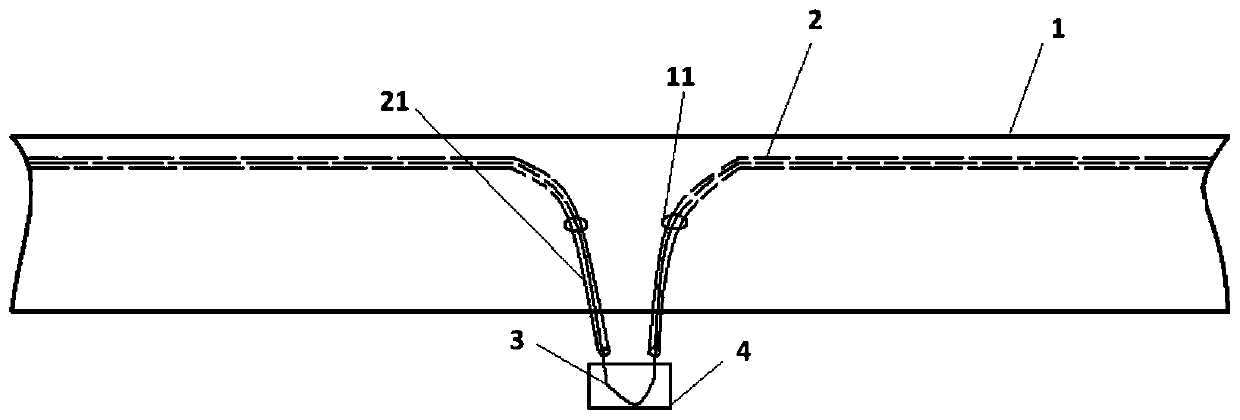

Pipe-in-pipe structure convenient for optical cable laying and replacing and laying method

PendingCN110174738AImprove delivery efficiencyImprove efficiencyOptical fibre/cable installationElectrical and Electronics engineeringOptical fiber cable

The invention discloses a pipe-in-pipe structure convenient for optical cable laying and replacing and a laying method. The structure comprises a conveying pipeline and optical cable channels, whereinthe optical cable channels are divided into a plurality of sections; each section comprises a main body and lead-out sections at both ends; the main bodies are fixed on the inner wall of the conveying pipeline; the lead-out sections at both ends respectively pass through corresponding lead-out holes in the conveying pipeline to be led out of the conveying pipeline; and gaps at the lead-out holesare sealed. During laying, micro tubes are fixed on the inner wall of the conveying pipeline to form the optical cable channels and gaps among the micro tubes are sealed to prevent the micro tubes from gas leaking and water leaking; the micro tubes are led out of the conveying pipeline from the lead-out holes every 1500m to 2500m to form the lead-out sections and gaps between the micro tubes and the lead-out holes are sealed to avoid gas leakage and water leakage; optical cables are laid in the micro-tubes of each section and two ends of the optical cables are exposed out of the micro-tubes; and the optical cables of the adjacent sections are fused together, joints are protected by joint boxes and gaps between the optical cables and the micro tubes are sealed. After the micro tubes are laid, faulty optical cables in the micro tubes can be replaced at the lead-out sections without stopping of the medium conveying in the conveying pipeline.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

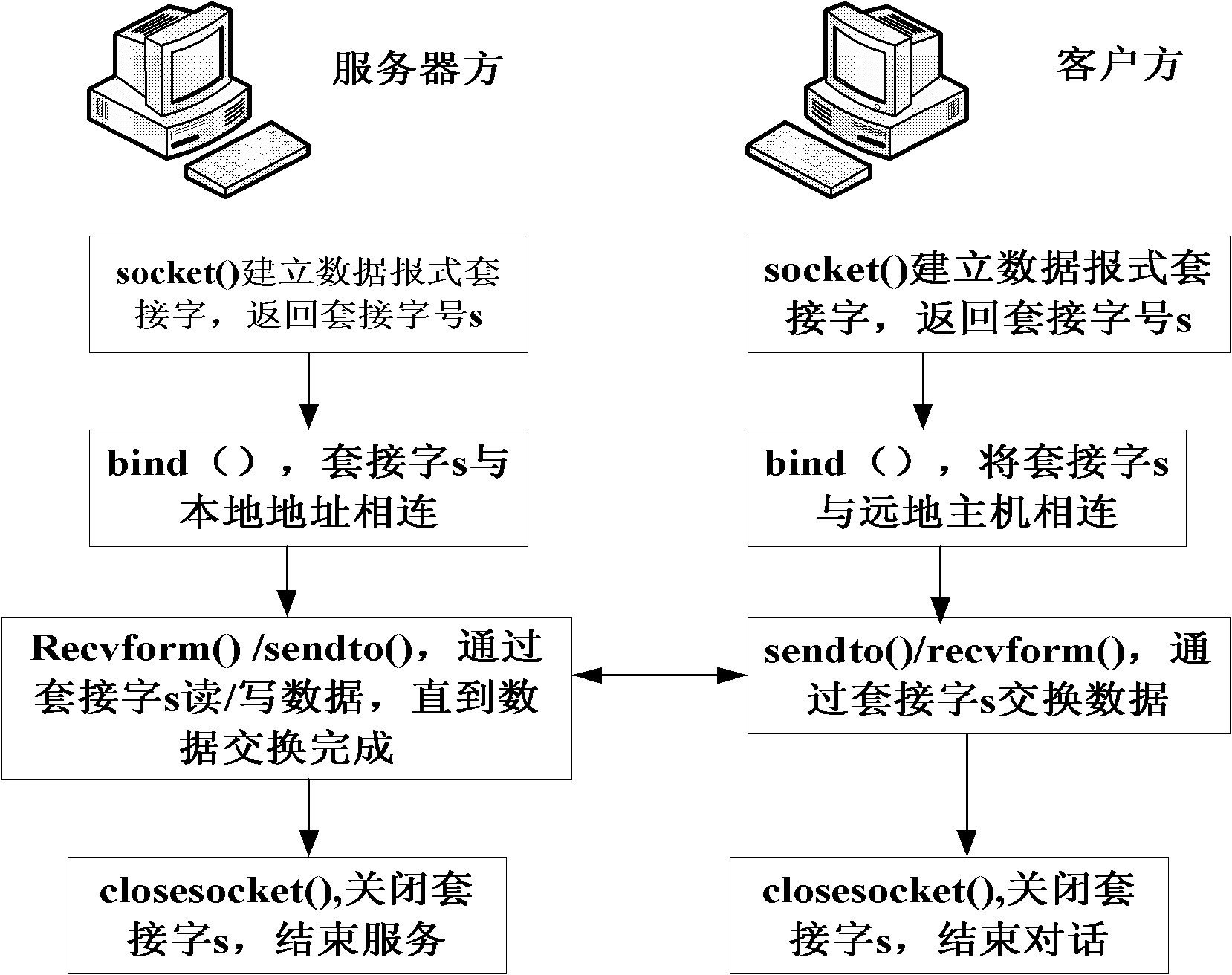

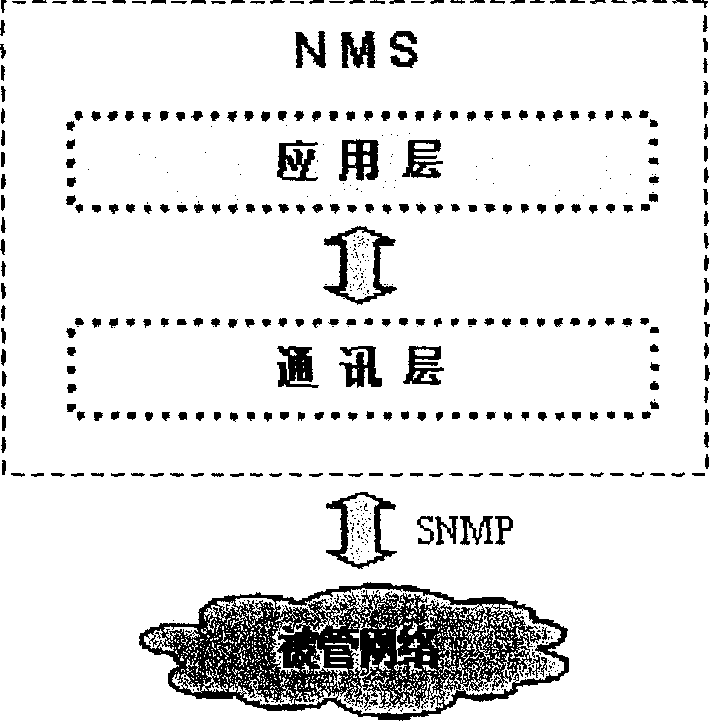

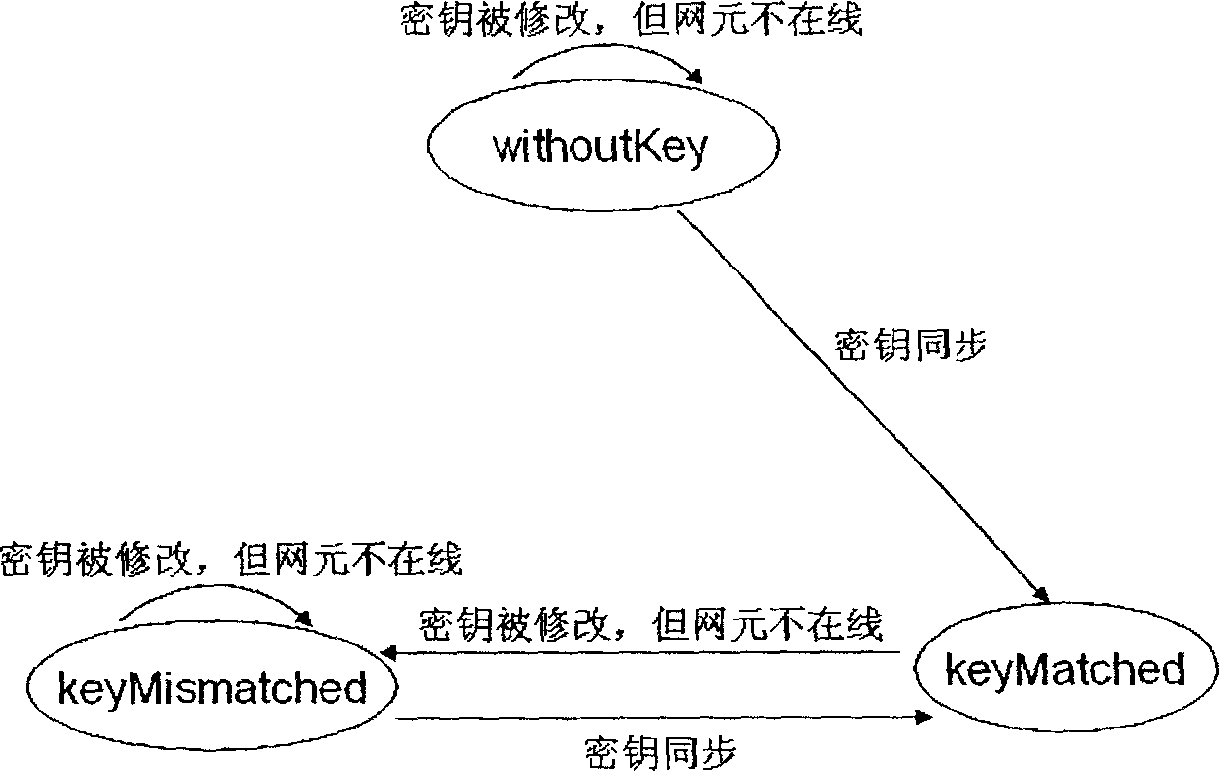

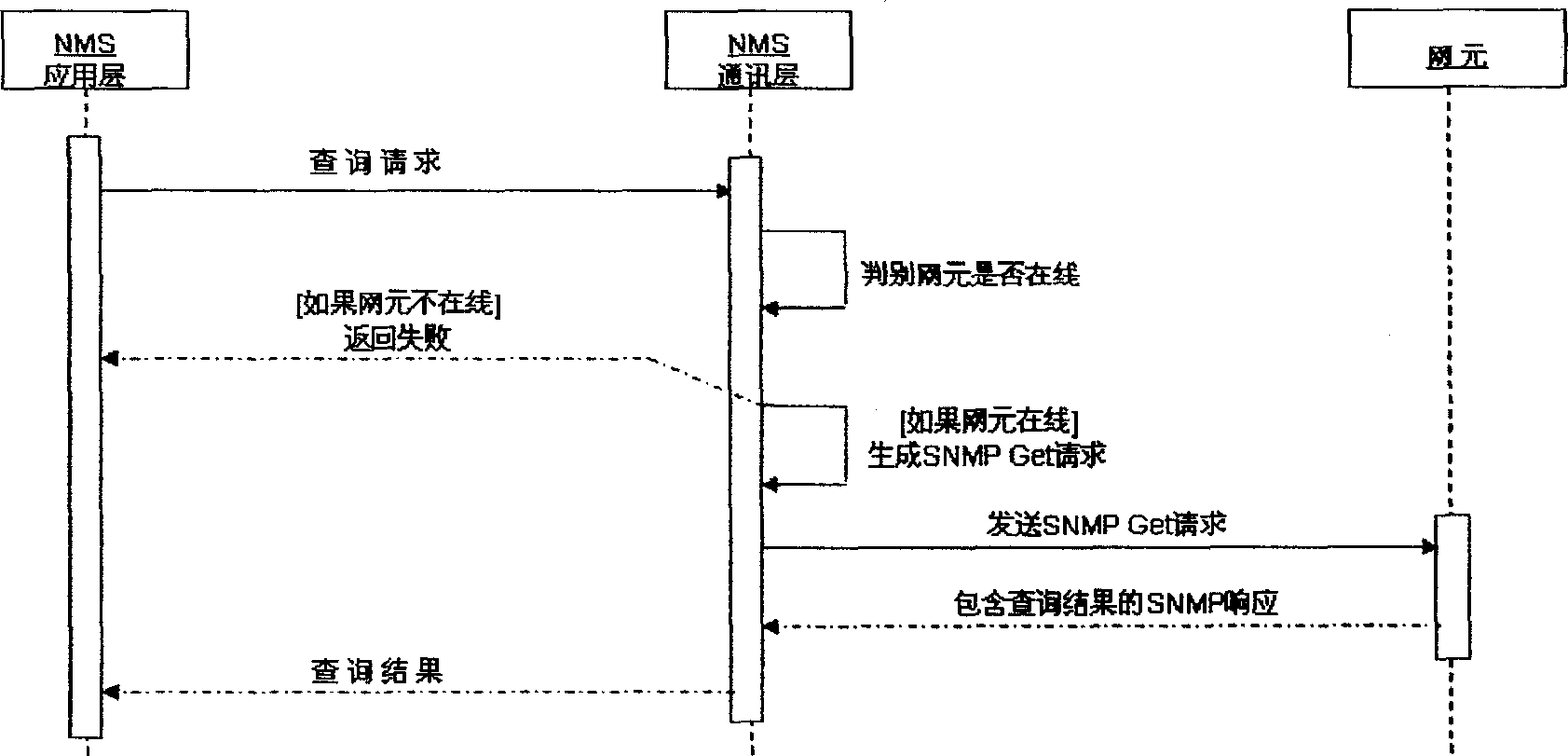

Network managing method based on SNMP

InactiveCN1901478AEnough securityNot easily imitatedStar/tree networksComputer hardwareNetwork management

This invention puts forward a high safety network management method based on SNMP including the following steps: a, NMS starts up and carries out initialization, b, the NMS tests the communication state of NE and the state of cryptographic key to determine if it's necessary to carry out cryptographic key synchronization with the NE, c, the NMS generates the SNMP Get request for enquiring the current information of the NE and sends it to the NE, which feeds back the SNMP response containing the required current information of the NE, d, the NMS generates the SNMP Set requirement for controlling / configuring NE to be ciphered and sent to the NE, which feeds back the SNMP response containing the control / configuration result.

Owner:UTSTARCOM TELECOM CO LTD

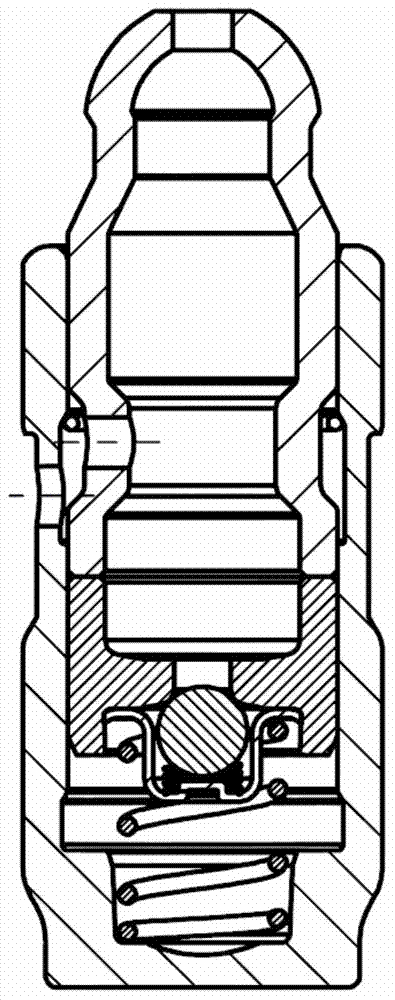

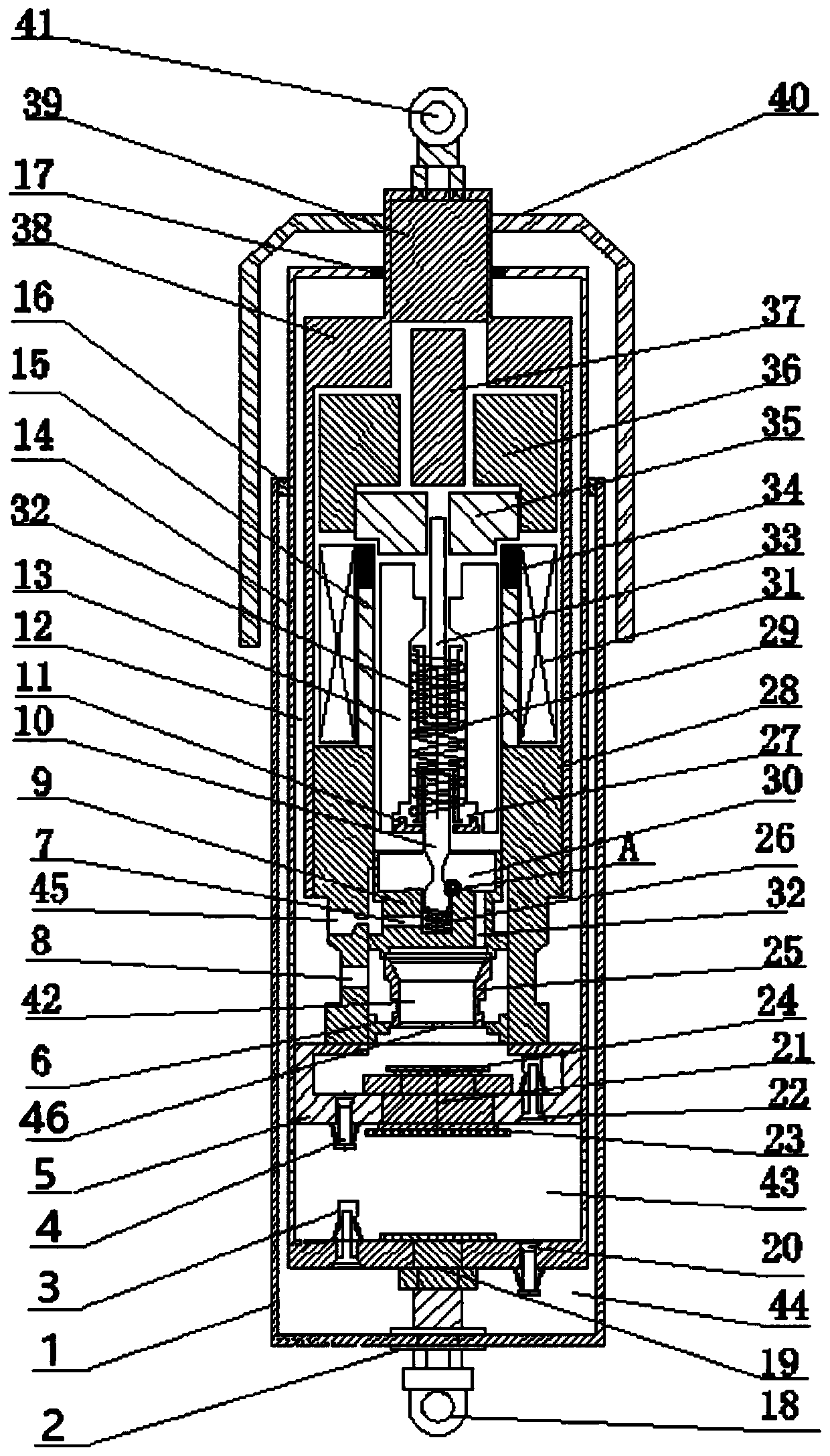

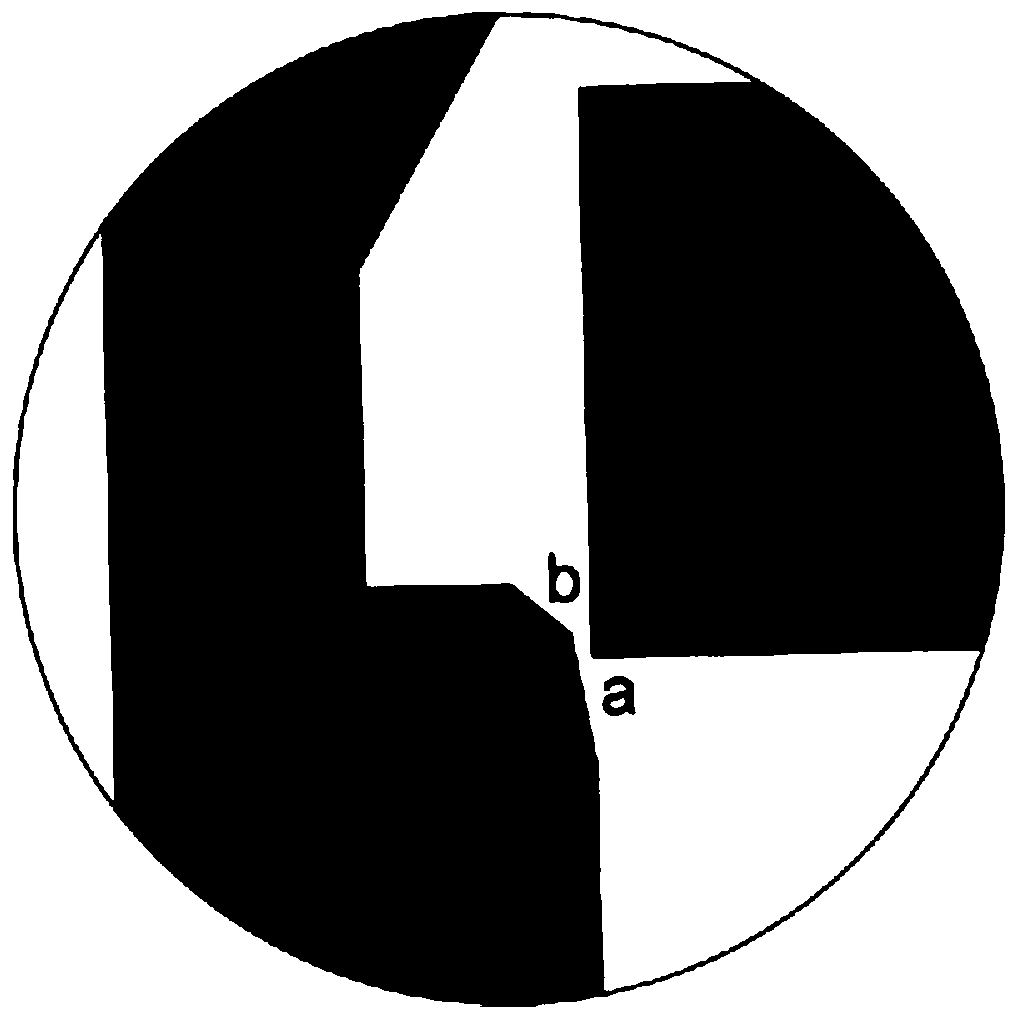

Built-in electromagnetic-valve-type semi-active damping-continuous-adjustable shock absorber, and control method

The invention belongs to the technical field of vehicle damping devices and specifically relates to a built-in electromagnetic-valve-type semi-active damping-continuous-adjustable shock absorber, anda control method. The built-in electromagnetic-valve-type semi-active damping-continuous-adjustable shock absorber comprises a shock absorber body and a shock absorber control system and is characterized in that the shock absorber body comprises a working cylinder barrel, an oil storage cylinder barrel, a shock absorber dustproof cover, a bottom valve assembly, a piston assembly and an electromagnetic valve assembly. The invention also discloses the control method for the built-in damping-continuous-adjustable shock absorber. The control method is characterized in that continuous switching control of different modes can be realized for soft and hard damping of the shock absorber; an electromagnetic valve can be rationally integrated with a piston inside the damping-continuous-adjustable shock absorber; different cross section structures are adopted for a valve core; guidance structures are designed around the valve core, so the valve core is more stable; damping is realized, and damping adjustment of different comfort degrees can be realized; use is convenient; space is saved; use prospect is wide; and promotion and use are easy.

Owner:XIAN UNIV OF SCI & TECH

Immersed phase change cooling medium and application thereof in cooling system of electronic device

InactiveCN111343837AHigh electrical insulationLow viscosityCooling/ventilation/heating modificationsMeth-Engineering

The invention discloses an immersed phase change cooling medium and application thereof in a cooling system of an electronic device. The cooling medium is one or a mixture of two or more of perfluoro-4-methyl-2-pentene, perfluoro-2-methyl-3-pentanone, perfluoro-2-methyl-2, 3-epoxypentane and perfluorohexanone. The immersed phase-change cooling medium provided by the invention has the characteristics of high electrical insulation property, low viscosity, lower boiling point, high gasification latent heat, good compatibility and stability, incombustibility, combustion inhibition, low global warming potential (GWP), zero ozone consumption potential (ODP) and the like.

Owner:浙江诺亚氟化工有限公司

Novel solar head lamp

InactiveCN104832796ANo fireNot poisonousLighting support devicesElectric circuit arrangementsEngineeringElectric wire

The invention discloses a novel solar head lamp. The novel solar head lamp comprises a rechargeable lithium battery and a head lamp holder with a bulb, wherein the rechargeable lithium battery is installed in a battery box, the battery box is provided with a solar panel which is electrically connected with lithium battery, the lithium battery is connected to the bulb in the head lamp holder by virtue of a circuit board, an electric wire and a switch button, and a head strap is installed between the battery box and the head lamp holder; a dimming ring is installed on the head lamp holder; a signal lamp which is connected with the circuit board and the rechargeable lithium battery is installed on the battery box; the rechargeable lithium battery is a soft-packaged battery. The novel solar head lamp has the beneficial effects that the practicability is realized, the production cost is low, the charging way is diversified, the use is convenient, convenience in carrying is realized, and the use is safe.

Owner:宁波市奉化浩轩光电有限公司

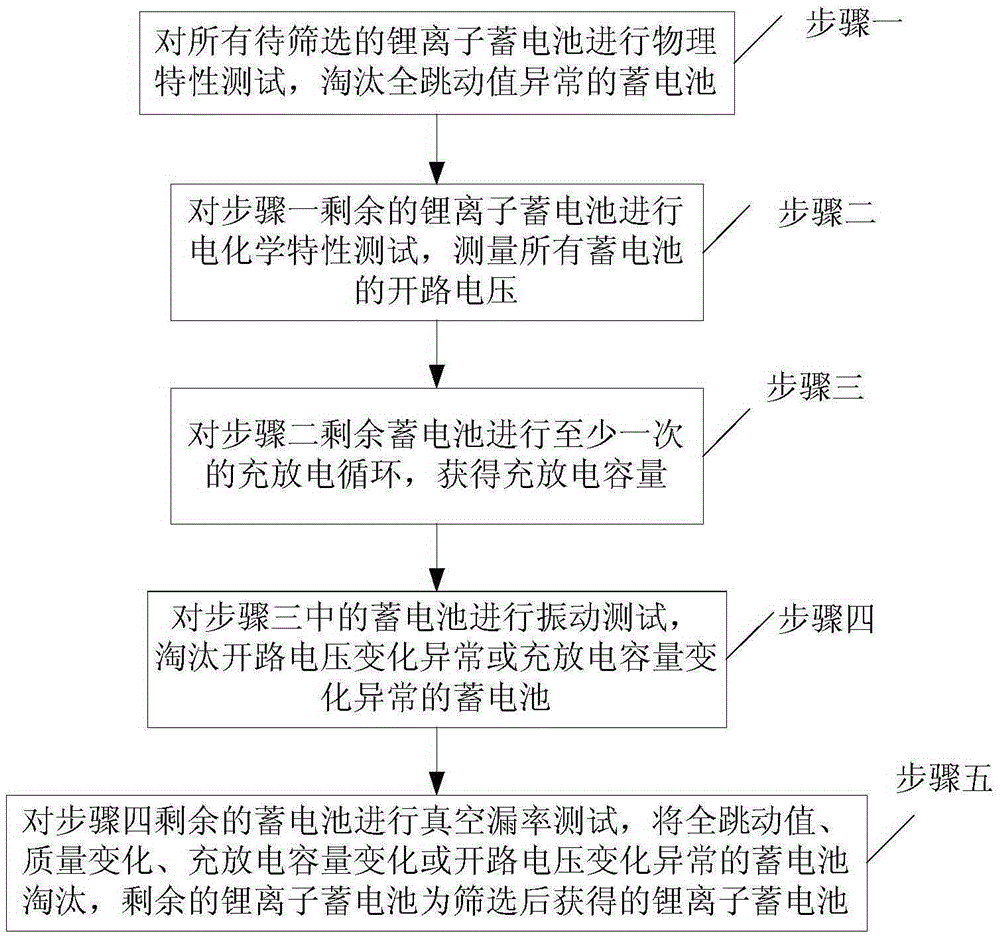

Screening method for lithium-ion storage battery

The invention discloses a screening method for a lithium-ion storage battery, belongs to the field of satellite power supply and aims to solve the problem that the production cost of a storage battery in an existing Pina satellite power supply subsystem is high. The method comprises the following steps: step (1) testing physical characteristics of all to-be-screened lithium-ion storage batteries to obtain the size and quality of the storage batteries, and weeding out the storage batteries of which the total run-out value is abnormal; step (2) testing electrochemical characteristics, and measuring open-circuit voltage; step (3) obtaining charging capacity and discharging capacity; step (4) performing a vibration test, comparing the vibration test with the last measurement, and weeding out the storage batteries of which the open-circuit voltage is abnormal or the charging and discharging capacity changes are abnormal; step (5) performing a vacuum leakage rate test, comparing the vacuum leakage rate test with the last measurement, weeding out the storage batteries of which the total run-out value, quality changes, charging and discharging capacity changes or open-circuit voltage changes are abnormal, and taking the rest lithium-ion storage batteries as the lithium-ion storage batteries obtained after screening. The storage batteries screened by the method disclosed by the invention are applied to the Pina satellite power supply subsystems.

Owner:HARBIN INST OF TECH

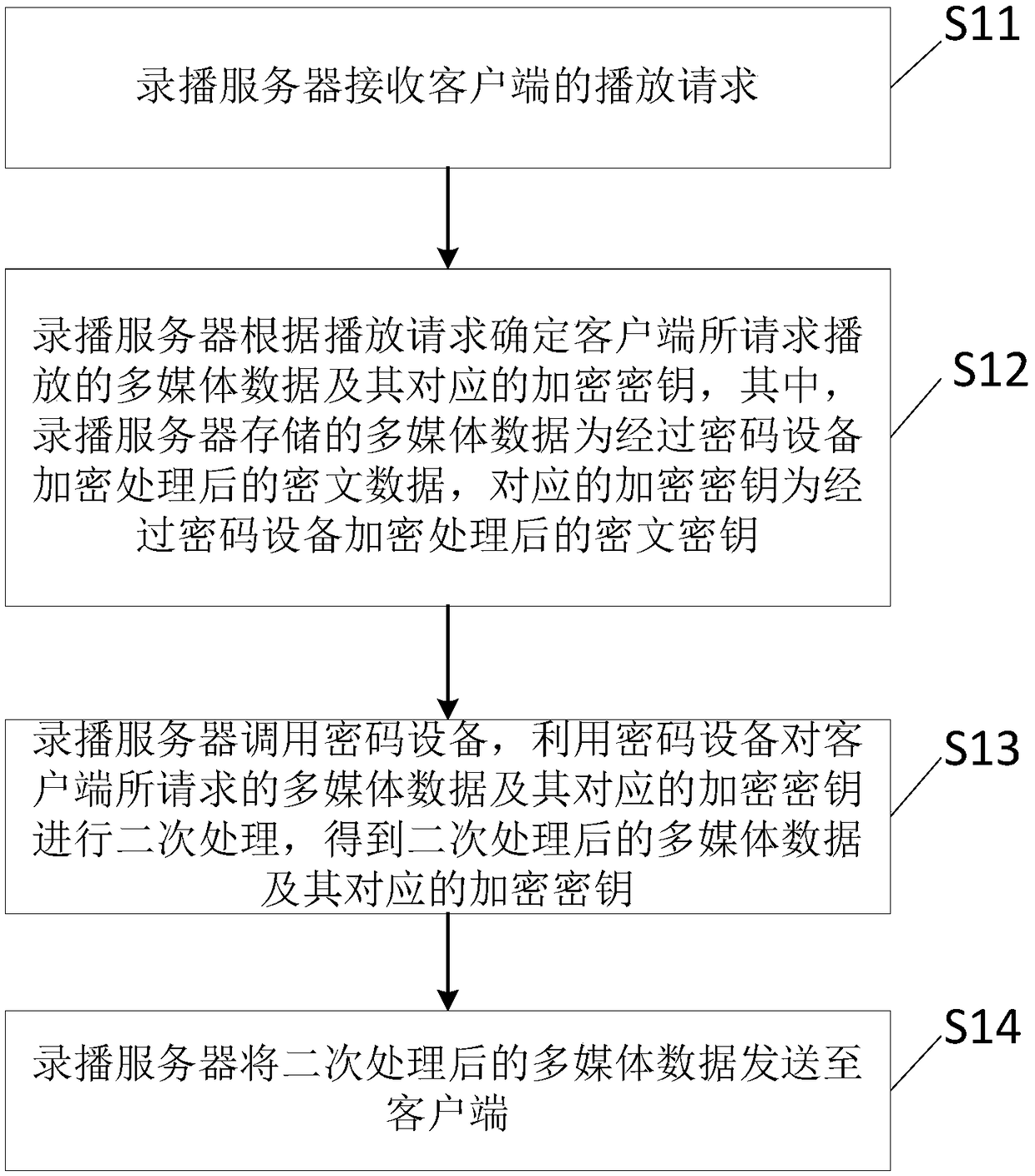

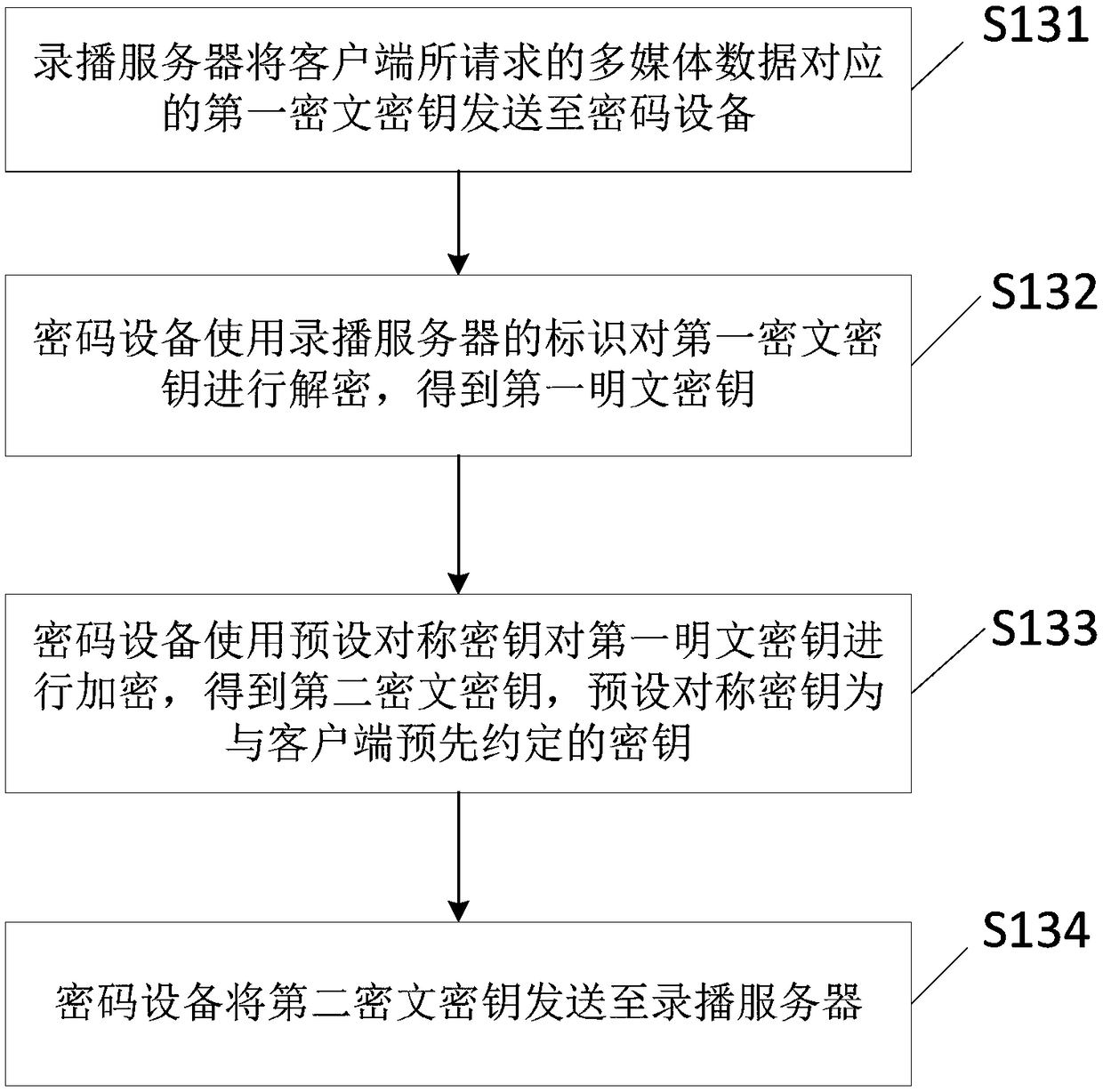

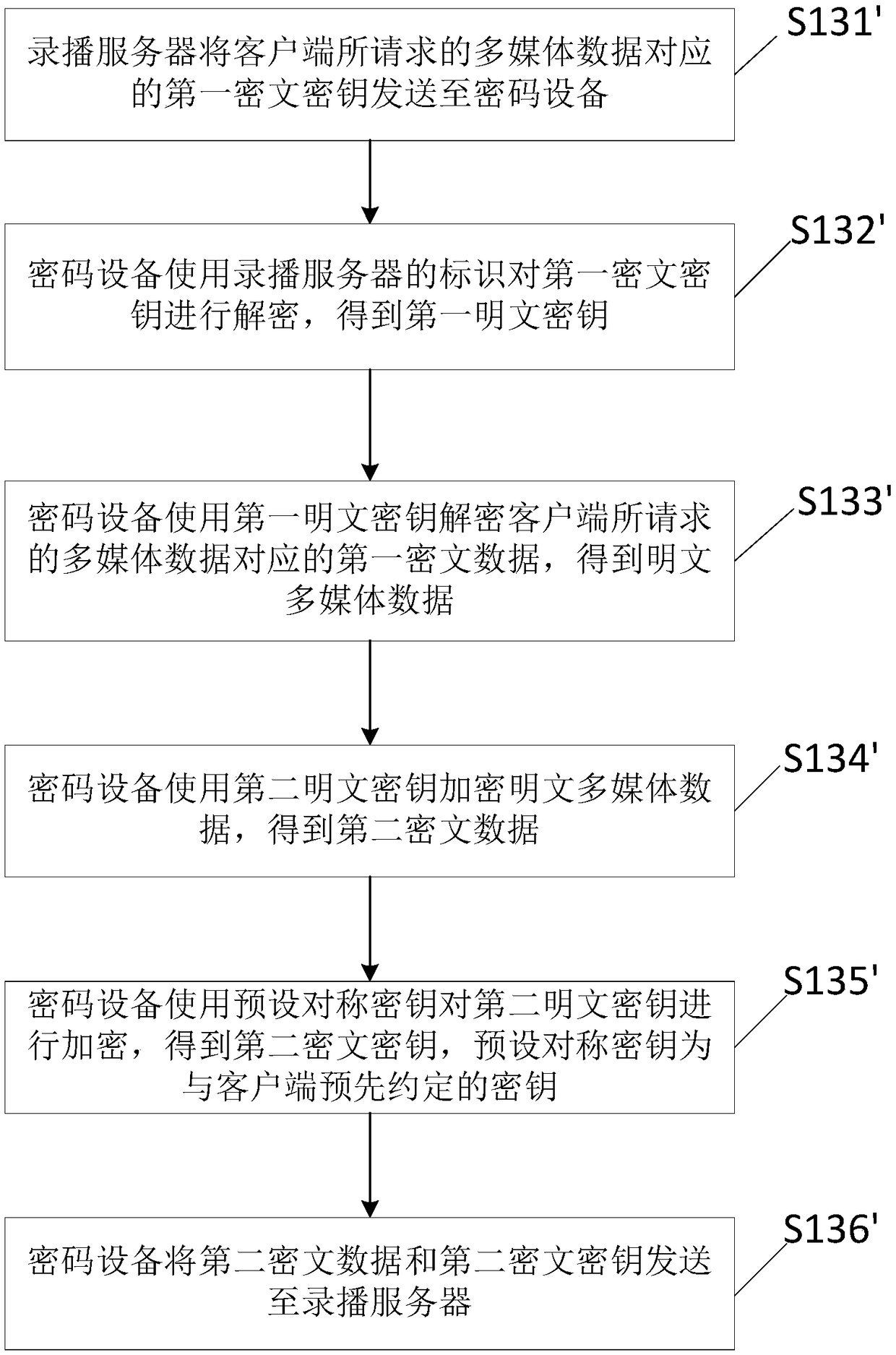

Recording and broadcasting data processing method and device

ActiveCN108768920AEnsure safetyNot easy to attackKey distribution for secure communicationEncryption apparatus with shift registers/memoriesPlaintextMan-in-the-middle attack

The present invention relates to the technical field of recording and broadcasting, and discloses a recording and broadcasting data processing method and device. The method comprises the steps that: arecording and broadcasting server receives a play request of a client; the recording and broadcasting server determine multimedia data required by the client and corresponding encryption keys according to the broadcasting request, wherein the multimedia data stored in the recording and broadcasting server are ciphertext data after encryption processing by a password device, and the correspondingencryption keys are ciphertext secret keys after encryption processing by the password device; the recording and broadcasting server transfers the password device, employs the password device to perform secondary processing of the multimedia data required by the client and the corresponding encryption keys and obtains the multimedia data and the corresponding encryption keys after secondary processing; the recording and broadcasting server sends the multimedia data after secondary processing to the client. In the recording and broadcasting data transmission process, the plaintext is not fell to ensure the safety of the recording and broadcasting data in the transmission process and be not easy to be attacked by an intermediary.

Owner:SUZHOU KEDA TECH

Burying-free combined type quincuncial pile

InactiveCN105727537AHeight adjustableIncrease training difficultySport apparatusBuilding constructionSteel plates

The invention provides a burying-free combined type quincuncial pile which comprises a base pile, wherein a magnetic device for fixing is arranged in the base pile; a plurality of detachable adjustment piles, which are wooden piles, are arranged above the base pile; treading piles are arranged above the height adjustment piles; sliding chutes are formed in the treading piles; sliding columns capable of sliding are arranged in the sliding chutes; the upper sides of the sliding columns are fixedly connected with foot pedals which can be fixedly or movably connected with the treading piles. The quincuncial pile can be directly adsorbed on a steel plate under magnetic force; in the quincuncial pile construction process, complicated manual labor is not needed; furthermore, the quincuncial pile can be replaced conveniently and quickly and is height-adjustable and multifunctional, and construction or adjustment of the quincuncial pile can be completed with no auxiliary tool.

Owner:HENAN INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com