Urban rail transit switch rail and manufacture process thereof

A technology for urban rail transit and manufacturing process, which is applied in the field of urban rail transit turnout rails and manufacturing processes, can solve the problems of increasing the switching force of the turnout, affecting the overall quality of the urban rail turnout, and reducing the buckle pressure, so as to save steel raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

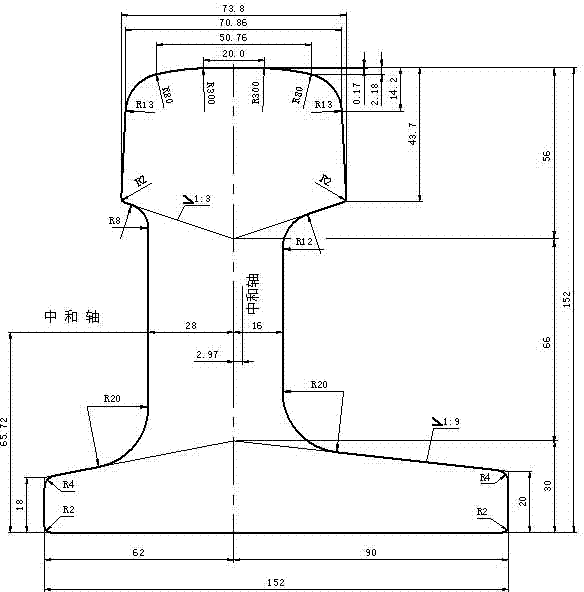

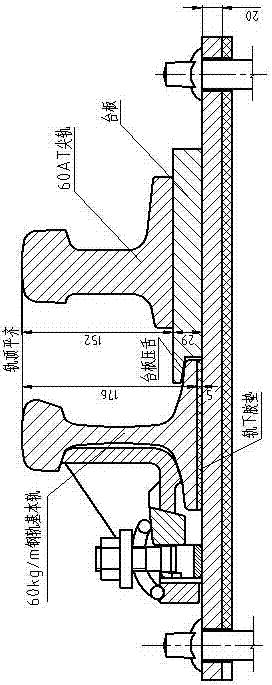

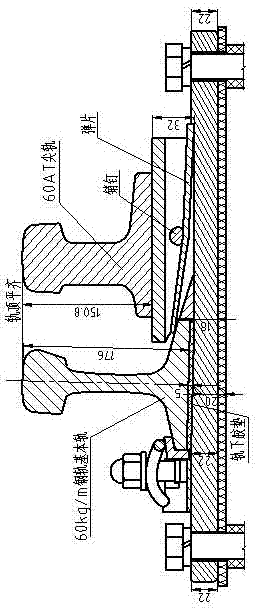

[0018] Embodiment 1: with reference to attached Figure 5 . The utility model relates to a switch point rail of urban rail transit, and the switch point rail of urban rail transit adopts 60D40 steel rail. The geometric parameters of the 60D40 rail section are: rail height 142 cm, rail waist thickness 32.5 cm, rail bottom width 150 cm, cross-sectional area 89 cm 2 , x-axis moment of inertia 2040I x cm 4 , The unit weight is 70kg / m, so the lateral rigidity of 60D40 rail is small, which greatly reduces the pulling force of the switch rail, which is beneficial to the traction conversion of the switch rail. Since the 60D40 rail is 142 cm high, it is convenient to use wedge-shaped adjustment shrapnel fasteners in the sliding bed, which can permanently and elastically buckle the inner rail limbs of the basic rail and improve the stability of the turnout.

Embodiment 2

[0019] Embodiment 2: On the basis of Embodiment 1, a manufacturing process of urban rail transit switch point rails, 60D40 point rail parts realization measures and process steps: numbering→sawing→press forming section→straightening→marking→milling Forming section rail bottom→grinding, flaw detection→numbering→sawing→hole numbering→drilling→straightening→milling working side rail limbs→milling working side rail limbs R5 arc→milling non-working side rail limbs→milling non-working side Rail leg R5 arc → milling bendable section → milling rail head working side → milling rail head non-working side → milling rail waist bolt groove → milling rail top reduction value → milling rail top length 1:40 oblique → both sides of rail leg Planing the meat → planing the meat on both sides of the rail head → planing the top surface of the formed section rail → flaw detection → quenching → fine adjustment → grinding and derusting the rail body, rail waist, and rail top surface → assembly. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com