Pipe-in-pipe structure convenient for optical cable laying and replacing and laying method

An optical cable laying and pipe-in-pipe technology, which is applied in the field of pipe-in-pipe structure, can solve the problems of long construction period, large lost labor costs, and the quality of optical fiber communication is easily affected by the outside world, and achieves the effect of improving transmission efficiency and increasing benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

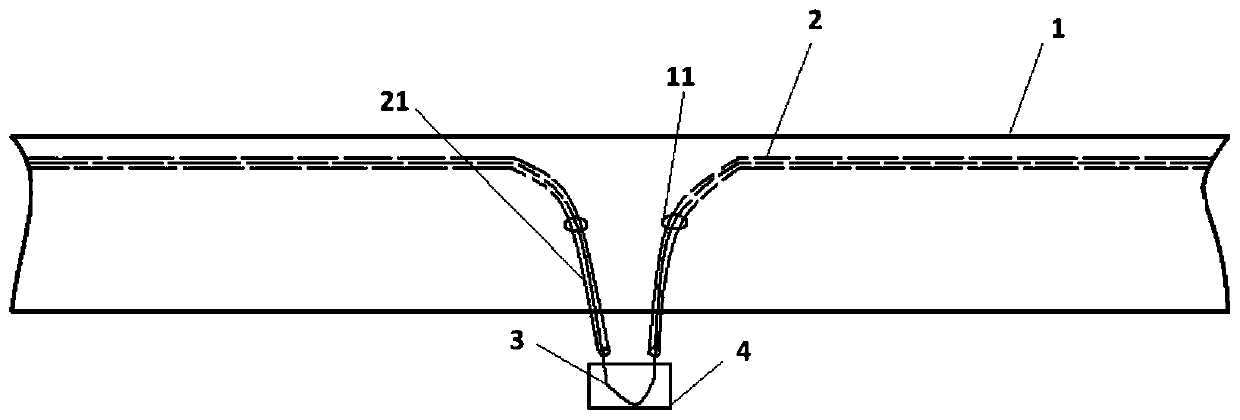

[0030] Such as figure 1 As shown, a pipe-in-pipe structure of the present embodiment that facilitates the replacement of faulty optical cables without pipeline failure includes a transport pipeline 1 and an optical cable channel formed by microtubes 2. The optical cable channel includes several sections, and each section It includes a main body and lead-out sections 21 at both ends. The main body is located on the inner wall of the conveying pipeline 1. The lead-out sections at both ends pass through the lead-out holes 11 on the conveying pipeline 1 and lead out of the conveying pipeline 1. The optical cable 3 is laid on the micro-section of each section. In the optical cable channel formed by the tube, and both ends protrude outside the lead-out section 21, they are fused with the optical fiber in the optical cable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com