Traction running mechanism for climbing girder crane

A technology of traveling mechanism and crane, which is applied in the direction of traveling mechanism, clockwork mechanism, erecting/assembling bridges, etc., and can solve problems such as car slipping, rail climbing, wheel slipping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

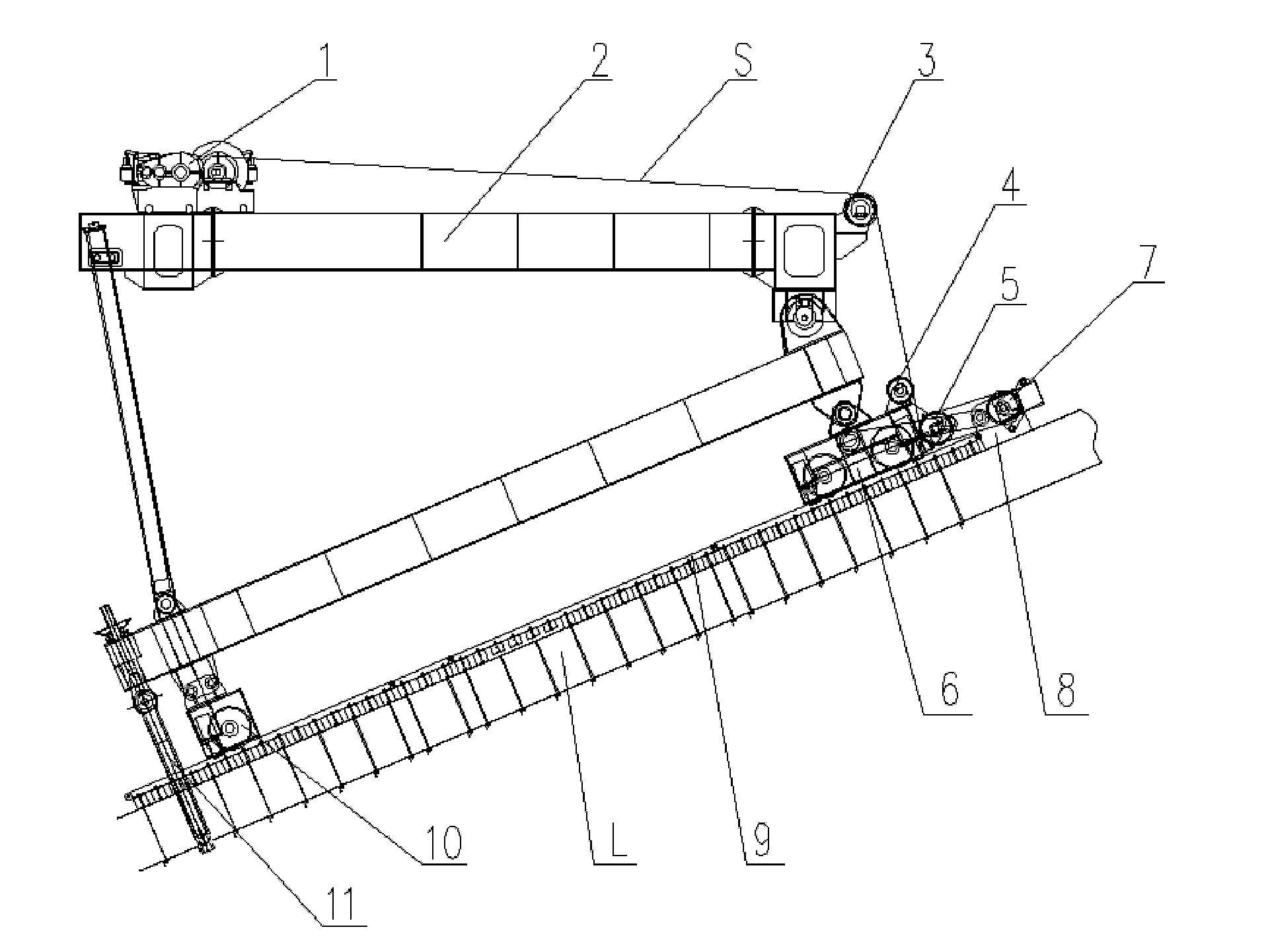

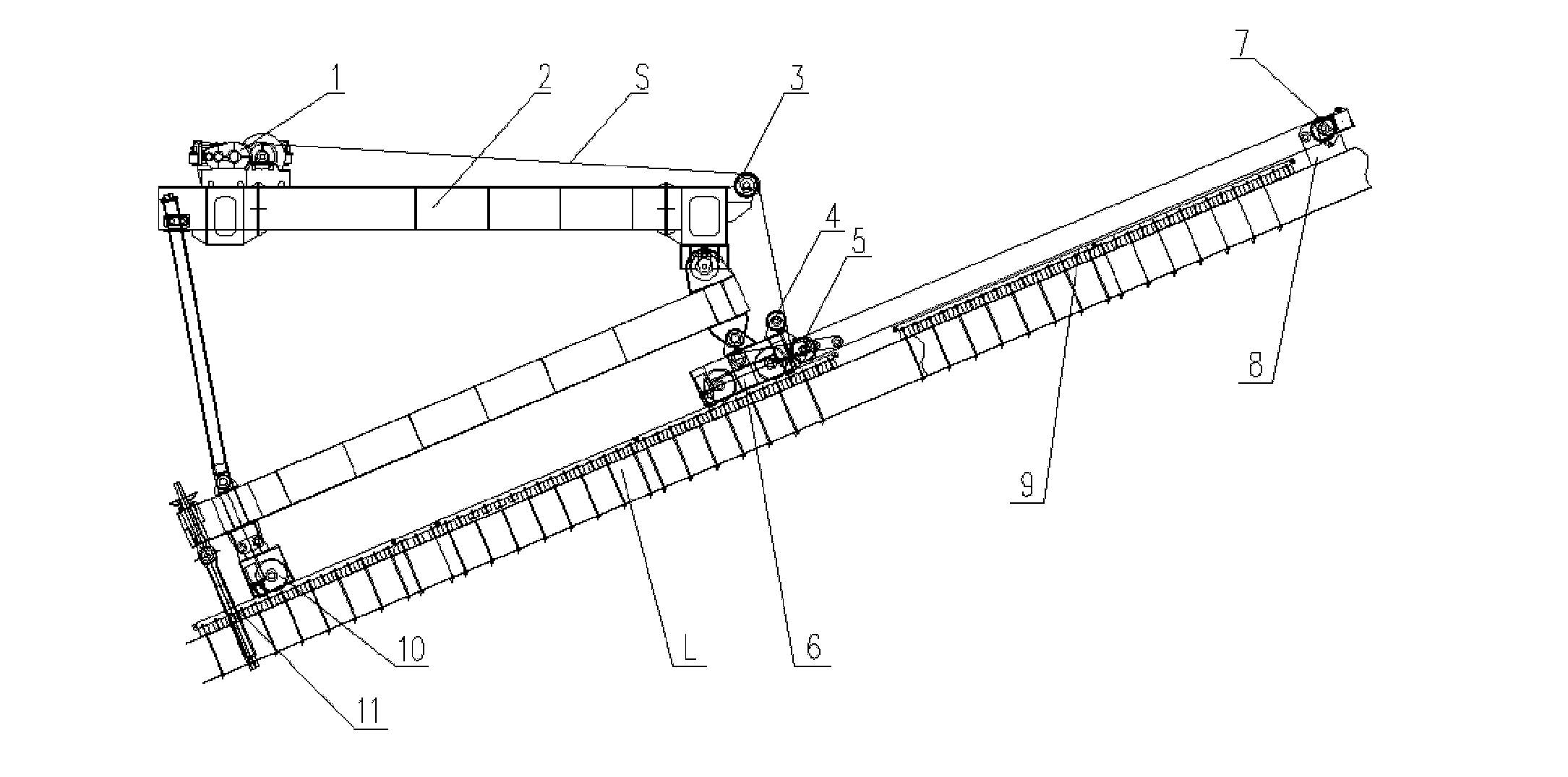

[0016] The crane traction running mechanism includes a traction winch, a front traveling trolley, a rear traveling trolley, a front anchoring mechanism, a rear anchoring mechanism, a traveling track and a wire rope-pulley block.

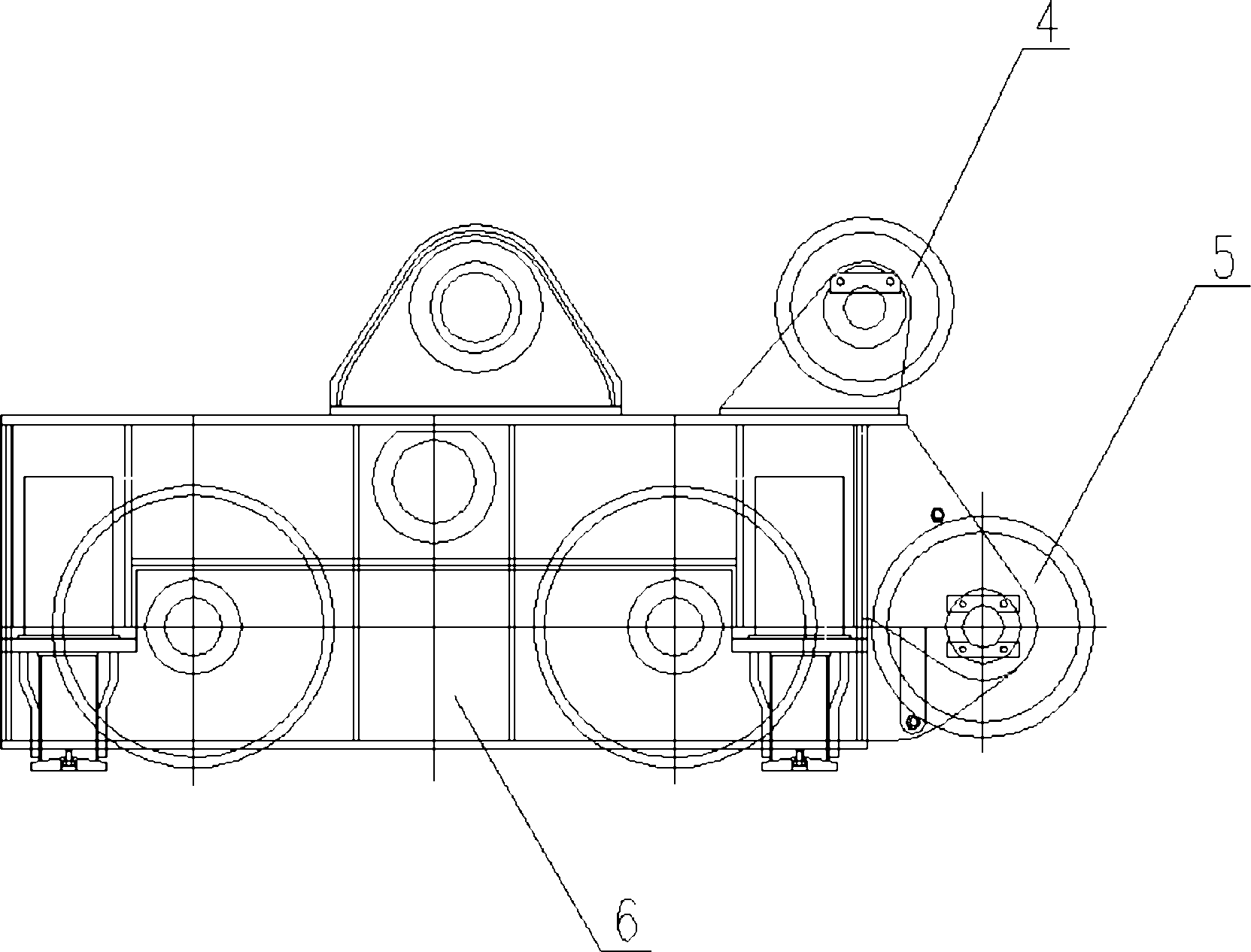

[0017] Such as figure 1 As shown, the traction hoist 1 is fixed on the upper chassis 2 of the crane through screw connection. The upper steering pulley 3 is welded to the front end of the upper chassis 2, the lower steering pulley 4 is welded to the front end of the table top of the front trolley 6, the traction pulley block 5 is welded to the front end of the front trolley 6, and the fixed pulley block 7 is installed on the steel box girder On the front anchor mechanism 8 of L.

[0018] Such as figure 2 As shown, before the hoisting of one section of steel girder is completed and the next section of steel girder is hoisted, the front an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com