Manufacturing method of hook body of large hook for polar region drilling machine

A manufacturing method and technology of a manufacturing method, applied in the direction of manufacturing tools, drill pipes, drill pipes, etc., can solve the problems of affecting quality, poor reliability, and failure to reach, and achieve the effect of economy, simplicity, and improvement of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present invention 1: the manufacture method of the large hook hook body of the 3000-meter polar drilling rig adopts the following manufacture method:

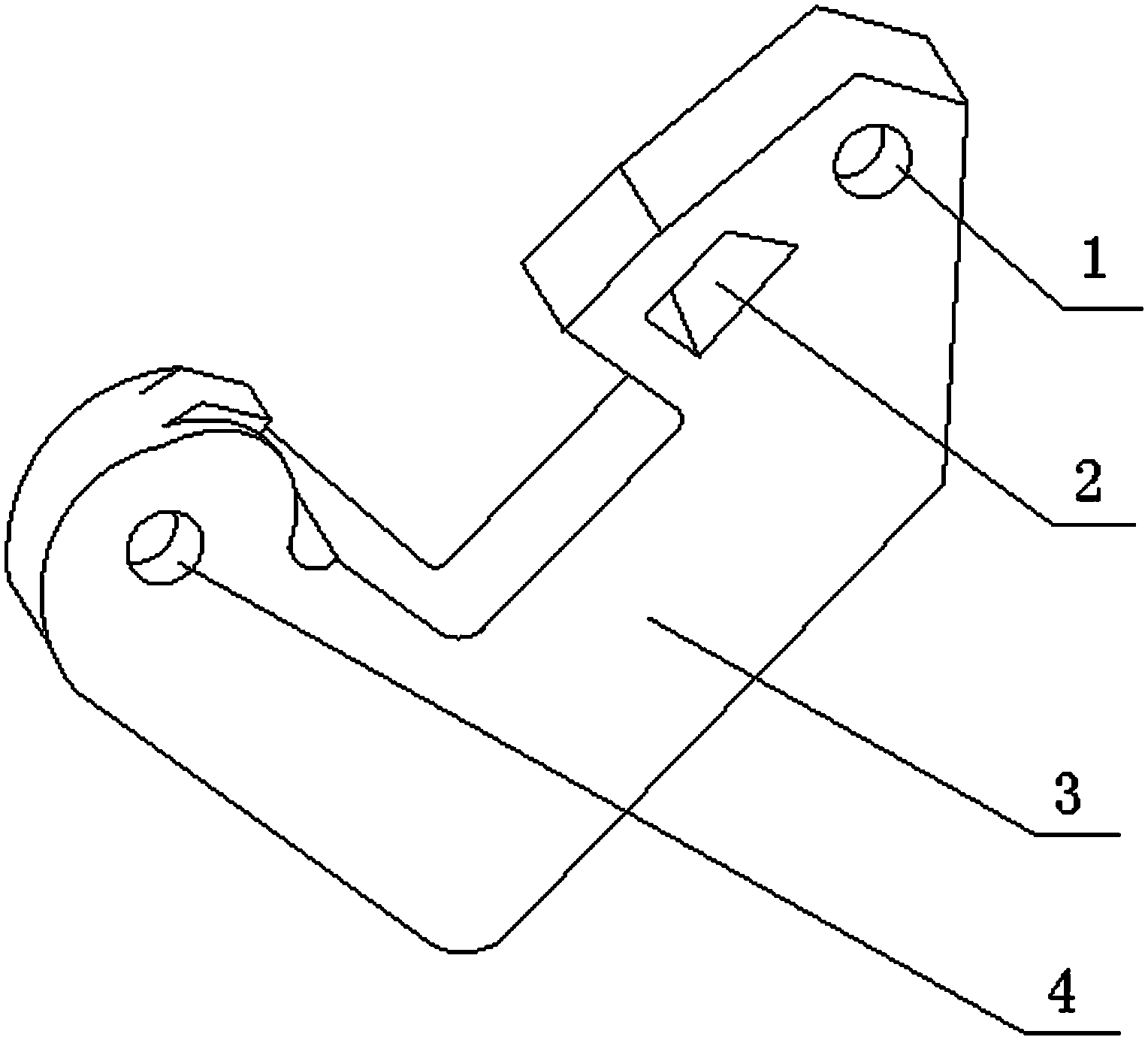

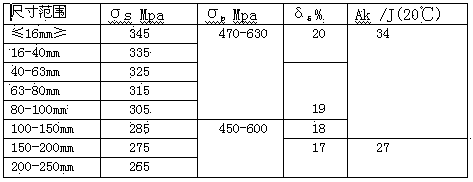

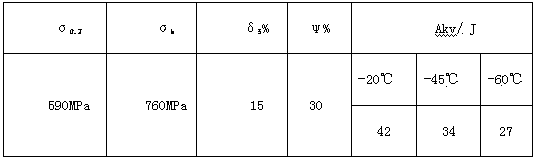

[0035] ①.Description of design blanking: rated load 2250KN, minimum service temperature -60℃, after design calculation, the shape is shown in figure 1 , plate thickness 160mm, inner diameter of hook body pin hole 100mm, auxiliary hook square pin hole 100×180mm, safety factor 2.80, material 35CrMoA, mechanical performance requirements: σ 0.2 ≥590MPa, σ b ≥780MPa, δ 5 ≥15%, ψ≥30%, Akv (-20°C) ≥42J, Akv (-60°C) ≥27J, conduct magnetic particle inspection and ultrasonic flaw detection according to API Specification 8C.

[0036] ②. Forging process: blanking, Ф500mm 35CrMoA round steel, length 1000mm. Oil furnace heating is adopted, and the furnace loading temperature is lower than 600°C. The heating temperature and time must not only ensure that the forgings do not overheat or overburn, but also ensure the deformation ...

Embodiment 2

[0045] The present invention 2: the manufacture method of the big hook hook body of 2000 meters polar drilling rig, adopts following manufacture method:

[0046] ①.Description of design blanking: the rated load is 1350KN, the minimum service temperature is -60℃, after design calculation, the shape is shown in figure 1, plate thickness 140mm, inner diameter of hook body pin hole 90mm, auxiliary hook square pin hole 80Χ160mm, safety factor 3.0, material 35CrMoA, mechanical performance requirements: σ 0.2 ≥590MPa, σ b ≥780MPa, δ 5 ≥15%, ψ≥30%, Akv (-20°C) ≥42J, Akv (-60°C) ≥27J, conduct magnetic particle inspection and ultrasonic flaw detection according to API Specification 8C.

[0047] ②. Forging process: blanking, Ф450mm 35CrMoA round steel, length 985mm. Oil furnace heating is adopted, and the furnace loading temperature is lower than 600°C. The heating temperature and time must not only ensure that the forgings do not overheat or overburn, but also ensure the deformation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com