Concrete block regeneration aggregate processing vehicle

A technology for recycling aggregates and concrete blocks, which is applied in the direction of roads, road repair, roads, etc., to save costs, improve work efficiency, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

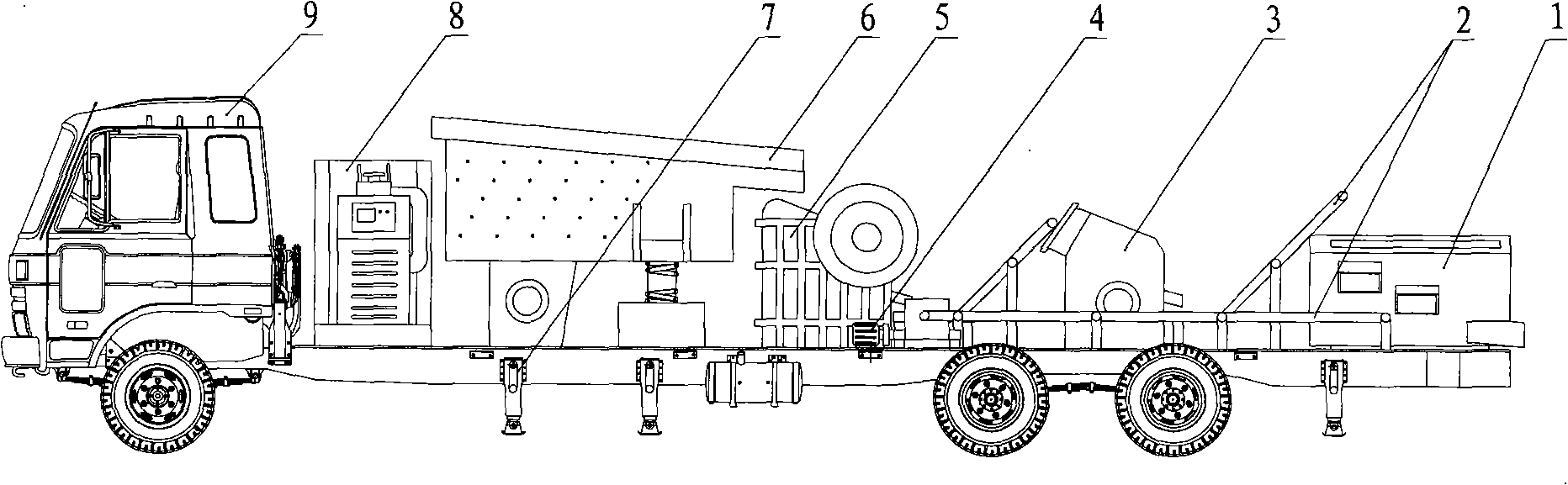

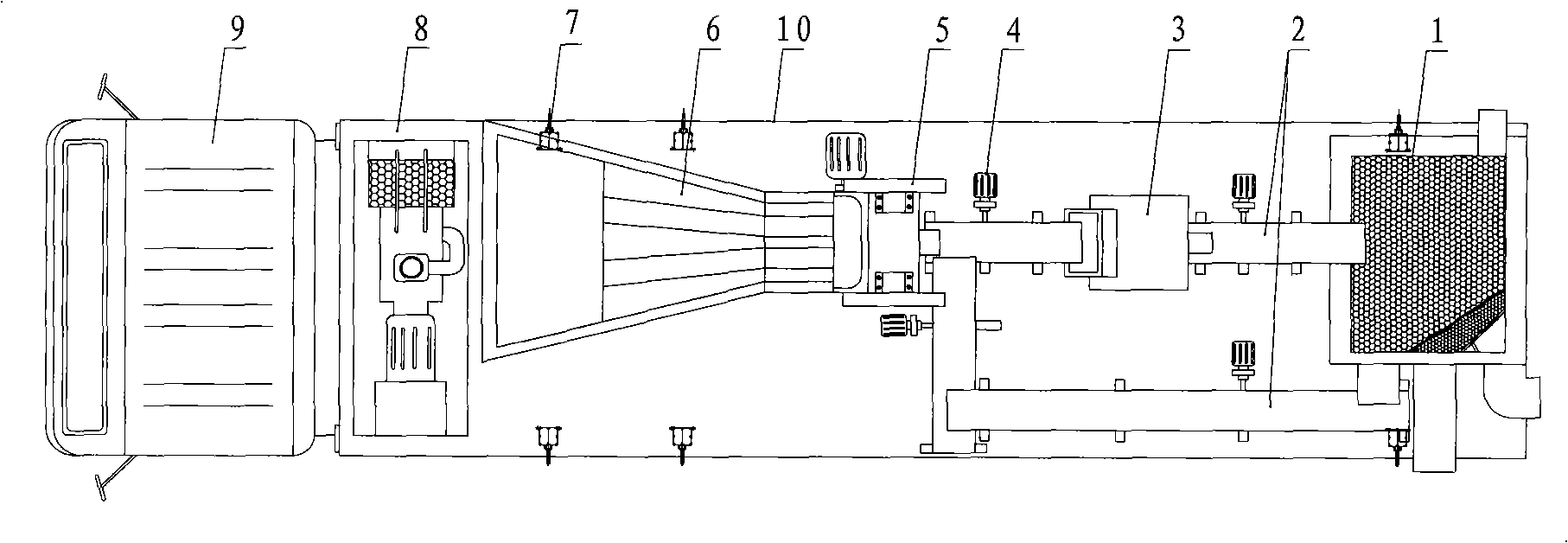

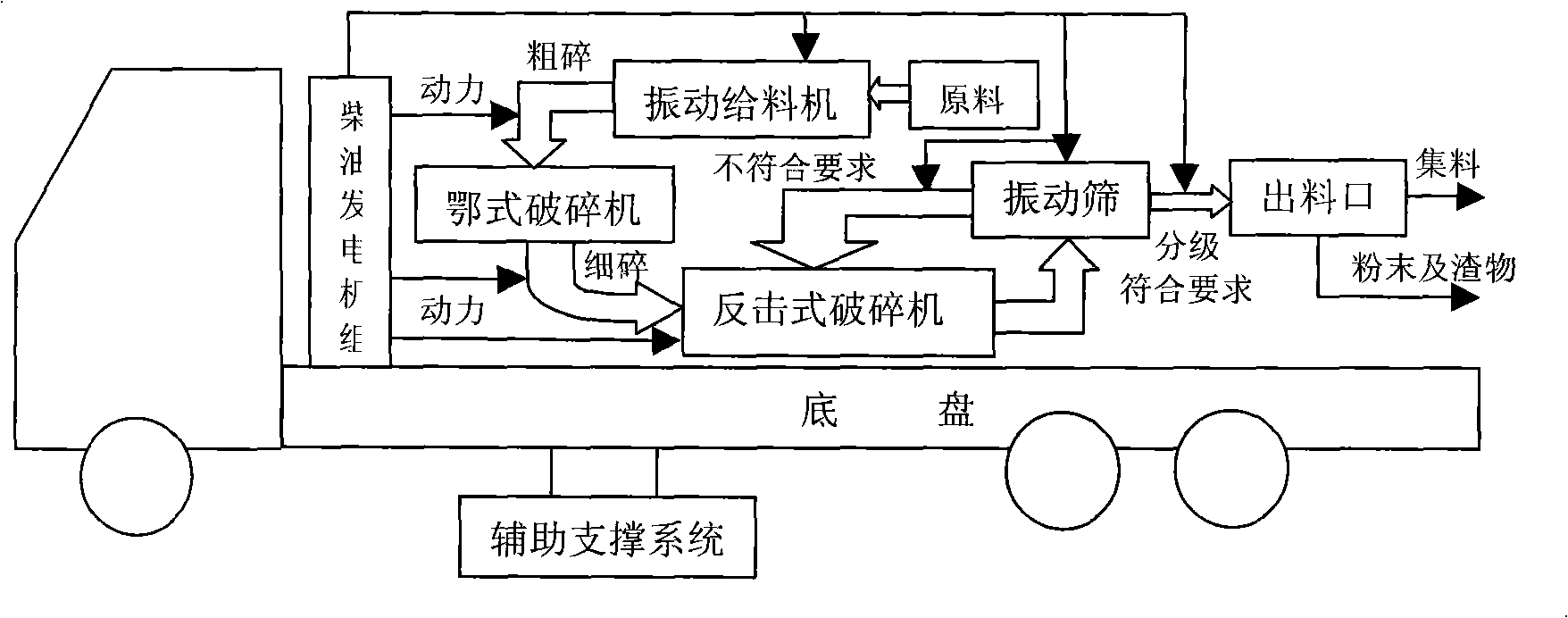

[0018] The concrete block recycled aggregate processing vehicle provided by the invention has a structure such as figure 1 with figure 2 Shown: including the main body of the vehicle; on the vehicle frame 10 of the chassis, according to the production flow line of the stone processing plant, there are integrated arrangements for processing and producing concrete mixed waste or other equipment to send the waste concrete mixture into the silo, and then The vibrating feeder 6 evenly sends the jaw crusher 5 to the final equipment. The production and processing system is powered by a diesel generator set 8 arranged between the cab 9 and the vibrating feeder 6; the production process line includes feeding, vibrating feeding, jaw crushing, impact crushing, vibrating Sieve and discharge.

[0019] The equipment is provided with a vibrating feeder 6, a jaw crusher 5, an impact crusher 3, a vibrating screen 1, a belt conveyor 2 and a motor 4, all of which can be purchased from the mar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com