Front frame of refrigerated container

A technology of refrigerated container and front frame, which is applied in the direction of packaging, transportation and packaging, and transportation of passenger cars. The effect of refueling frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

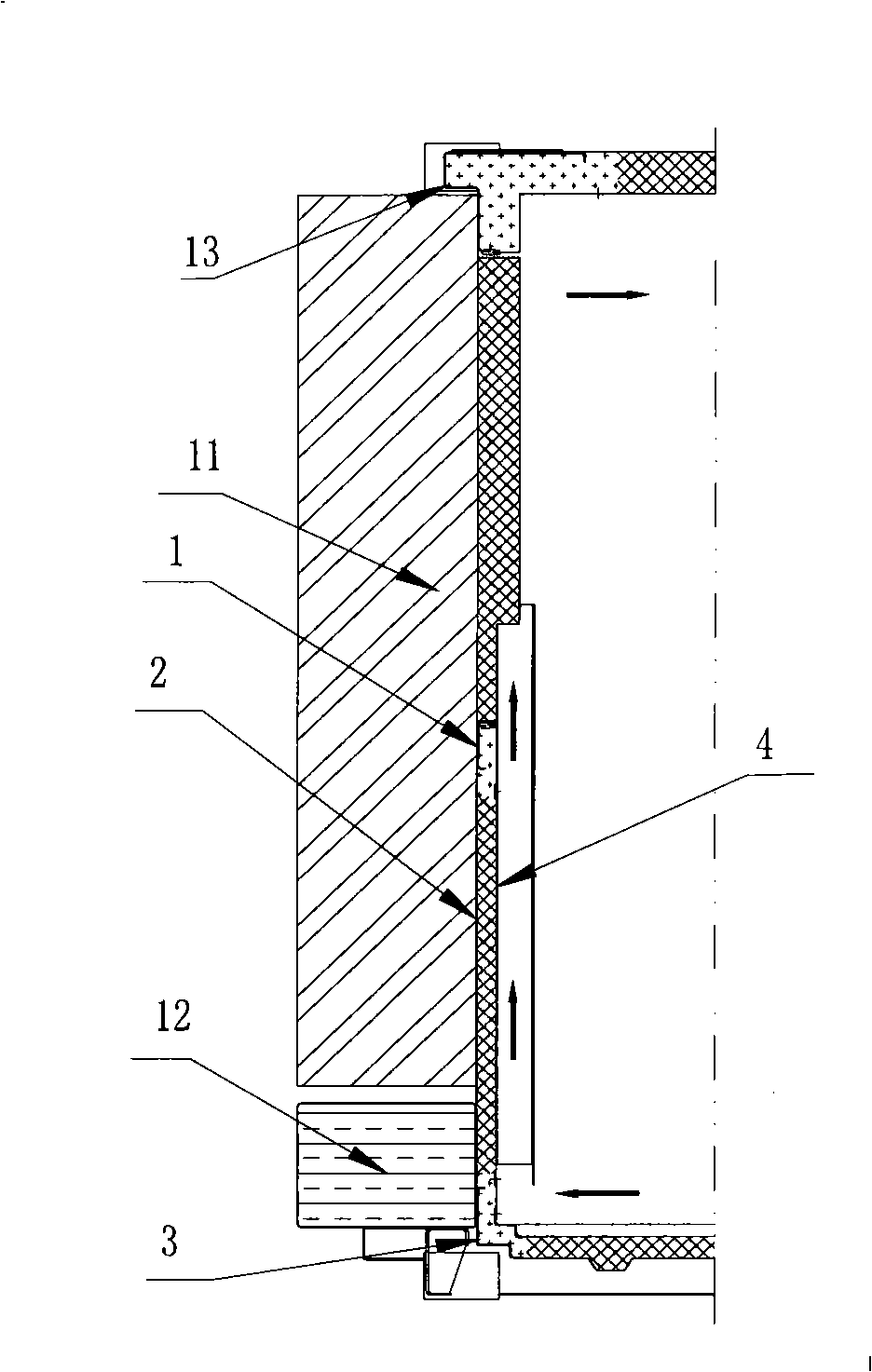

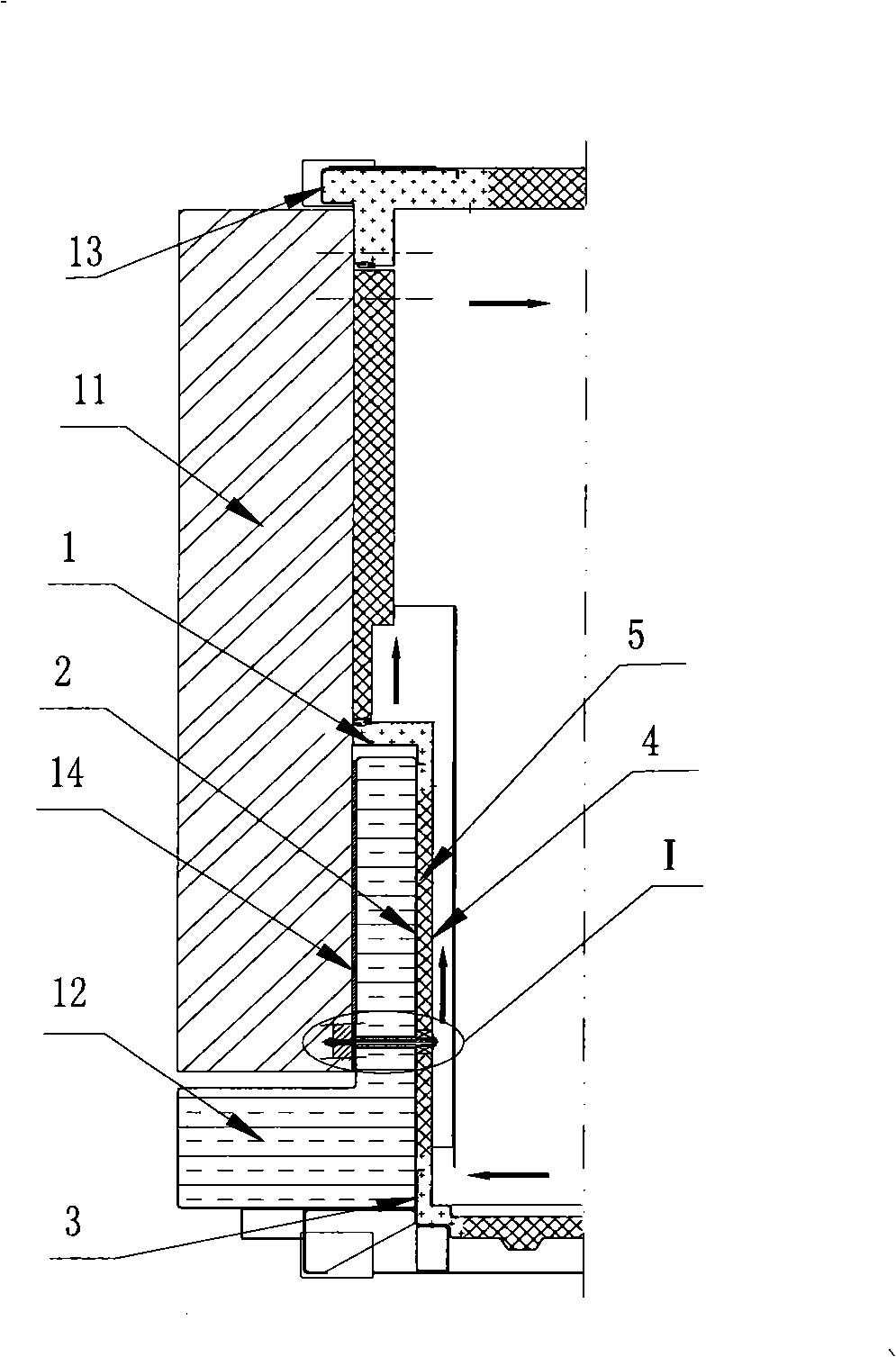

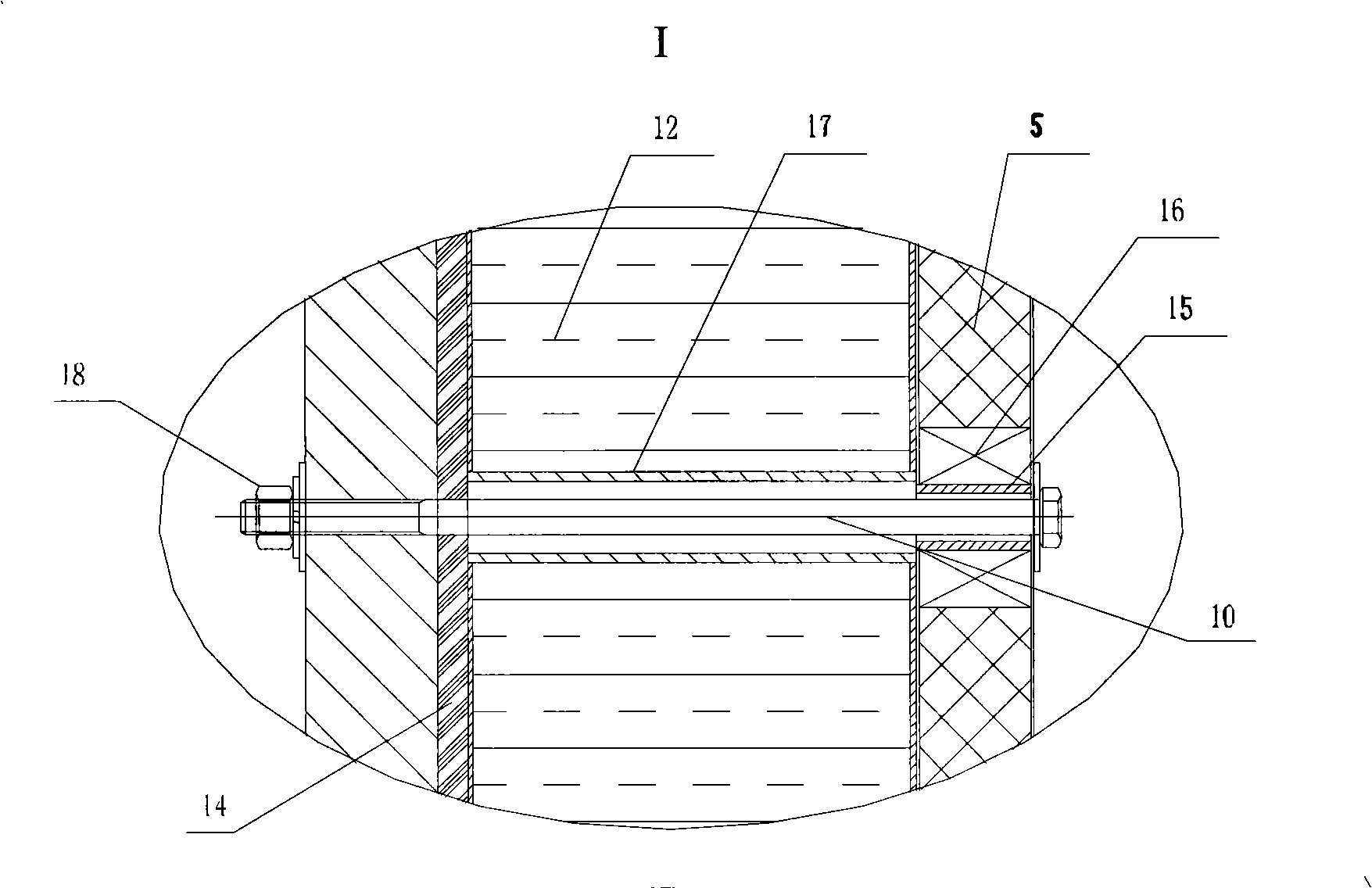

[0015] Such as figure 2 , 3 As shown, a refrigerated container front frame includes a front upper beam 13, a middle beam 1, a front lower beam 3, the three of which are connected by the front wall outer panel 2, the front wall inner panel 4, and become a whole. An insulation layer 5 is provided between the plates 2, 4, and the inner and outer plates 2, 4 of the front wall are divided into upper and lower parts by the middle beam 1. The middle beam 1 is a special-shaped beam bent inward, and its cross section is Shape, a cavity is formed between the middle beam 1, the lower part of the cooler 11 and the outer panel 2 of the front wall, and the fuel tank 12 is The vertical part of the upper part of the oil tank 12 is set in the cavity between the middle beam 1, the cooler 11, and the outer panel 2 of the front wall. The lower part of the cooler 11 is fixed to the inner and outer panels of the front wall by a fixing member that crosses the fuel tank. On 2, 4, there are two fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com