Cylinder inner wall network oil storage structure manufacturing method

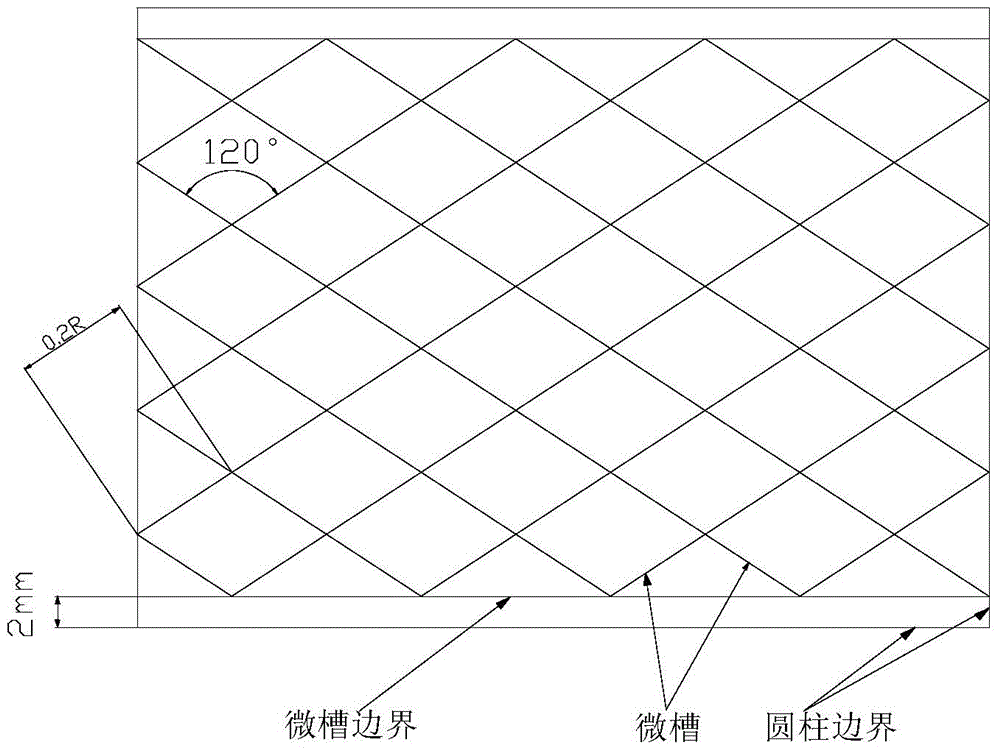

A network and cylinder technology, which is applied in the field of preparing the network oil storage structure on the inner wall of the cylinder, can solve problems such as insufficient wear resistance, and achieve the effects of increasing fluidity, improving wear resistance and reducing inner wall corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for preparing a cylindrical inner wall network oil storage structure, comprising the following steps:

[0018] Step 1), prepare the quasi-alloying solution first, so that the weight percentage ratio of the quasi-alloying coating is: 15% Al 2 o 3 , 16% ZrO 2 , 55% Ni, 10% Cr, 1% B, 1% Si, 2% CeO 2 ; Then prepare the alloying solution, so that the weight percentage ratio of the alloying solution is: 20% alloying coating corresponds to 80% acetone;

[0019] Step 2), and then carry out the pre-alloying coating, using the immersion pre-setting method, the prefabricated thickness is 0.32mm, that is, the cylindrical workpiece is completely immersed in the alloying solution for 30 minutes, and the post-mounting is put on the chuck for rotation at a speed of 10 rpm / min, rotate at a constant speed for 20min, the thickness of a single layer is 0.15mm, the thickness of two layers is 0.25mm, and the thickness of three layers reaches 0.32mm;

[0020] Step 3), then make ...

Embodiment 2

[0025] A method for preparing a cylindrical inner wall network oil storage structure, comprising the following steps:

[0026] Step 1), prepare the quasi-alloying solution first, so that the weight percentage ratio of the quasi-alloying coating is: 9% Al 2 o 3 , 11% ZrO 2 , 58% Ni, 12% Cr, 3% B, 2% Si, 5% CeO 2 ; Then prepare the alloying solution, so that the weight percentage ratio of the alloying solution is: 20% alloying coating corresponds to 80% acetone;

[0027] Step 2), and then carry out pre-alloying coating, using the immersion pre-setting method, that is, immersing the cylindrical workpiece in the alloying solution for 50 minutes, and then putting it on the chuck for rotation after being raised, at a speed of 12 rpm, and rotating at a constant speed 40min, the thickness of a single layer is 0.17mm, the thickness of two layers is 0.28mm, and the thickness of three layers reaches 0.34mm;

[0028] Step 3), then make the inner wall of the cylinder laser alloyed, the...

Embodiment 3

[0033] A method for preparing a cylindrical inner wall network oil storage structure, comprising the following steps:

[0034] Step 1), prepare the quasi-alloying solution first, so that the weight percentage ratio of the quasi-alloying coating is: 6% Al 2 o 3 , 8% ZrO 2 , 65% Ni, 13% Cr, 2% B, 2% Si, 4% CeO 2 ; Then prepare the alloying solution, so that the weight percentage ratio of the alloying solution is: 20% alloying coating corresponds to 80% acetone;

[0035] Step 2), and then carry out pre-alloying coating, using the immersion pre-setting method, that is, immerse the cylindrical workpiece in the alloying solution for 80 minutes, put it out and put it on the chuck for rotation, the speed is 10 rpm, and rotate at a constant speed 20 minutes, the thickness of a single layer is 0.15mm, the thickness of two layers is 0.25mm, and the thickness of three layers reaches 0.32mm;

[0036] Step 3), then make the inner wall of the cylinder laser surface alloyed, the laser pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com