Oil tank-containing track frame of continuous miner

A technology for a crawler frame and a shearer, which is applied to crawler vehicles, motor vehicles, substructures, etc., can solve the problems of insufficient oil, increased volume of continuous shearers, and increased oil storage capacity of continuous shearers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

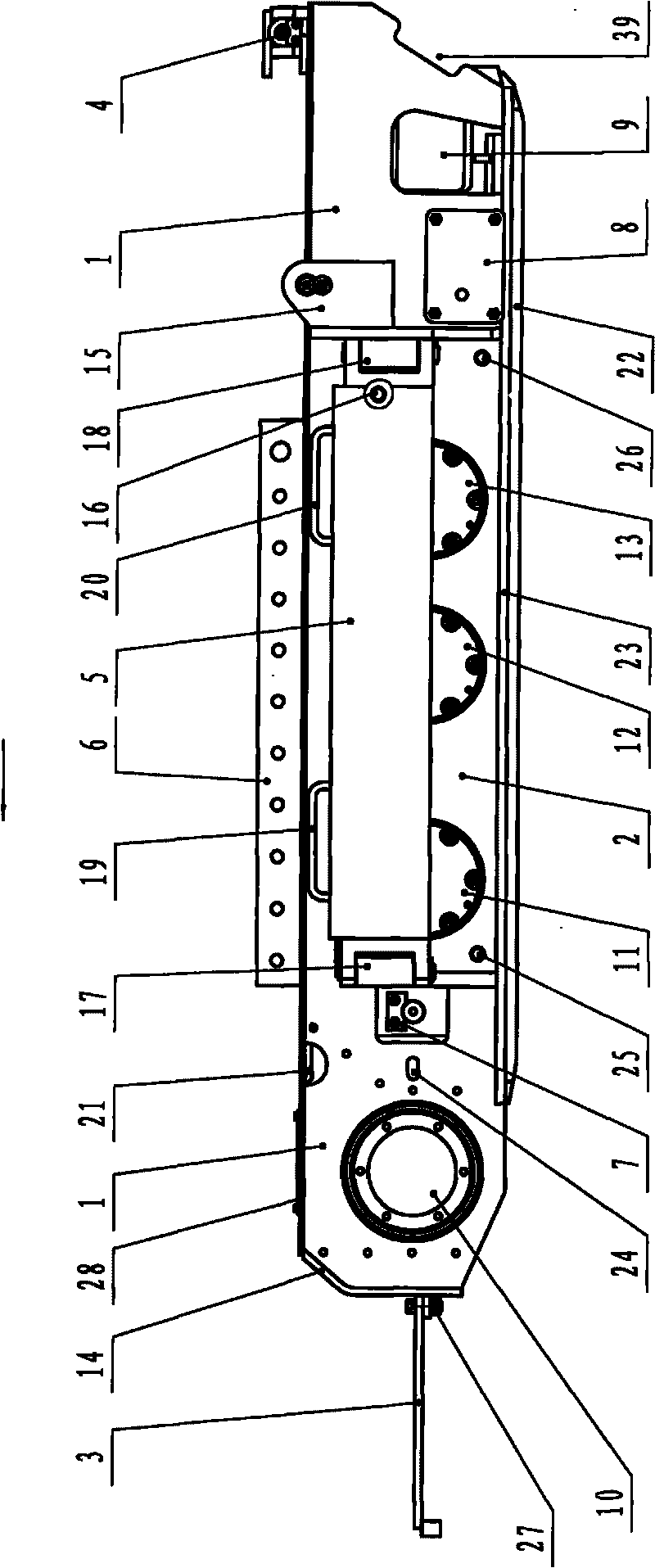

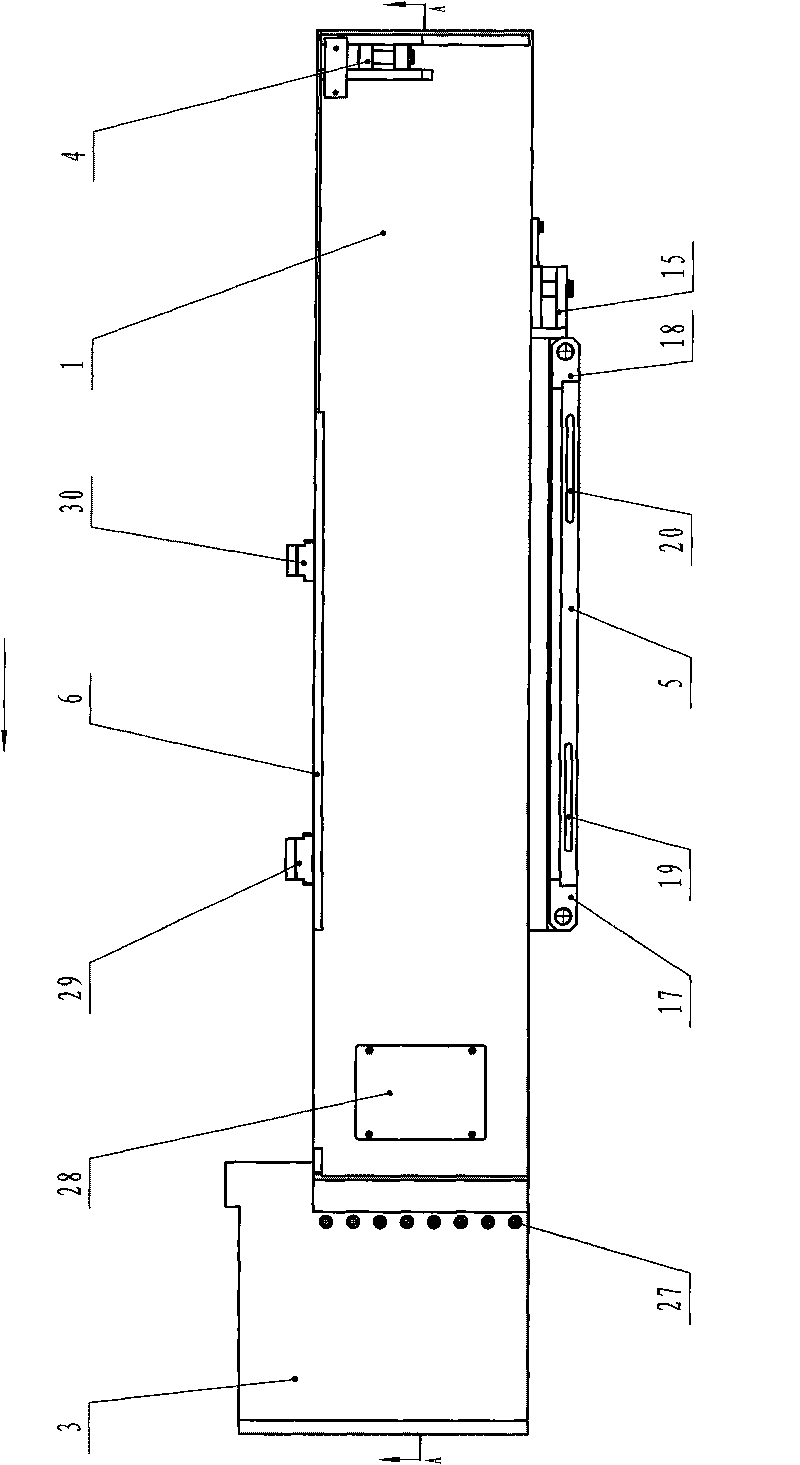

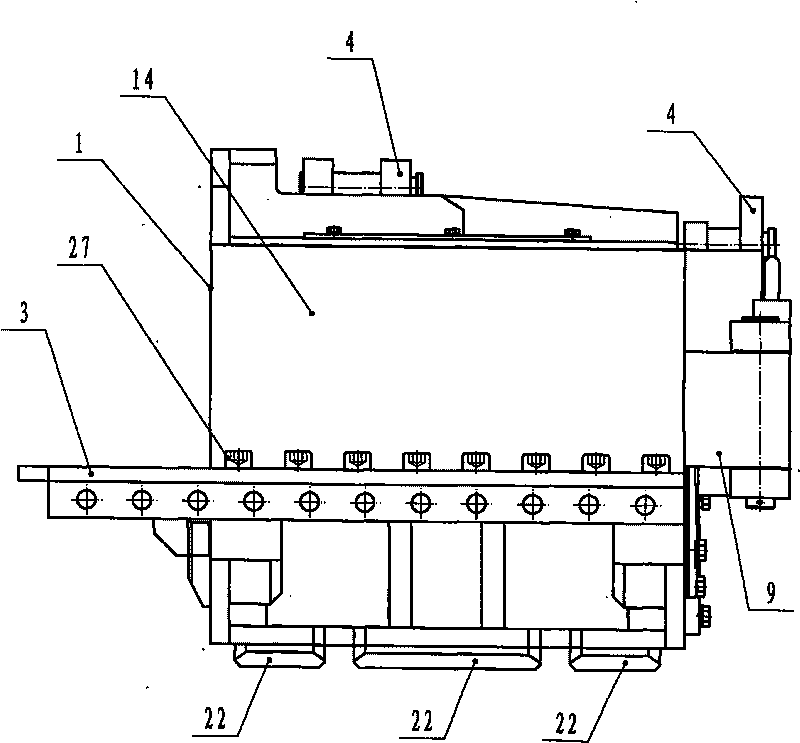

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] figure 1 , 2 , 3, and 4 show the overall structure diagram, and the position and connection relationship of each part must be correct, coordinated, and installed firmly.

[0021] The fuel tank is installed in the inner space of the track frame, and the outside is protected by the left, middle and right fuel tank caps, upper and lower anti-friction plates, left and right vertical guards, fuel tank top guards, and fuel tank bottom guards, forming a fully enclosed double-layer protection of up and down, left and right, so that the fuel tank Inside the track frame, it is safe, stable and reliable, and not affected by the bumps of walking. The process of oil storage and oil delivery is completed during the walking process, making full use of the space inside the track frame.

[0022] Figure 5 As shown, it is a three-dimensional view of the overall structure. It can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com