A silicone oil torsional vibration damper

A technology of torsional vibration damper and silicone oil, which is applied in the direction of shock absorbers, liquid shock absorbers, shock absorbers, etc., can solve the problems of high temperature rise of shock absorbers, easy hard contact, frictional heating, etc., and achieve The effect of increasing the axial clearance, increasing the oil storage capacity and prolonging the life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the description of the drawings and specific embodiments.

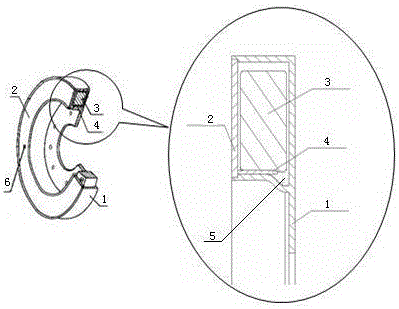

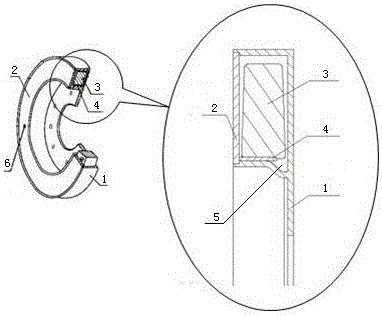

[0023] see figure 2 , a silicone oil torsional vibration damper, which includes a shell 1 and a side cover 2 matched with the shell 1, the shell 1 is formed by stamping steel plate (or processed after casting), the shell The body 1 is fixedly connected to the front end of the crankshaft of the engine. An annular groove is arranged on the end surface of one side of the housing 1, and the side cover 2 is covered at the opening of the annular groove. Welding technology welds the covered side cover 2 and the housing 1 to form an annular sealed chamber, the two longitudinal side walls of the annular sealed chamber are parallel, and in the annular sealed chamber, the bushing 4 is fixedly sleeved in the annular sealed chamber On the side wall of the inner ring (that is, the side wall of the inner ring of the annular groove), the iner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com