Component, provided with a thread

A thread and component technology, which is applied in the field of threaded components, can solve the problems of reducing thread engagement and load capacity, and achieves the effects of easy movement, simplified finishing process, and simple rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

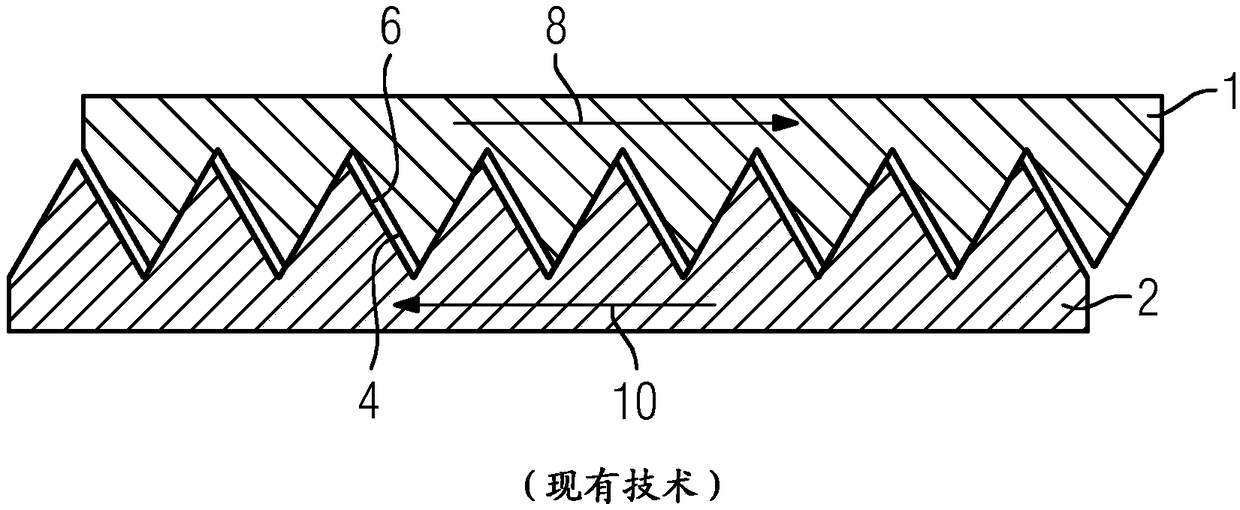

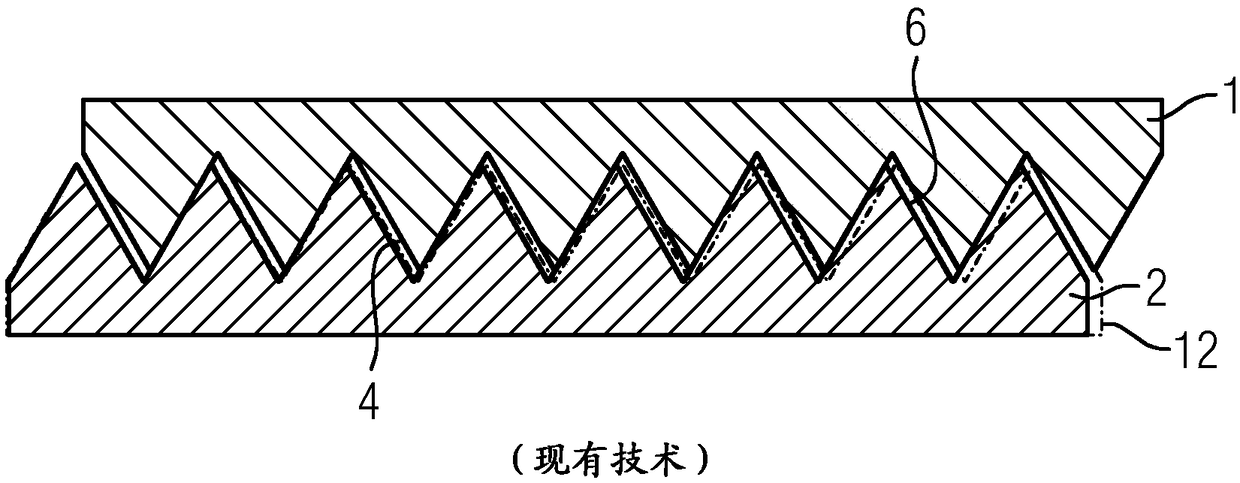

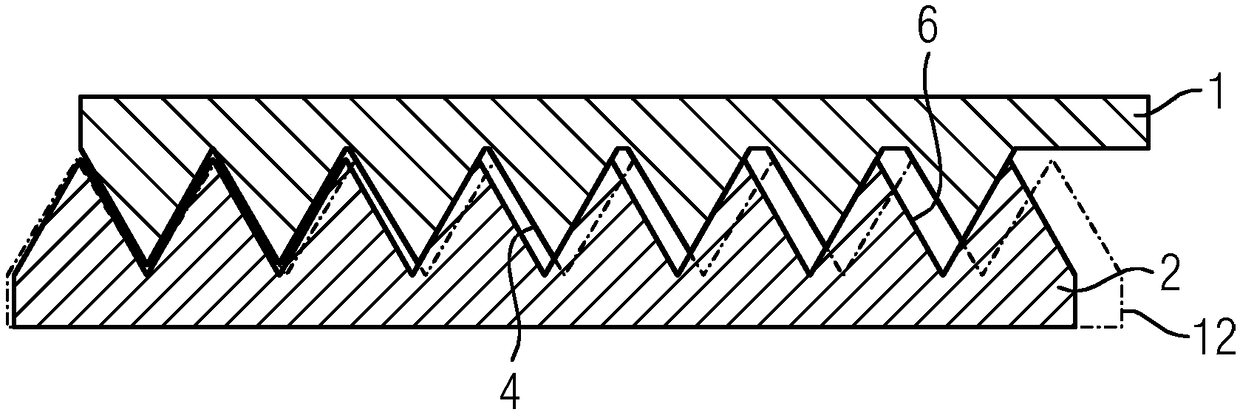

[0030] figure 1 A schematic partial longitudinal section through the upper part of the screw connection is shown. The profiles of two threaded fittings, namely nut 1 and bolt 2, are shown. The threads 4 and 6 of the nut 1 are configured as standard threads, ie according to metric ISO standard threads (DIN 13 and DIN 14), threads according to the unified thread standard (ANSI / ASME B1.1-2003), or Whitworth threads. In any case, in such threads 4 , 6 there is no definite situation of Δxmin provided. In contrast, the axial play Δxmin is produced only by the production-related tolerance range of the pitch circle diameter. Arrows 8, 10 indicate the direction of loading of the nut 1 and the bolt 2.

[0031] The nut 1 and bolt 2 described here are designed for particularly high loads. In an exemplary embodiment, the bolt 2 may be arranged, for example, at the end of a shaft of a gas turbine (not shown in more detail), so that it is coaxial with said shaft and can fix the shaft and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com