Patents

Literature

48results about How to "Simplify the finishing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

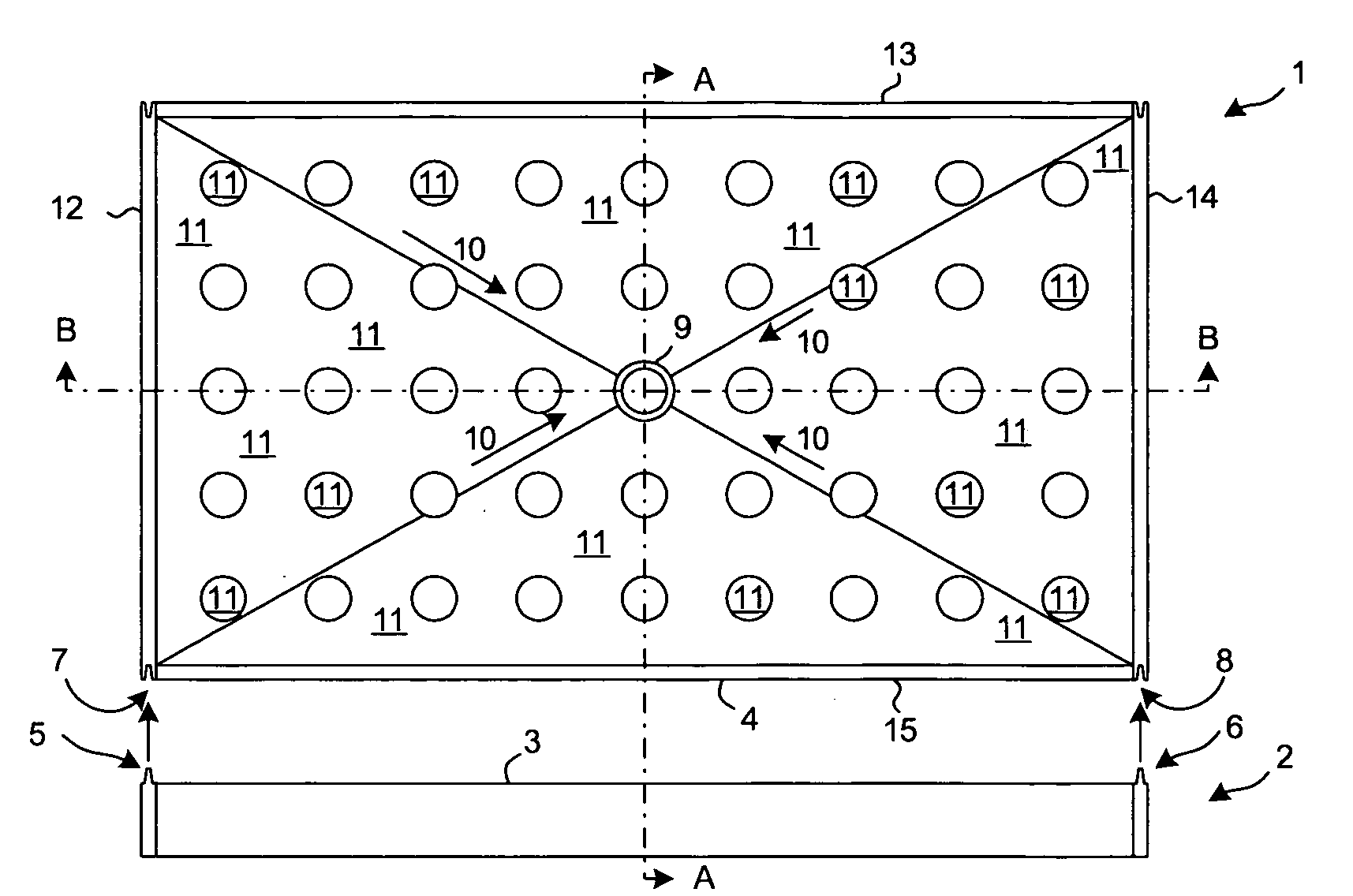

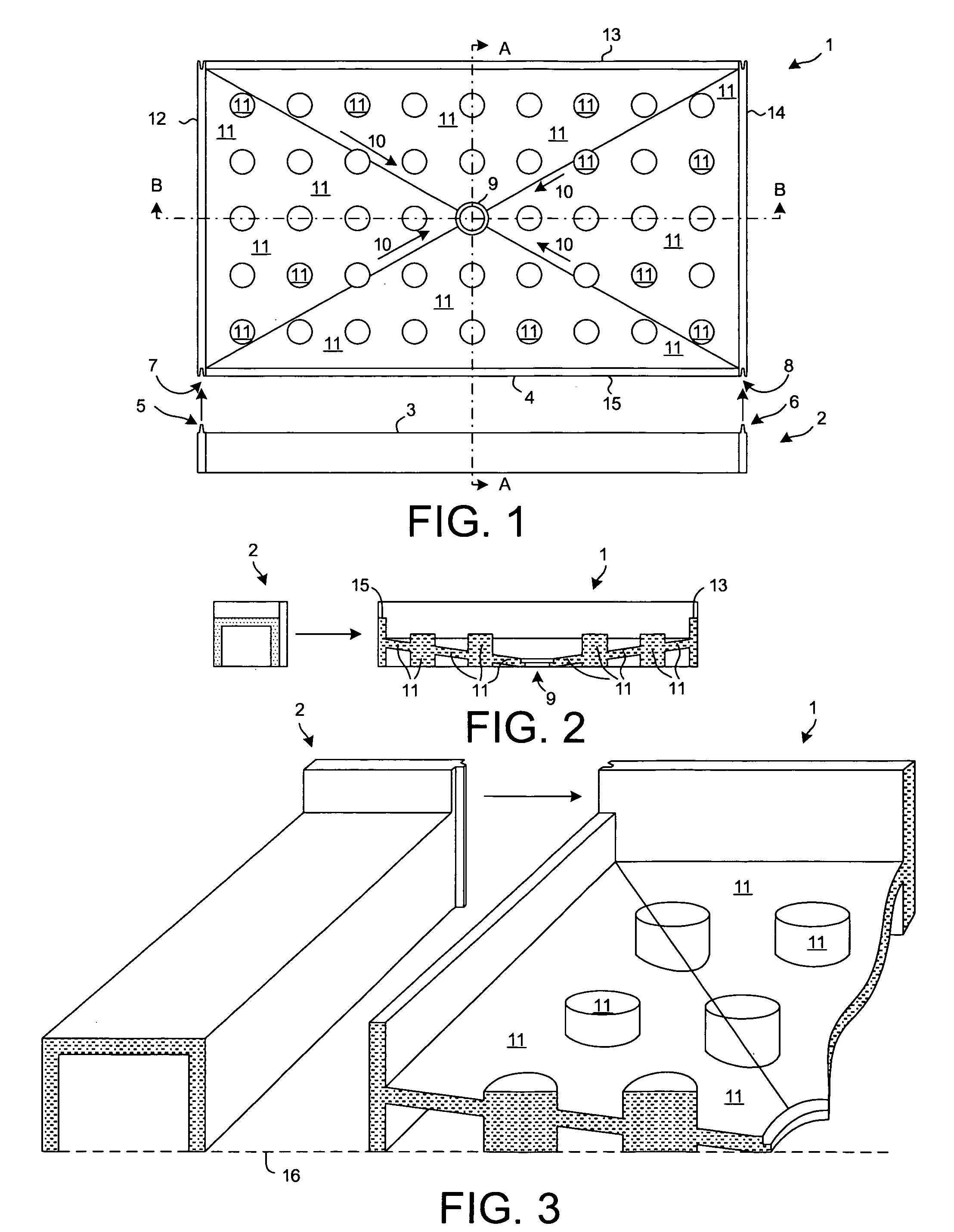

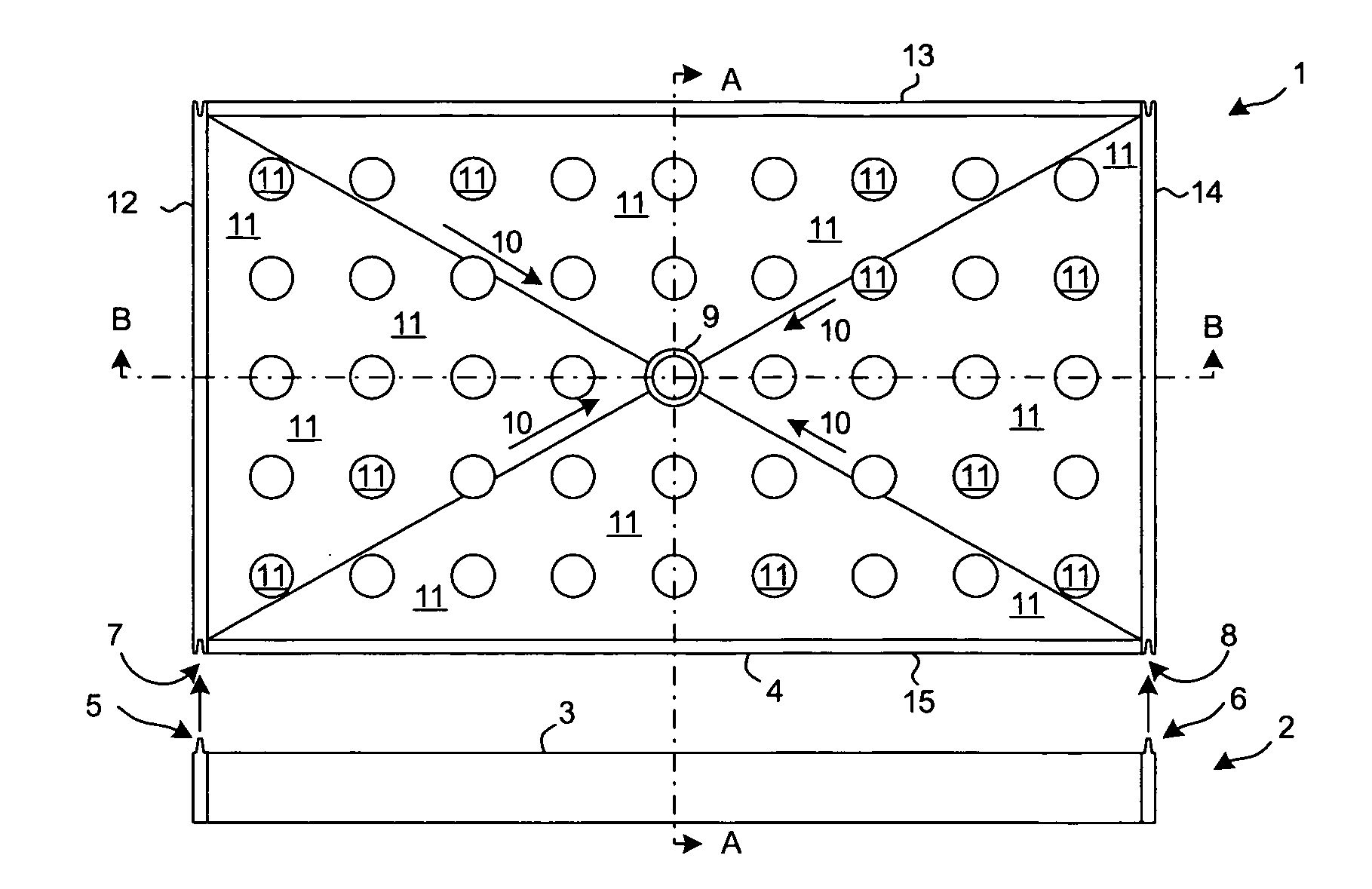

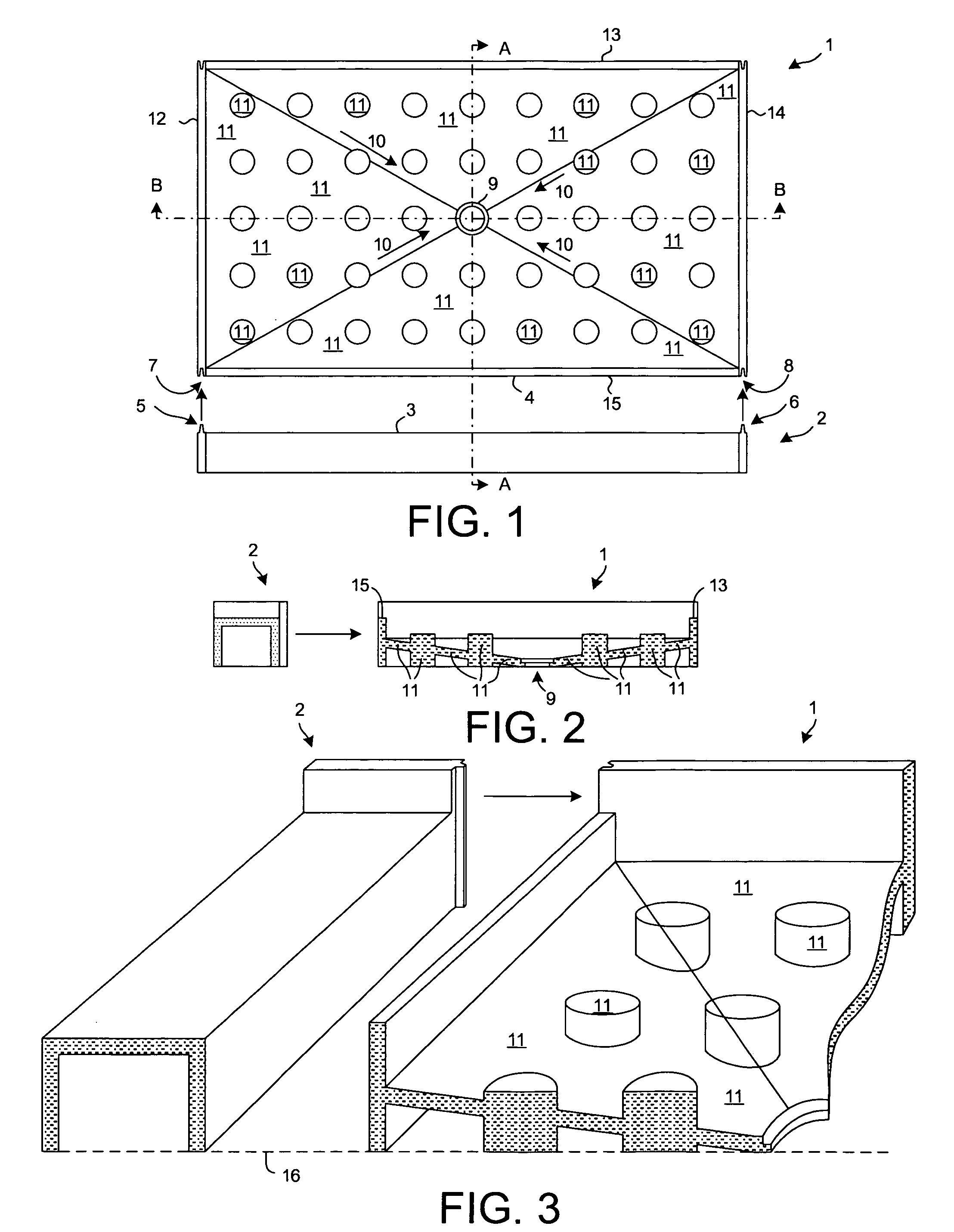

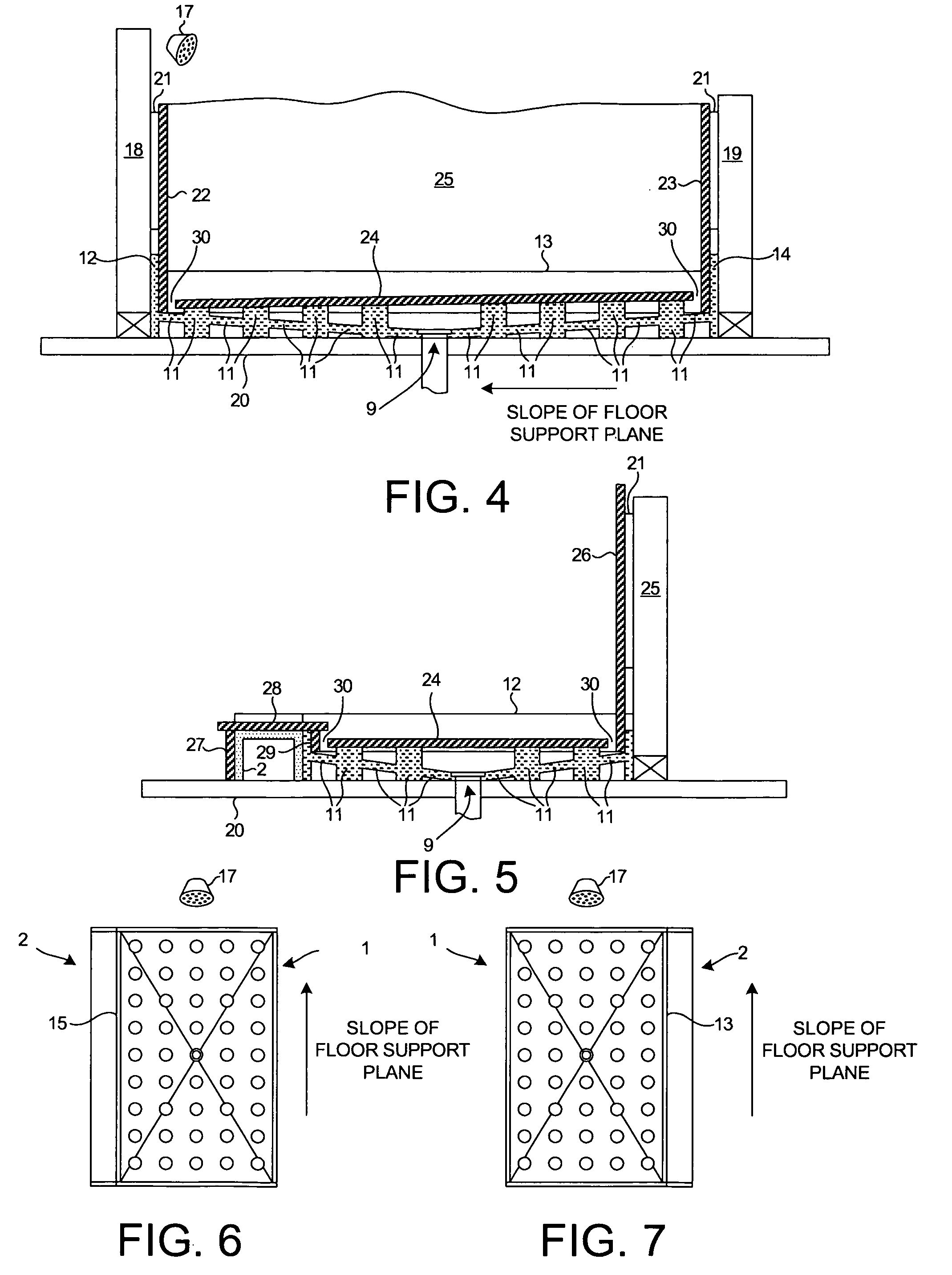

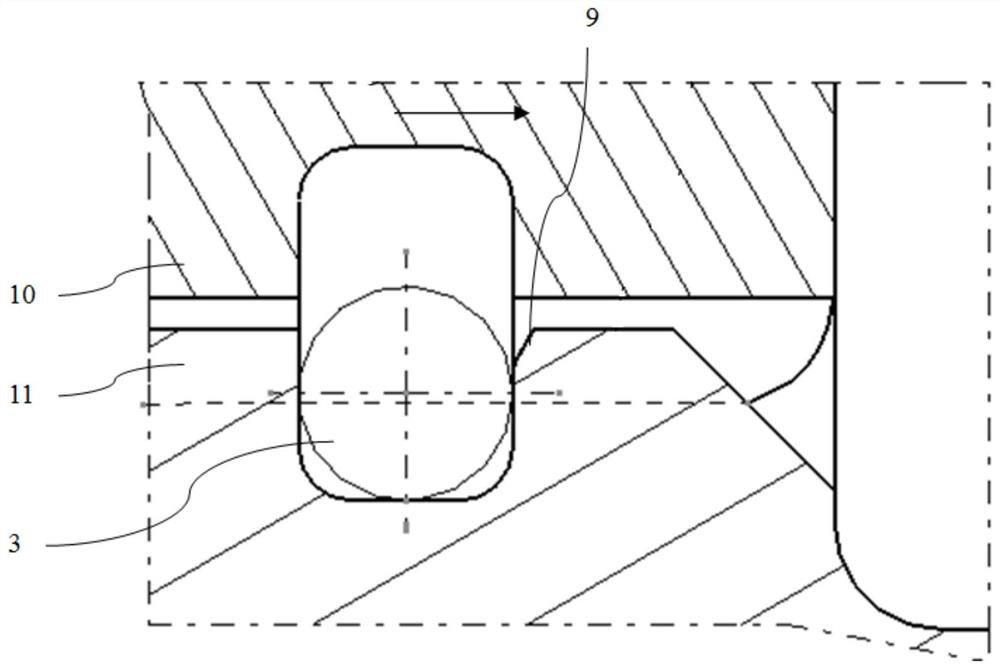

Infinity shower pan

InactiveUS20060236452A1Prevent slippingAvoid excessive movementBathsDouchesEngineeringEngineered stone

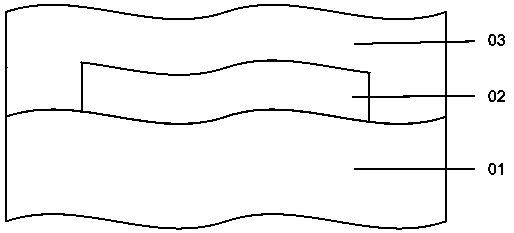

A shower pan includes a draining base portion that drains to an orifice. The draining base portion includes a support structure for supporting a slab floor member (for example, a single piece of granite, marble, or engineered stone) above the orifice such that a planar upper surface of the floor member has a slight tilt. The pan is installed such that the tilt is toward a shower head. The shower enclosure is finished by cladding the enclosure walls with a finishing material (for example, granite, marble or engineered stone) such that the finishing material extends down into the pan. The floor member is placed on the support structure such that water from the shower head that falls on the floor member runs off one or more edges of the floor member and is conducted to the orifice under the floor member by a draining portion of the draining base portion.

Owner:POLIMENO JOHN

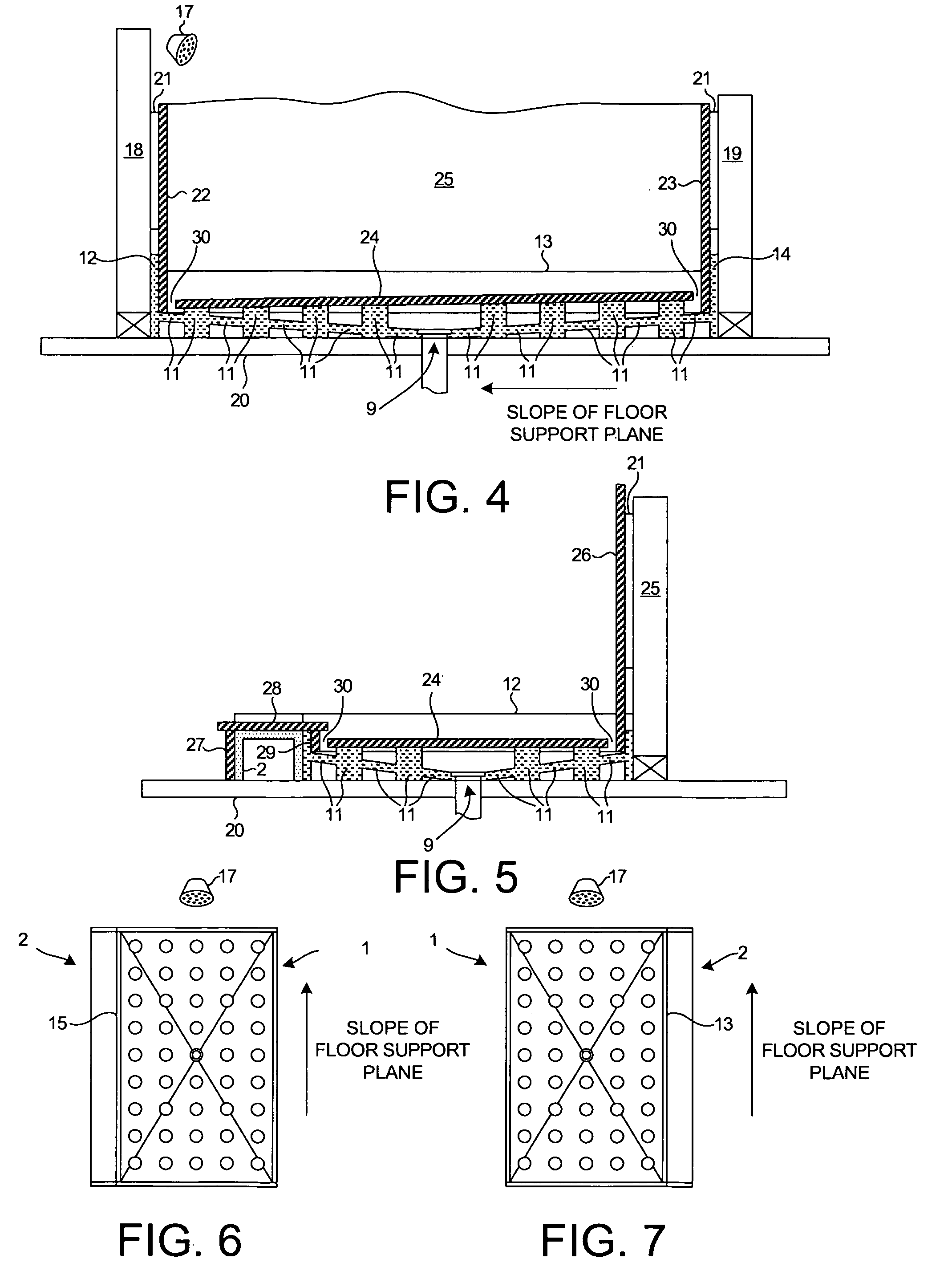

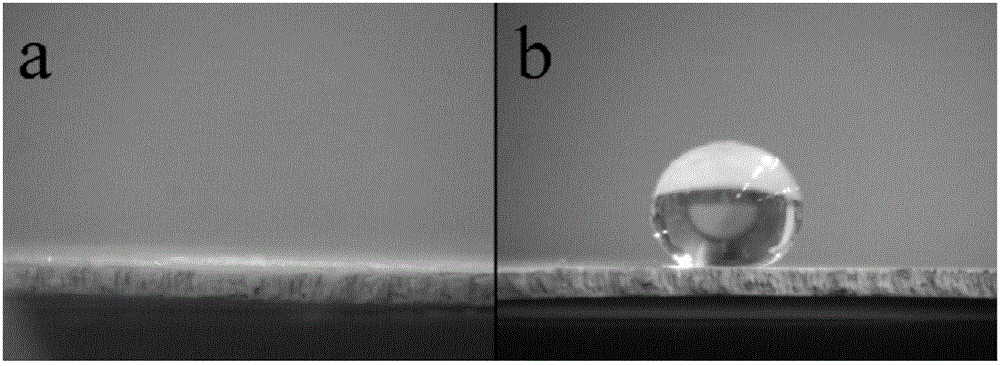

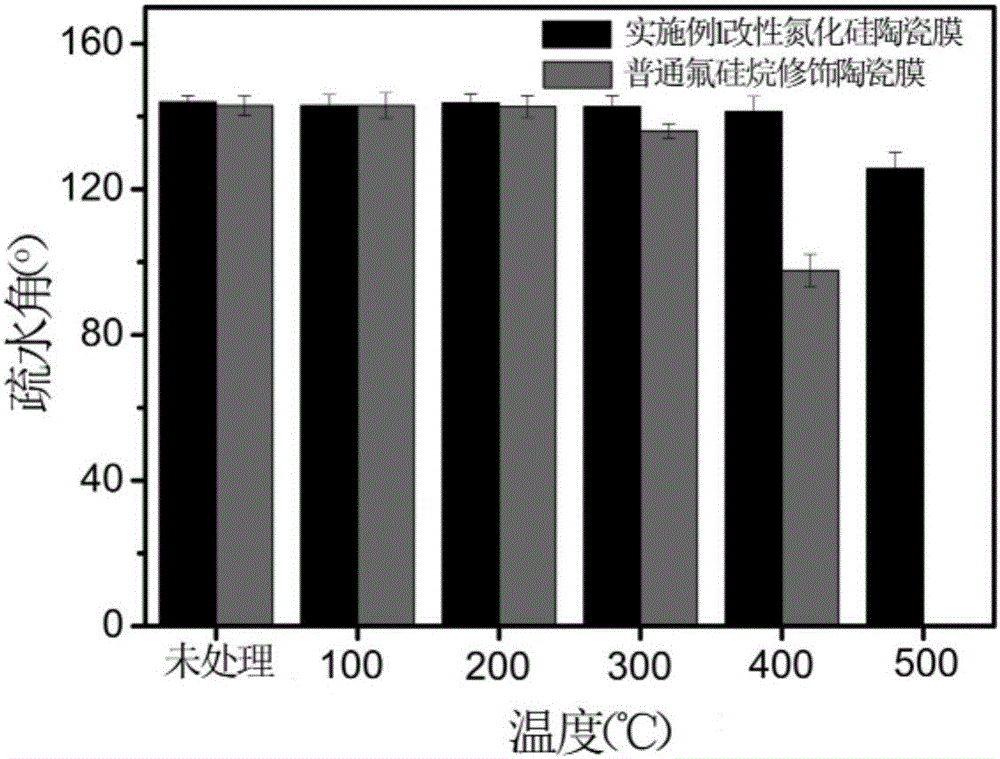

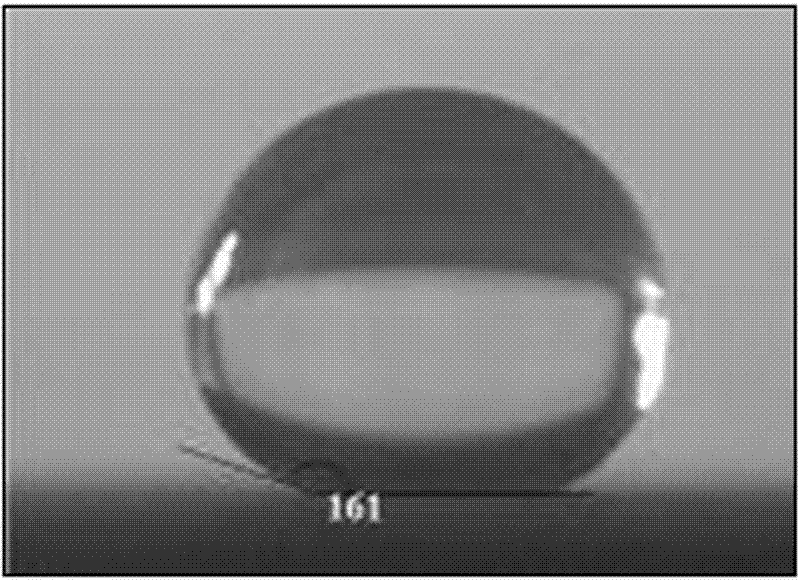

Modification method of ceramic membrane and modified ceramic membrane

ActiveCN106669440AGood chemical stabilityExtended service lifeSemi-permeable membranesSilane compoundsDesalination

The invention provides a modification method of a ceramic membrane and a modified ceramic membrane. The modification method of the ceramic membrane comprises the following steps: performing surface treatment on the ceramic membrane to obtain a fresh ceramic membrane; coating the surface of the ceramic membrane with a silane compound through an impregnation method or a sedimentation method; performing thermal treatment on the coated ceramic membrane under a protective atmosphere, naturally cooling to obtain the modified ceramic membrane after the modification. The modification method of the ceramic membrane provided by the invention has advantages that the modification process is simple, the raw material cost is low, and secondary pollution on the environment can be avoided in the modification process; compared with the common organic modification material, the modified ceramic membrane prepared through modification has the features of high long-term stability, strong acid-base resistance, and strong hydrophobic property; and the modified ceramic membrane can be extensively applied to sea water desalinization, oil-water separation, wastewater treatment and other fields.

Owner:PETROCHINA CO LTD +1

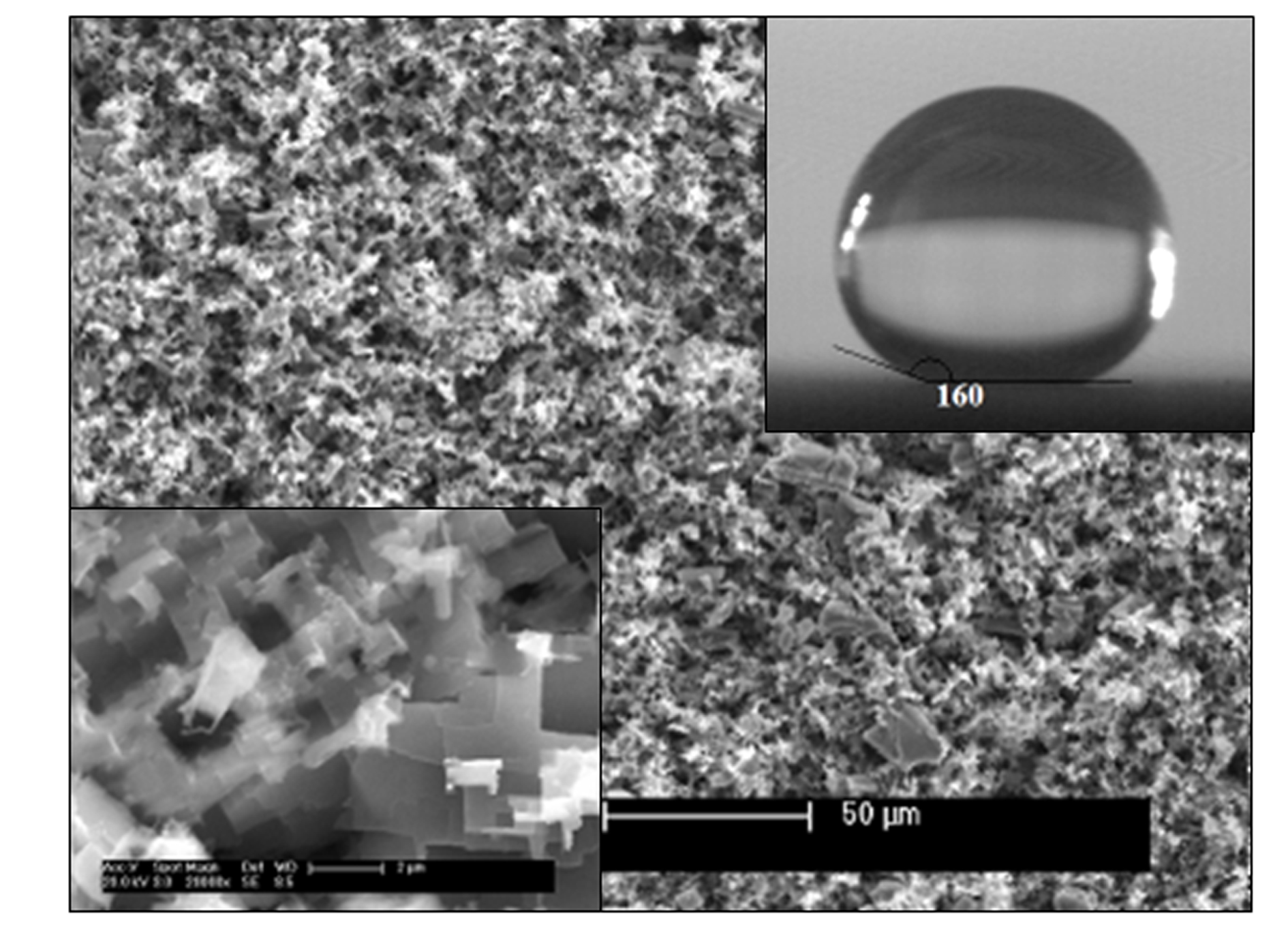

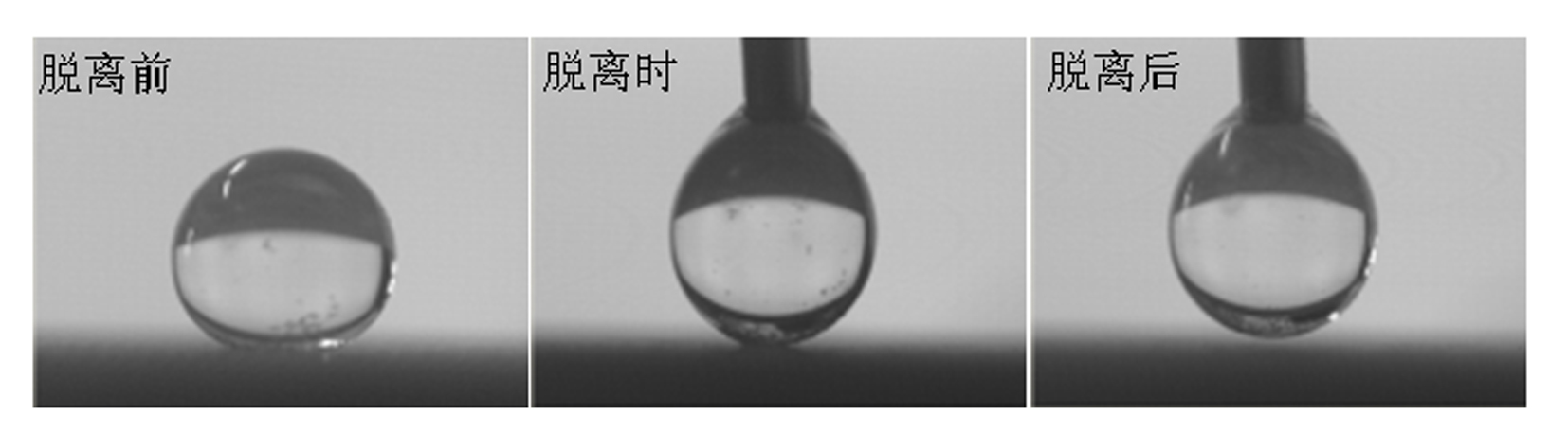

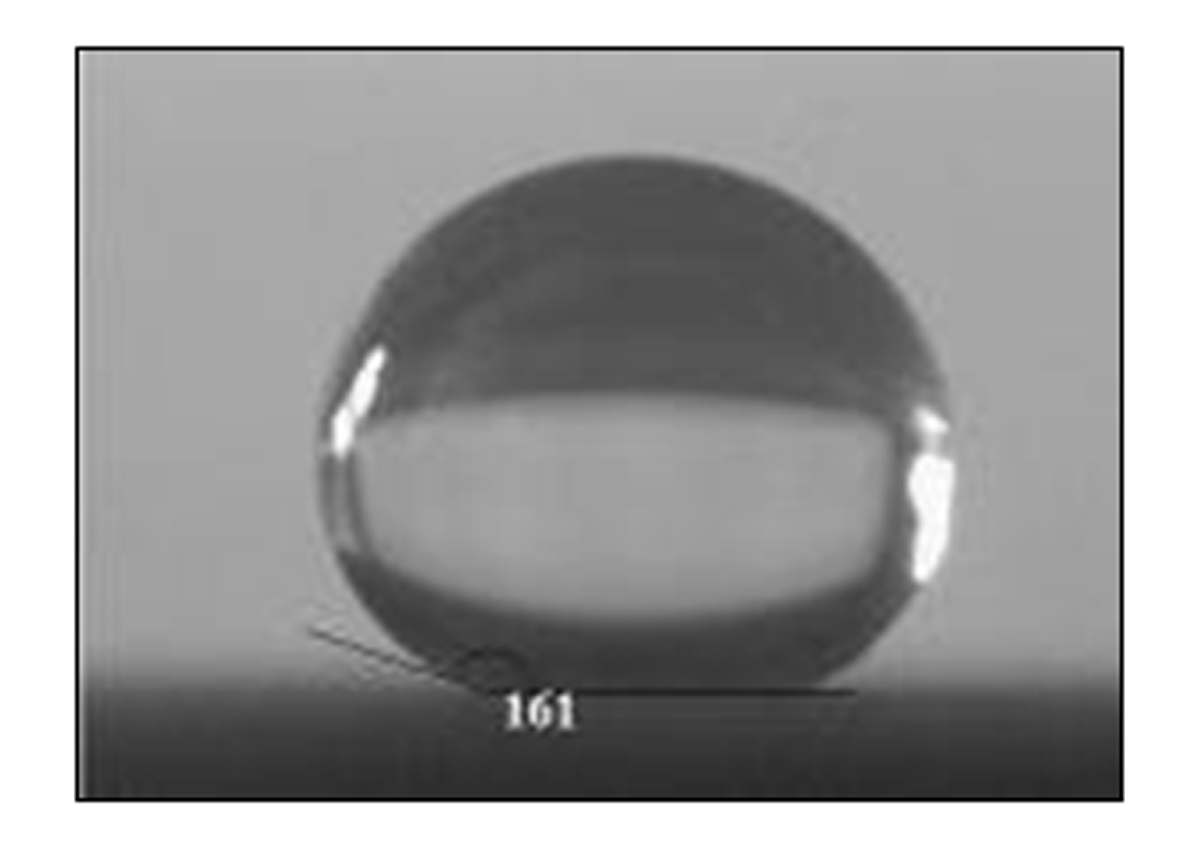

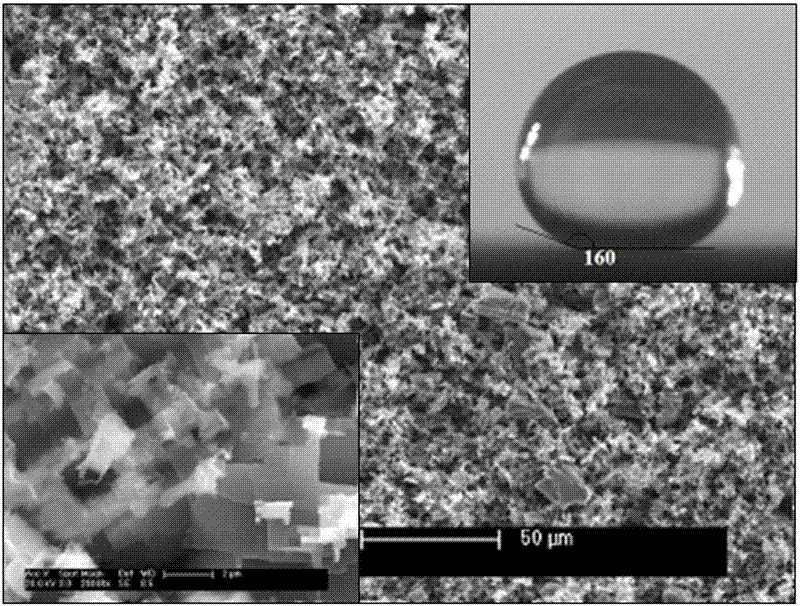

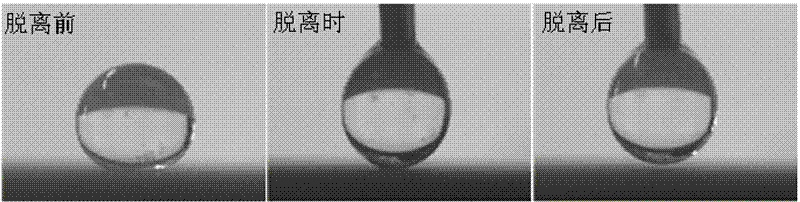

Low-cost superhydrophobic surface treatment method of aluminum alloy

InactiveCN101982560AEasy to operateSimple manufacturing processSolid state diffusion coatingStearic acidHydrophobic surfaces

The invention provides a low-cost superhydrophobic surface treatment method of aluminum alloy, which comprises the following steps: (1) carrying out chemical etching on the surface of the aluminum alloy by utilizing hydrochloric acid aqueous solution with the mass-volume concentration of 70g / L-95g / L in water bath at the temperature of 30-50 DEG C for 3-6min; and (2) carrying out evaporation modification on the surface of the aluminum alloy by utilizing long chain fatty acid solution by an evaporation method, wherein, the long chain fatty acid comprises at least one of lauric acid and stearic acid, and the long chain fatty acid solution is prepared by dissolving fatty acid into an ethanol solvent based on the mass percent of 3wt.%-15wt.%. The evaporation method comprises the following steps: placing the long chain fatty acid solution and the aluminum alloy subject to chemical etching treatment in a sealed container; putting the sealed container in a chamber electric furnace, heating until the temperature of the mixture is up to 100-200 DEG C, and performing heat preservation for 1-3h; and taking out the aluminum alloy and placing the aluminum alloy in the chamber electric furnace again, curing at the temperature of 50-90 DEG C for 0.5-1.5h, and finally taking out the aluminum alloy, and carrying out air cooling on the aluminum alloy to obtain the aluminum alloy surface which has the advantages of good superhydrophobic characteristic and less possibility of being adhered to water drops.

Owner:SOUTHEAST UNIV

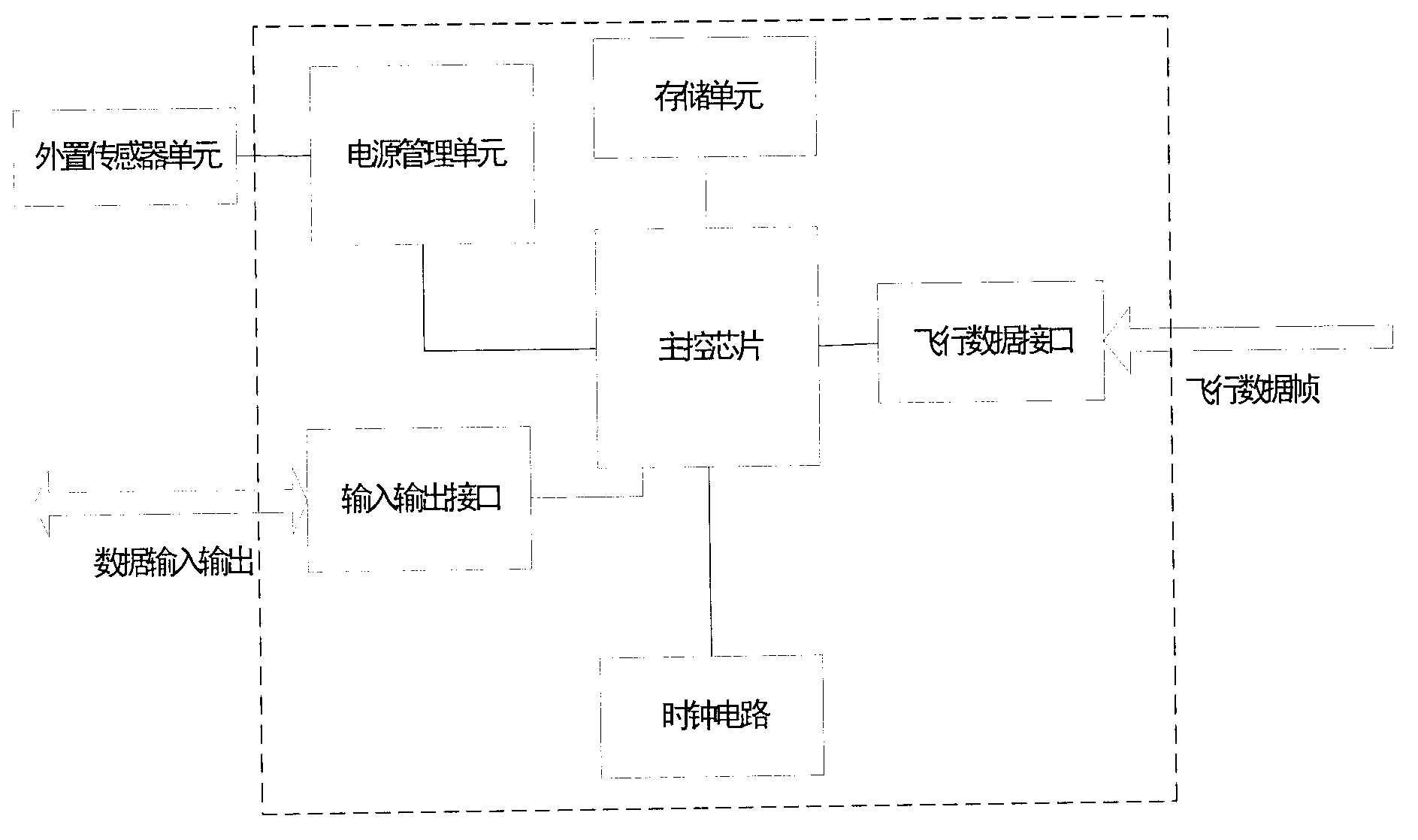

Electronic resume recording device of unmanned aerial vehicle

ActiveCN102915576ARealize simultaneous recordingAchieve finishingRegistering/indicating working of machinesUncrewed vehicleWork status

The invention discloses an electronic resume recording device of an unmanned aerial vehicle, which comprises a main control chip, a flight data receiving interface, a clock circuit, a storage unit and a power management chip, wherein the main control chip reads flight data frames through the flight data receiving interface, and extracts a status bit and UTC (universal time coordinated) time in the flight data frames; the flight data frames are added with time stamps output by the clock circuit and output to the flight data region in the storage unit; the status bit is output to the resume use region of the storage unit; the UTC time is output to the clock circuit to carry out time correction on the clock circuit; the status bit is used for identifying the flight operation condition of the unmanned aerial vehicle; and the main control chip periodically queries the power supplying state of the power management chip and outputs the power supplying state to the resume use region of the storage unit. The electronic records such as device working conditions, storage environment, mounted equipment configuration information, flight and task data of the unmanned aerial vehicle are recorded.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

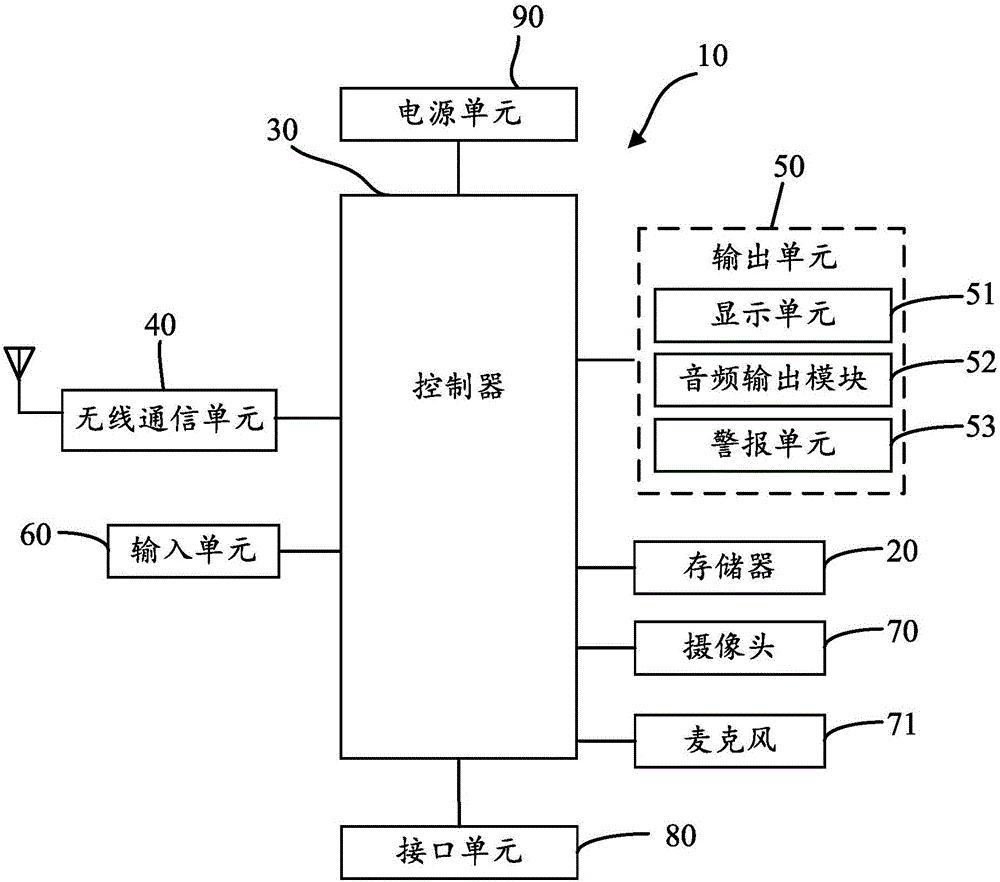

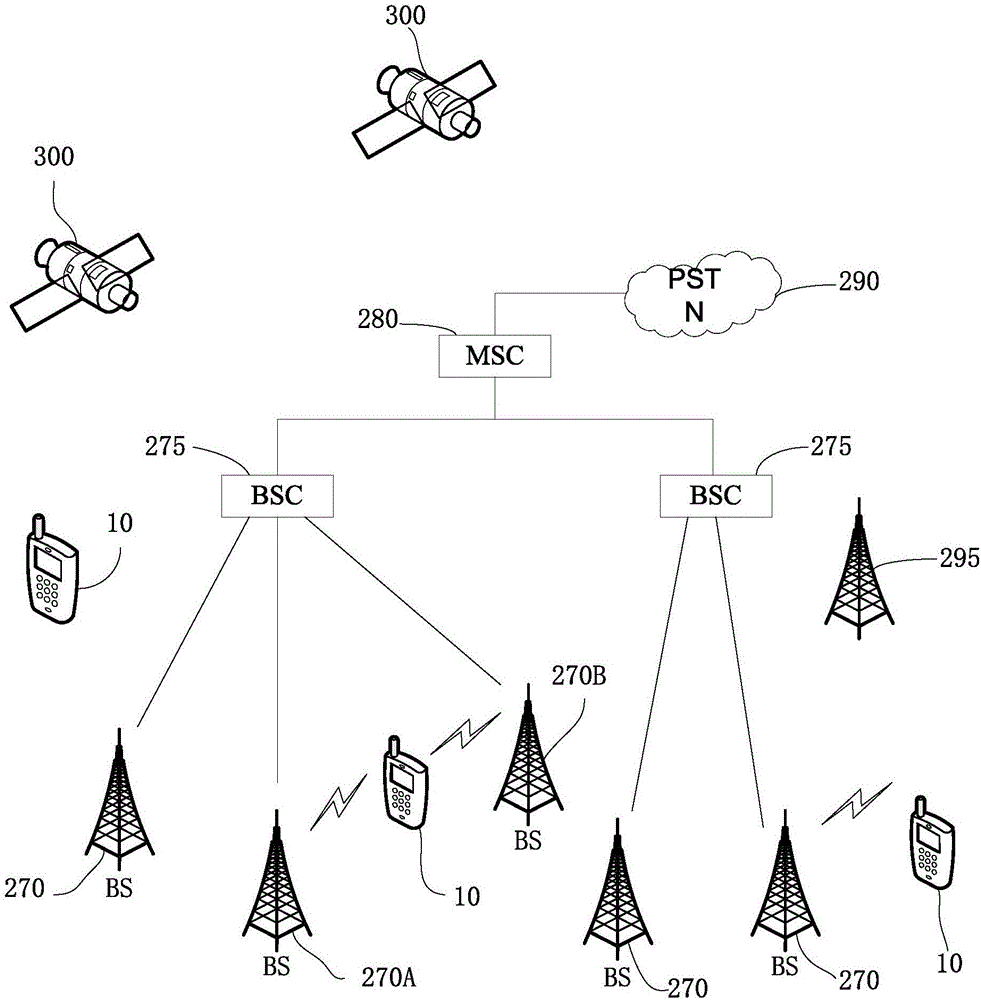

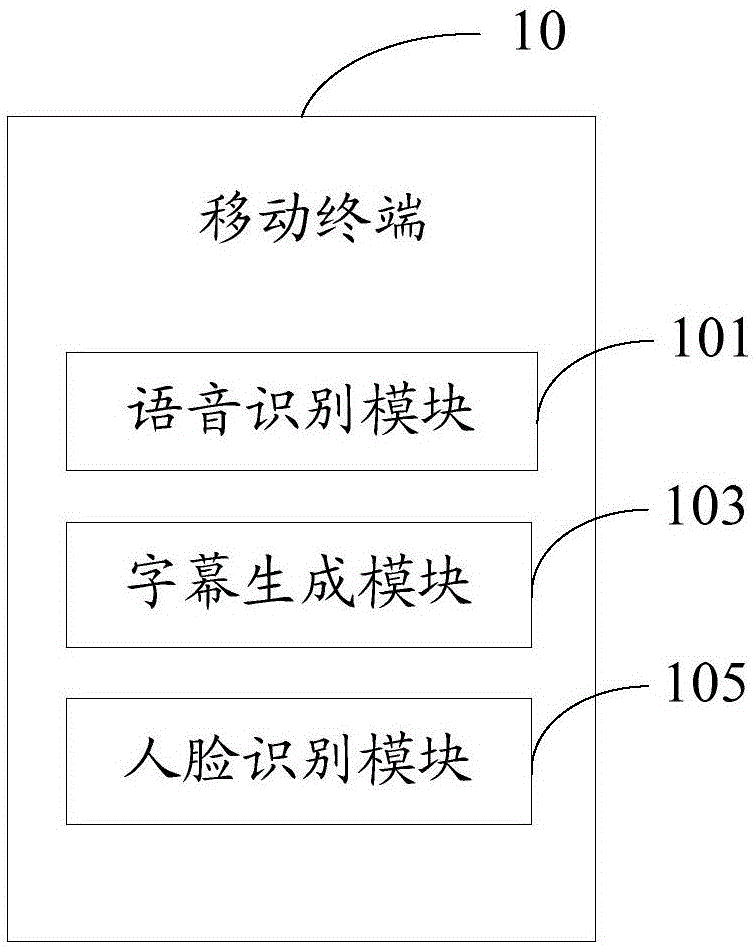

Mobile terminal and method for generating video captions

InactiveCN106385548ASimplify the text finishing processEasy to readTelevision system detailsCharacter and pattern recognitionSpeech soundMultimedia

Owner:NUBIA TECHNOLOGY CO LTD

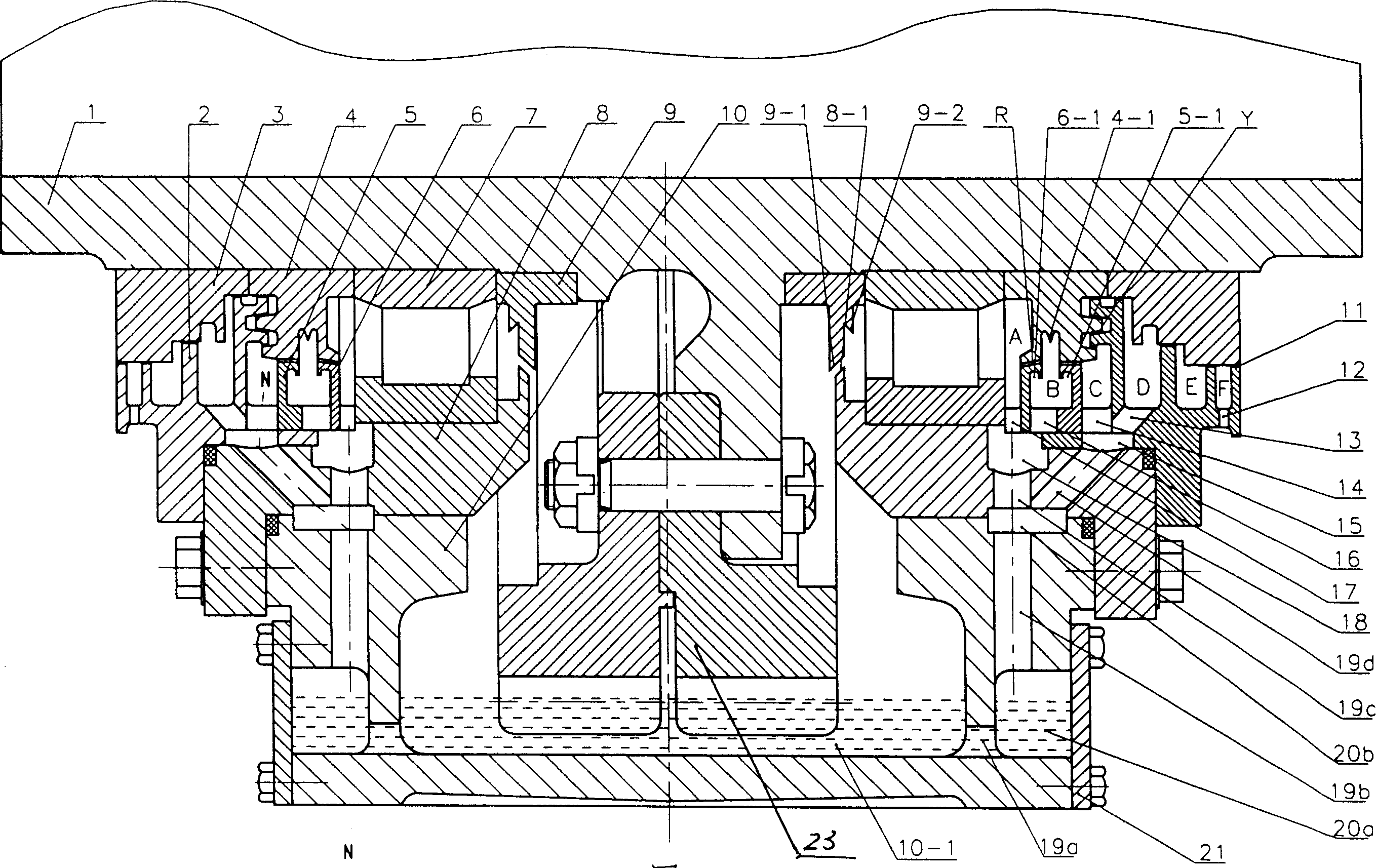

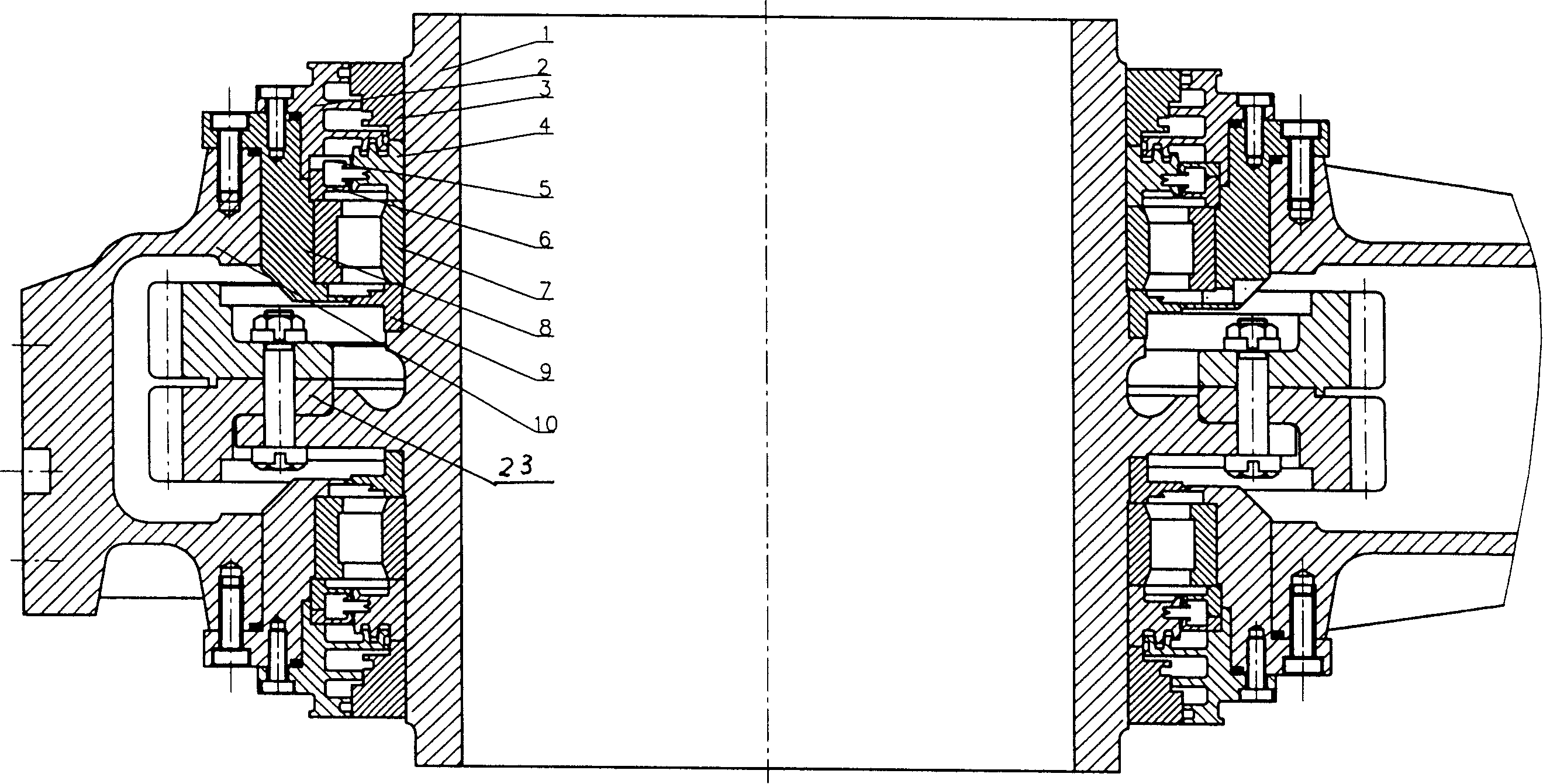

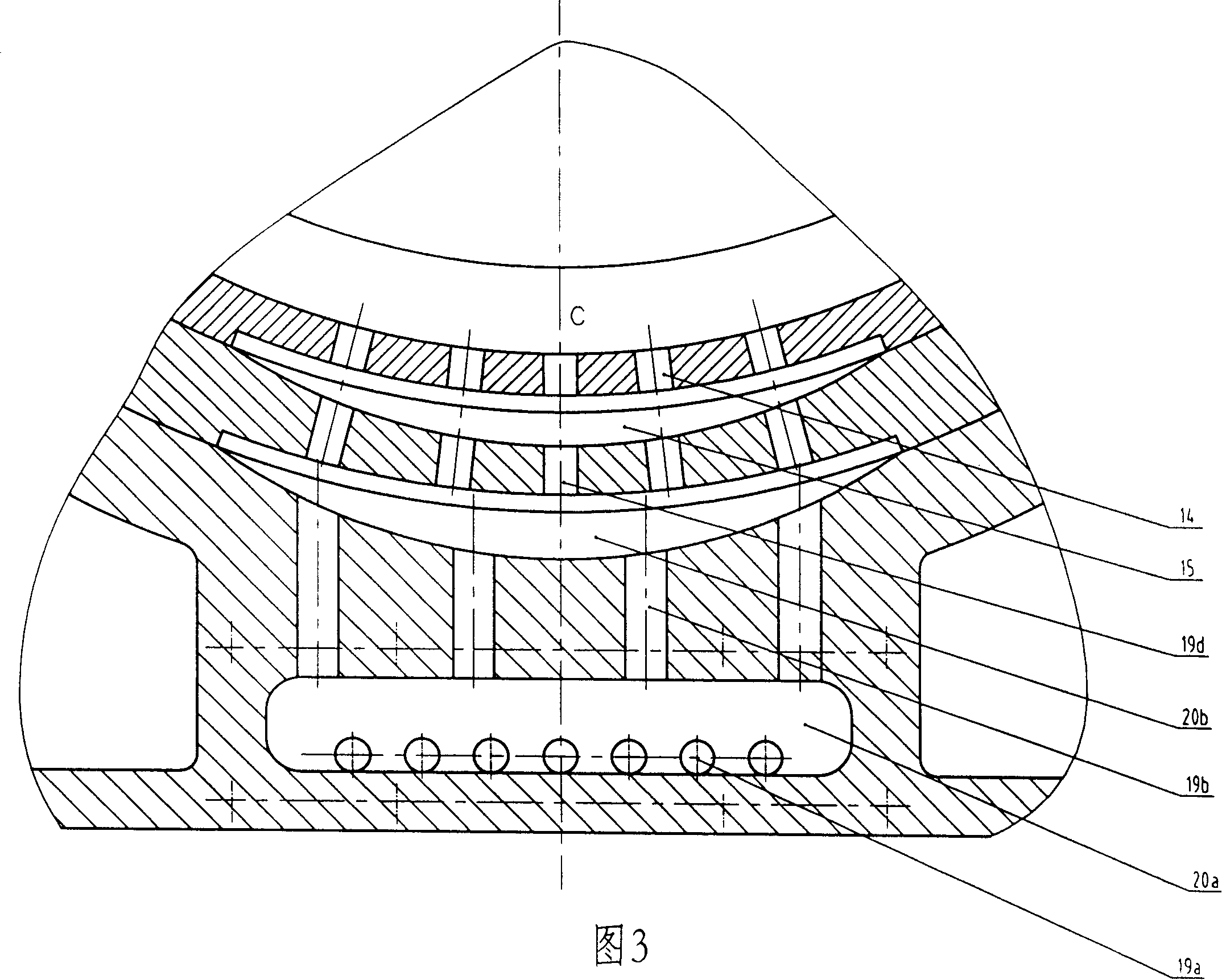

Airproof equipment for power driven gear case of high speed train

InactiveCN1467118AAvoid the problem of poor oil returnOvercoming the Limitations of InfluxRotary prime mover transmissionAxle-boxesLabyrinth sealPetroleum engineering

A sealing unit for the driven gear box of high-speed locomotive, where the lubricating oil is used, has a non-contact labyrinth seal mechanism, which features that a return oil buffering cavity is arranged in the return oil channel communicated with the internal cavity of box, the outlet of final return oil orifice is lower than the level of lubricating oil in the oil pool, and said return oil buffering cavity is communicated with said oil pool via said final return oil orifice. Its advantages are reasonable structure and high saeling effect.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

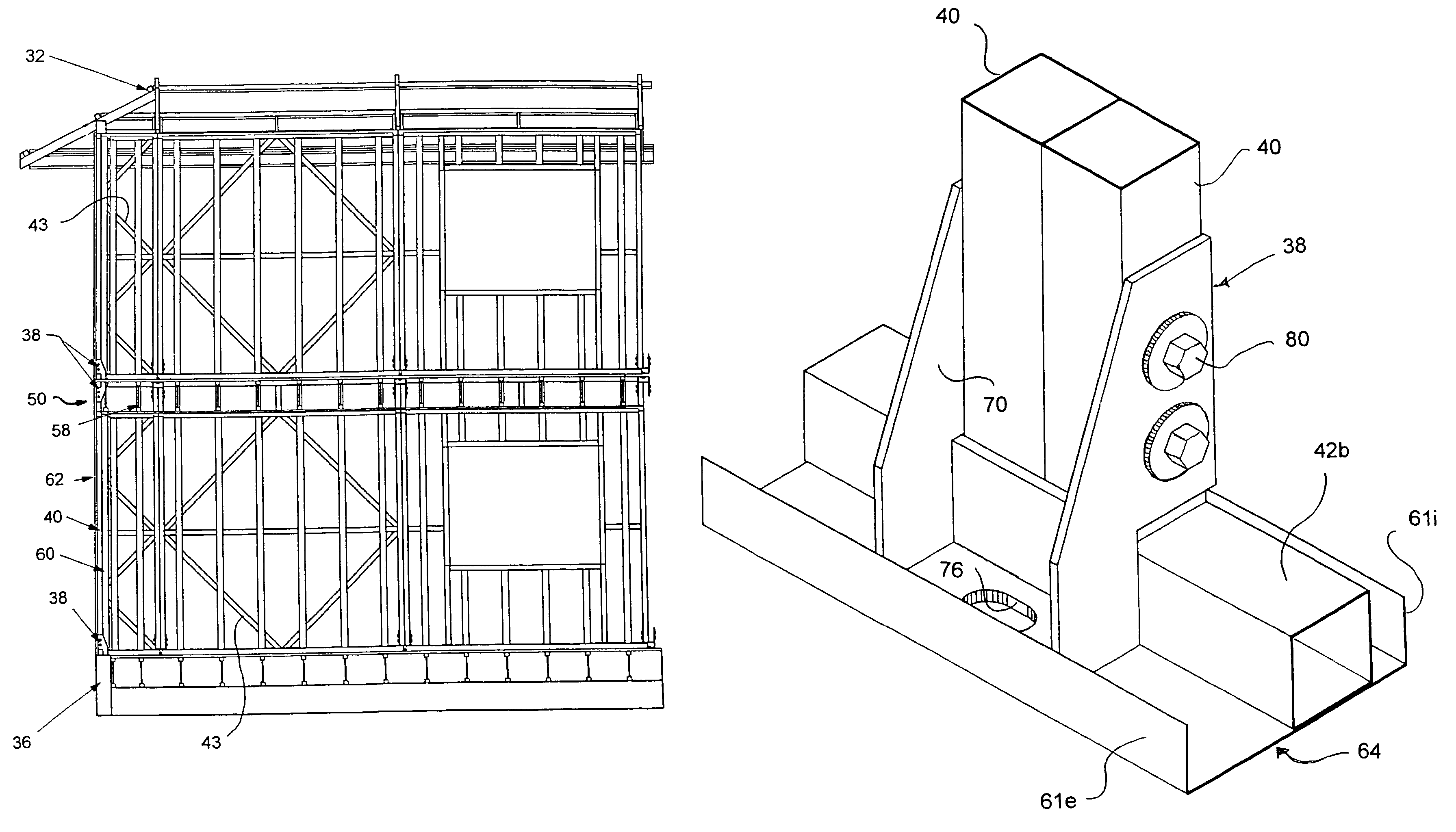

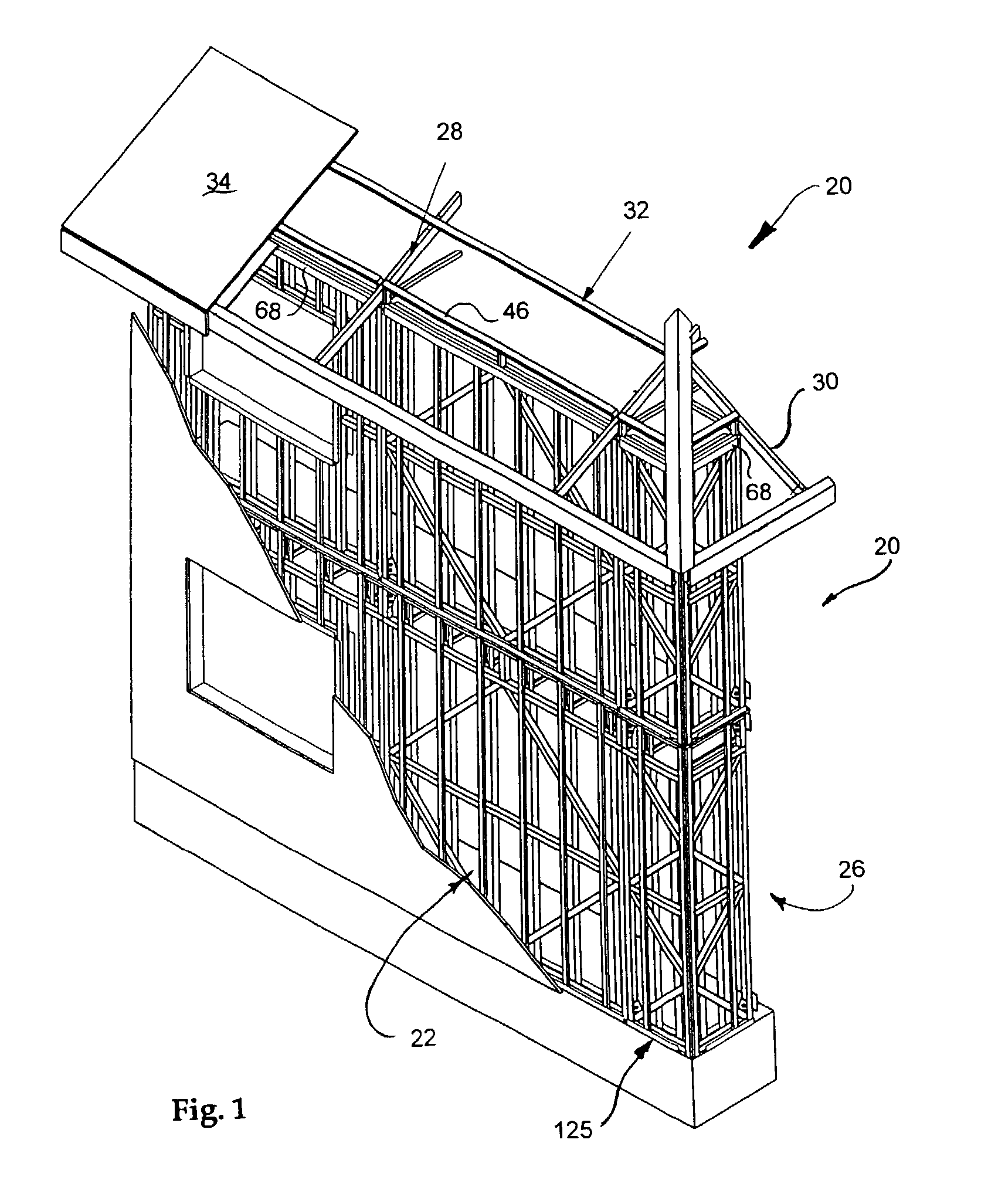

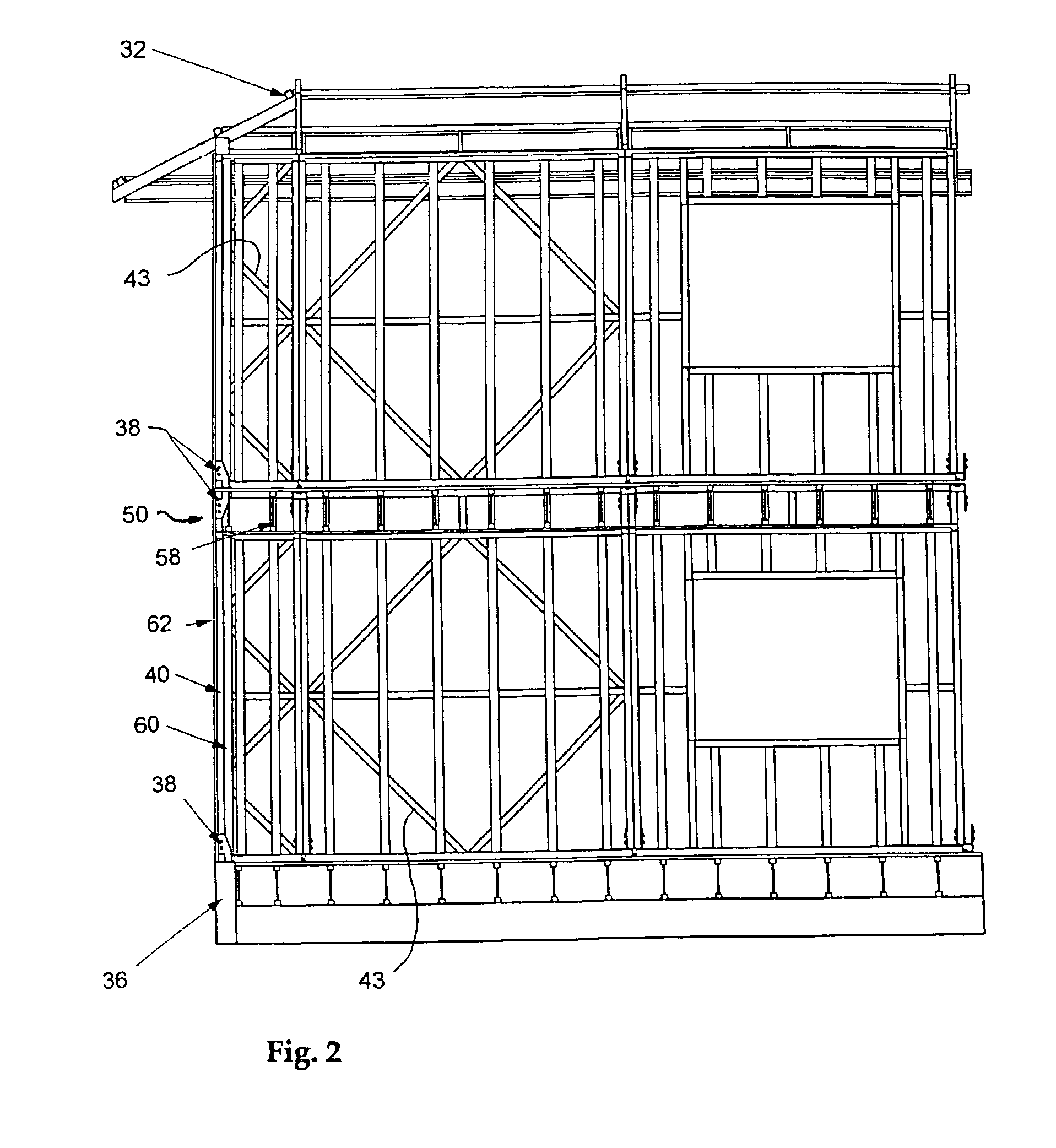

Modular building frame

ActiveUS7992352B2Simplify the finishing processLow costBuilding roofsPublic buildingsEngineeringWind force

A building frame resistant to earthquakes, gale-force wind loads, fire, insects and rot includes a peripheral frame wall constructed of rectangular steel tubing. Side wall frame modules and end wall modules bolted together along adjacent edges form the peripheral frame wall. Diagonal bracing is built into selected side and end wall modules as required for the desired degree of wind resistance. Trusses made of various size tube such as 2×3 inch rectangular steel tubing for supporting a roof, including a hip roof, on the peripheral wall, are assembled and welded in a welding shop and the prefabricated trusses and wall modules are trucked to the building site. Multiple stories may be erected and fastened together by anchor brackets arranged bottom-to-bottom above and below the second and higher floors. The building frame is secured to a foundation by attaching the anchor brackets to anchor bolts set in the foundation.

Owner:ALLIED TUBE CONDUIT +1

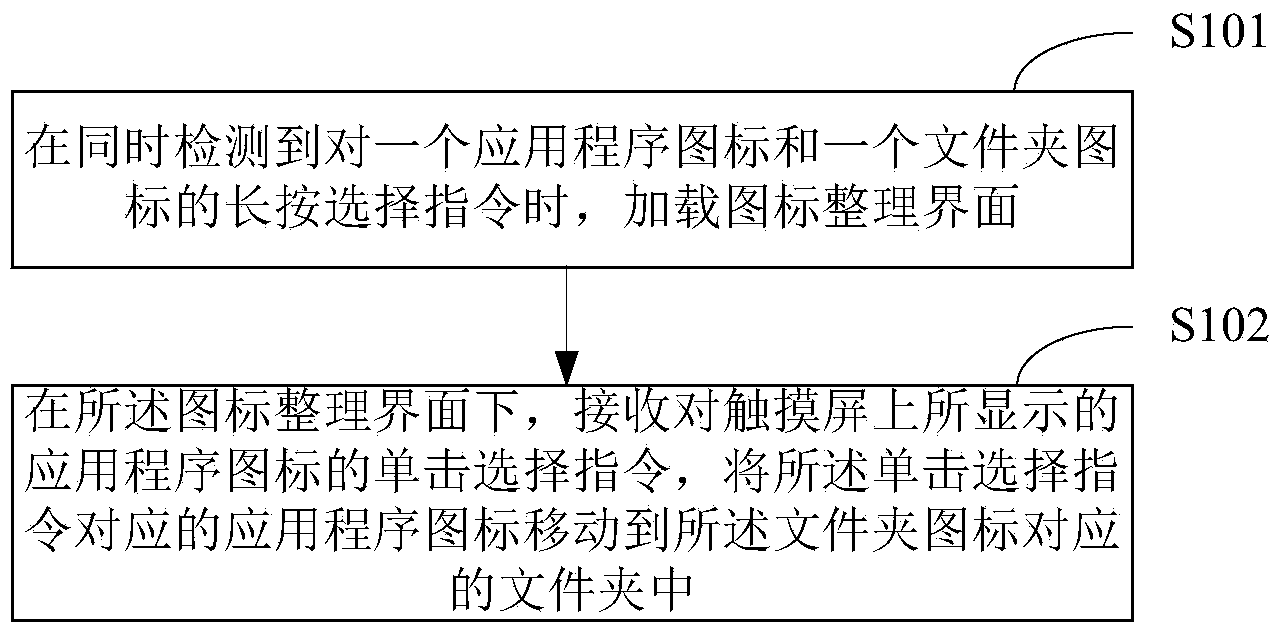

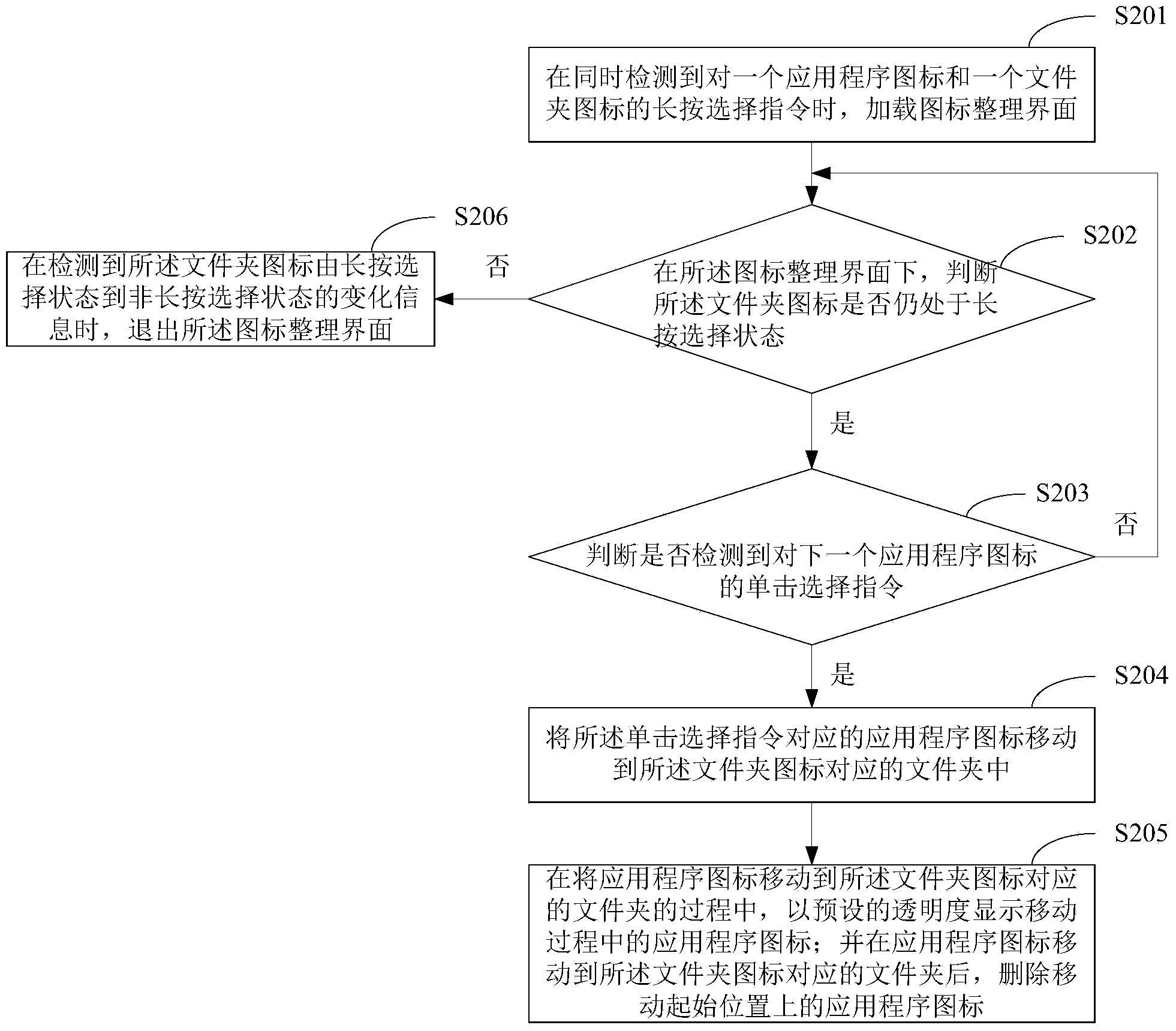

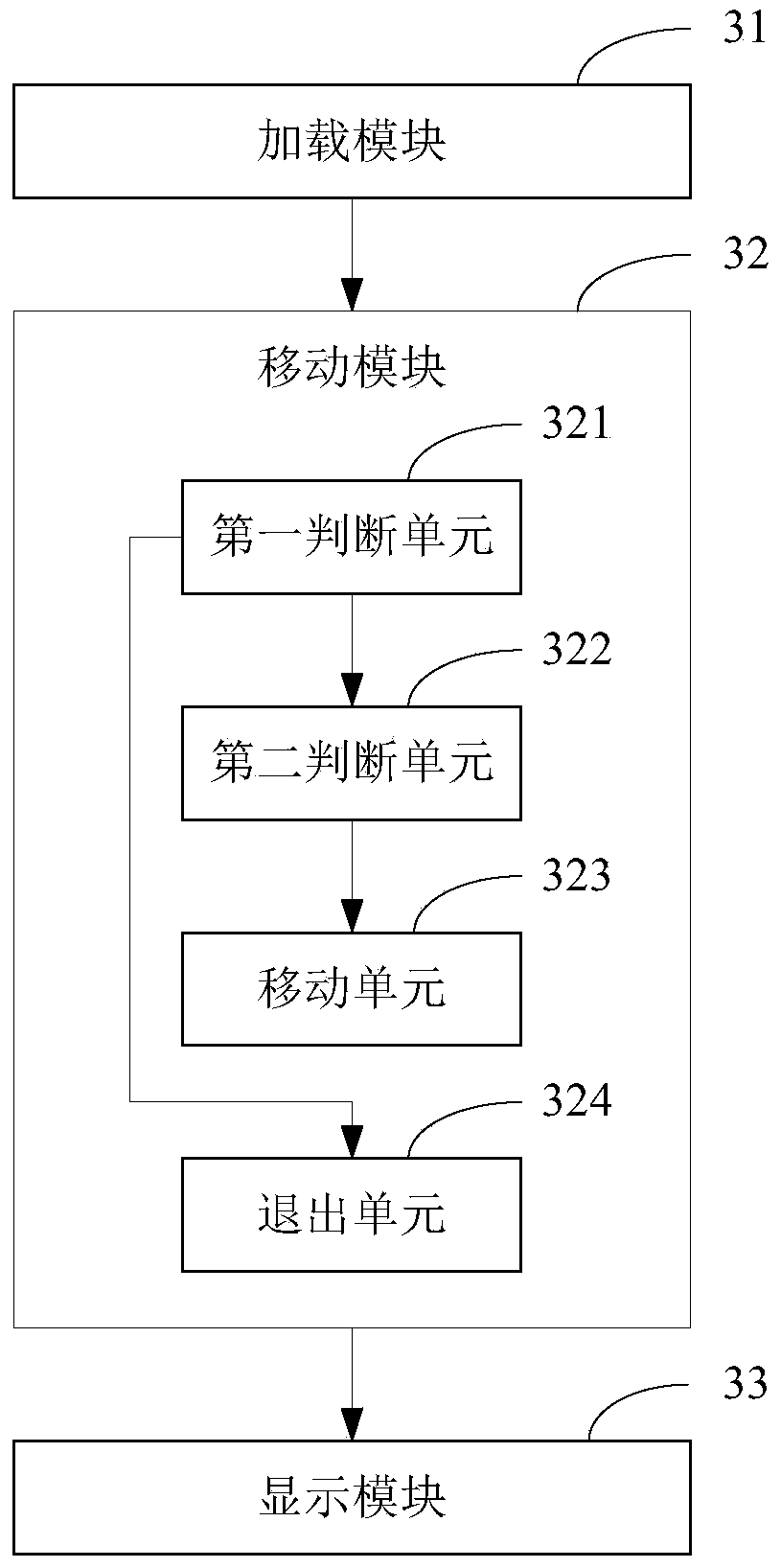

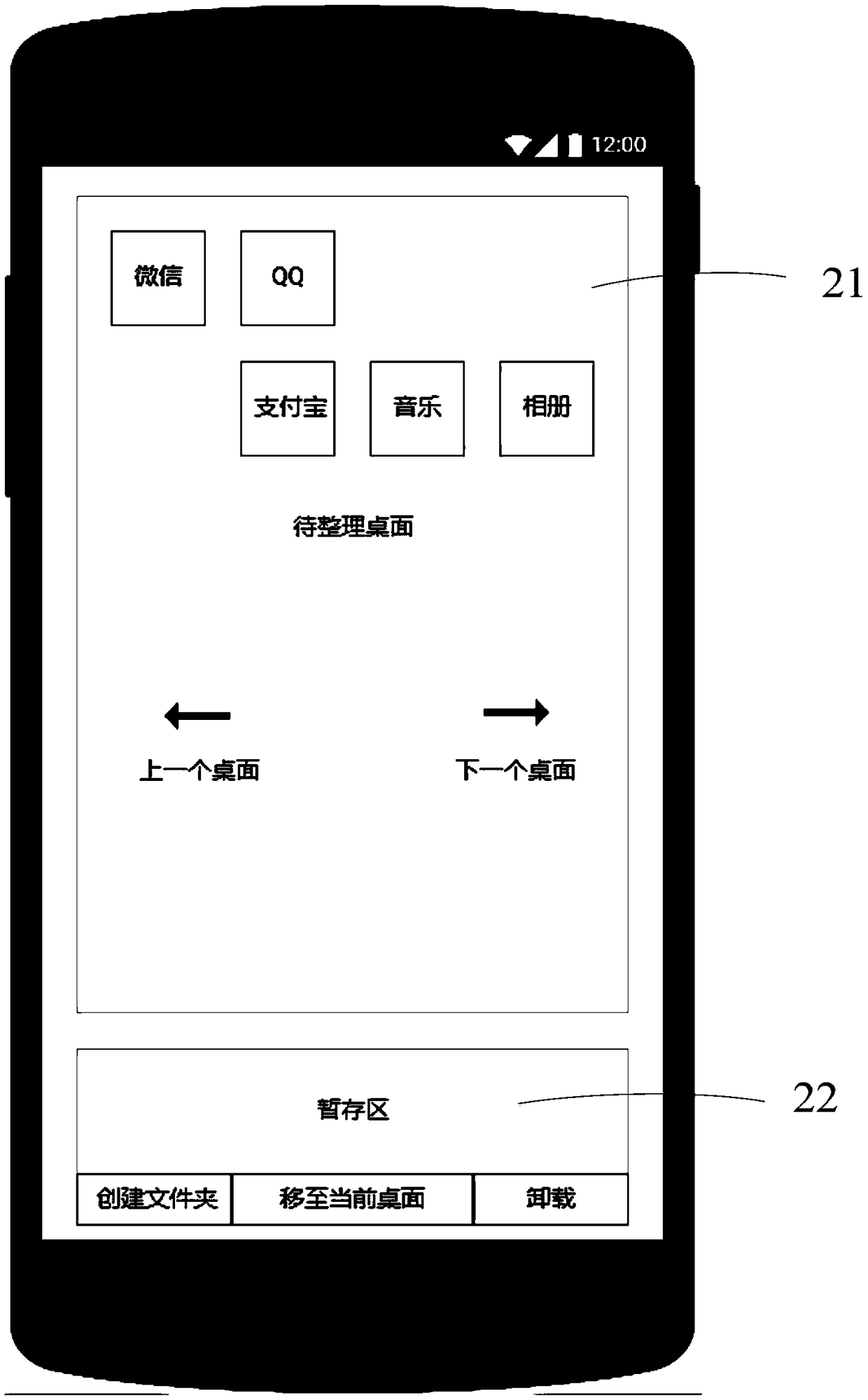

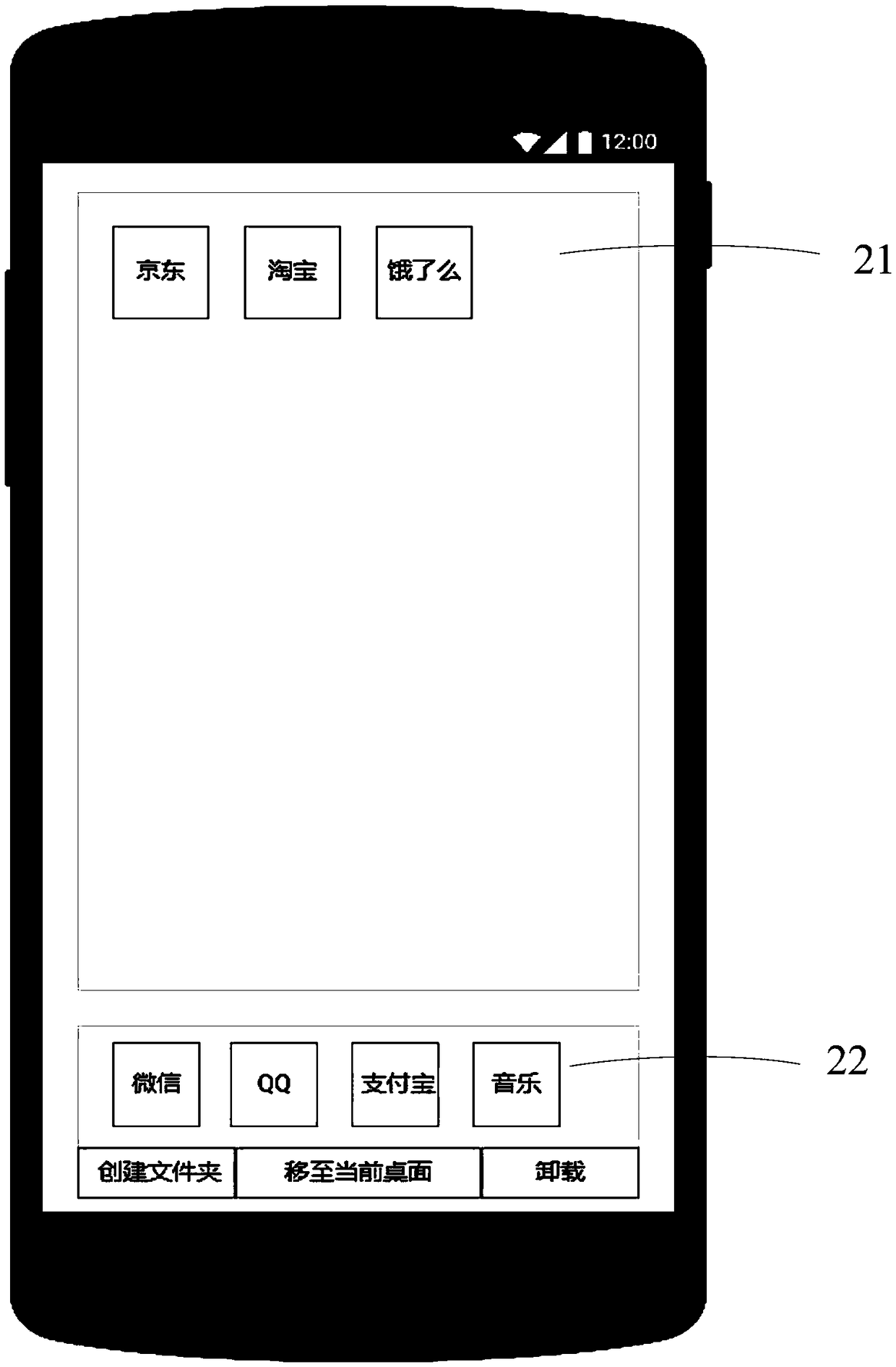

Method and device for moving application icons

ActiveCN104298428ASimplify the finishing processExecution for user interfacesSpecial data processing applicationsMultiple applicationsApplication software

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Infinity shower pan

A shower pan includes a draining base portion that drains to an orifice. The draining base portion includes a support structure for supporting a slab floor member (for example, a single piece of granite, marble, or engineered stone) above the orifice such that a planar upper surface of the floor member has a slight tilt. The pan is installed such that the tilt is toward a shower head. The shower enclosure is finished by cladding the enclosure walls with a finishing material (for example, granite, marble or engineered stone) such that the finishing material extends down into the pan. The floor member is placed on the support structure such that water from the shower head that falls on the floor member runs off one or more edges of the floor member and is conducted to the orifice under the floor member by a draining portion of the draining base portion.

Owner:POLIMENO JOHN

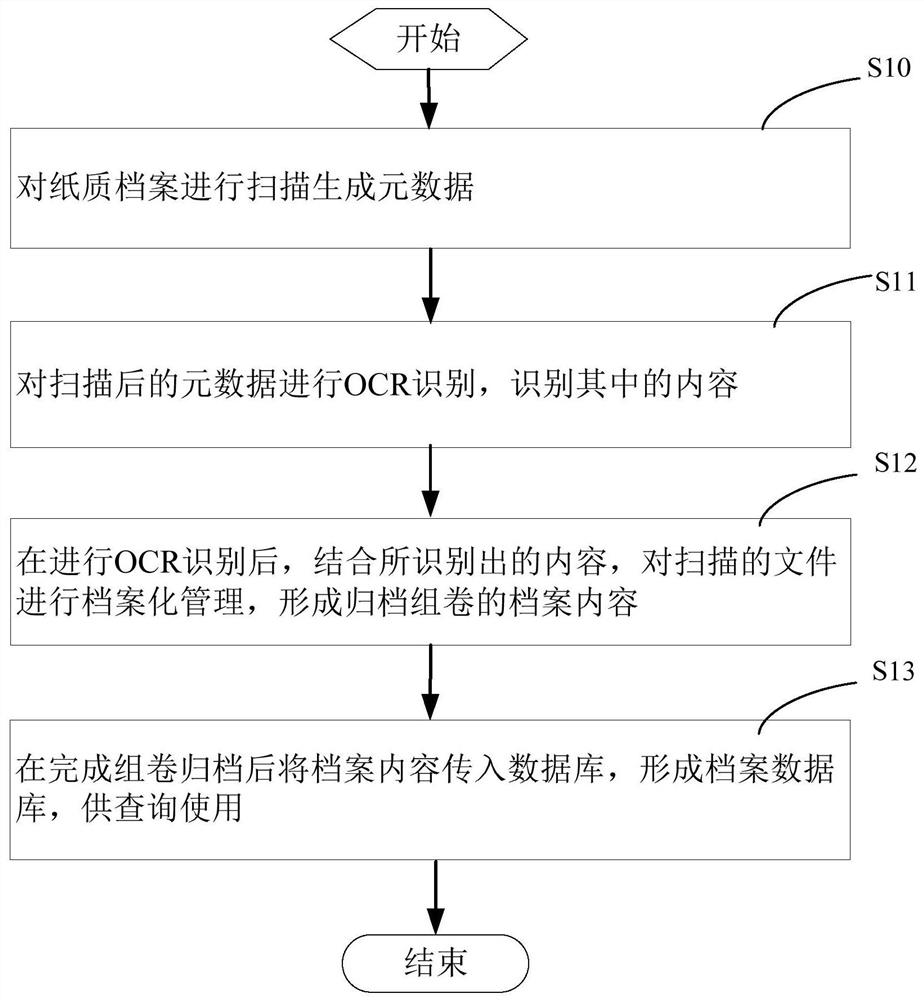

Automatic archiving method for mobile financial bills

PendingCN112463726ASimplify the finishing processImprove finishing efficiencyFinanceFile system administrationEngineeringData library

The invention discloses an automatic archiving method for mobile financial bills. The automatic archiving method comprises the steps of: S10, scanning paper archives to generate metadata; S11, carrying out OCR on the scanned metadata to recognize the content in the metadata; S12, after OCR recognization is carried out, performing archiving management on the scanned files in combination with the identified contents, and archived contents of archiving and test paper forming are formed; and S13, transmitting the file content to a database after the completion of test paper composition and filingto form a file database for query and use. According to the invention, the paper archives can be scanned, identified and archived, the archiving efficiency is improved, and the cost is reduced.

Owner:SHENZHEN POWER SUPPLY BUREAU

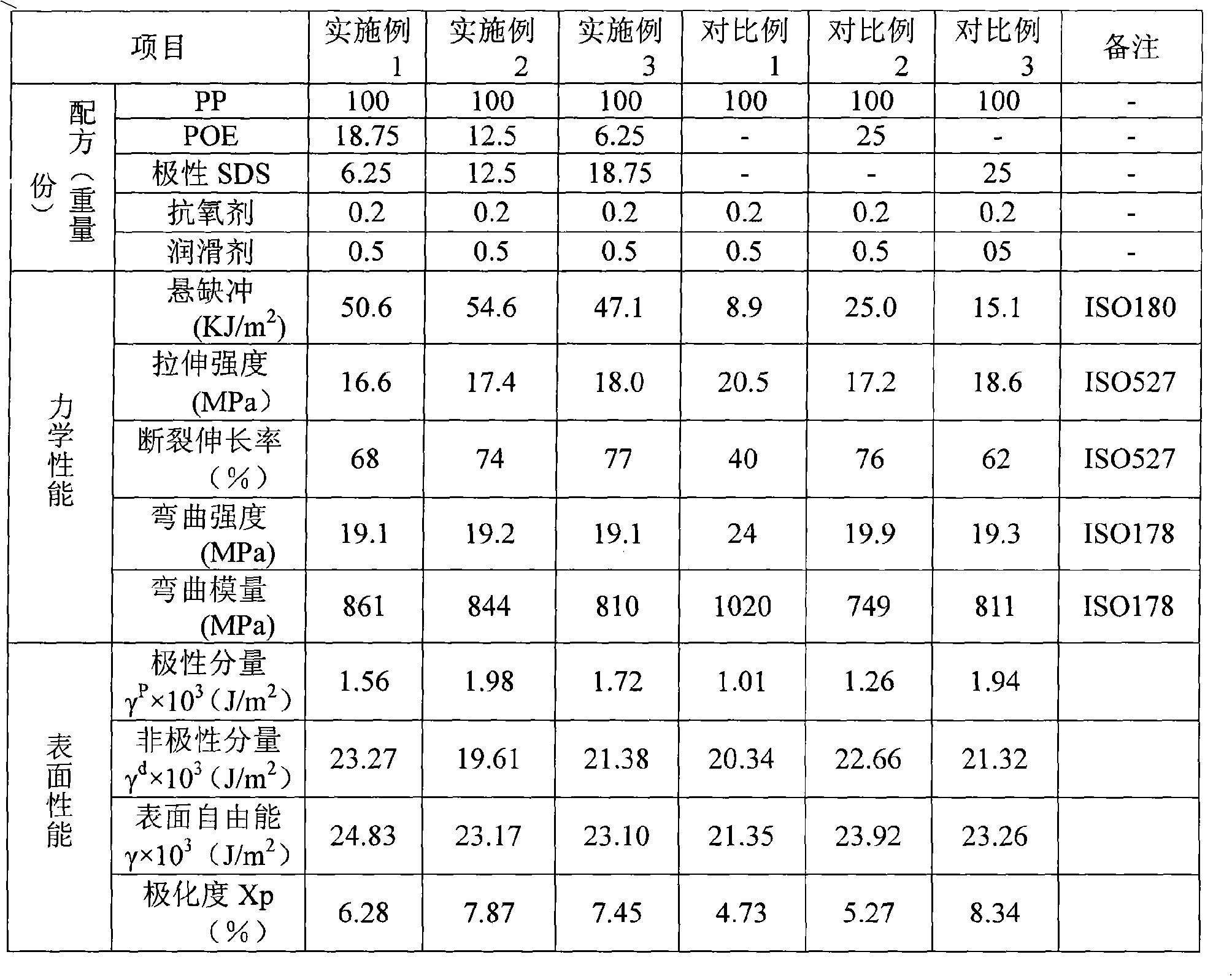

Sprayable and toughened polypropylene composition and preparation method thereof

The invention provides a sprayable and toughened polypropylene composition, which contains the following blended components: 100 weight parts of acrylic resin, 5 to 30 weight parts of thermoplastic polyolefin elastomer, and 5 to 30 weight parts of thermoplastic elastomer graft, wherein the thermoplastic polyolefin elastomer is an ethylene-octene copolymer; and the thermoplastic elastomer graft isa styrene-butadiene-styrene block copolymer or a graft of a styrene-pentadiene-styrene block copolymer and a polar monomer, and the polar monomer is at least one of 2-vinylpyridine, 4-vinylpyridine orisomers thereof. The sprayable polypropylene composition is prepared by melt blending of the components. The polypropylene composition has good toughness and sprayable performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

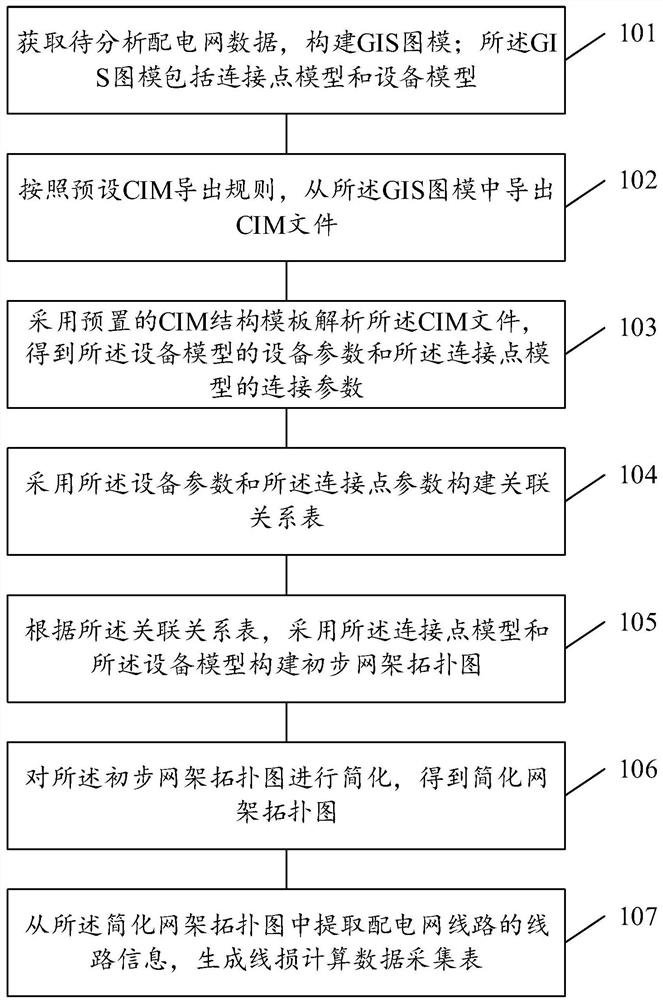

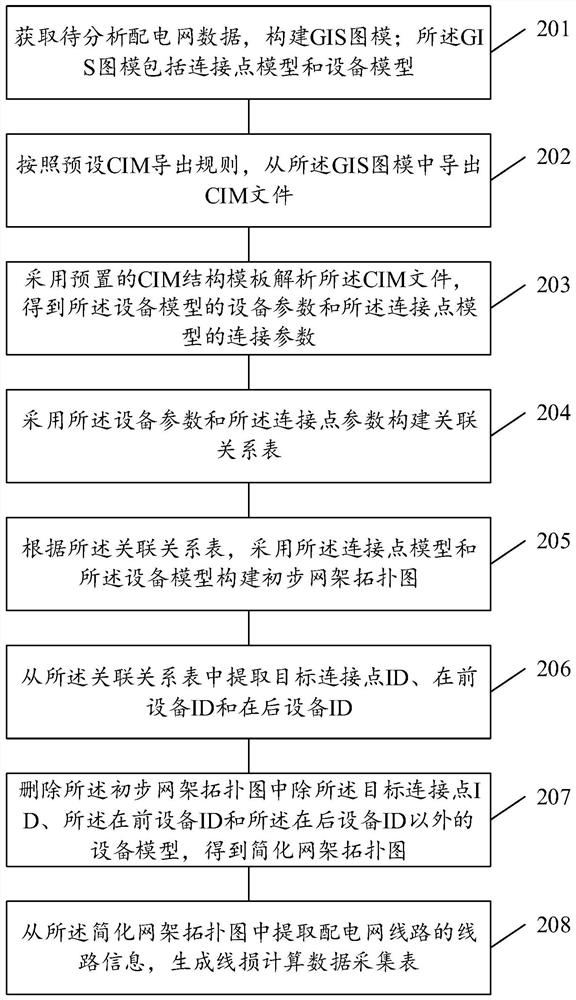

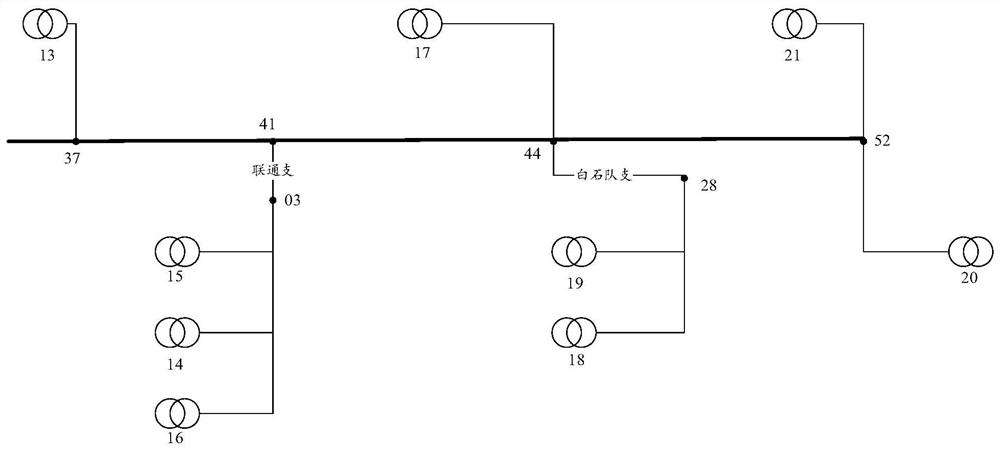

GIS-based power distribution network line loss data acquisition method and related device

PendingCN112507499ASimplify the finishing processImprove accuracyGeometric CADCircuit arrangementsCalculated dataData preparation

The invention discloses a GIS-based power distribution network line loss data acquisition method and a related device, and the method comprises the steps: obtaining to-be-analyzed power distribution network data, and constructing a GIS graph model, wherein the GIS graph model comprises a connection point model and an equipment model; exporting a CIM file from the GIS graph model according to a preset CIM exporting rule; analyzing the CIM file by adopting a preset CIM structure template to obtain equipment parameters of the equipment model and connection parameters of the connection point model; constructing an association relationship table by adopting the equipment parameters and the connection point parameters; according to the association relationship table, constructing a preliminary grid structure topological graph by adopting the connection point model and the equipment model; simplifying the preliminary grid structure topological graph to obtain a simplified grid structure topological graph; extracting line information of a power distribution network line from the simplified network frame topological graph, and generating a line loss calculation data acquisition table. According to the method, the workload of data preparation in the line loss calculation process is reduced, manual intervention is not needed, the calculation cost is reduced, and the accuracy of theoretical line loss calculation is improved.

Owner:GUANGDONG POWER GRID CO LTD +1

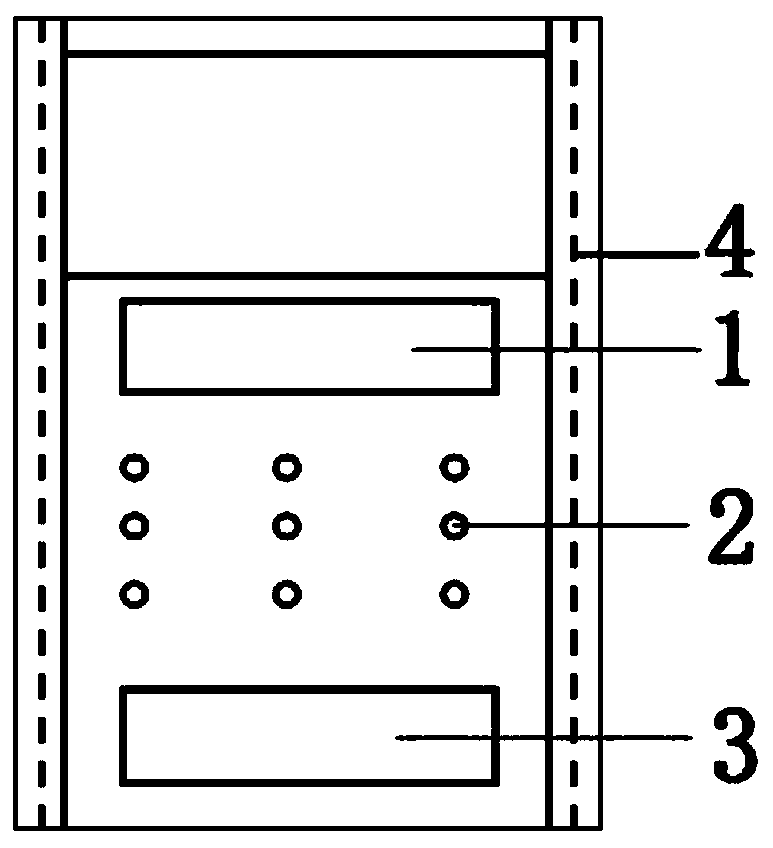

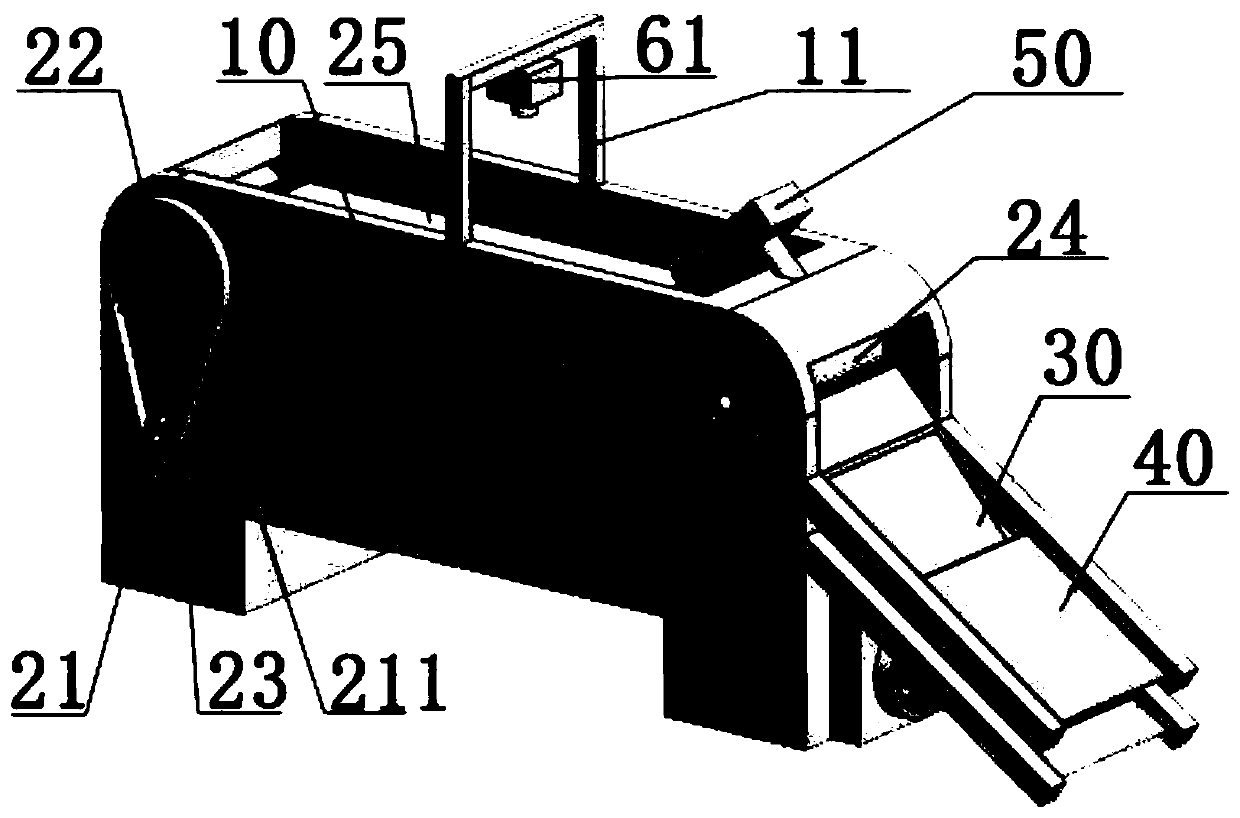

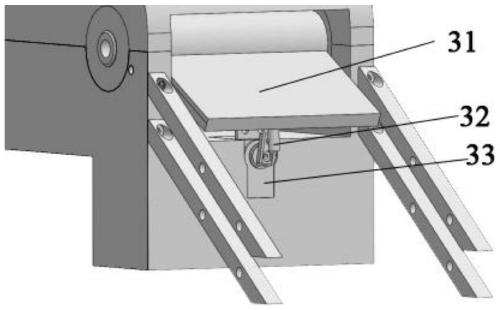

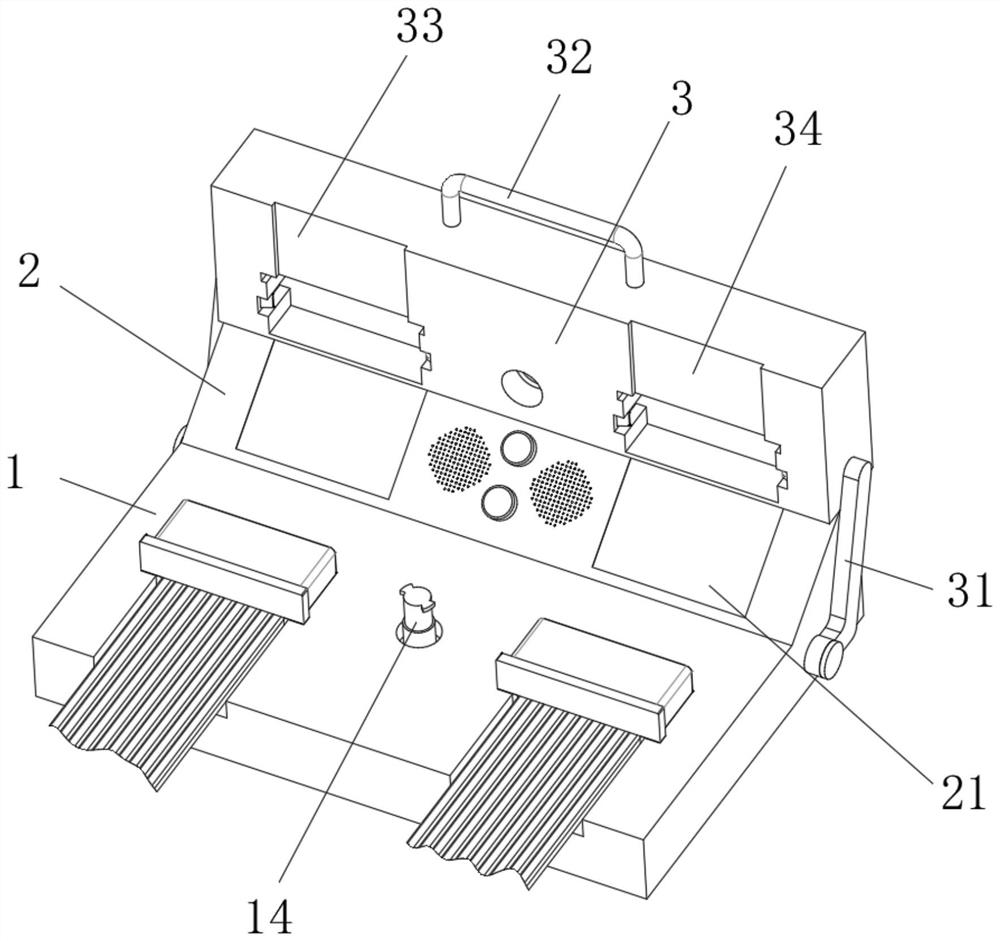

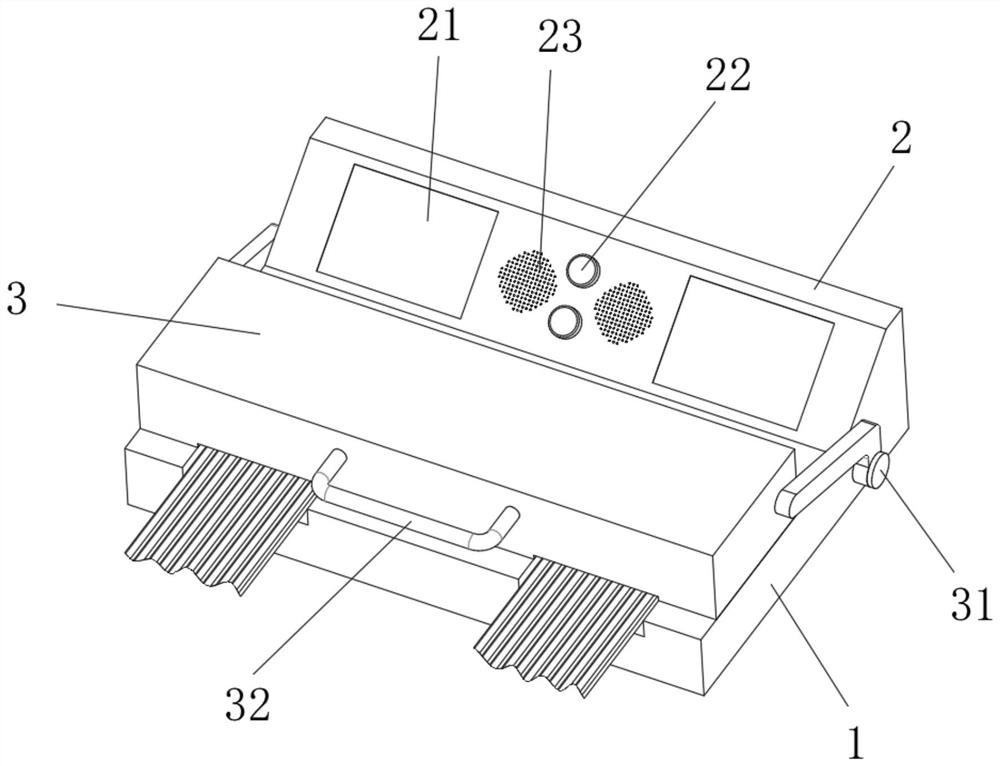

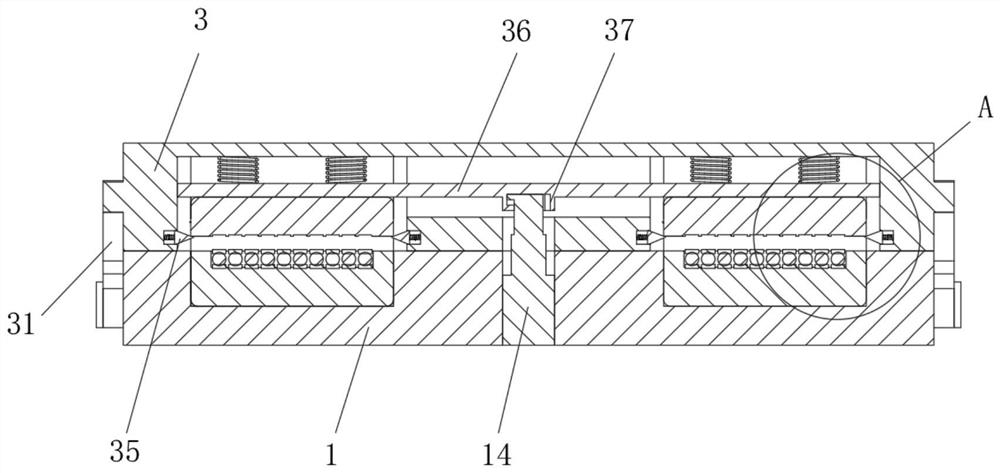

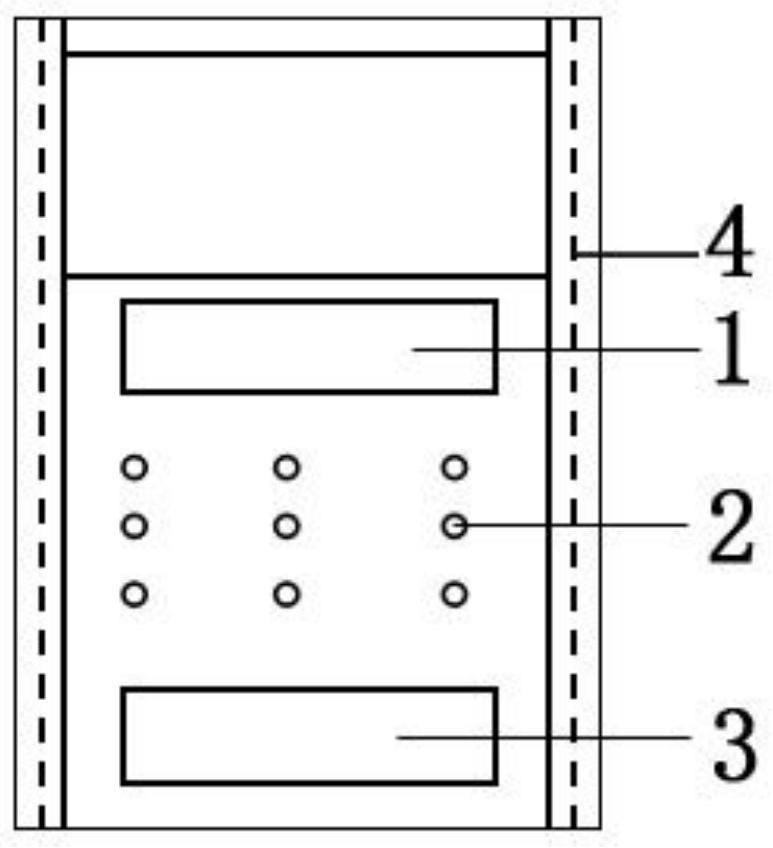

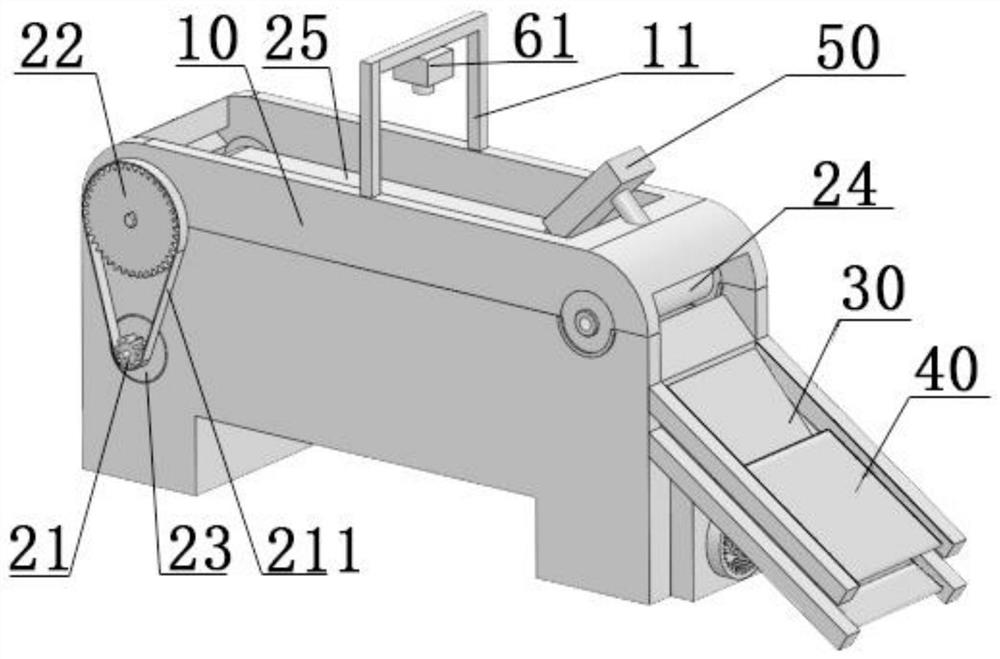

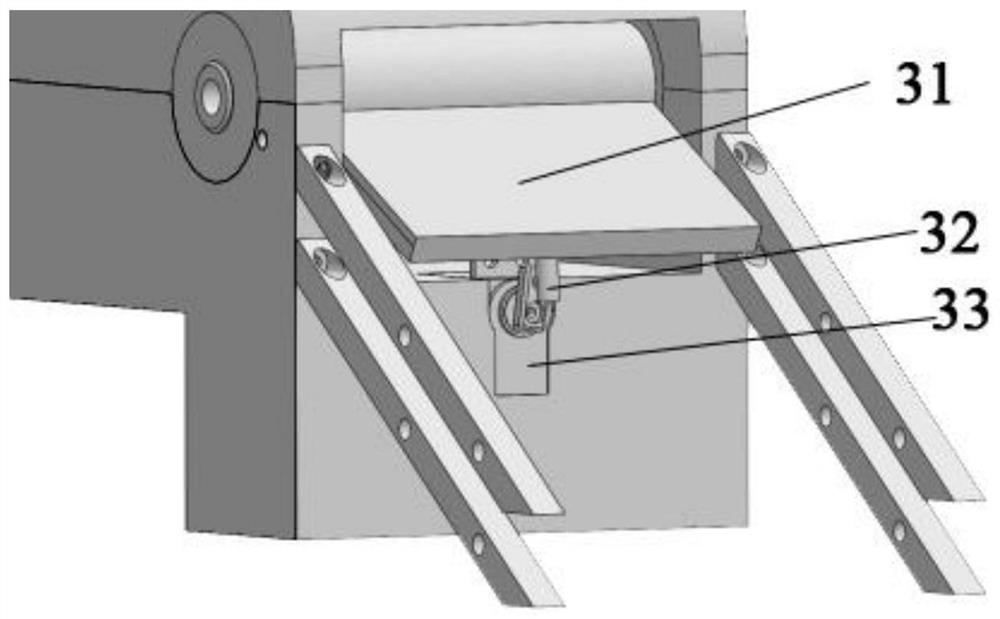

Automatic sorting and numbering device and method for breeding material bags

InactiveCN111186220ASolve the problems of traditional manual sortingSimple actionTypewritersOther printing apparatusEngineeringMechanical engineering

The invention discloses an automatic sorting and numbering device and method for breeding material bags. The device comprises an equipment shell, a conveying system, a mechanical arm, sorting channels, a printing nozzle, an image acquisition system, an upper computer and a main control unit; the conveying system is arranged on the equipment shell, and the top end of the mechanical arm is rotationally arranged at the outlet end of the equipment shell; the top ends of the sorting channels are fixed to the outlet end of the equipment shell and make contact with the bottom end of the mechanical arm, the bottom ends of the sorting channels make contact with or abut against the ground or a placement platform, and the two sorting channels are arranged at the outlet end of the equipment shell in parallel up and down; and the printing nozzle is fixedly arranged at the top of the outlet end of the equipment shell, and the image acquisition system is used for acquiring image information on the breeding material bags, acquiring original images of material numbers on the breeding material bags and transmitting the image information to the upper computer. The device achieves automatic sorting and numbering, and improves the sorting accuracy and the working efficiency of rice breeding materials.

Owner:SOUTHWEAT UNIV OF SCI & TECH

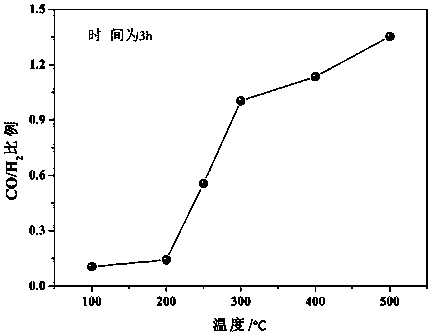

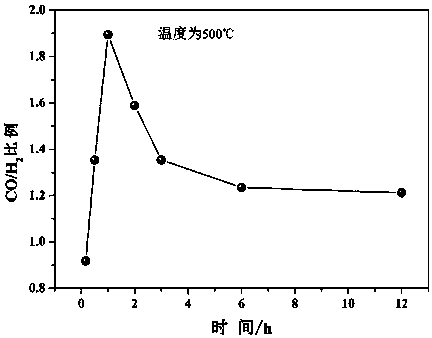

Cathode material for generating ratio-controllable synthesis gas through carbon dioxide reducing under electrocatalysis, preparation method and application

ActiveCN108193228AThe selection of materials is cheap and easy to obtainIncrease the effective areaElectrodesElectricitySyngas

The invention relates to a cathode material for generating ratio-controllable synthesis gas through carbon dioxide reducing under electrocatalysis, a preparation method and application. The preparation method comprises the following steps that (a) an h62 brass strip is heated and calcined in flowing air bath; and (b) after cooling is conducted, the calcined brass strip is subjected to electrochemical reduction in an electrolyte, and finally the cathode material is obtained. The preparation method is simple, operation is easy, treatment conditions are changed to form different catalysis surfaces, the performance of Co and H2 generated through catalysis is adjusted and controlled accordingly, and thus ratio adjusting and controlling of the synthesis gas composed of CO and H2 is achieved.

Owner:北京中立鸿环境技术有限公司

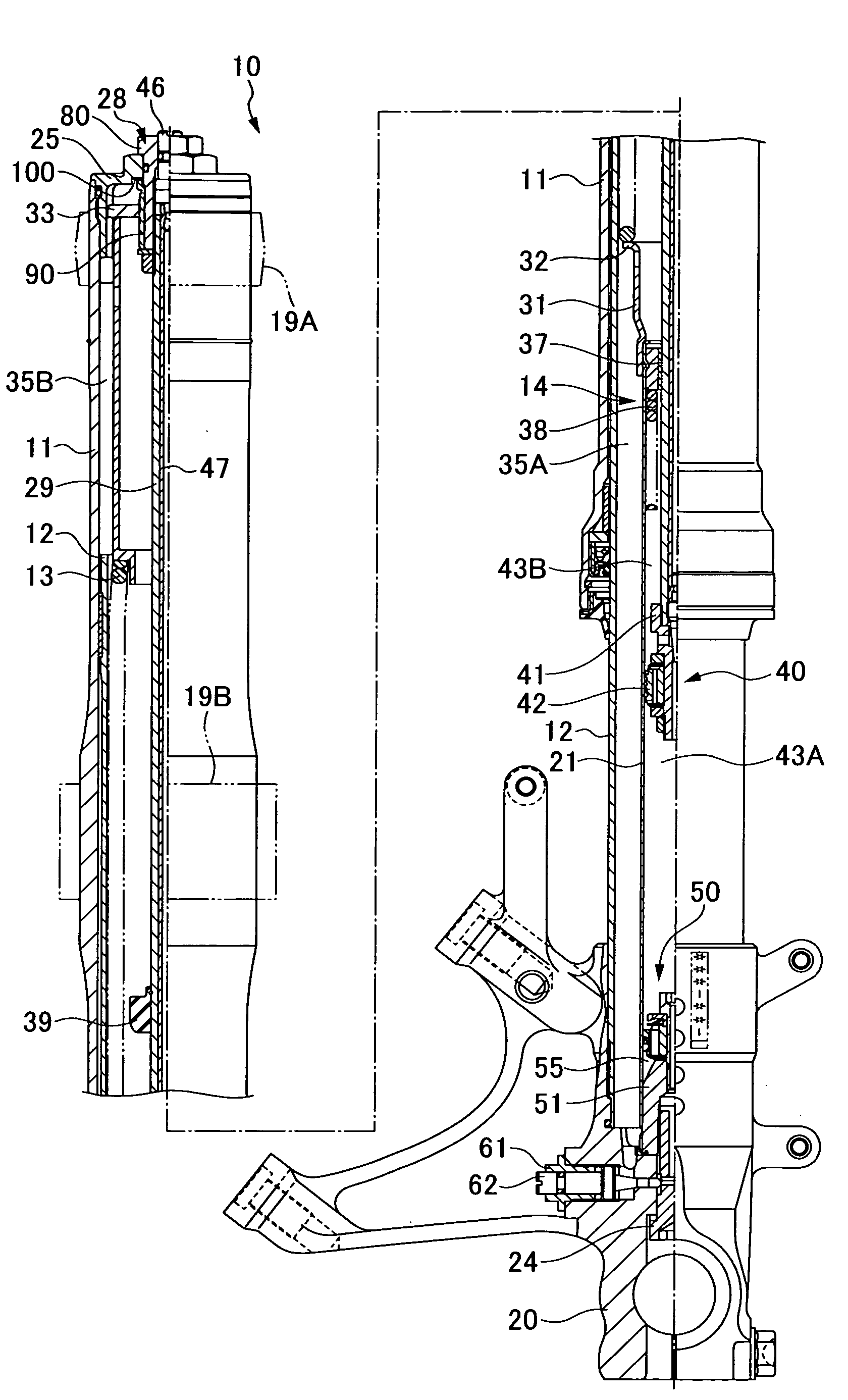

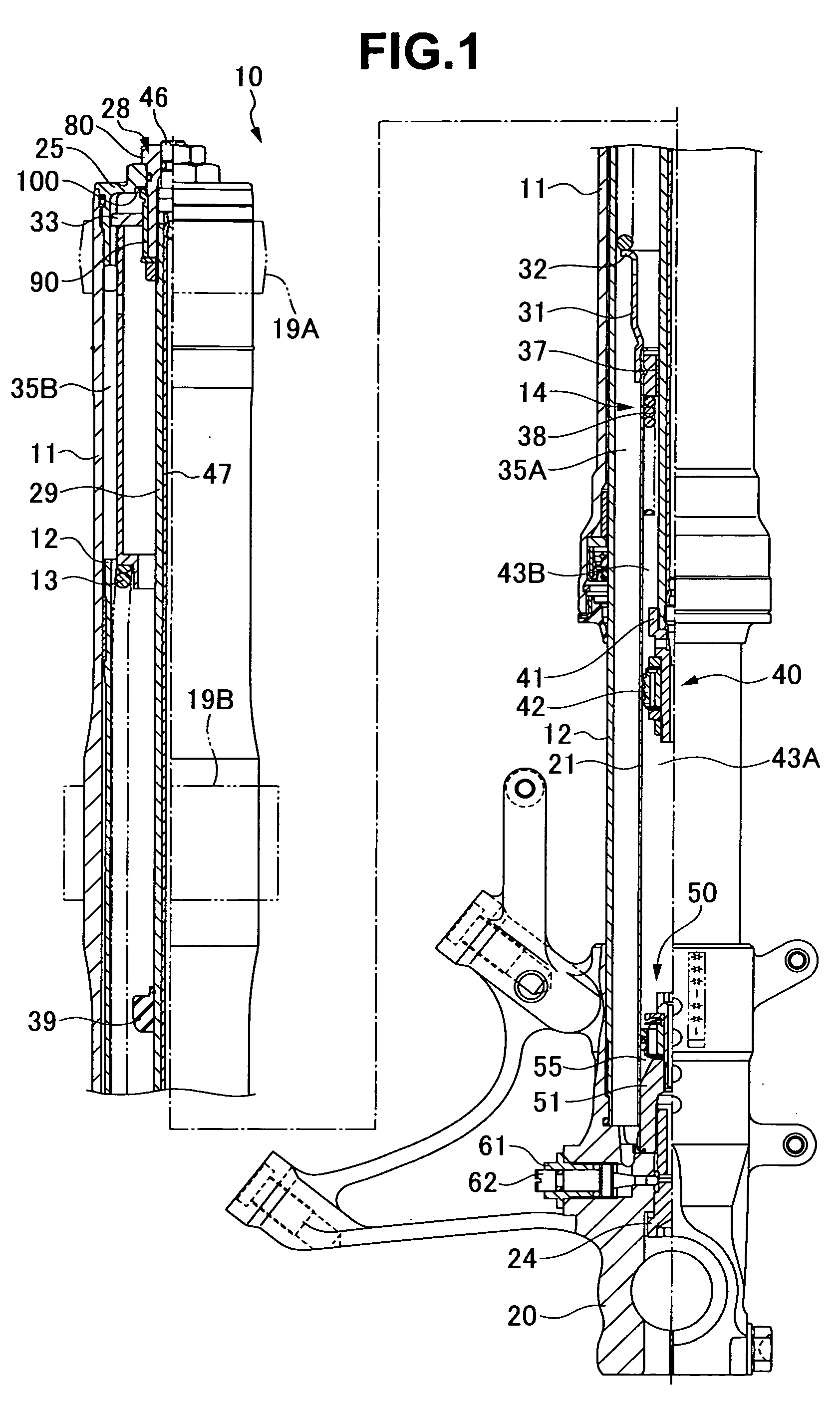

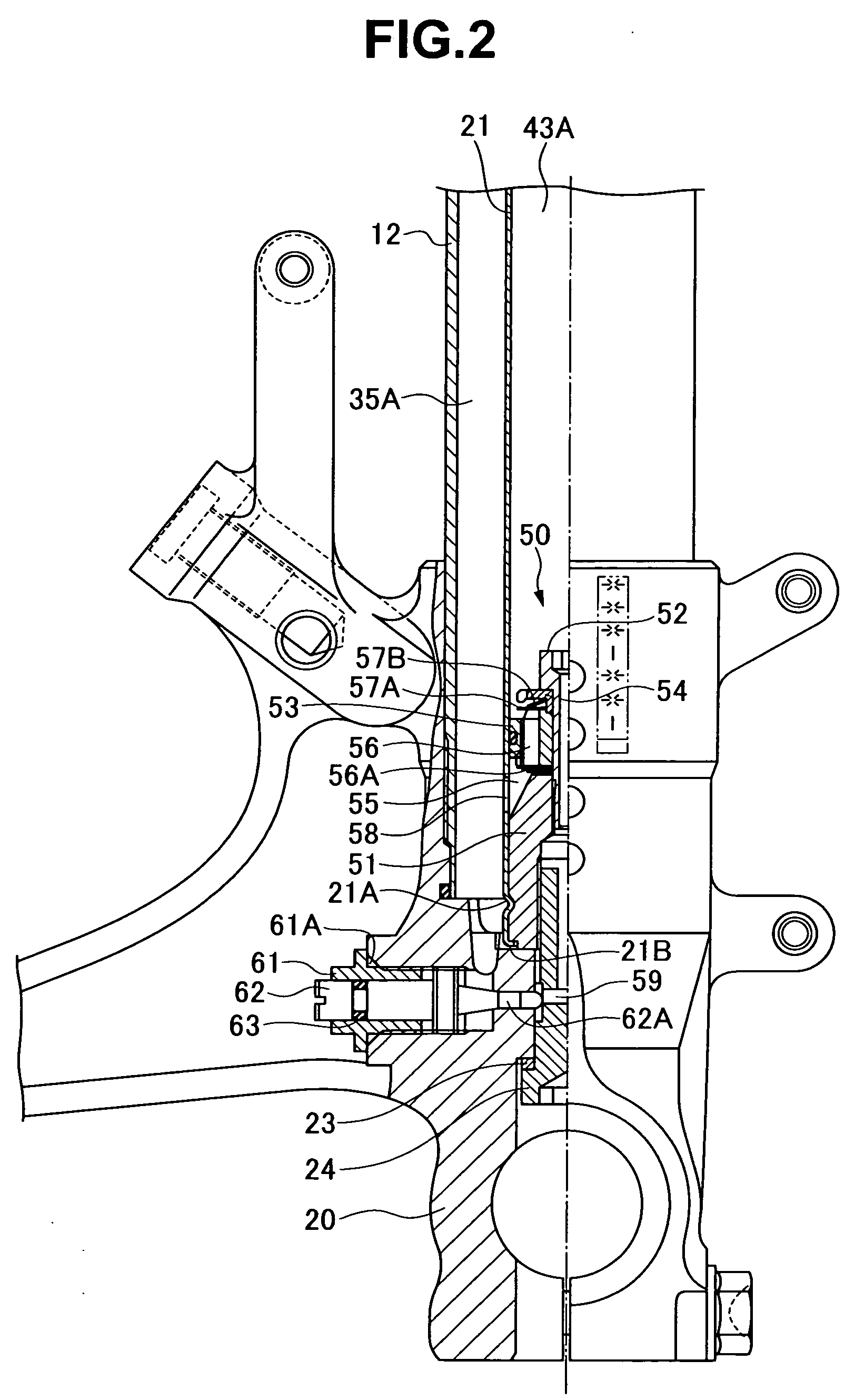

Front fork

InactiveUS20070096376A1Simplify the finishing processReduced Thickness DimensionsSpringsAxle suspensionsMechanical engineering

In a front fork, a bottom piece is inserted to an inner periphery of a lower end portion of a damper cylinder, and the lower end portion of the damper cylinder is fixed by caulking to an outer periphery of the bottom piece, and a bottom bolt locked into a bottom portion of the axle side tube is screwed from an outer side with the bottom piece, whereby a lower surface of the bottom piece is fastened to a bottom surface of an axle side tube.

Owner:SHOWA CORP

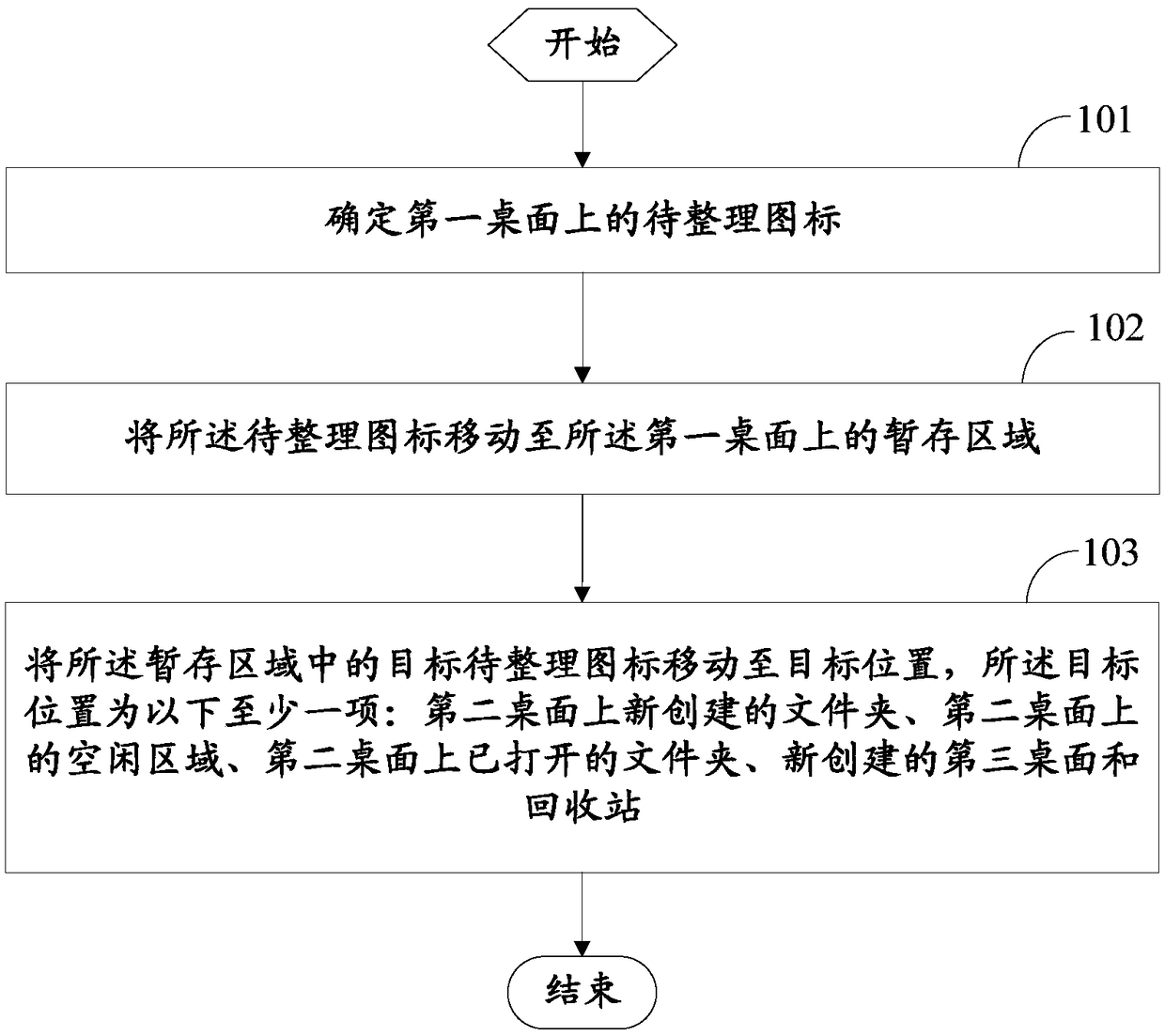

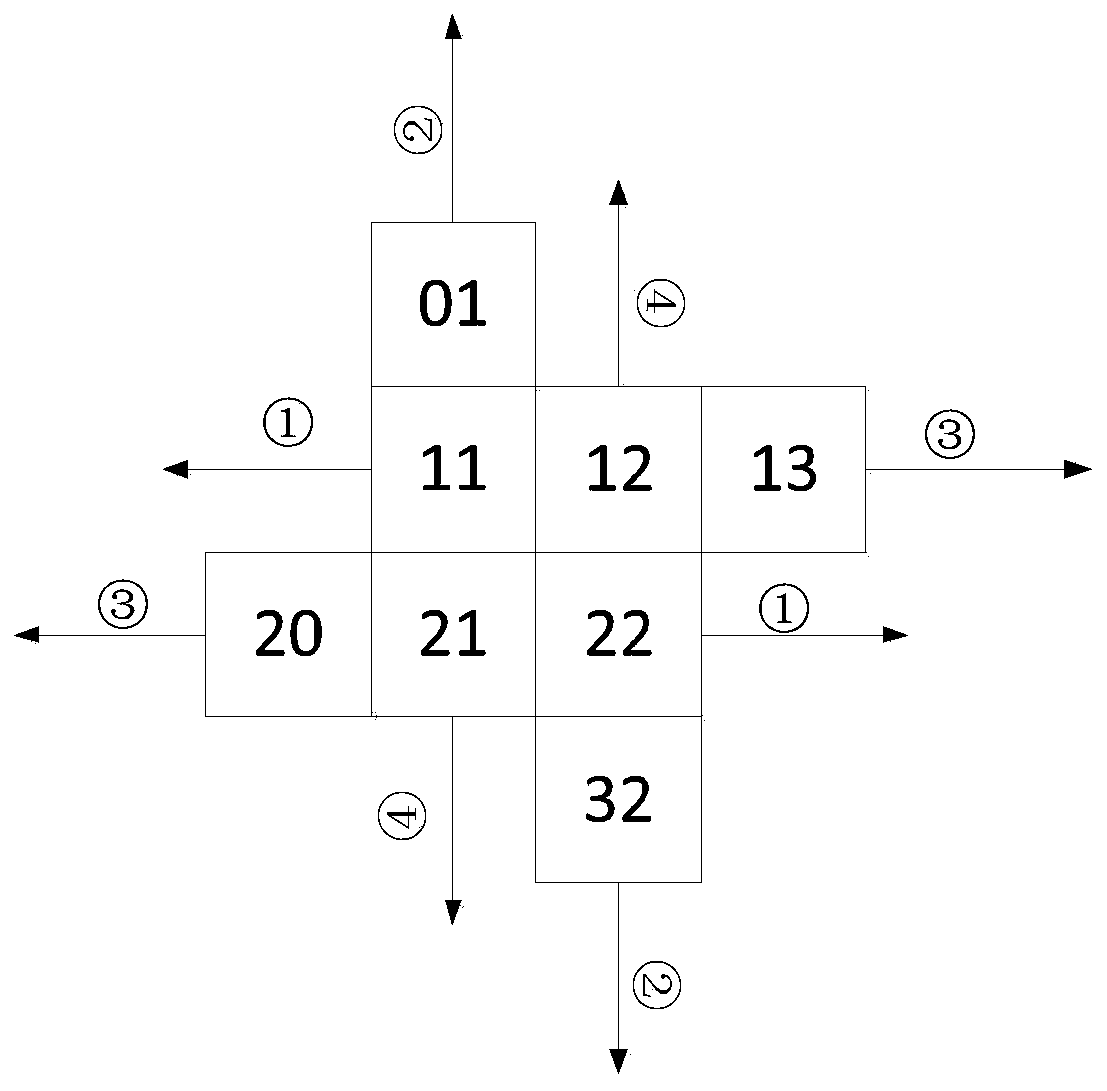

Method for sorting icons, terminal device, and storage medium

InactiveCN109358784ARealize batch sortingImprove experienceInput/output processes for data processingTerminal equipmentOperating system

The embodiment of the invention provides a method for sorting icons, a terminal device and a storage medium. The method comprises the following steps: determining icons to be arranged on a first desktop; moving the icon to be sorted to a temporary storage area on the first desktop; moving a target icon to be sorted in the temporary storage area to a target location, wherein the target location isat least one of a newly created folder on a second desktop, an idle area on the second desktop, an opened folder on the second desktop, a newly created third desktop and a recycle bin. Compared with the traditional way of arranging icons, the embodiment of the invention can simplify the process of arranging icons and improve the experience of users.

Owner:VIVO MOBILE COMM CO LTD

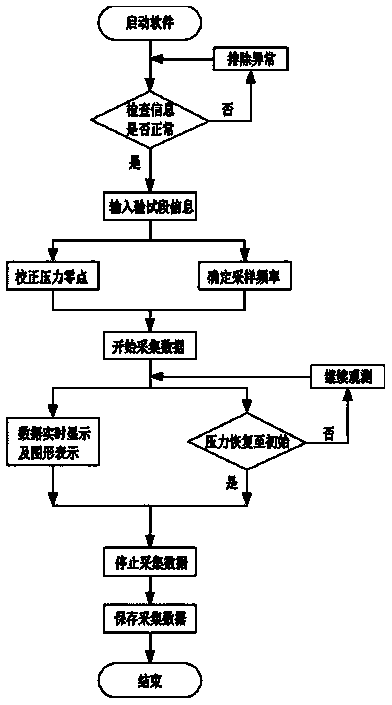

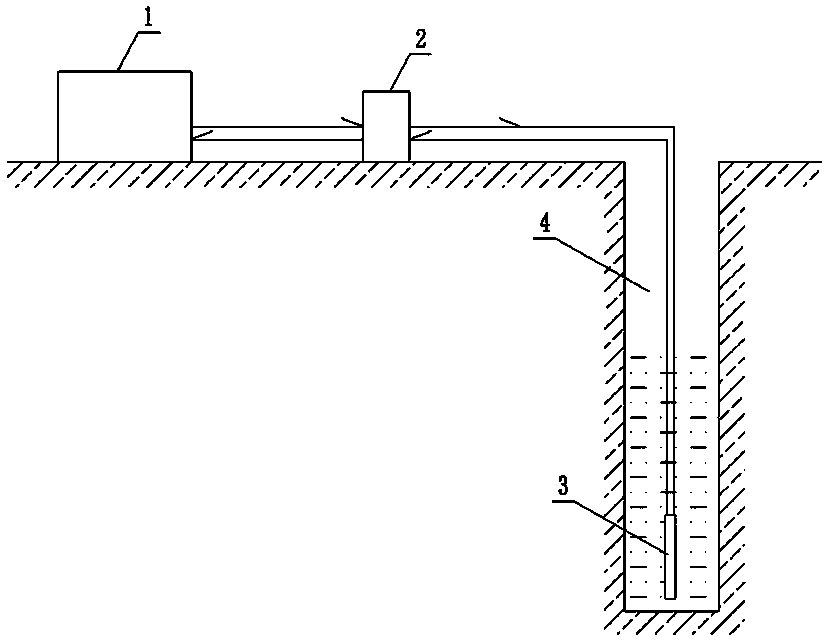

Bore slug test method

InactiveCN107941675AEasy to masterEasy to operatePermeability/surface area analysisData acquisitionPore water pressure

The invention discloses a bore slug test method, which comprises the following steps: (1) a portable computer is connected to the data output port of a data acquisition card through a signal transmission cable, and the data input port of the data acquisition card is connected to the data output port of a pressure transmitter and sealed to resist water; (2) the pressure transmitter is put into a tested borehole, and gets to a specified depth below the underground water level, and the depth is set on the site according to an excited water head height; (3) sampling frequency is set through the software interface of the portable computer, and the pressure transmitter is started to acquire data; (4) after obtaining the data acquired by the pressure transmitter, the portable computer carries outinstant excitation on the underground water level in the tested borehole; (5) through the software interface of the portable computer, the changing and recovering process of water pressure is observed, and when displayed pressure data approximates or reaches an initial value, the test is over. The bore slug test method has the advantages that the manual operation process is simplified, the bore slug test method can be conveniently mastered by on-site technicians, and the on-site working efficiency is increased.

Owner:YELLOW RIVER ENG CONSULTING

DMTD-COFs material as well as modification method and application thereof

ActiveCN113117652AImprove adsorption capacityLarge adsorption capacityOther chemical processesWater contaminantsEthanedithiolOrganic solvent

The invention relates to a DMTD-COFs material as well as a modification method and application thereof, in particular to a DMTD-COFs material capable of efficiently adsorbing low-concentration heavy metals in water as well as a modification method and application thereof, and belongs to the technical field of material modification and drinking water deep purification. The DMTD-COFs material capable of efficiently adsorbing the low-concentration heavy metal in the water is obtained by grafting 2, 5-dimercapto-1, 3, 4-thiadiazole on a COFs material. The modification method comprises the following steps: dissolving DMTD in dithioglycol under heating and inert atmosphere; in an inert atmosphere, adding a DMTD-ethanedithiol solution into a Schlenk tube containing a COFs material and AIBN; keeping inert atmosphere, heating and stirring at constant temperature for reaction; washing a solid sample with an organic solvent; and carrying out vacuum drying on the solid sample. The material can quickly and efficiently adsorb low-concentration heavy metals in water, and is large in adsorption capacity and good in adsorption selectivity.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Sulfuric acid dew point corrosion resisting steel capable of avoiding surface cracks and rolling technology of sulfuric acid dew point corrosion resisting steel capable of avoiding surface cracks

ActiveCN110983206ASimplify the finishing processReduce consumptionTemperature control deviceWork treatment devicesCrazingHeating furnace

The invention provides a sulfuric acid dew point corrosion resisting steel capable of avoiding surface cracks and a rolling technology of the sulfuric acid dew point corrosion resisting steel capableof avoiding the surface cracks. Compared with the prior art, according to the steel and the rolling technology thereof, a steel billet is heated in a heating furnace, and the heating furnace is divided into a preheating section, a first heating section, a second heating section, a first soaking section and a second soaking section in the length direction of the furnace; in the furnace, the temperature of the preheating section is lower than or equal to 750 DEG C, the temperature of the first heating section is 600-900 DEG C, the temperature of the second heating section is 850-1000 DEG C, thetemperature of the first soaking section is 1120-1160 DEG C, and the temperature of the second soaking section is 1100-1140 DEG C; and the quick temperature increasing heating time of the preheating section and the first heating section is 55-65 min, the heating time of the second heating section is 25-35 min, and the heat preservation time of the first soaking section and the second soaking section is 90-120 min. Formation of the surface cracks of the steel billet in the heating process is controlled by reasonably optimizing the heating temperature and the heat preservation time, and thus mesh cracks on the surface of rolled materials are avoided.

Owner:WUHU XINXING DUCTILE IRON PIPES

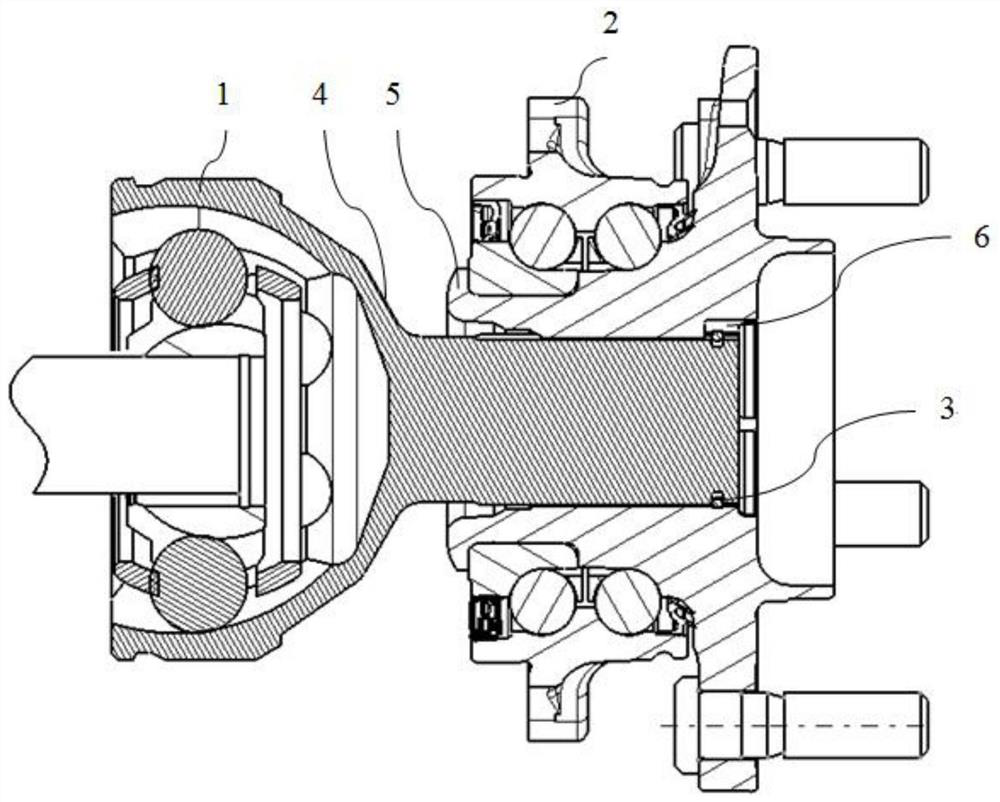

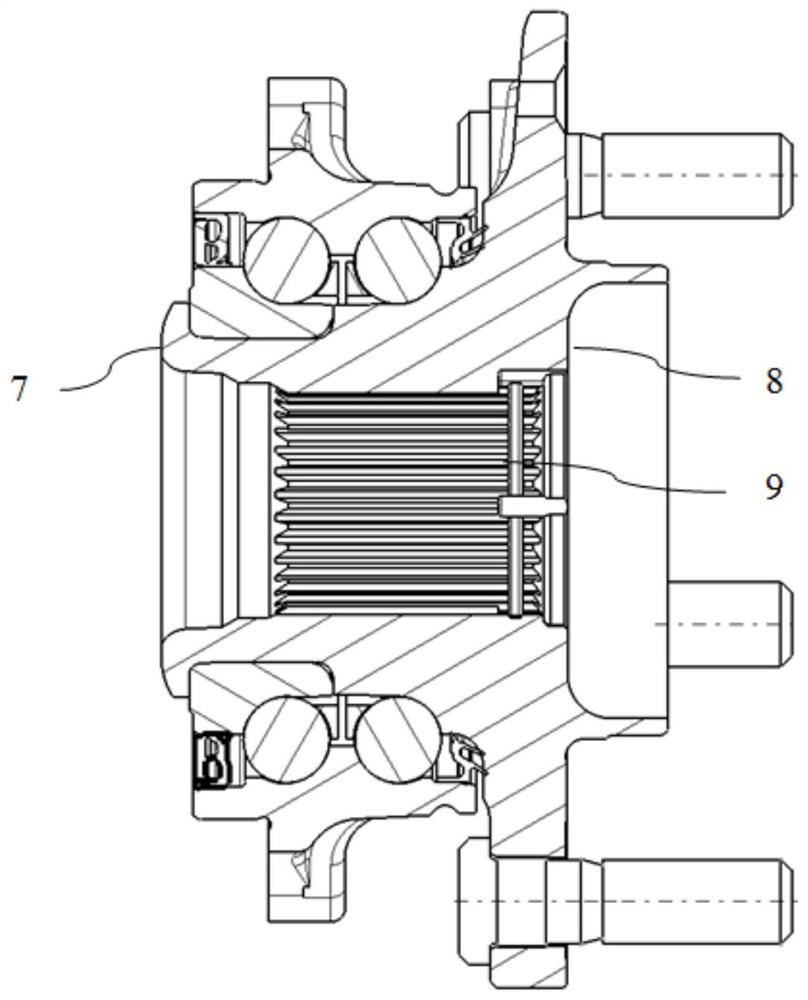

Passenger vehicle wheel edge spline matching and fastening structure

PendingCN112026438ALow costSimplify the assembly and disassembly processHubsAxle unitsDrive shaftControl theory

The invention belongs to the technical field of riding chassis parts, and particularly relates to a passenger vehicle wheel edge spline matching and fastening structure. The structure comprises a driving shaft, a hub bearing and an elastic check ring, the driving shaft is sleeved with the elastic check ring, the driving shaft is connected into the hub bearing through a spline and connected into the hub bearing in a matched mode through the elastic check ring on the driving shaft, and a plurality of hub bearing disassembling process holes used for disassembling the driving shaft are formed in the right side end face of the hub bearing; the elastic check ring which is convenient to assemble and disassemble is adopted for positioning, a shaft head thread pair is not needed for fastening, endface contact does not exist between the driving shaft and the hub bearing, the assembling and disassembling process is simplified, the purchasing cost is reduced, and the problem of vehicle starting abnormal sound can be solved fundamentally.

Owner:FAW CAR CO LTD

Composition for improving anti-pilling performance of all-cotton fabric and anti-pilling finishing technology

InactiveCN105220496ASoft touchFeel smoothSucessive textile treatmentsBleaching apparatusAcetic acidEmulsion

The invention provides a composition for improving the anti-pilling performance of all-cotton fabric and an anti-pilling finishing technology. The composition is prepared from modified polyether emulsion, amino fatty acid emulsion, modified polysiloxane emulsion, acrylic-acid-modified polyurethane polymer emulsion, acetic acid and water. The finishing technology comprises the steps that a grey fabric is sequentially processed through singeing, enzyme rolling and cold heaping, boiling-out, bleaching, mercerizing, whitening, printing, ageing, washing, anti-pilling finishing, press polishing and preshrinking. The composition not only can enable the fabric to have the good skin-friendly performance and soft hand feeling, but also has the good anti-pilling performance.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

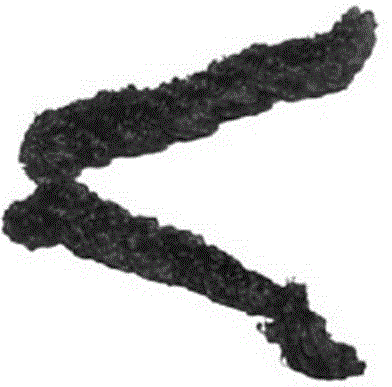

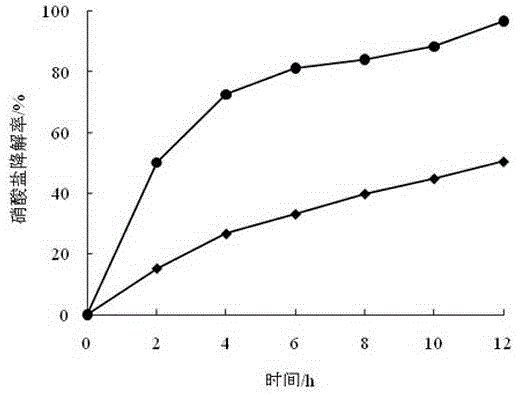

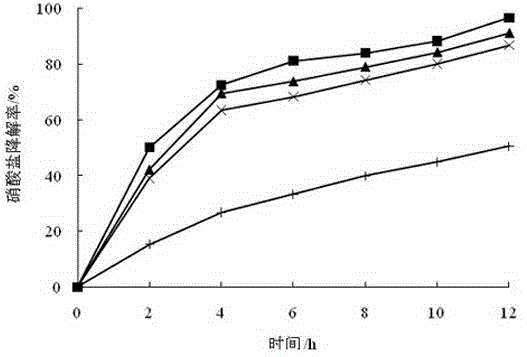

Quinones-modified biological vector and application thereof in accelerating microbial denitrifying process

InactiveCN102060380BGood compatibilitySimplify the finishing processTreatment with anaerobic digestion processesBiotechnologySulfonate

The invention relates to a quinones-modified biological vector and application thereof in accelerating a microbial denitrifying process. The quinones-modified biological vector is prepared by performing a modification reaction on a vector by using quinones. The preparation method for the quinones-modified biological vector comprises the following steps of: performing the modification reaction in the aqueous solution of methylene-bis-naphthalene sulfonate, wherein the vector, the quinones, the methylene-bis-naphthalene sulfonate and water are in the weight part ratio of 20-30:10-20:0.5-5:500-1,000; adjusting the pH to be 5 to 9; and reacting for 3 to 10 hours with stirring at the temperature of 60 to 120 DEG C. The invention also comprises the application of the quinones-modified biological vector in accelerating the microbial denitrifying process. The quinones-modified biological vector has the advantages of high microbial compatibility, simple modification process and low production cost, is suitable for modifying various biological vectors by various quinones, and can strengthen, regulate and control the microbial denitrifying process.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Film packaging method of stretchable organic photoelectric device

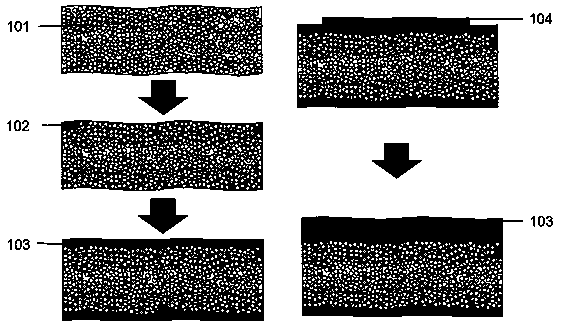

ActiveCN110085764AImprove packaging effectThe finishing process is simpleSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmPolymer science

The invention provides a film packaging method of a stretchable organic photoelectric device. A film packaging structure prepared by the method is provided with a stretchable organic polymer substratewith high water and oxygen obstruction performance, a stretchable organic photoelectric device and an inorganic / organic fused overlapped film packaging layer with high water and oxygen obstruction performance successively from bottom to top, inorganic / organic overlapped films are used in the high water and oxygen obstruction layer, the infiltration time of a precursor of atomic layer deposition in a reaction chamber is controlled, and an inorganic filling material is formed in the surfaces of the stretchable organic polymer substrate and the organic film layer to improve the water and oxygenobstruction performance thereof.

Owner:FUZHOU UNIV

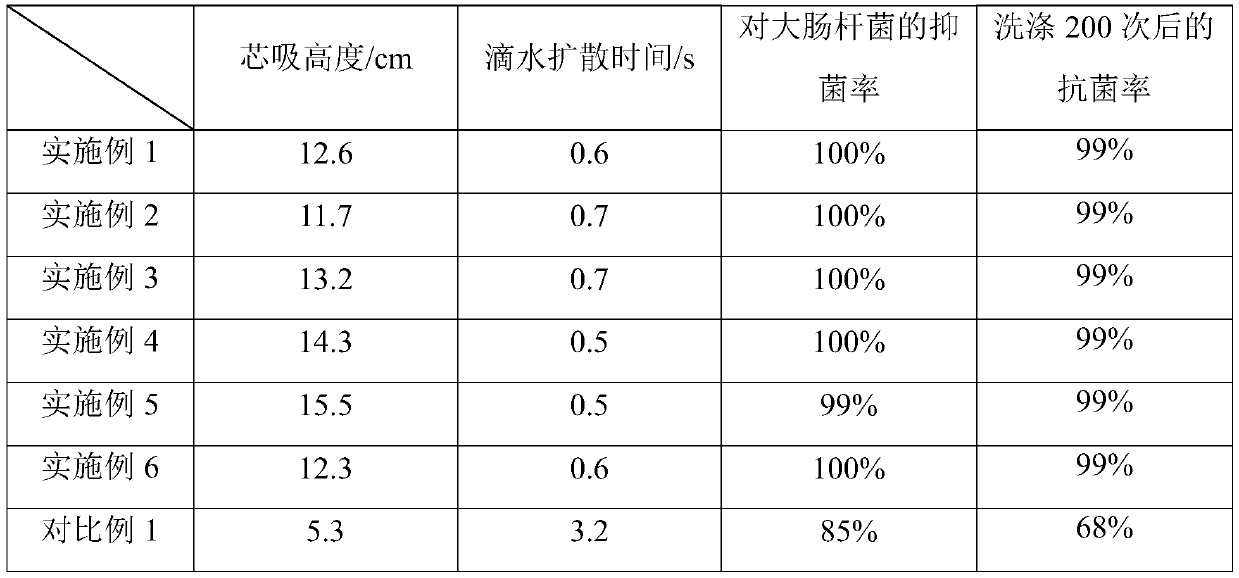

Antibacterial sock and preparation method thereof

PendingCN110644231AEasy to takeSimplify the finishing processBiochemical fibre treatmentFibre typesChemistryAnti bacterial

The invention relates to an antibacterial sock and a preparation method thereof. Antibacterial silver-plated fibers are woven to obtain the antibacterial sock. The prepared antibacterial sock has excellent antibacterial properties and good breathable performance, a processing technology saves energy, protects environments and is harmless to human bodies and the environments, the antibacterial sockhas good moisture absorption and sweat releasing performances and bacteria production can be effectively stopped.

Owner:DONGHUA UNIV +2

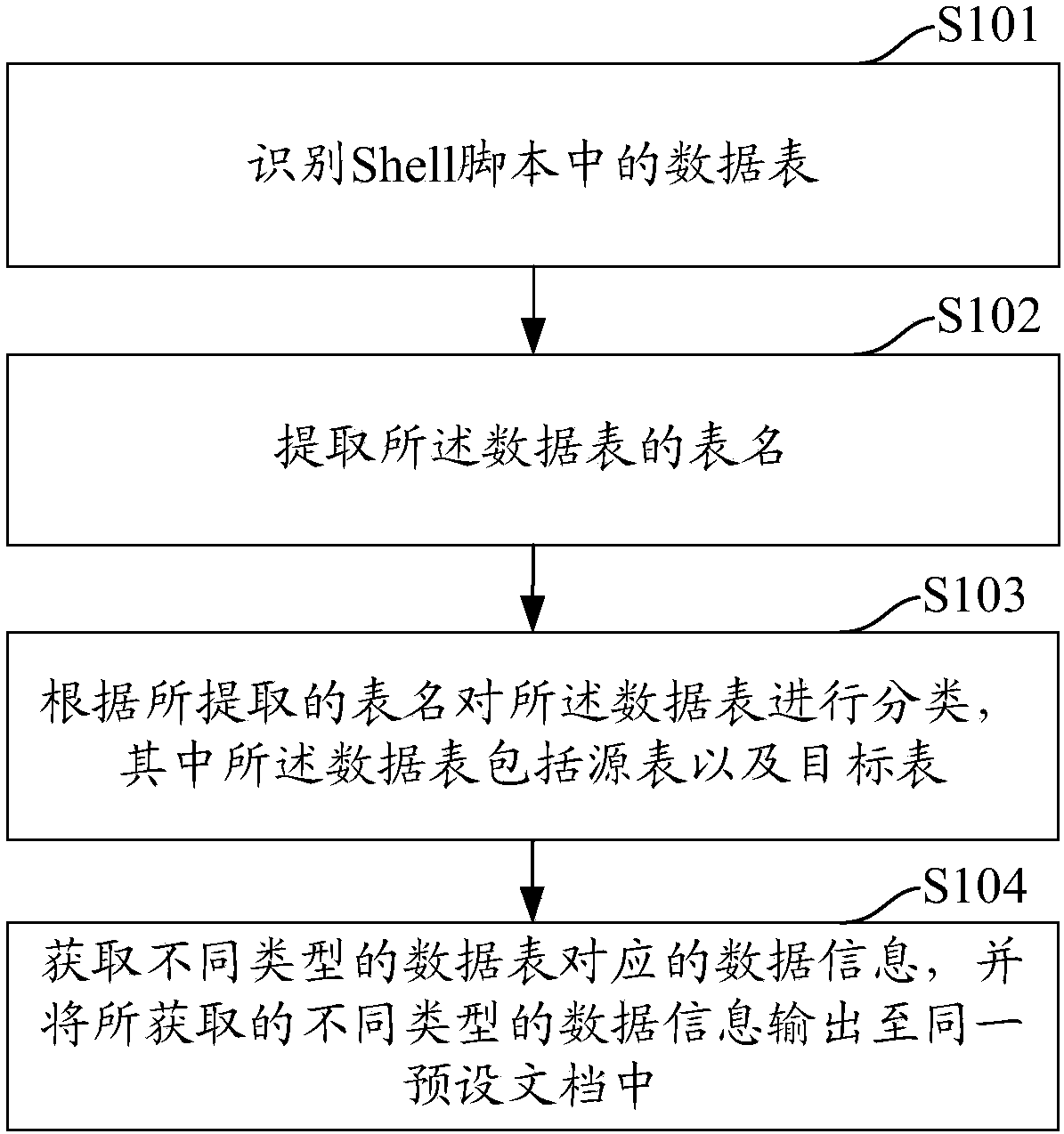

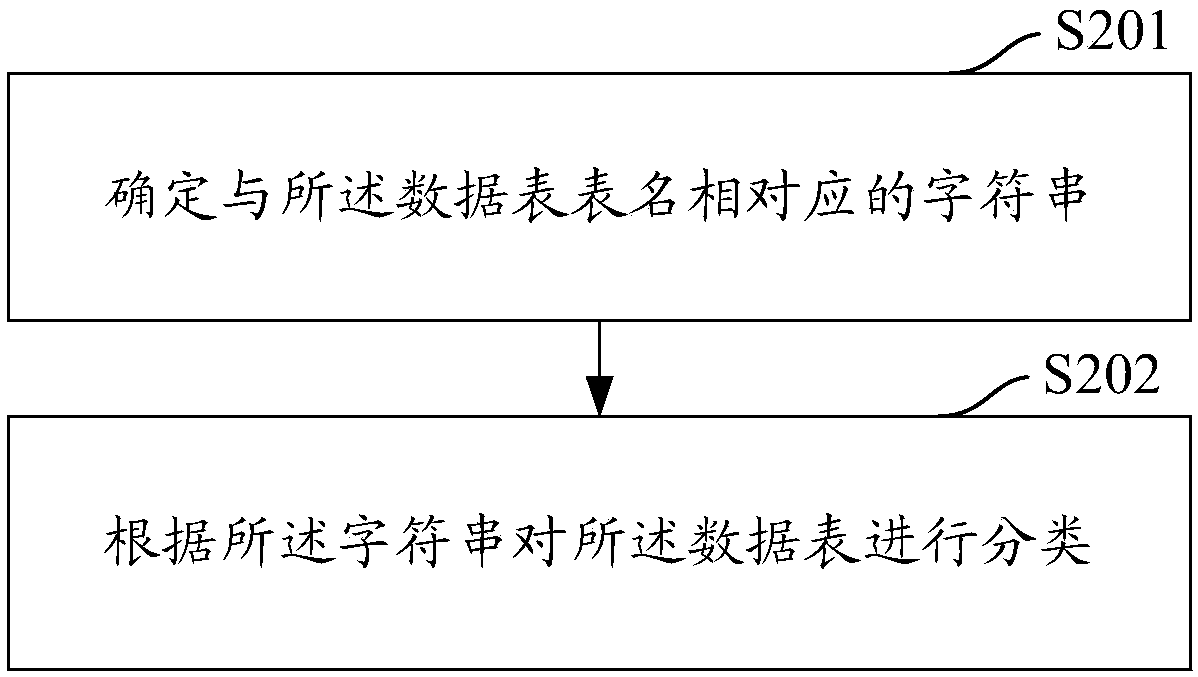

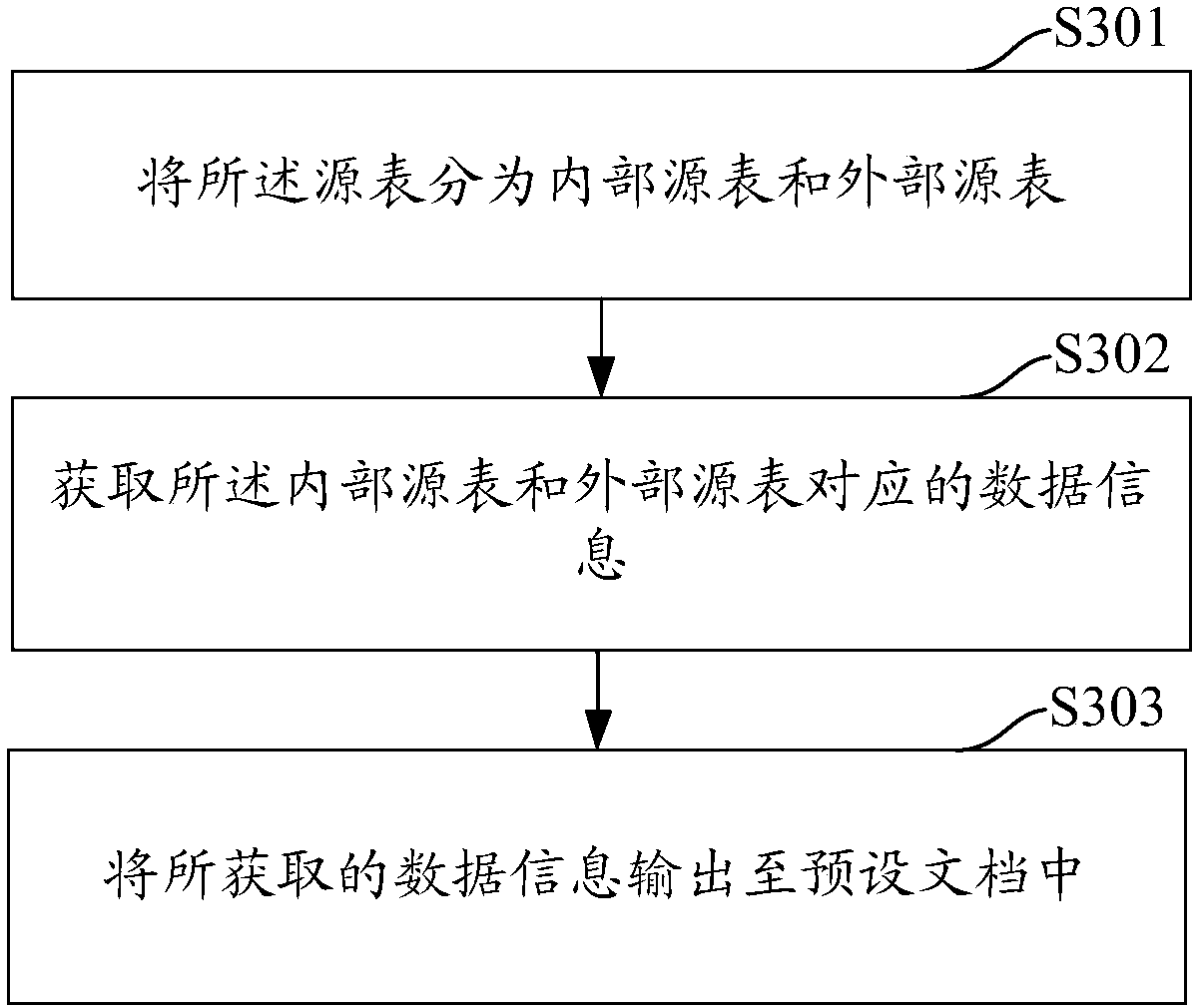

Data table extraction method based on Shell, terminal, equipment and storage medium

ActiveCN108536745ASimplify the finishing processSimplify the update processSpecial data processing applicationsData informationComputer terminal

The invention discloses a data table extraction method based on Shell, a terminal, equipment and a storage medium. The method comprises the following steps: identifying data tables in a Shell script;extracting table names of the data tables; classifying the data tables which comprise a source tables and target tables according to the extracted table names; obtaining data information correspondingto different types of data tables, and outputting the obtained different types of data information into the same preset document. Through the modified data table extraction method, data tables relevant to each script are not required to be manually complicatedly found out, processing and updating processes are furthest simplified, and a large amount of manpower resources can be saved.

Owner:PING AN TECH (SHENZHEN) CO LTD

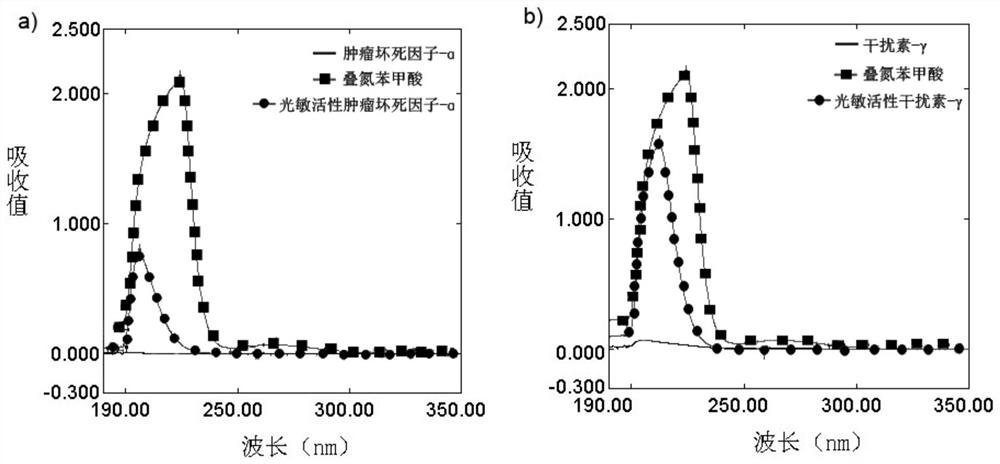

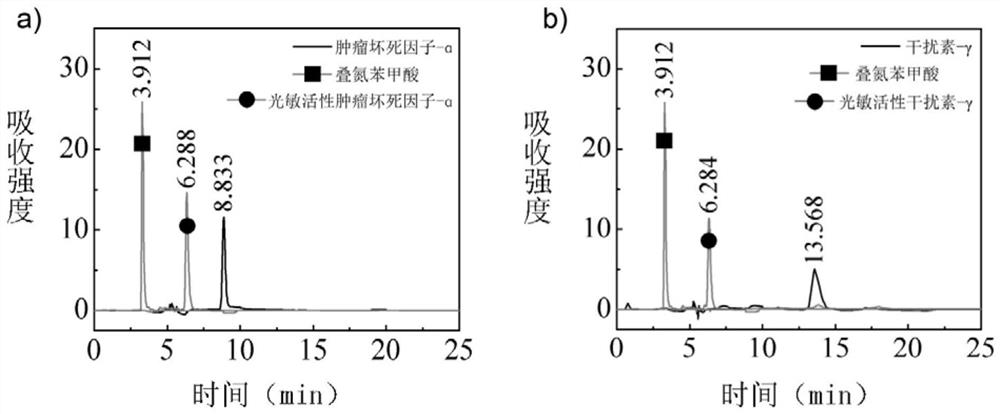

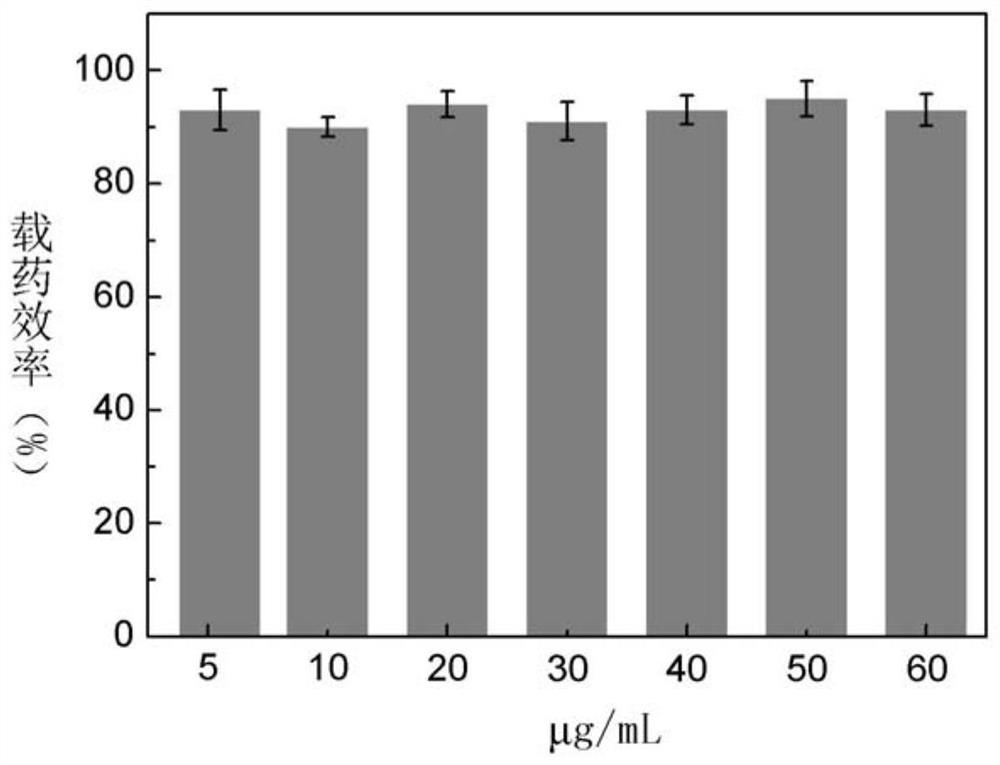

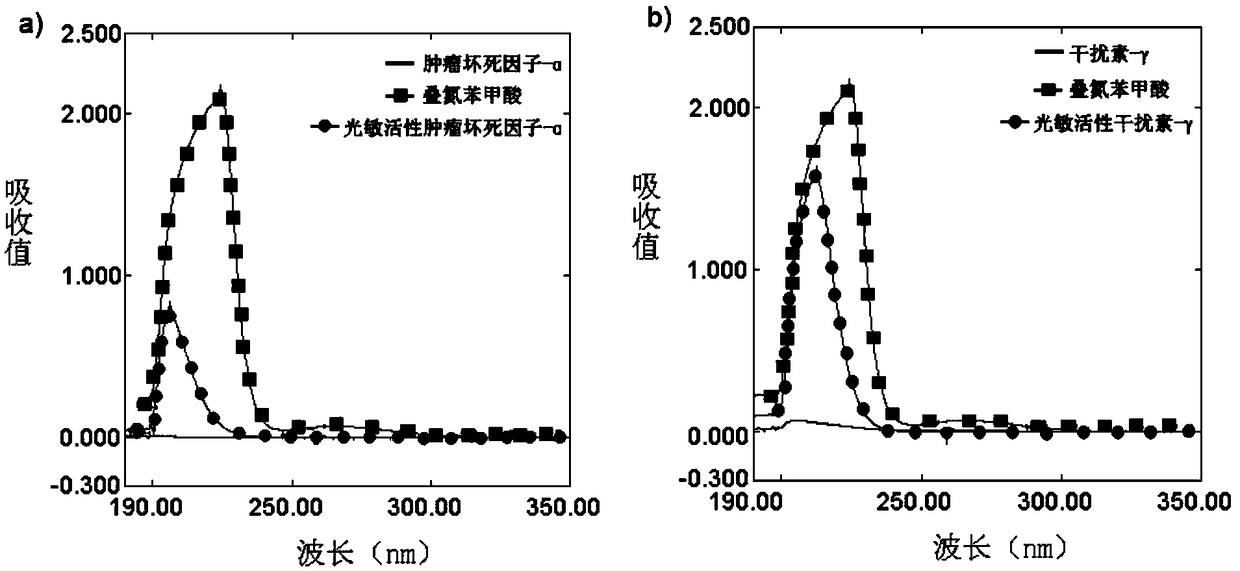

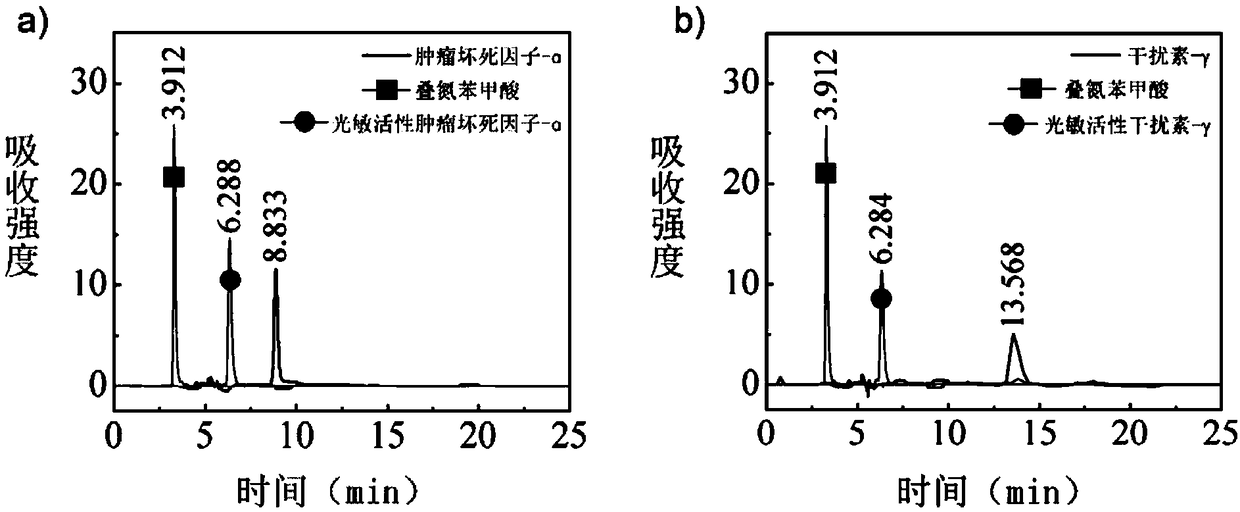

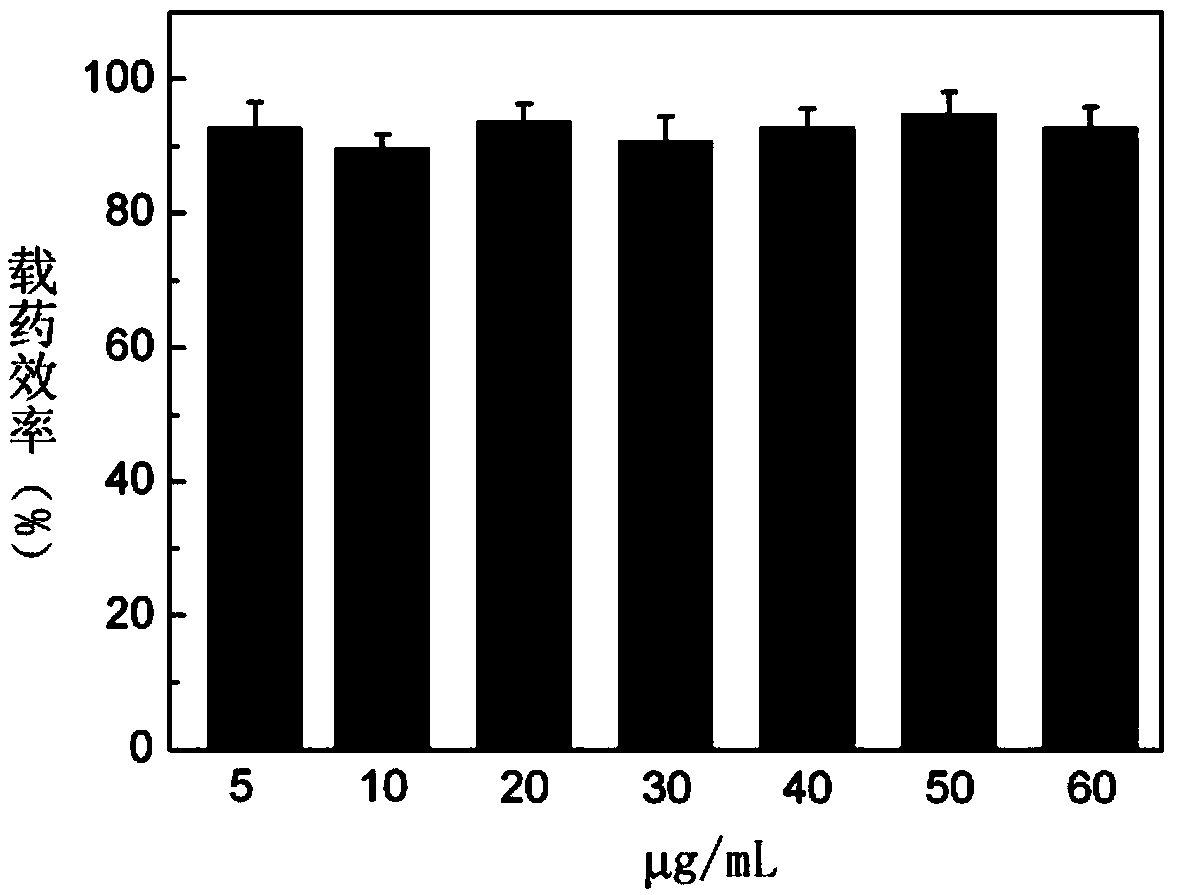

Antitumor drug, antitumor drug for external application and preparation method thereof

ActiveCN108815532BClosely connectedEasy to achieve sheddingPeptide/protein ingredientsPharmaceutical delivery mechanismTherapeutic effectTopical drug

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Antitumor drug and antitumor external application drug, and preparation methods thereof

ActiveCN108815532AClosely connectedEasy to achieve sheddingPeptide/protein ingredientsPharmaceutical delivery mechanismExternal applicationTherapeutic effect

The invention discloses an antitumor drug and an antitumor external application drug, and preparation methods thereof. Raw materials of the antitumor drug include a protein antitumor biomaterial containing at least one group of -OH, -COOH and -NH2, a photocoupler and a solvent; the photocoupler includes an aromatic azide. The preparation process includes that the protein antitumor biomaterial, thephotocoupler and the solvent are subjected to mixed reaction under light shielding conditions. The photocoupler aromatic azide is used as a modifier to modify the protein antitumor biomaterial, and the preparation method has the advantages of low cost, good modification effect, high yield and wide application range. The synthesized antitumor drug contains azidophenyl, has photosensitive activityand can be fixed on medical dressings through photochemistry to form the antitumor external application drug; the drugs are closely linked and not easy to fall off, death induction signals can be continuously sent to tumor cells, the action time of the drugs is prolonged, and the therapeutic effect is improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Low-cost superhydrophobic surface treatment method of aluminum alloy

InactiveCN101982560BEasy to operateSimple manufacturing processSolid state diffusion coatingLong chain fatty acidSuperhydrophobe

The invention provides a low-cost superhydrophobic surface treatment method of aluminum alloy, which comprises the following steps: (1) carrying out chemical etching on the surface of the aluminum alloy by utilizing hydrochloric acid aqueous solution with the mass-volume concentration of 70g / L-95g / L in water bath at the temperature of 30-50 DEG C for 3-6min; and (2) carrying out evaporation modification on the surface of the aluminum alloy by utilizing long chain fatty acid solution by an evaporation method, wherein, the long chain fatty acid comprises at least one of lauric acid and stearic acid, and the long chain fatty acid solution is prepared by dissolving fatty acid into an ethanol solvent based on the mass percent of 3wt.%-15wt.%. The evaporation method comprises the following steps: placing the long chain fatty acid solution and the aluminum alloy subject to chemical etching treatment in a sealed container; putting the sealed container in a chamber electric furnace, heating until the temperature of the mixture is up to 100-200 DEG C, and performing heat preservation for 1-3h; and taking out the aluminum alloy and placing the aluminum alloy in the chamber electric furnace again, curing at the temperature of 50-90 DEG C for 0.5-1.5h, and finally taking out the aluminum alloy, and carrying out air cooling on the aluminum alloy to obtain the aluminum alloy surface which has the advantages of good superhydrophobic characteristic and less possibility of being adhered to water drops.

Owner:SOUTHEAST UNIV

Flat wire harness terminal pressing equipment for new energy automobile and pressing process thereof

PendingCN114791576APrevent crosstalkImprove pressing efficiencyContinuity testingNew energyCable harness

The invention relates to the technical field of new energy automobile manufacturing, and discloses flat wire harness terminal pressing equipment for a new energy automobile and a pressing process thereof.The flat wire harness terminal pressing equipment comprises a mounting base, a detector is arranged on the side, close to the back face, of the mounting base, and a pressing device is movably arranged above the mounting base; the detector is used for detecting the circuit connection condition at the two ends of the wire harness and making a response. The detector detects the connectivity of the wire harness through a plurality of detection points and the lower half parts of the terminals and performs corresponding display and prompt, so that not only is the on-off of each circuit in the wire harness detected, but also the on-off condition of the connecting parts of the terminals is detected at the same time; and the detector respectively detects the endpoint distribution condition of each line in the wiring harness through a plurality of detection points, so as to measure whether the lines of each endpoint at the two ends of the flat wiring harness correspond or not, and perform corresponding display and prompt according to the corresponding condition, thereby preventing the connection error of the lines between the corresponding endpoints after the terminals are pressed, and improving the reliability of the wiring harness. And the occurrence of a circuit crossing condition is prevented.

Owner:许路生

An automatic sorting and numbering device and method for breeding material bags

InactiveCN111186220BSimple actionRealize sortingTypewritersOther printing apparatusRobotic armEngineering

The invention discloses an automatic sorting and numbering device and method for breeding material bags. The device comprises: an equipment casing; a transmission system arranged on the equipment casing; a mechanical arm whose top end is rotated and arranged at the outlet of the equipment casing end; the sorting channel, the top of which is fixed on the outlet end of the equipment casing, and is in contact with the bottom end of the mechanical arm, and its bottom end is in contact with or against the ground or the placement platform, and is parallel up and down at the outlet end of the equipment casing. There are two printing nozzles, which are fixedly arranged on the top of the outlet end of the equipment housing; an image acquisition system, which is used to collect the image information on the breeding material bag, obtain the original image of the material number on the breeding material bag, and The image information is transmitted to the host computer; and the host computer and the main control unit. The device of the invention realizes automatic sorting and numbering, and improves the sorting accuracy and work efficiency of rice breeding materials.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com