Low-cost superhydrophobic surface treatment method of aluminum alloy

A superhydrophobic surface and treatment method technology, applied in the field of superhydrophobic surface treatment of aluminum alloys, can solve the problems of difficult hydrolysis and modification process, high toxicity of mercaptans, high cost, etc., and achieve good superhydrophobic performance, preparation process and all The effect of requiring simple equipment and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

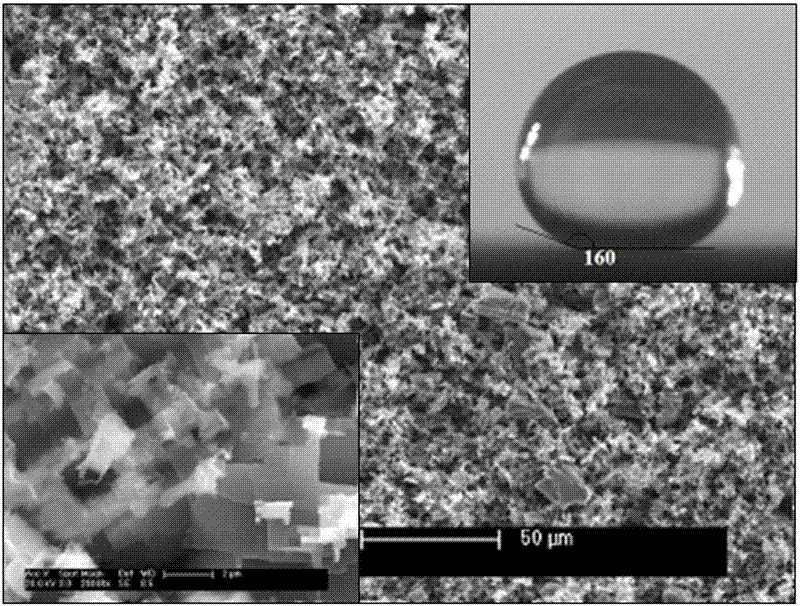

[0030] The surface of the A356 aluminum alloy was chemically etched with an aqueous hydrochloric acid solution with a concentration of 80g / L, the etching temperature was 40°C (water bath), and the etching time was 5min, so as to build a rough structure on the surface. Wash the aluminum alloy after hydrochloric acid etching with deionized water to remove residual hydrochloric acid, then take it out and dry it;

[0031] Prepare stearic acid solution: dissolve stearic acid in ethanol solvent, and the mass percentage of stearic acid to ethanol is 8wt.%.

[0032] Add the stearic acid solution into the test tube, then put the test tube and the processed sample in a sealed container, put the sealed container in a box-type electric furnace, heat it to 150°C, and keep it warm for 2 hours, then take out the aluminum alloy and put it in the box Heat it to 80°C in a type electric furnace, keep it warm for 0.5 hours, and then take it out and air-cool it.

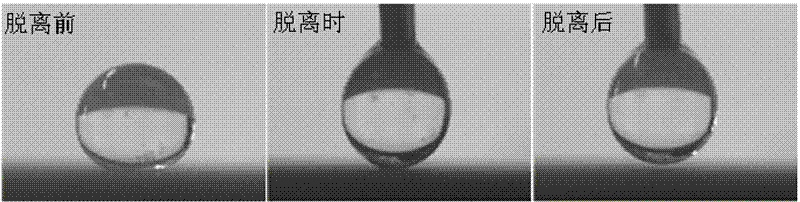

[0033] After the sample is etche...

Embodiment 2

[0035] The surface of the A356 aluminum alloy was chemically etched with a hydrochloric acid aqueous solution with a concentration of 92g / L, the etching temperature was 40°C (water bath), and the etching time was 3min, so as to build a rough structure on the surface. Wash the aluminum alloy after hydrochloric acid etching with deionized water to remove residual hydrochloric acid, then take it out and dry it;

[0036] Preparation of lauric acid solution: Dissolve lauric acid in ethanol solvent, the mass percentage of lauric acid to ethanol is 4wt.%.

[0037] Add the lauric acid solution into the test tube, then put the test tube and the processed sample into a sealed container, put the sealed container into a box-type electric furnace, heat it to 150°C, and keep it warm for 2 hours, then take out the aluminum alloy and place it in a box-type electric furnace. Heat it to 80°C in an electric furnace, keep it warm for 0.5 hours, and then take it out and air-cool it.

[0038] Afte...

Embodiment 3

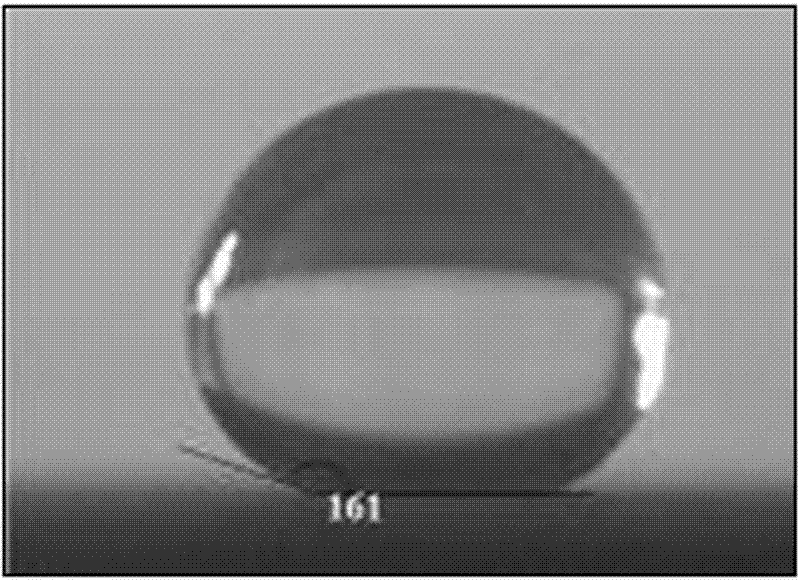

[0040]The surface of the A356 aluminum alloy was chemically etched with a hydrochloric acid solution with a concentration of 87g / L, the etching temperature was 40°C (water bath), and the etching time was 4min, so as to build a rough structure on the surface. Wash the aluminum alloy after hydrochloric acid etching with deionized water to remove residual hydrochloric acid, then take it out and dry it;

[0041] Prepare a mixed solution of lauric acid and stearic acid: dissolve lauric acid and stearic acid in an ethanol solvent, and the mass percentages of lauric acid, stearic acid and ethanol are 1wt.% and 5wt.% respectively.

[0042] Add the mixed solution of lauric acid and stearic acid into the test tube, then put the test tube and the processed sample in a sealed container, put the sealed container in a box-type electric furnace, heat it to 150°C, keep it warm for 2 hours, and then put the aluminum alloy Take it out, heat it to 80°C in a box-type electric furnace, keep it war...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com