Airproof equipment for power driven gear case of high speed train

A technology for high-speed trains and sealing devices, which is applied in the field of railway machinery and can solve problems such as oil and gas backflow, oil leakage from gearboxes, and unsuitable gearboxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

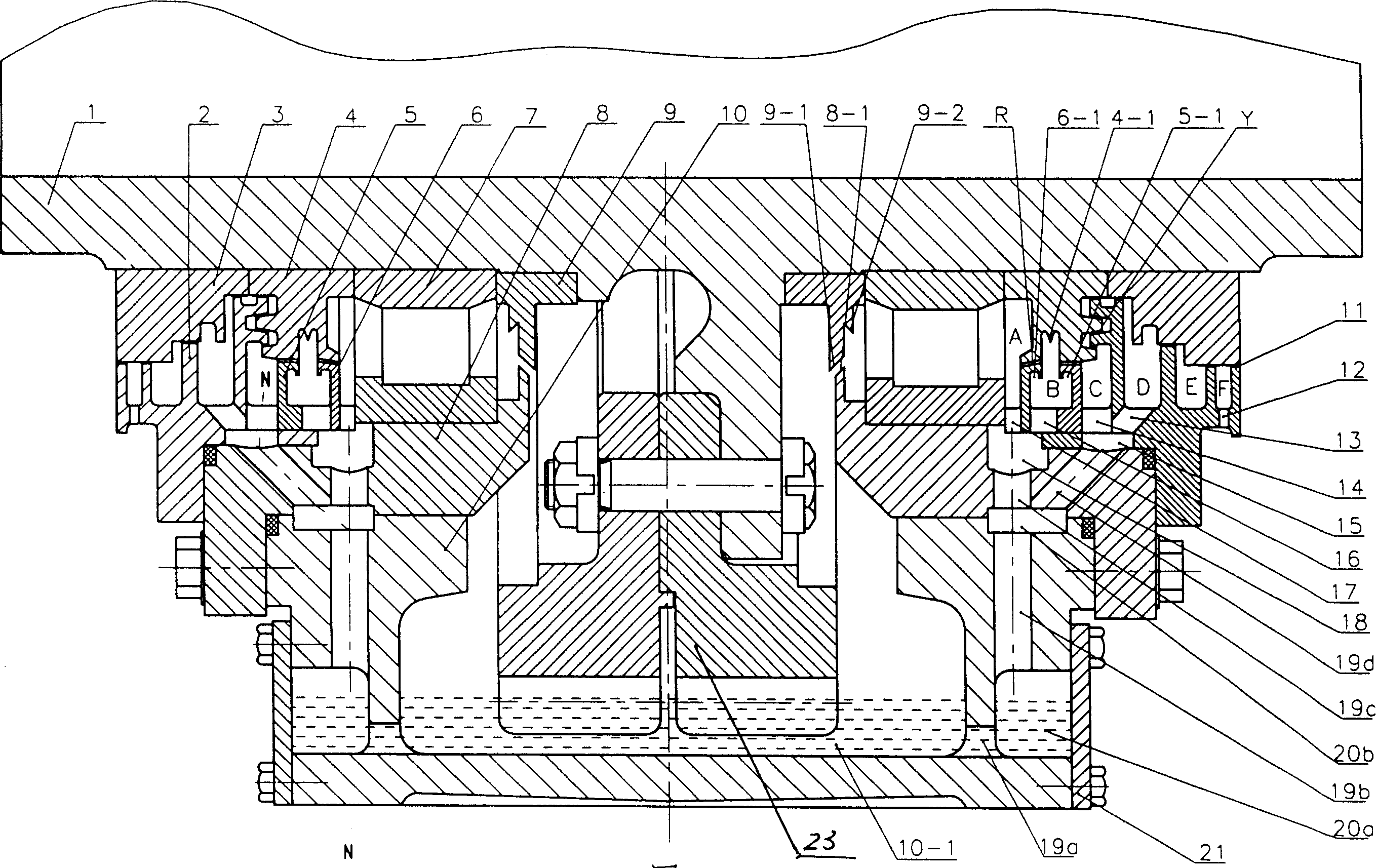

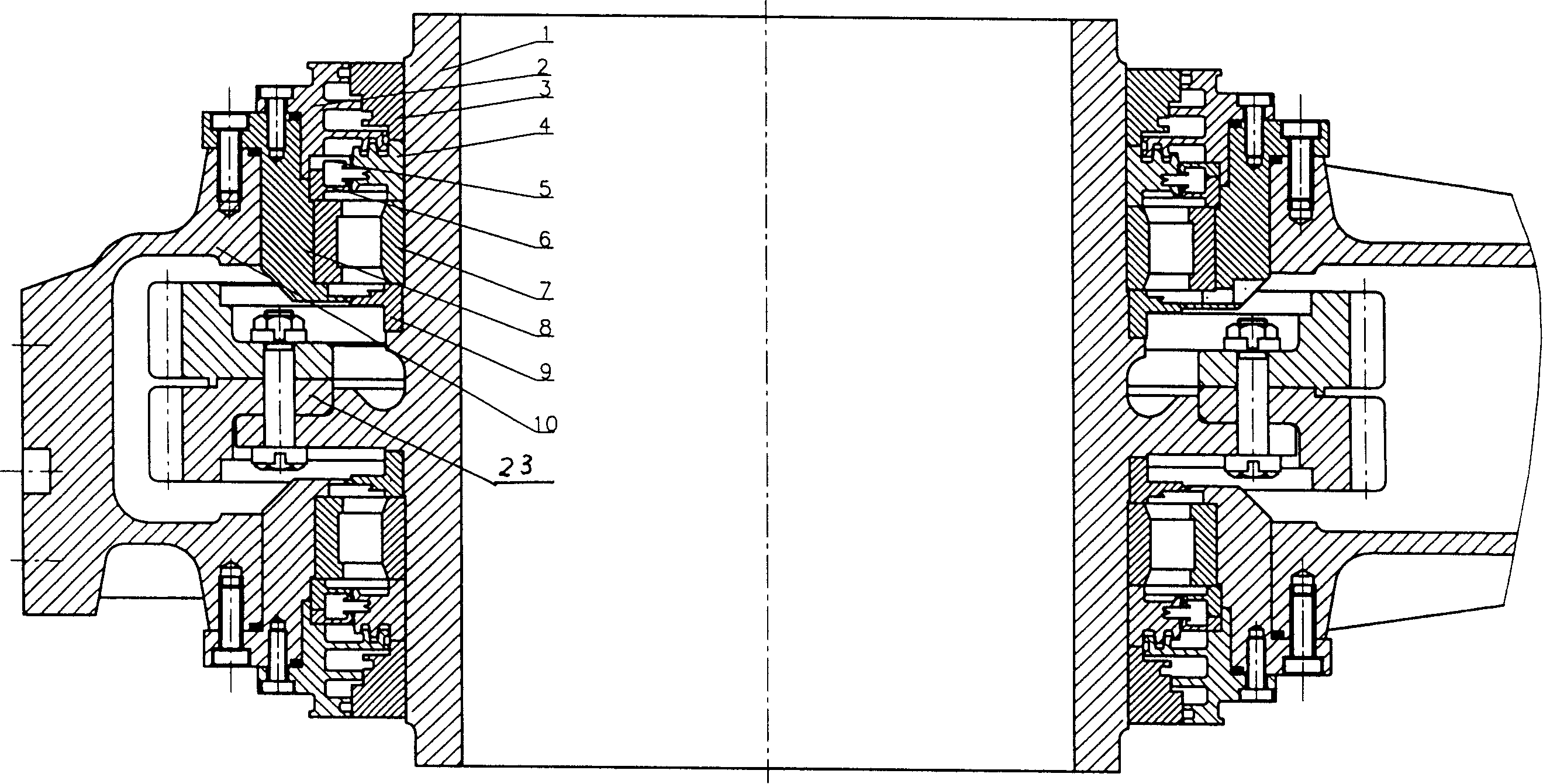

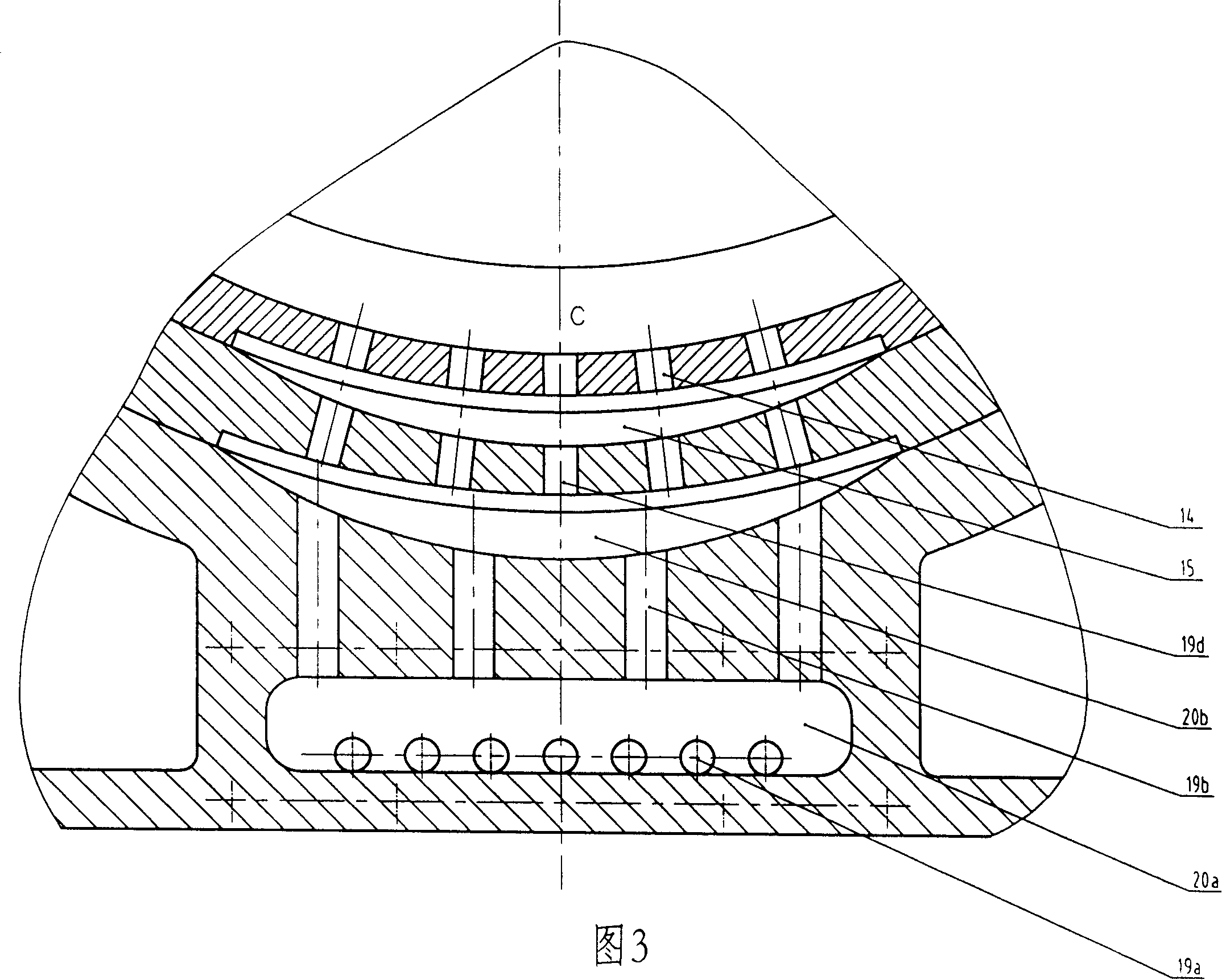

[0031] From the accompanying drawings given above, the technical solution of the present invention can be clearly understood. The object of the present invention and the technical solution for achieving the object will be more clearly understood through the description of specific embodiments in conjunction with the accompanying drawings.

[0032] One of the specific implementation methods:

[0033] It refers to an inventive structure with bearings in the penetrating part of the gearbox body, please refer to the attached figure 1 , 2 , 3. The gear case 10 among the present invention, the first static oil seal ring 6, the second static oil seal ring 5 and the third static oil seal ring 2 are all made of aluminum alloy, and the three static oil seal rings 2, 5 and 6 are processed respectively Afterwards, it is welded into one body; the bearing seat 8 and the first dynamic oil seal ring 4, the second dynamic oil seal ring 3 and the oil deflector ring 9 are all made of steel, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com