Centrifugal rotor filter device with by-pass branch pipe

A centrifugal rotor and filter technology, used in the installation/connection of lubricant purification devices, lubricating parts, pressure lubricants, etc., can solve the problems of not meeting the requirements of light weight, poor oil return, and poor oil return. , to achieve the effect of occupying less space, ensuring smooth oil return, and reducing the weight of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

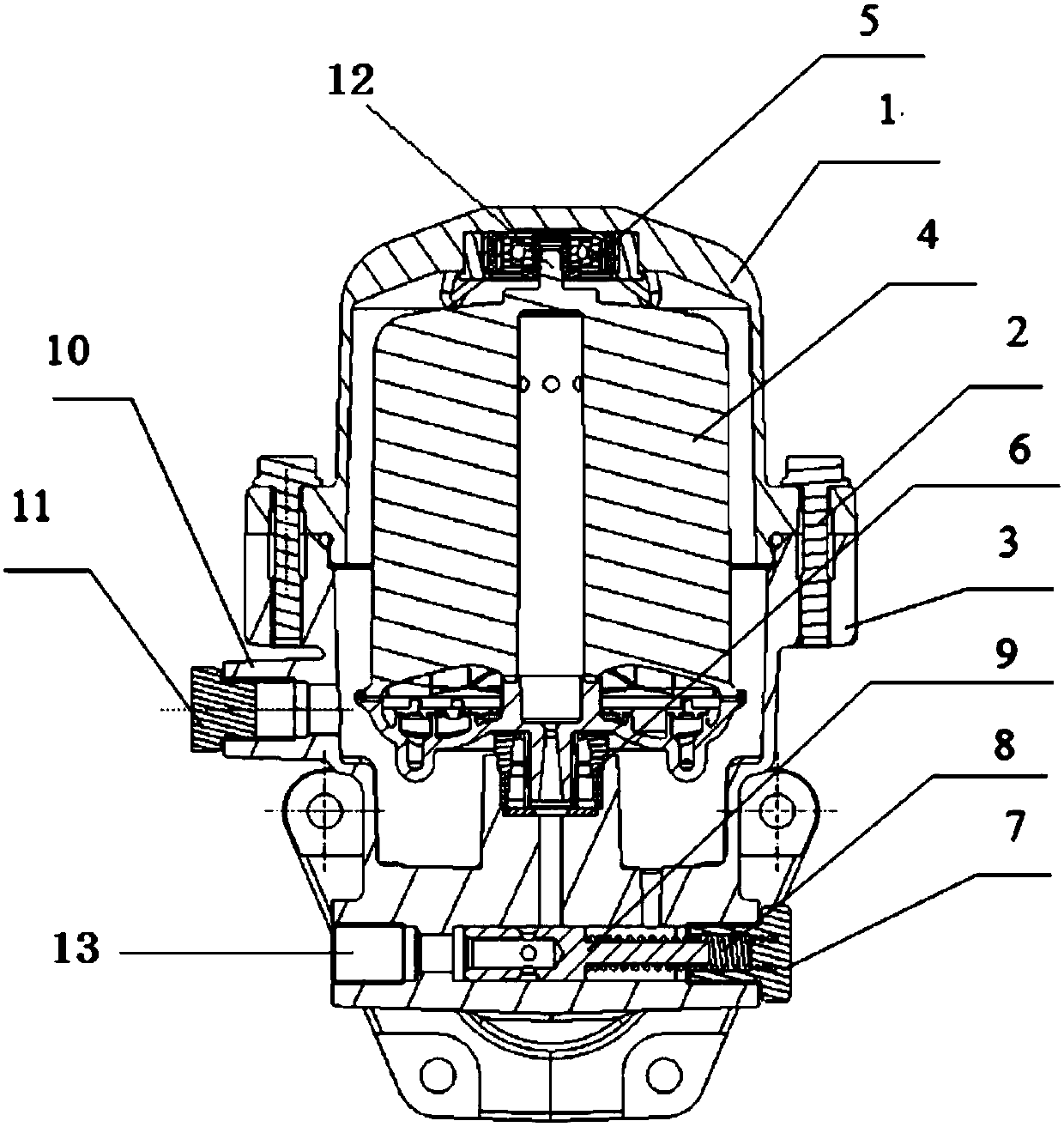

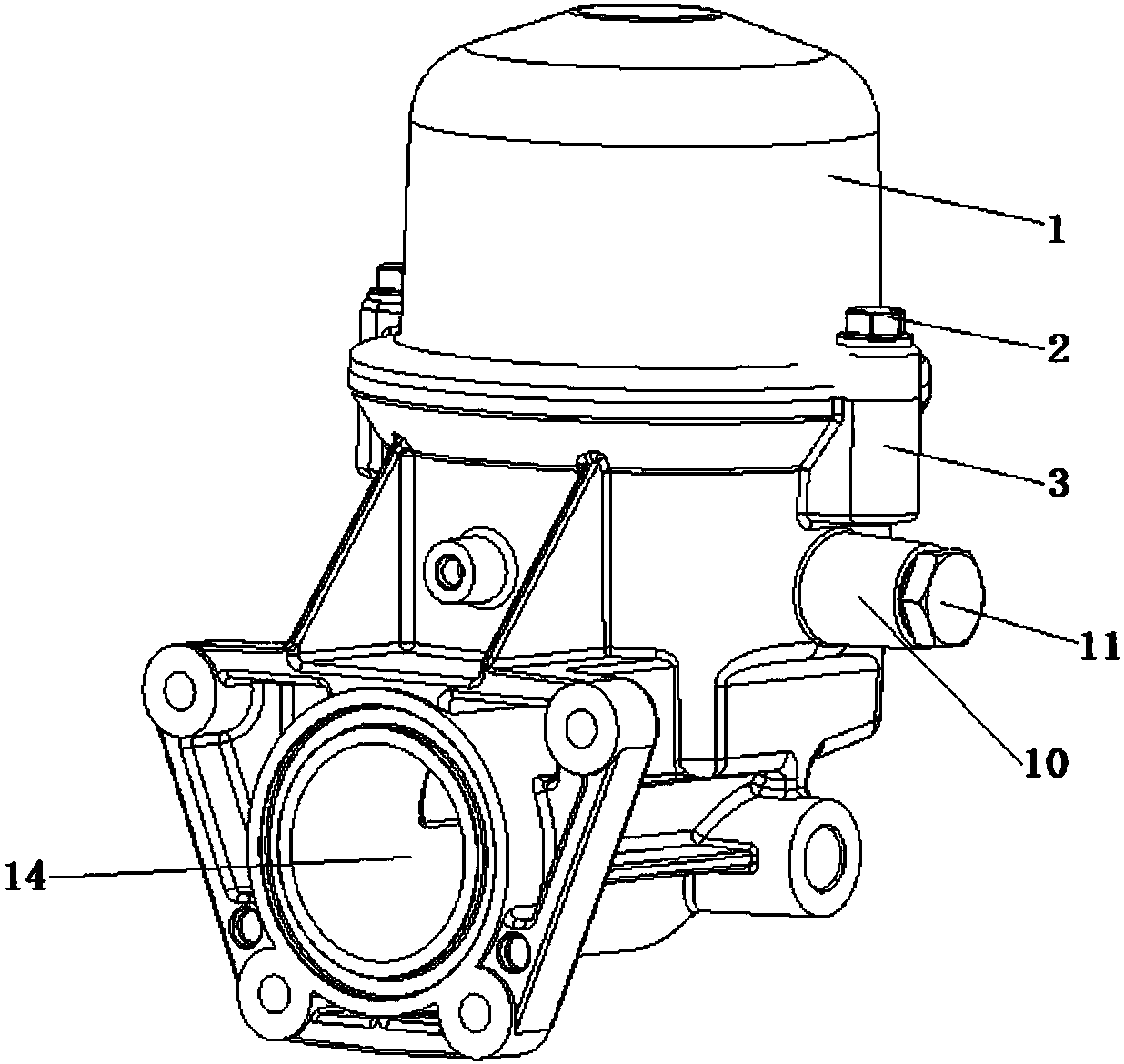

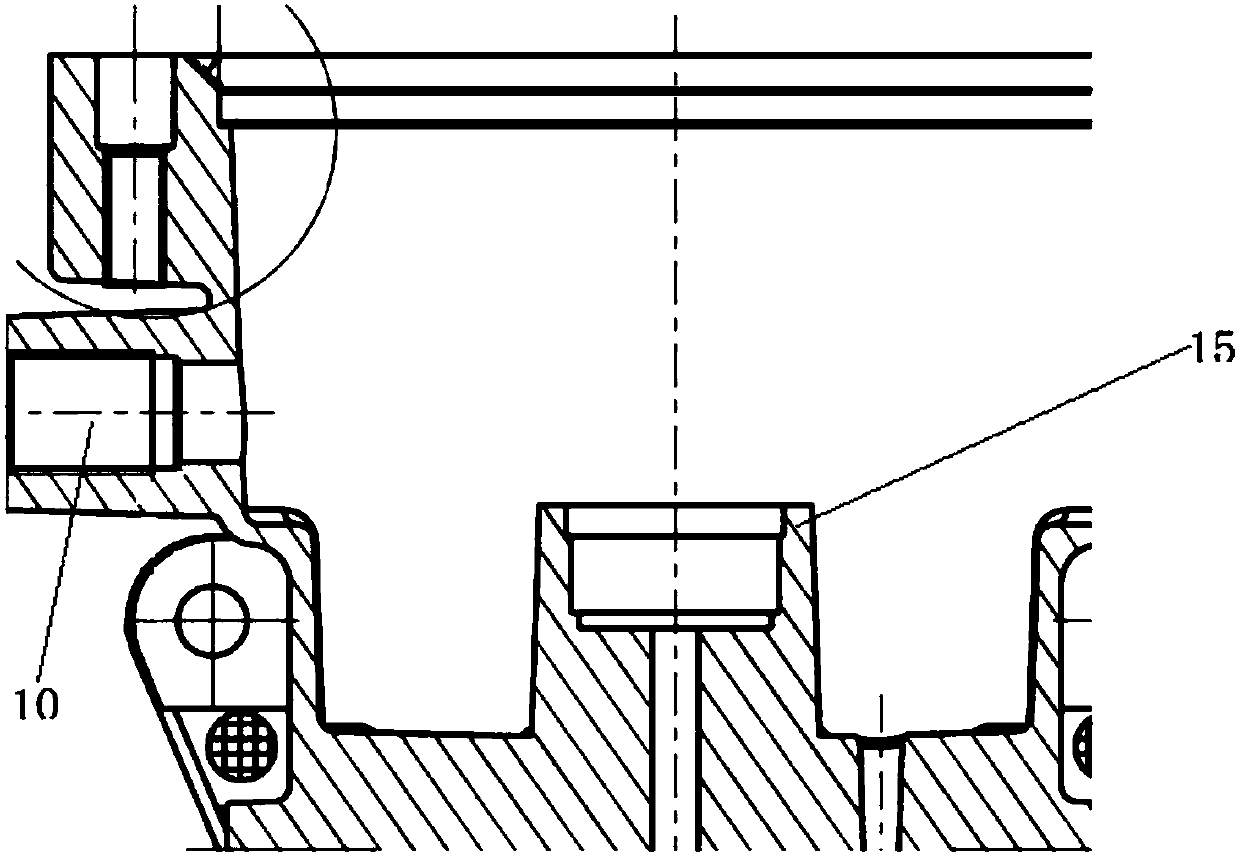

[0020] A centrifugal rotor filter unit with a bypass branch such as Figure 1-3 As shown, it includes an upper cover 1, a lower casing 3 and a rotor 4. The upper cover 1 is connected to the lower casing 3 through bolts 2, and the rotor 4 is fixed in the upper cover 1 and the lower casing 3 through the upper bearing 5 and the lower bearing 6. , the middle part of the upper and lower ends of the rotor 4 is provided with a rotating shaft 12, the rotating shaft at the upper end is connected to the upper bearing 5, the rotating shaft at the lower end is connected to the lower bearing 6, the bottom of the lower housing 3 is provided with an oil inlet pipeline 13, and a shut-off valve 9 is arranged in the oil inlet pipeline 13 , the cut-off valve 9 is connected to the spring 8, the spring 8 is fixed by the second plug 7, the lower housing 3 is provided with a bypass branch pipe 10, the bypass branch pipe 10 communicates with the centrifugal rotor filter, and the bypass branch pipe 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com