Cathode material for generating ratio-controllable synthesis gas through carbon dioxide reducing under electrocatalysis, preparation method and application

A cathode material, carbon dioxide technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., to achieve the effect of good catalytic stability, cheap and easy to obtain materials, and simple modification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Cut the h62 brass sheet into a size suitable for the shape of the electrolytic cell;

[0035] 2) Carry out degreasing pretreatment on the cut brass sheet;

[0036] 3) While degreasing, raise the temperature of the tube furnace to the set temperature of 500°C, and continuously feed air at a flow rate of 300ml / min;

[0037] 4) Put the clean brass sheet in a tube furnace that has been raised to the set temperature, and heat it at a constant temperature for 1 hour, and cool it down naturally in the air atmosphere after treatment;

[0038] 5) Electrochemical reduction of the heat-treated brass sheet, the electrolyte is 0.5 M potassium bicarbonate solution, and the counter electrode is RuO 2 The coated titanium mesh electrode, the reference electrode is a saturated calomel electrode, the reduction potential is set to -1.3V, the reduction to the current curve remains stable, and the reduction treatment electrode sheet is taken out and dried with an inert gas to obtain the ...

Embodiment 2

[0041] 1) Cut the h62 brass sheet into a size suitable for the shape of the electrolytic cell;

[0042] 2) Carry out degreasing pretreatment on the cut brass sheet;

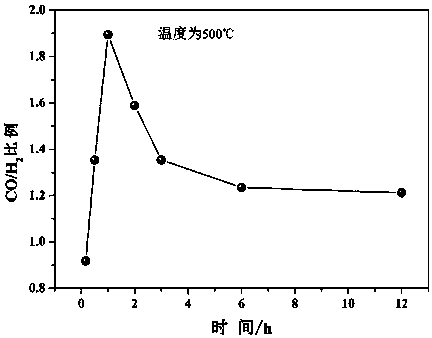

[0043] 3) While degreasing, raise the temperature of the tube furnace to the set temperature of 500°C, and continuously feed air at a flow rate of 300ml / min;

[0044] 4) Put the clean brass sheet in a tube furnace that has been raised to the set temperature, and heat it at a constant temperature for 3 hours, and cool it down naturally in the air atmosphere after treatment;

[0045] 5) Electrochemical reduction of the heat-treated brass sheet, the electrolyte is 0.5 M potassium bicarbonate solution, and the counter electrode is RuO 2 The coated titanium mesh electrode, the reference electrode is a saturated calomel electrode, the reduction potential is set to -1.3V, the reduction to the current curve remains stable, and the reduction treatment electrode sheet is taken out and dried with an inert gas to obtain the...

Embodiment 3

[0047] 1) Cut the h62 brass sheet into a size suitable for the shape of the electrolytic cell;

[0048] 2) Carry out degreasing pretreatment on the cut brass sheet;

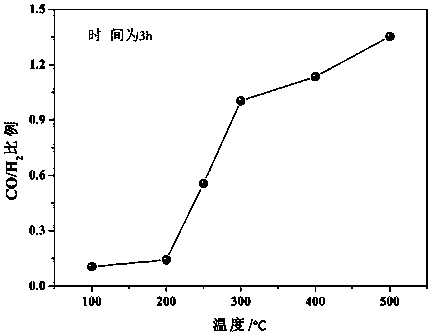

[0049] 3) While degreasing, raise the temperature of the tube furnace to the set temperature of 300°C, and continuously feed air at a flow rate of 300ml / min;

[0050] 4) Put the clean brass sheet in a tube furnace that has been raised to the set temperature, and heat it at a constant temperature for 3 hours, and cool it naturally in the air atmosphere after treatment;

[0051] 5) Electrochemical reduction of the heat-treated brass sheet, the electrolyte is 0.5 M potassium bicarbonate solution, and the counter electrode is RuO 2 The coated titanium mesh electrode, the reference electrode is a saturated calomel electrode, the reduction potential is set to -1.3V, the reduction to the current curve remains stable, and the reduction treatment electrode sheet is taken out and dried with an inert gas to obtain the cath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hole | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com