High-temperature dust removal and denitration integrated purifying ceramic filter element flange and preparation technology thereof

A ceramic filter element and technology of preparation process, applied in flange connection, chemical instruments and methods, filtration and separation, etc., to achieve the effects of excellent tensile strength, production cost saving, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

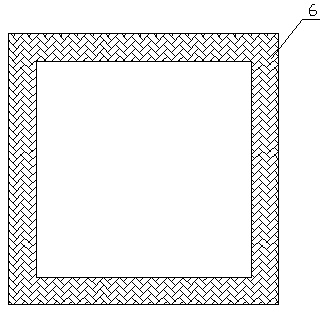

[0026] a. Form and sinter the ceramic powder with the same formulation as the ceramic filter element to make a square frame-shaped integral structure 6 with a thickness of 20mm and a height of 50mm (such as figure 1 shown), the inner diameter of the structural part should be slightly larger than the outer diameter of the square ceramic filter element 1, and the gap between the two should be controlled at 1.5mm;

[0027] b. Use a hardener to surface-treat the bonded interface parts of the filter element and the overall structural part;

[0028] c. Use the glue injection process to fill the high temperature refractory cement between the ceramic filter element and the structural parts. The amount of cement is based on fully filling the gap between the structural parts and the filter element;

[0029] d. The binder is naturally dried at room temperature for 12 hours, and then transferred to a drying oven at 200°C for 12 hours to ensure that the binder is fully cured, thereby makin...

Embodiment 2

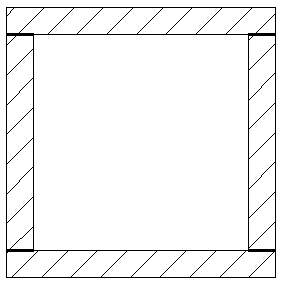

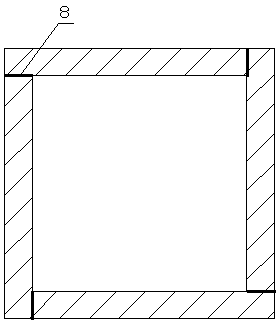

[0033] a. Process the ceramic fiberboard into a box-shaped combined structural part II7 with a thickness of 20mm and a height of 50mm and an adhesive layer 8 (such as figure 2 or image 3 shown), and the integral structural part 6 of the same size is superimposed on the combined structural part II to form a two-layer structural part; the gap between the inner surface of the two-layer structural part and the outer surface of the ceramic filter element is controlled at 3 mm.

[0034] b. Use a hardener to surface-treat the bonding surface of the filter element and the two-layer structure;

[0035] c. Use the glue coating process to brush high-temperature refractory cement on the outer surface of the ceramic filter element and the inner surface of the two-layer structural parts, assemble the ceramic filter element and the two-layer structural parts together, and scrape off the excess cement with a scraper;

[0036] d. The binder is naturally dried at room temperature for 4 hours...

Embodiment 3

[0039] a. Process the ceramic fiber felt into a square frame-shaped combined structural member I5 with a thickness of 25mm and a height of 20mm and an adhesive layer 8 (such as figure 2 or image 3 shown); and the above-mentioned two-layer structure of the same size is superimposed on the composite structure I to form a three-layer structure (such as Figure 4 and Figure 5 shown), the gap between the inner surface of the three-layer structure and the outer surface of the ceramic filter element is controlled at 5mm.

[0040] b. Use a hardener to treat the surface of the bonding interface between the ceramic filter element and the three-layer structure;

[0041] c. Select the ceramic powder and aluminum phosphate glue with the same formula as the ceramic filter element to mix at a ratio of 2:1 to prepare a high-temperature resistant adhesive, and use the glue injection process to fill the self-made high-temperature resistant adhesive between the filter element and the three-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com