A cathode material for electrocatalytic reduction of carbon dioxide to generate ratio controllable synthesis gas, its preparation method and application

A technology of carbon dioxide and cathode materials, applied in the direction of electrodes, electrolytic components, electrolytic processes, etc., to achieve the effects of good catalytic stability, cheap and easy-to-obtain materials, and simple modification processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Cut the h62 brass sheet into a size suitable for the shape of the electrolytic cell;

[0035] 2) Degreasing pretreatment of the cut brass sheet;

[0036] 3) While degreasing, heat up the tube furnace to a set temperature of 500°C, and continuously inject air at a flow rate of 300ml / min;

[0037] 4) Place the clean brass sheet in a tube furnace that has been raised to the set temperature, and maintain a constant temperature for heating treatment. The treatment time is maintained for 1 hour. After treatment, it is naturally cooled in an air atmosphere;

[0038] 5) The brass sheet after electrochemical reduction and heating treatment, the electrolyte is 0.5 M potassium bicarbonate solution, and the counter electrode is RuO 2 Coated titanium mesh electrode, the reference electrode is a saturated calomel electrode, the reduction potential is set to -1.3V, the reduction to the current curve remains stable, the reduction treatment electrode piece is taken out and dried with inert ga...

Embodiment 2

[0041] 1) Cut the h62 brass sheet into a size suitable for the shape of the electrolytic cell;

[0042] 2) Degreasing pretreatment of the cut brass sheet;

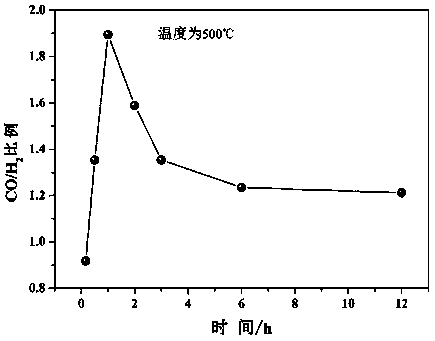

[0043] 3) While degreasing, heat up the tube furnace to a set temperature of 500°C, and continuously inject air at a flow rate of 300ml / min;

[0044] 4) Put the clean brass sheet in a tube furnace that has been raised to the set temperature, and keep it at a constant temperature for heat treatment, keep the treatment time for 3 hours, and cool down naturally in the air atmosphere after treatment;

[0045] 5) The brass sheet after electrochemical reduction and heating treatment, the electrolyte is 0.5 M potassium bicarbonate solution, and the counter electrode is RuO 2 Coated titanium mesh electrode, the reference electrode is a saturated calomel electrode, the reduction potential is set to -1.3V, the reduction to the current curve remains stable, the reduction treatment electrode piece is taken out and dried with inert gas to obtai...

Embodiment 3

[0047] 1) Cut the h62 brass sheet into a size suitable for the shape of the electrolytic cell;

[0048] 2) Degreasing pretreatment of the cut brass sheet;

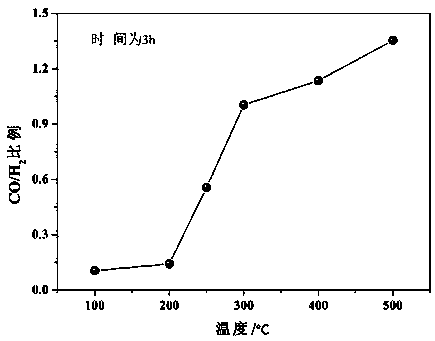

[0049] 3) While degreasing, heat up the tube furnace to the set temperature of 300°C, and continuously inject air at a flow rate of 300ml / min;

[0050] 4) Put the clean brass sheet in a tube furnace that has been raised to the set temperature, and keep it at a constant temperature for heat treatment, keep the treatment time for 3 hours, and cool down naturally in the air atmosphere after treatment;

[0051] 5) The brass sheet after electrochemical reduction and heating treatment, the electrolyte is 0.5 M potassium bicarbonate solution, and the counter electrode is RuO 2 Coated titanium mesh electrode, the reference electrode is a saturated calomel electrode, the reduction potential is set to -1.3V, the reduction to the current curve remains stable, the reduction treatment electrode piece is taken out and dried with inert gas to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com