Patents

Literature

49 results about "Engineered stone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

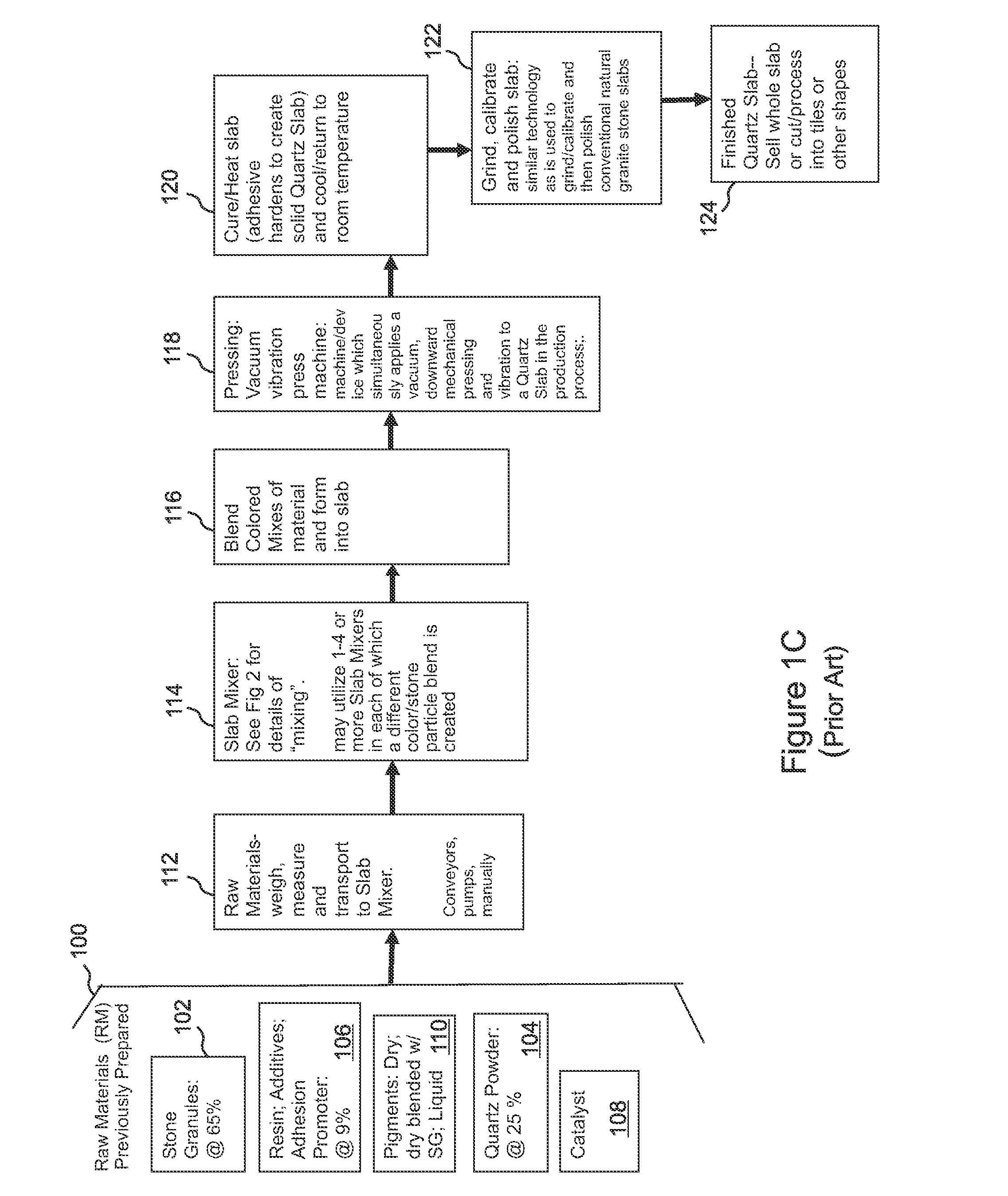

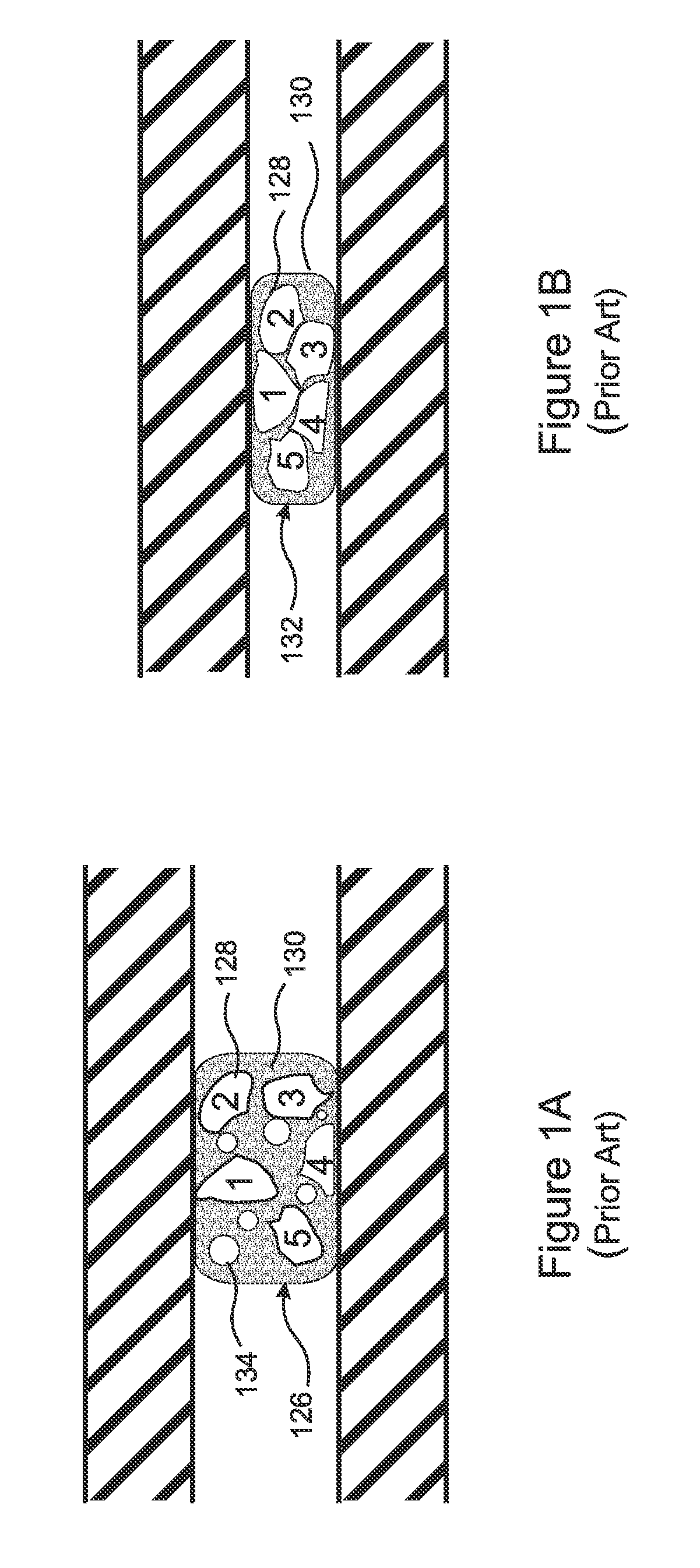

Engineered stone is a composite material made of crushed stone bound together by an adhesive, (most commonly polymer resin, with some newer versions using cement mix). This category includes engineered quartz, polymer concrete and engineered marble stone. The application of these products depends on the original stone used. For engineered marbles the most common application is indoor flooring and walls, while the quartz based product is used primarily for kitchen countertops as an alternative to laminate or granite. Related materials include geopolymers and cast stone. Unlike terrazzo, the material is factory made in either blocks or slabs, cut and polished by fabricators, and assembled at the worksite.

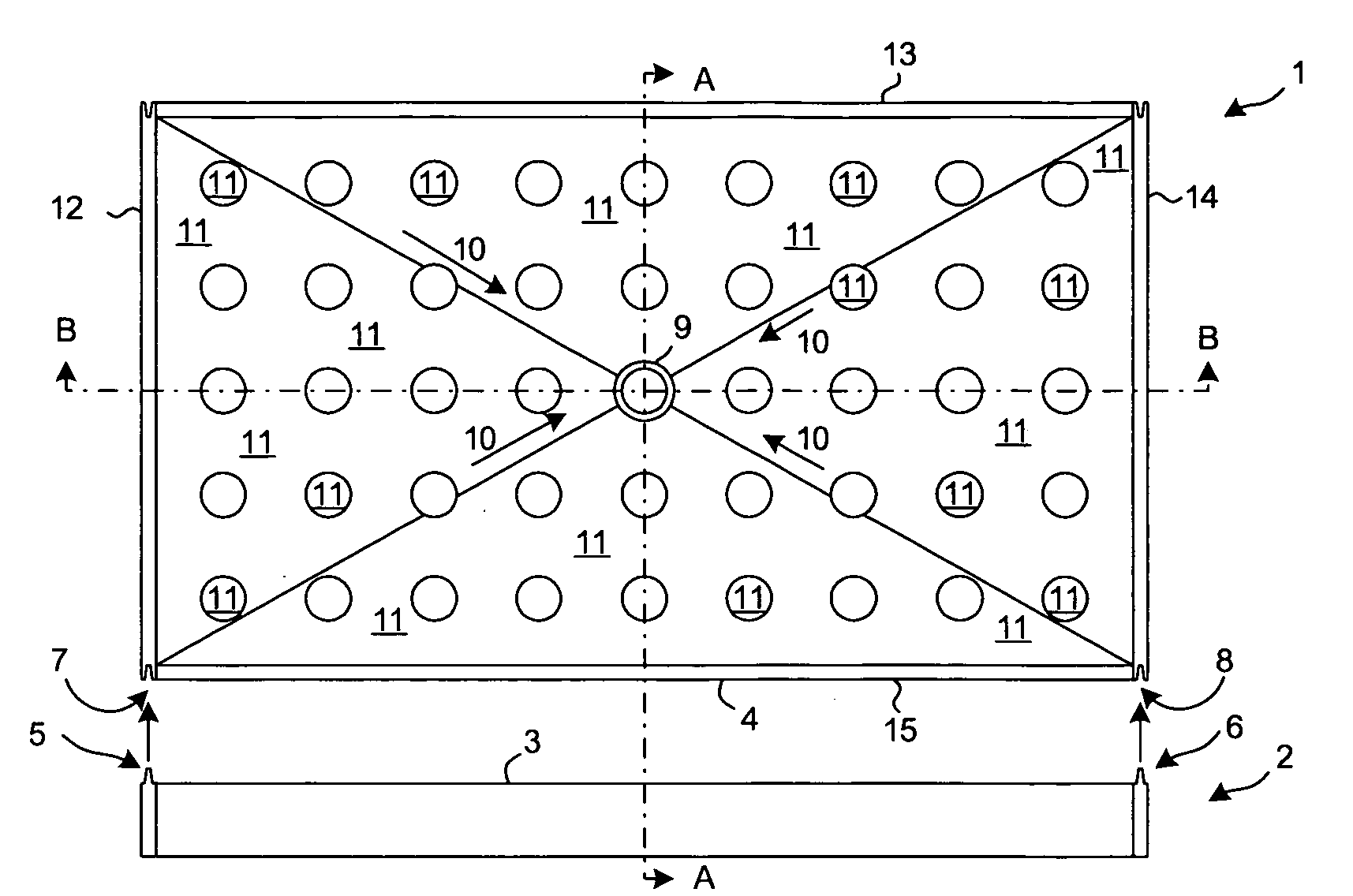

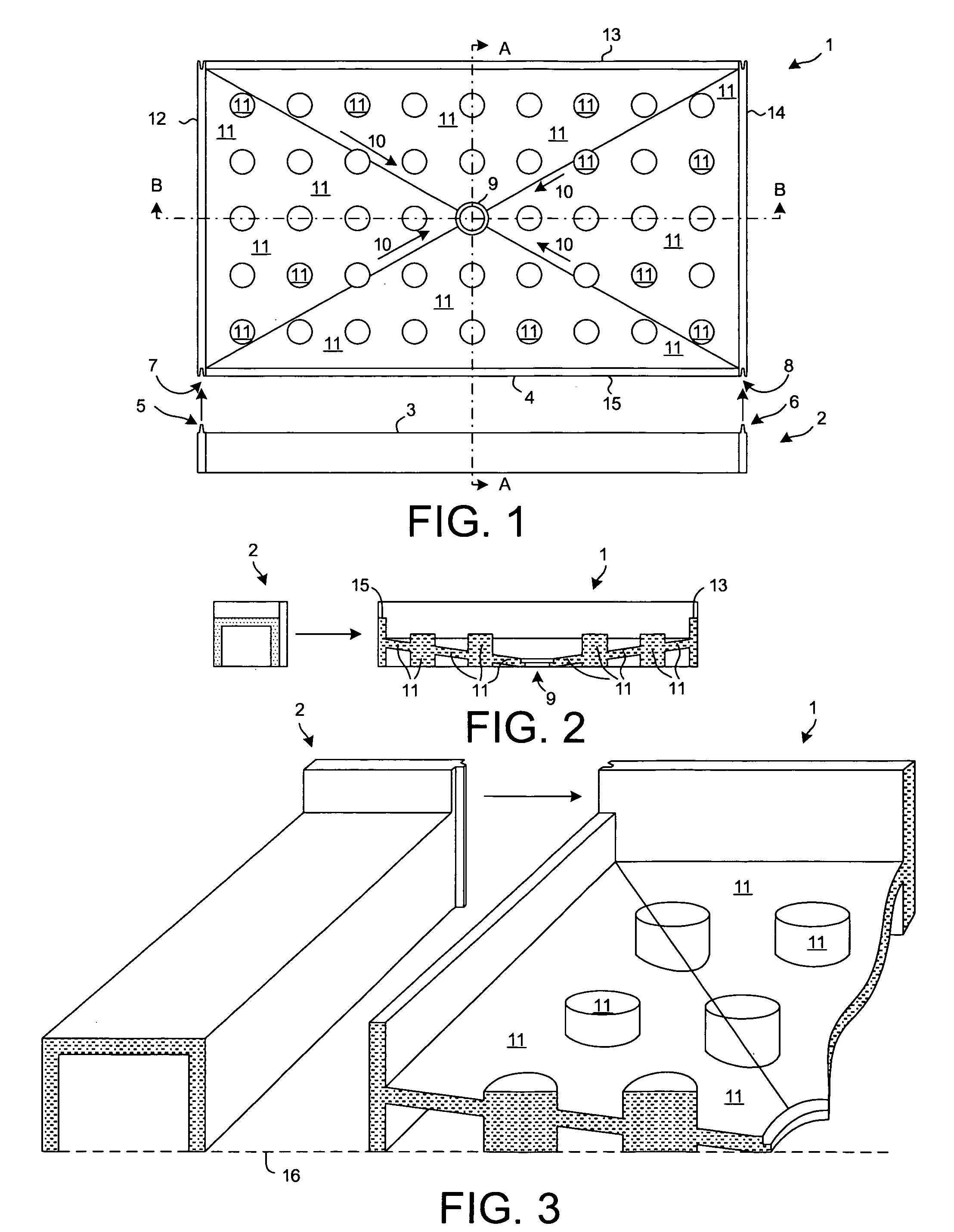

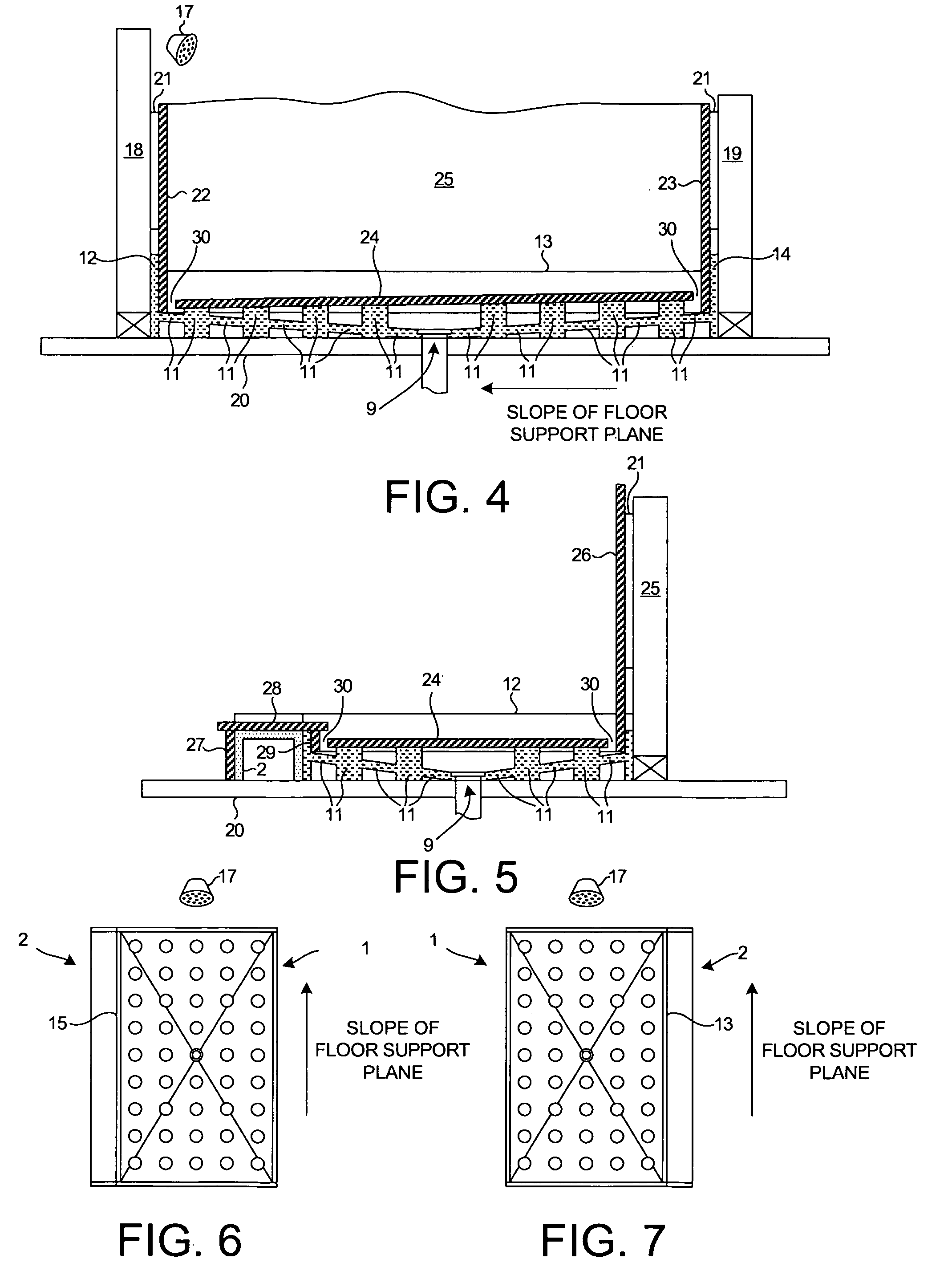

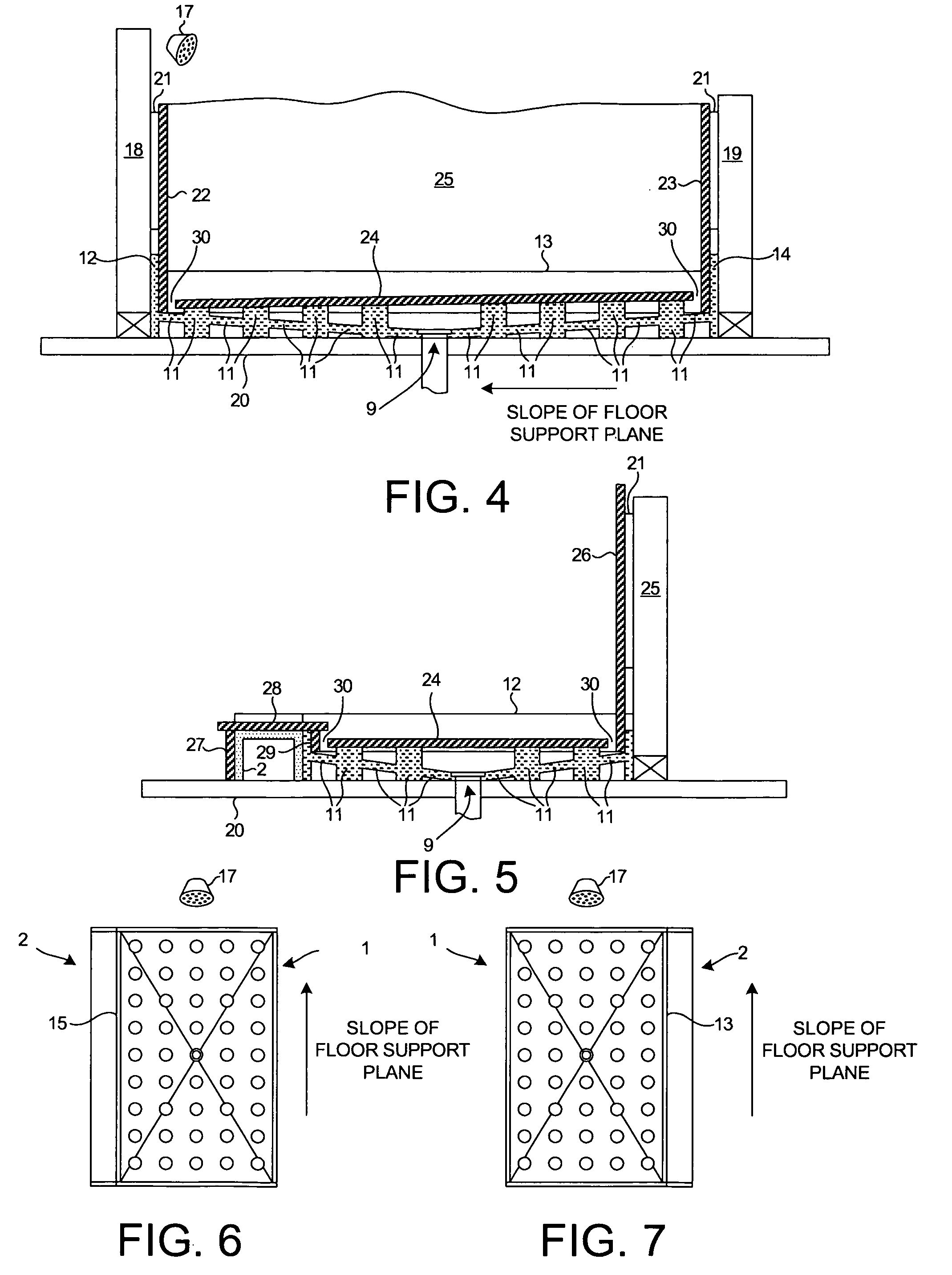

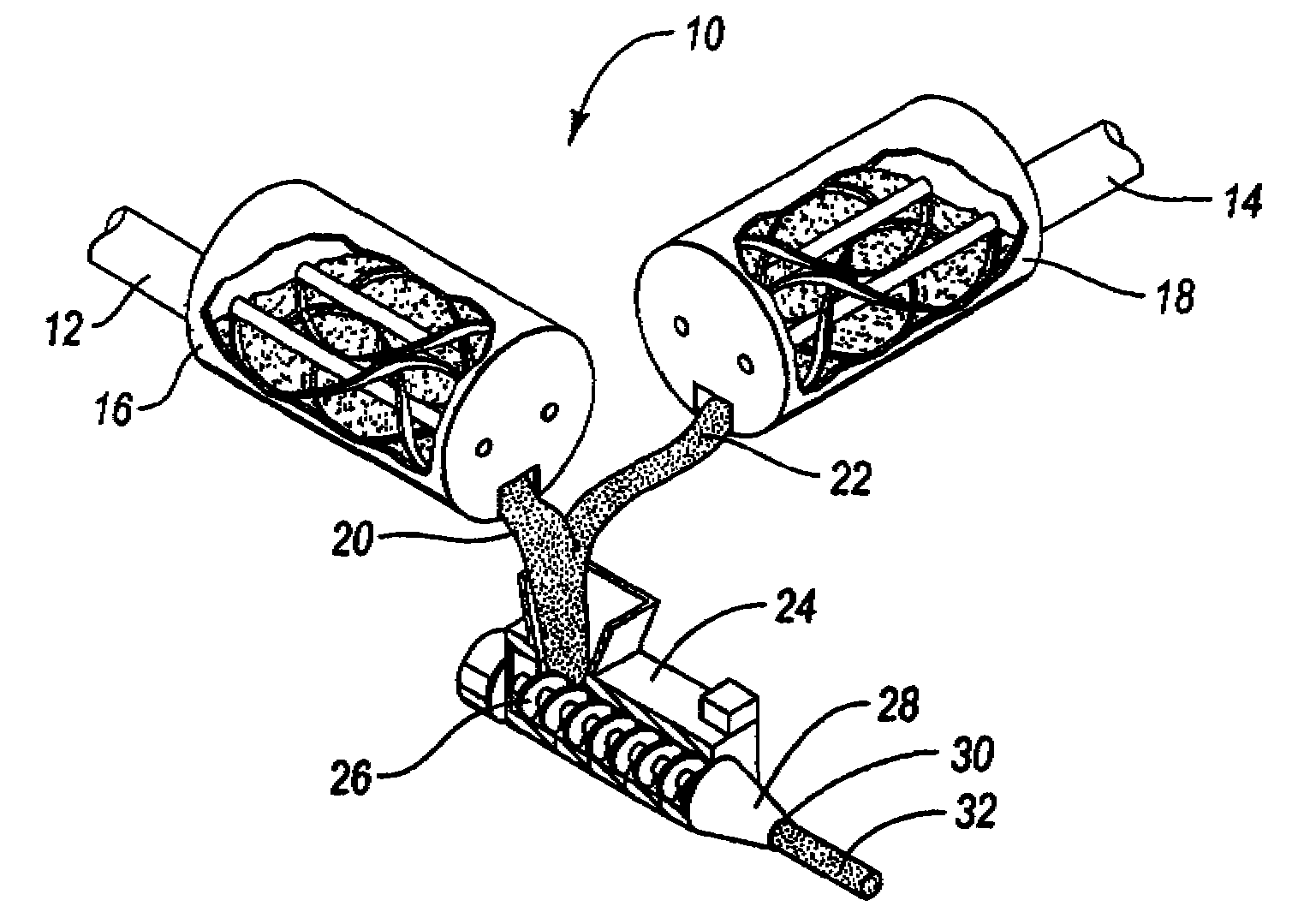

Infinity shower pan

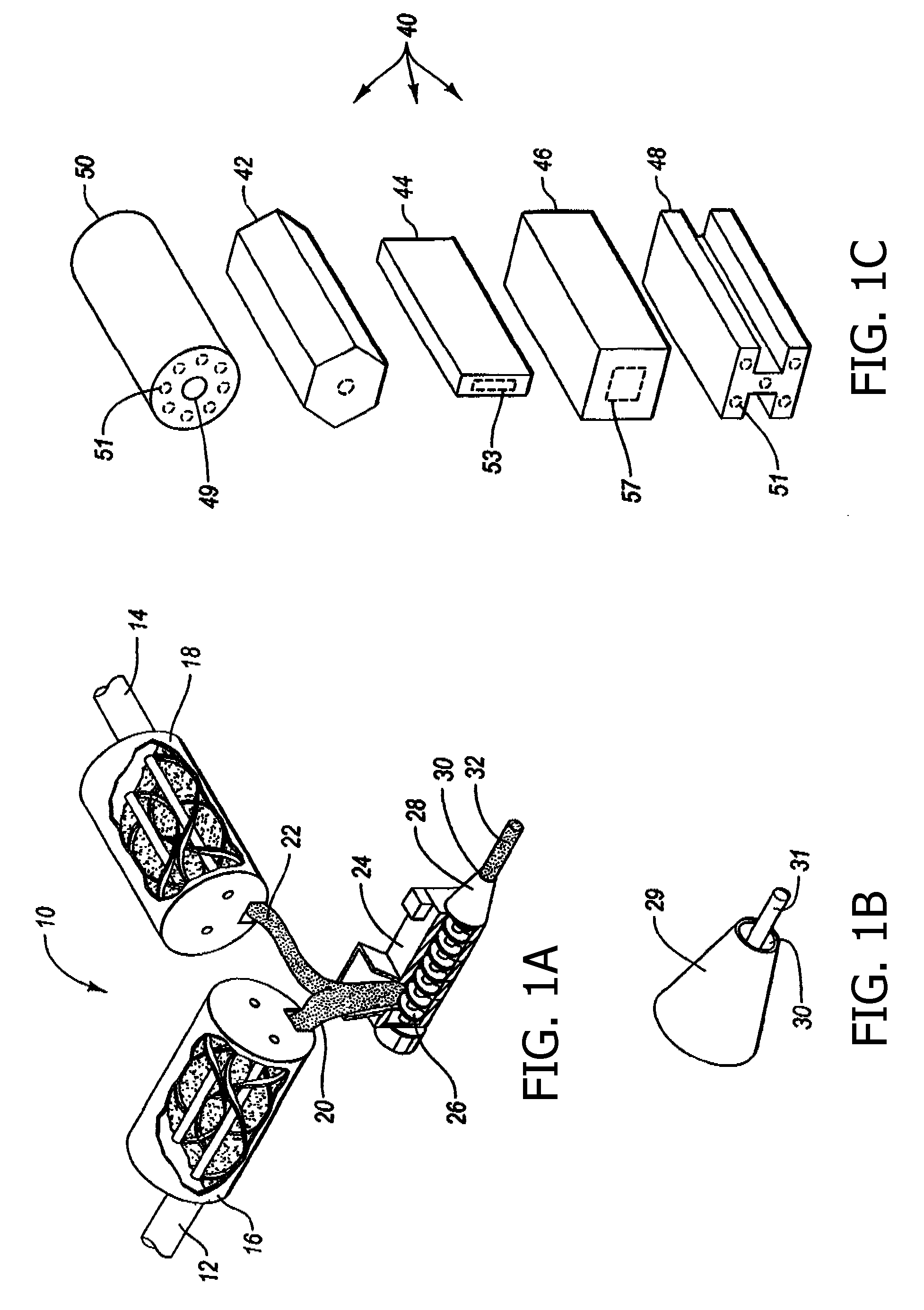

InactiveUS20060236452A1Prevent slippingAvoid excessive movementBathsDouchesEngineeringEngineered stone

A shower pan includes a draining base portion that drains to an orifice. The draining base portion includes a support structure for supporting a slab floor member (for example, a single piece of granite, marble, or engineered stone) above the orifice such that a planar upper surface of the floor member has a slight tilt. The pan is installed such that the tilt is toward a shower head. The shower enclosure is finished by cladding the enclosure walls with a finishing material (for example, granite, marble or engineered stone) such that the finishing material extends down into the pan. The floor member is placed on the support structure such that water from the shower head that falls on the floor member runs off one or more edges of the floor member and is conducted to the orifice under the floor member by a draining portion of the draining base portion.

Owner:POLIMENO JOHN

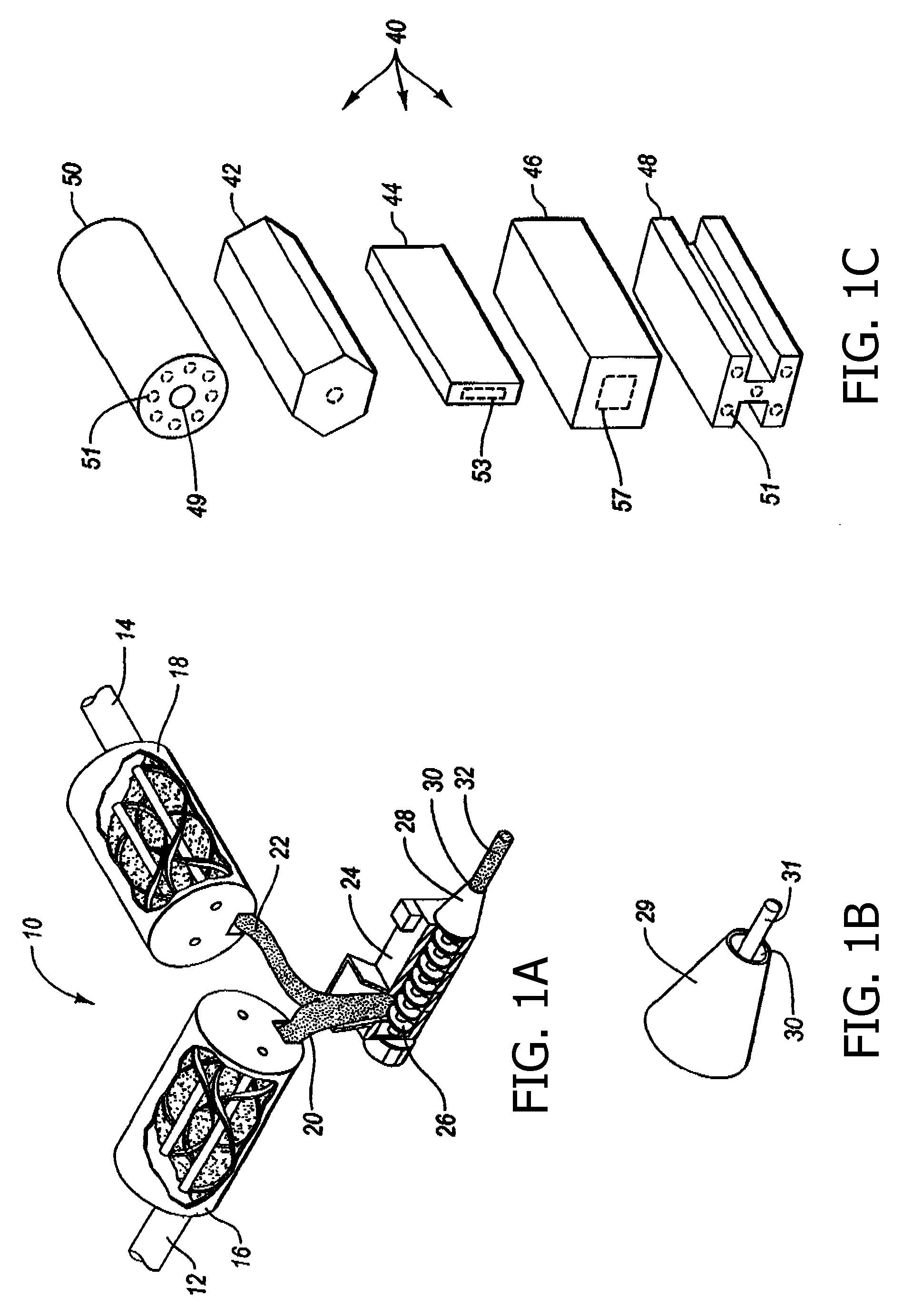

Extruded fiber reinforced cementitious products having stone-like properties and methods of making the same

InactiveUS20110120349A1Improve flexural strengthHigh tensile strengthConstruction materialSolid waste managementBuilding productCement composites

A cementitious composite product that can function as a substitute for stone and solid surface materials, such as granite, marble, and engineered stone is provided. Furthermore methods for manufacturing the cementitious composite product using an extrudable cementitious composition that can be extruded or otherwise shaped into stone-like building products that can be used as a substitute for many known stone products is disclosed. In one embodiment, the cementitious composite products can be manufactured more cheaply to be as tough or tougher and more durable than stone and solid surface materials.

Owner:E KHASHOGGI INDS

Engineered stone

ActiveUS20070244222A1Small sizeEasy laminationNatural patternsSpecial ornamental structuresHigh intensitySynthetic resin

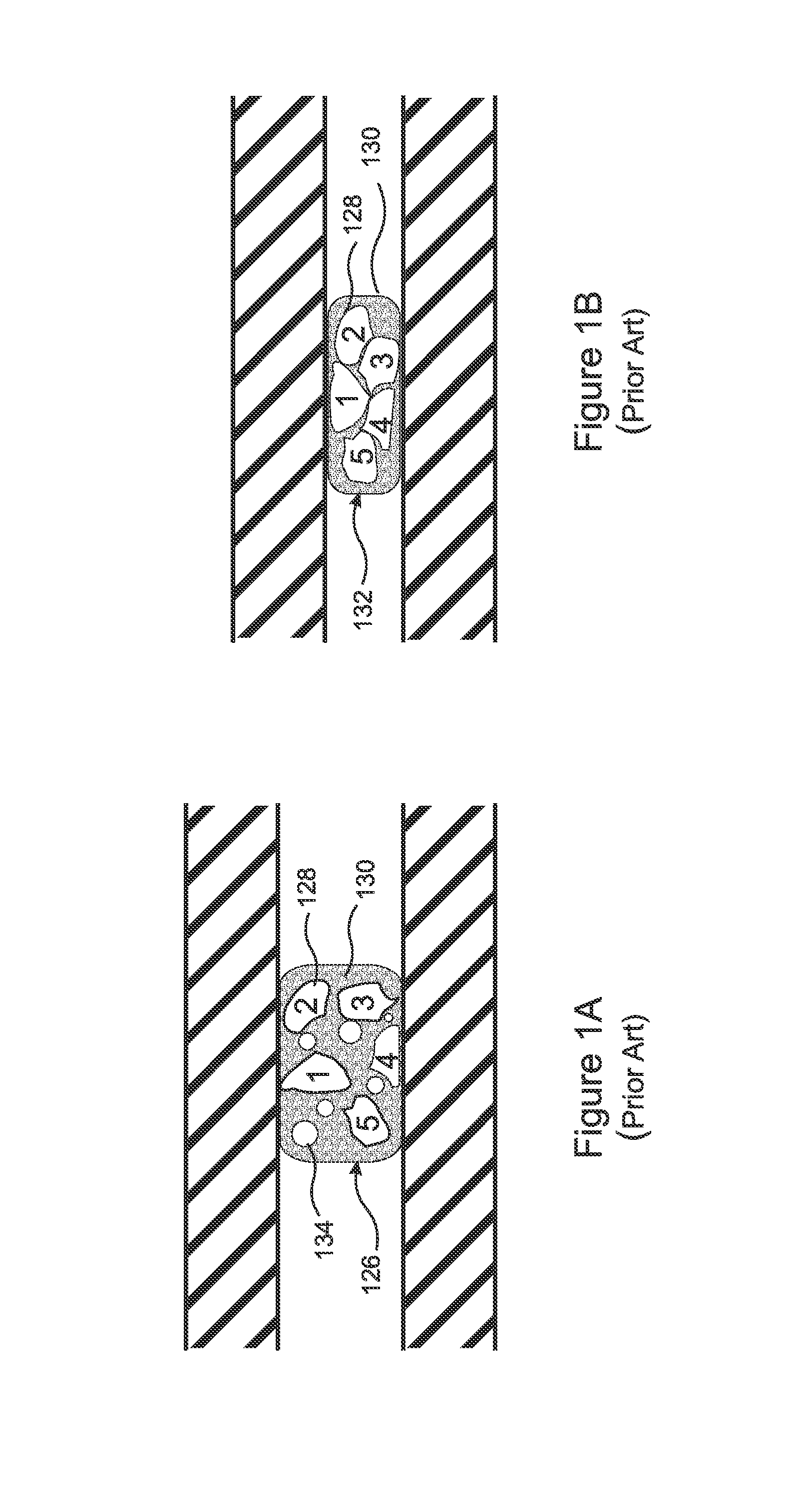

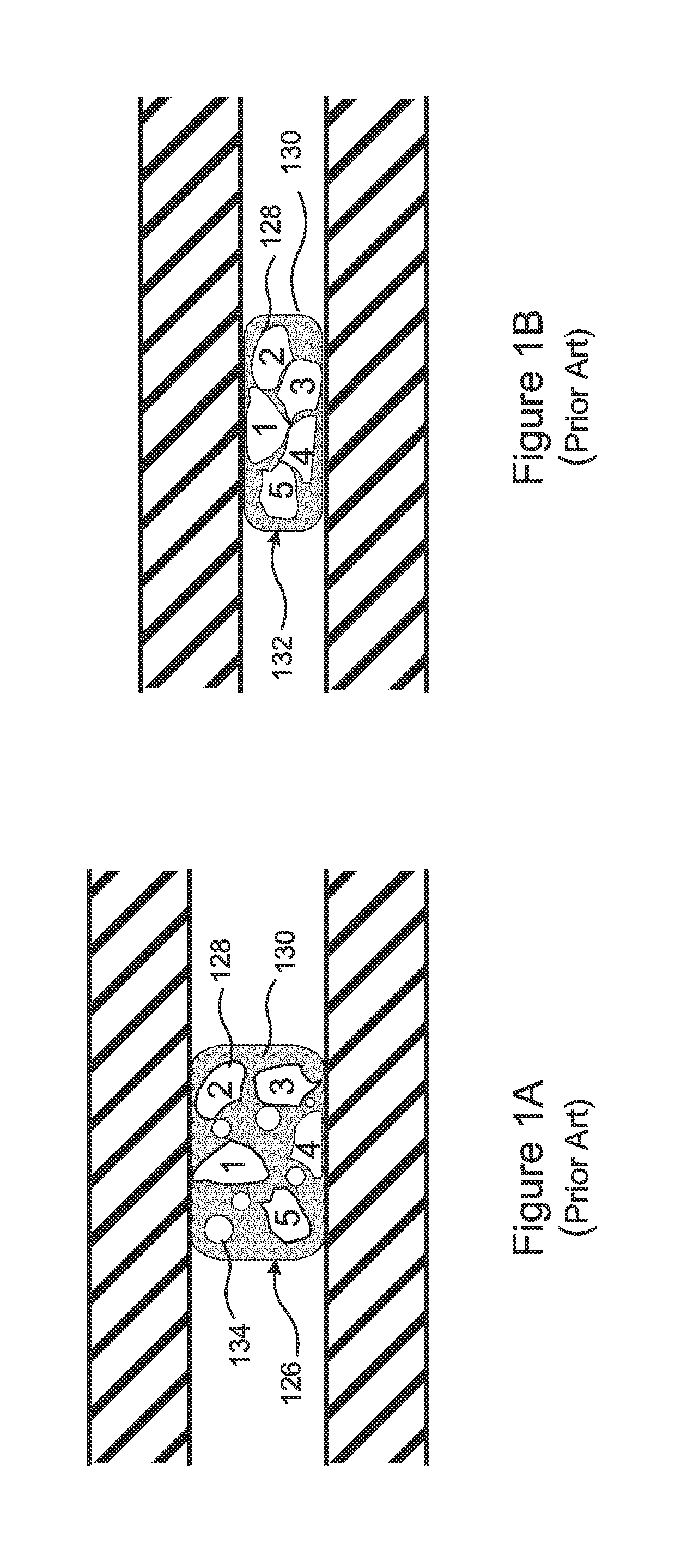

The present invention relates to an engineered stone composite produced from a mineral aggregate, a synthetic resin and a binder using compression and vibration to obtain a high strength mineral composite with a high mineral content and a method for its preparation.

Owner:SAFAS CORP

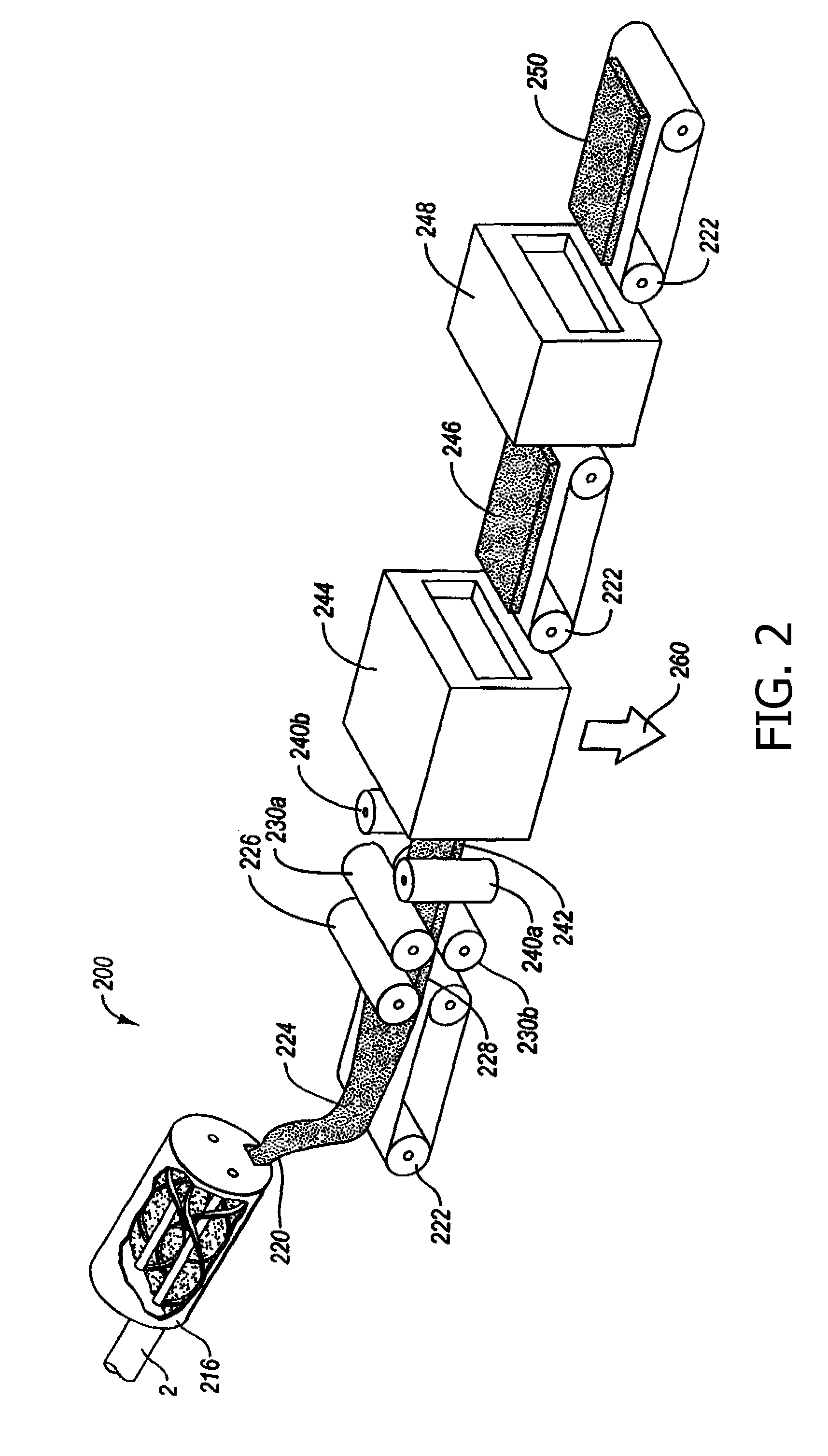

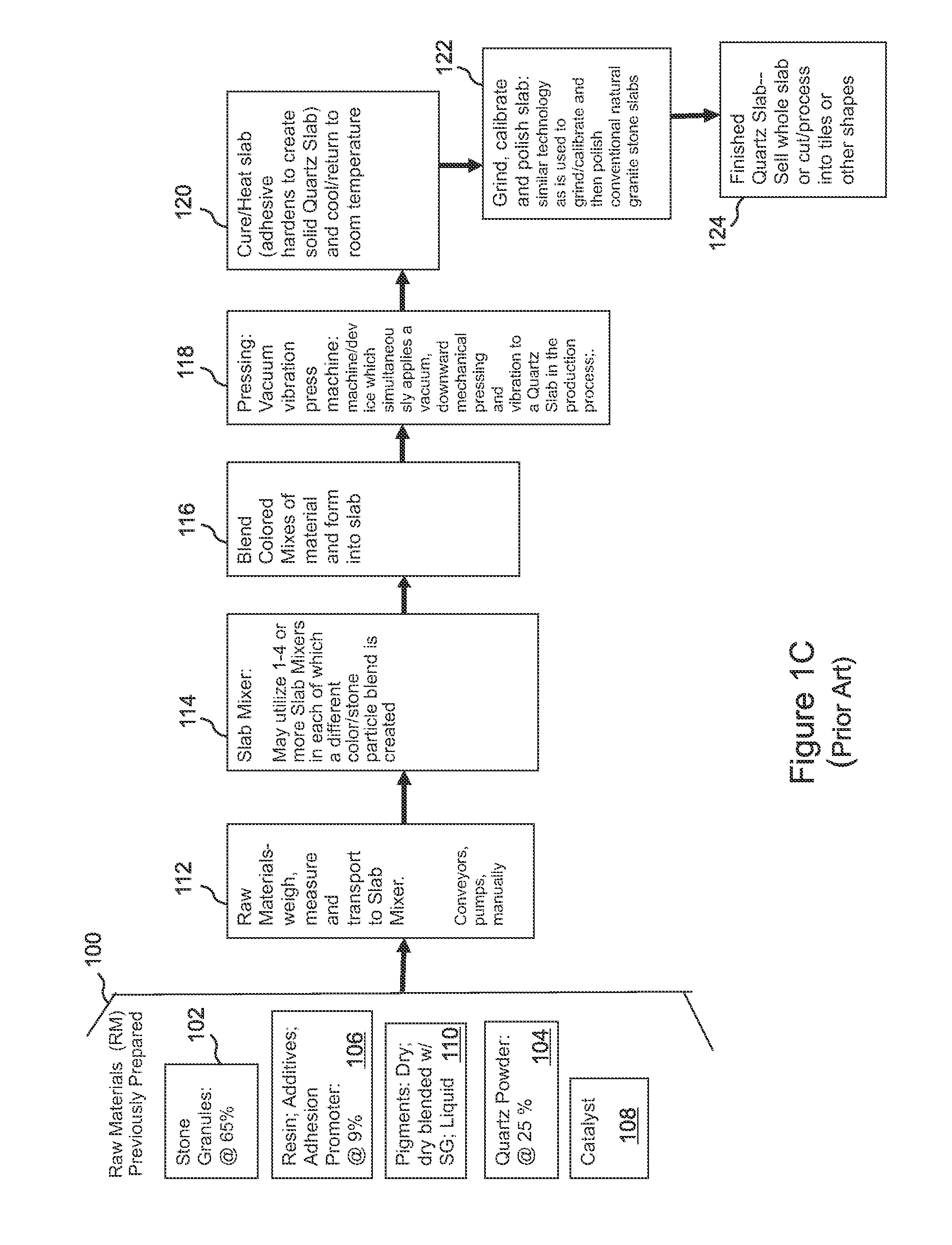

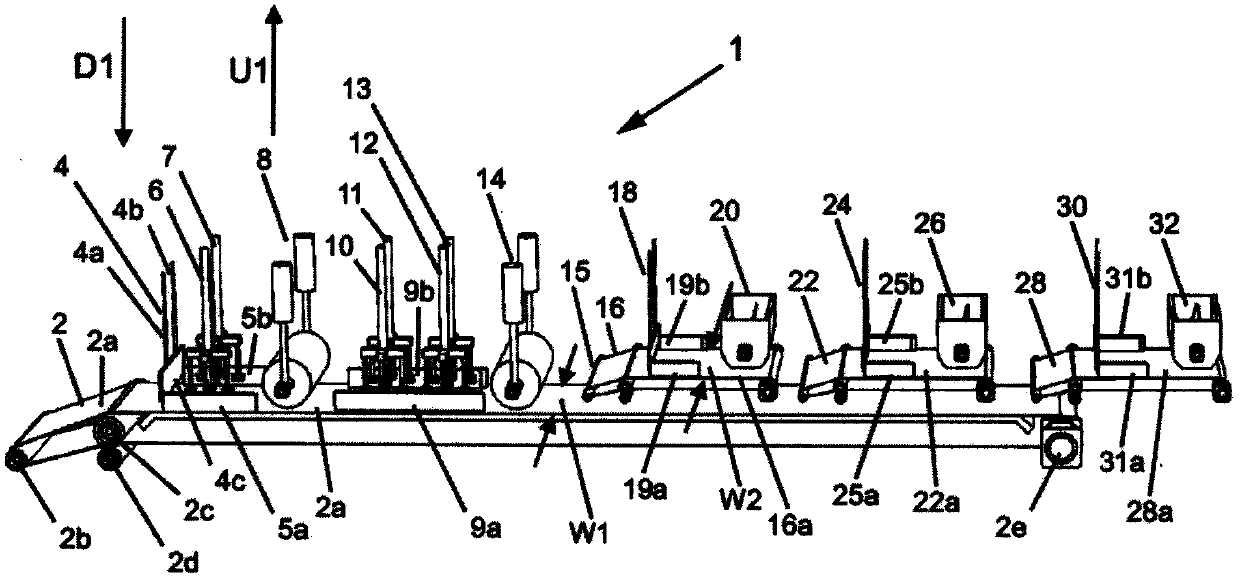

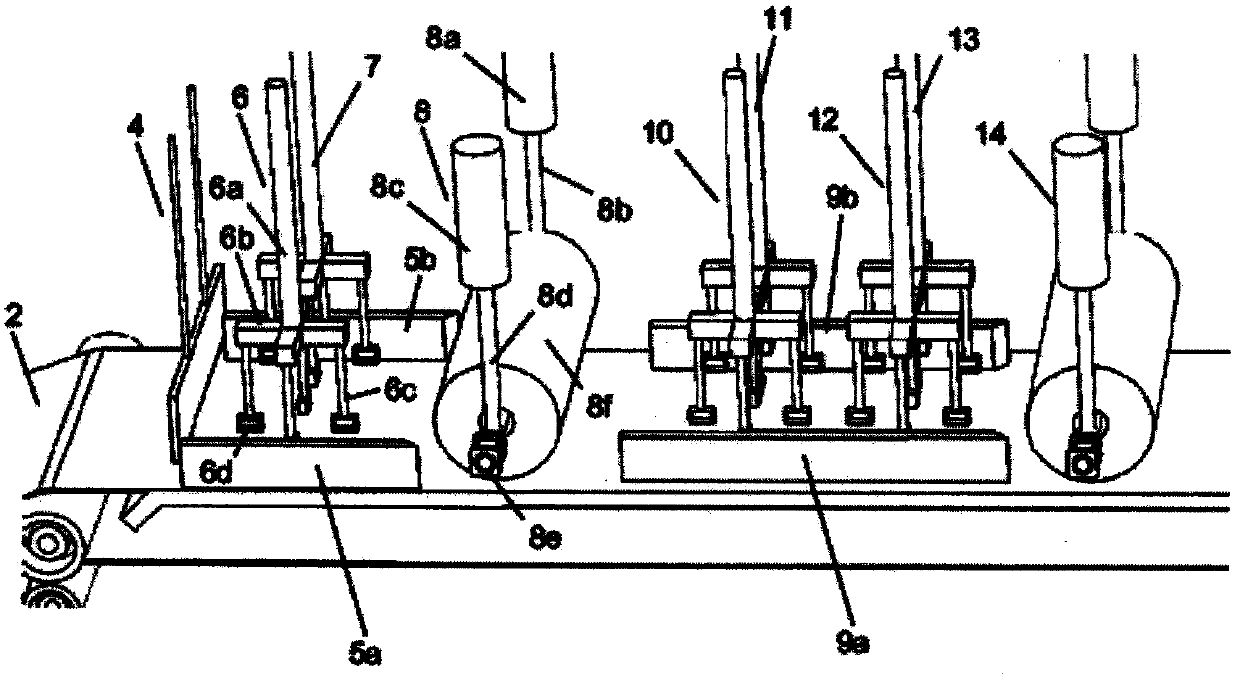

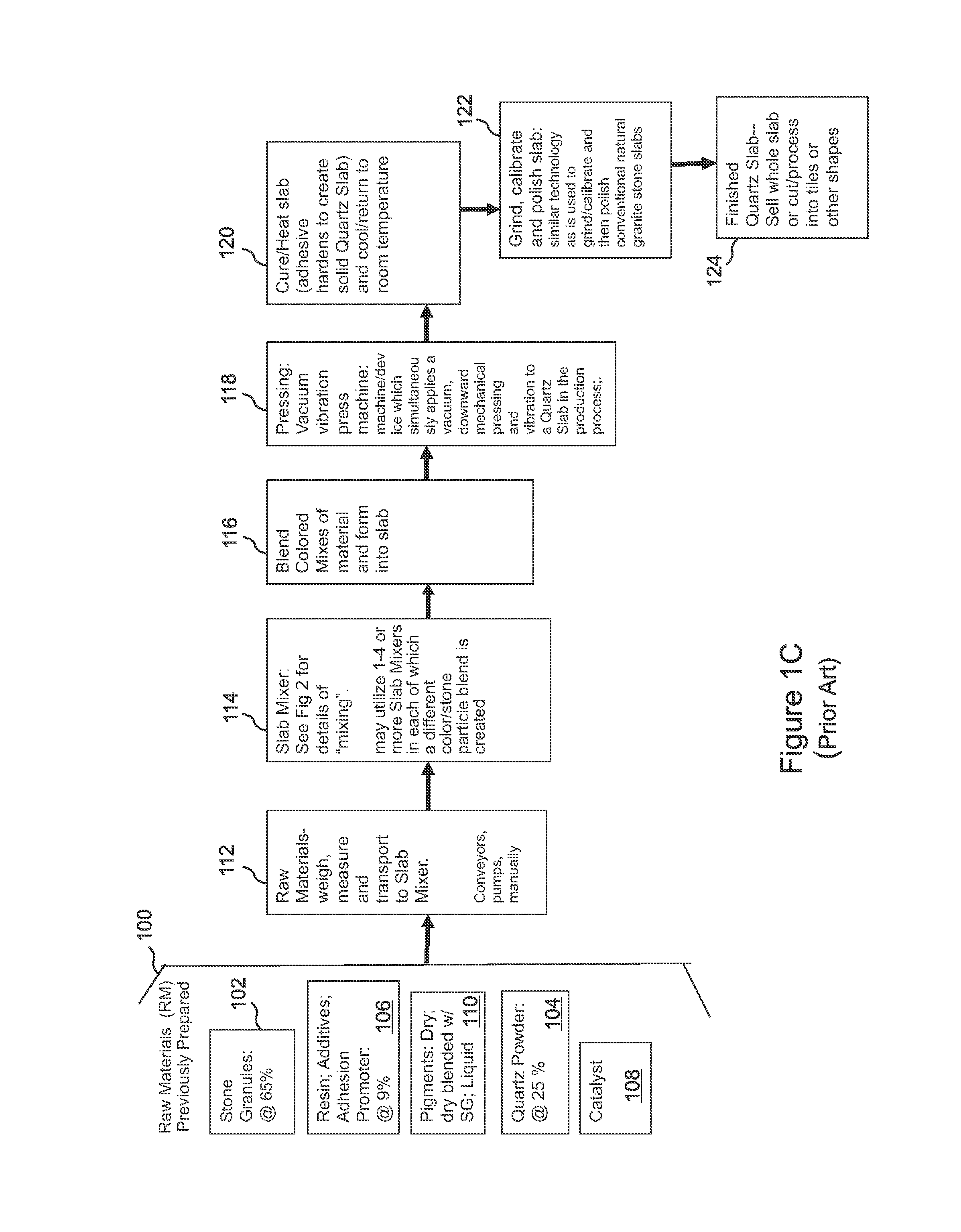

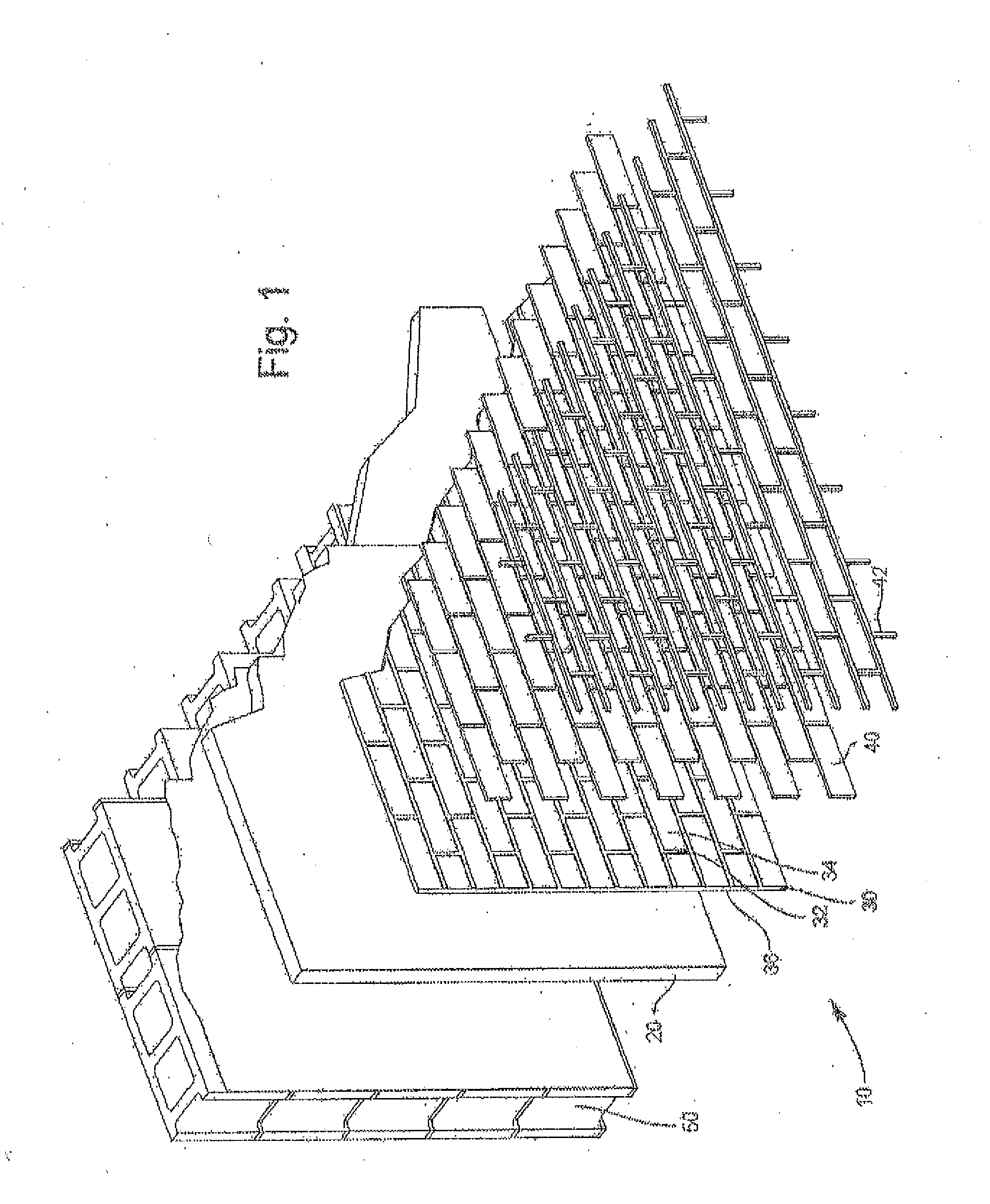

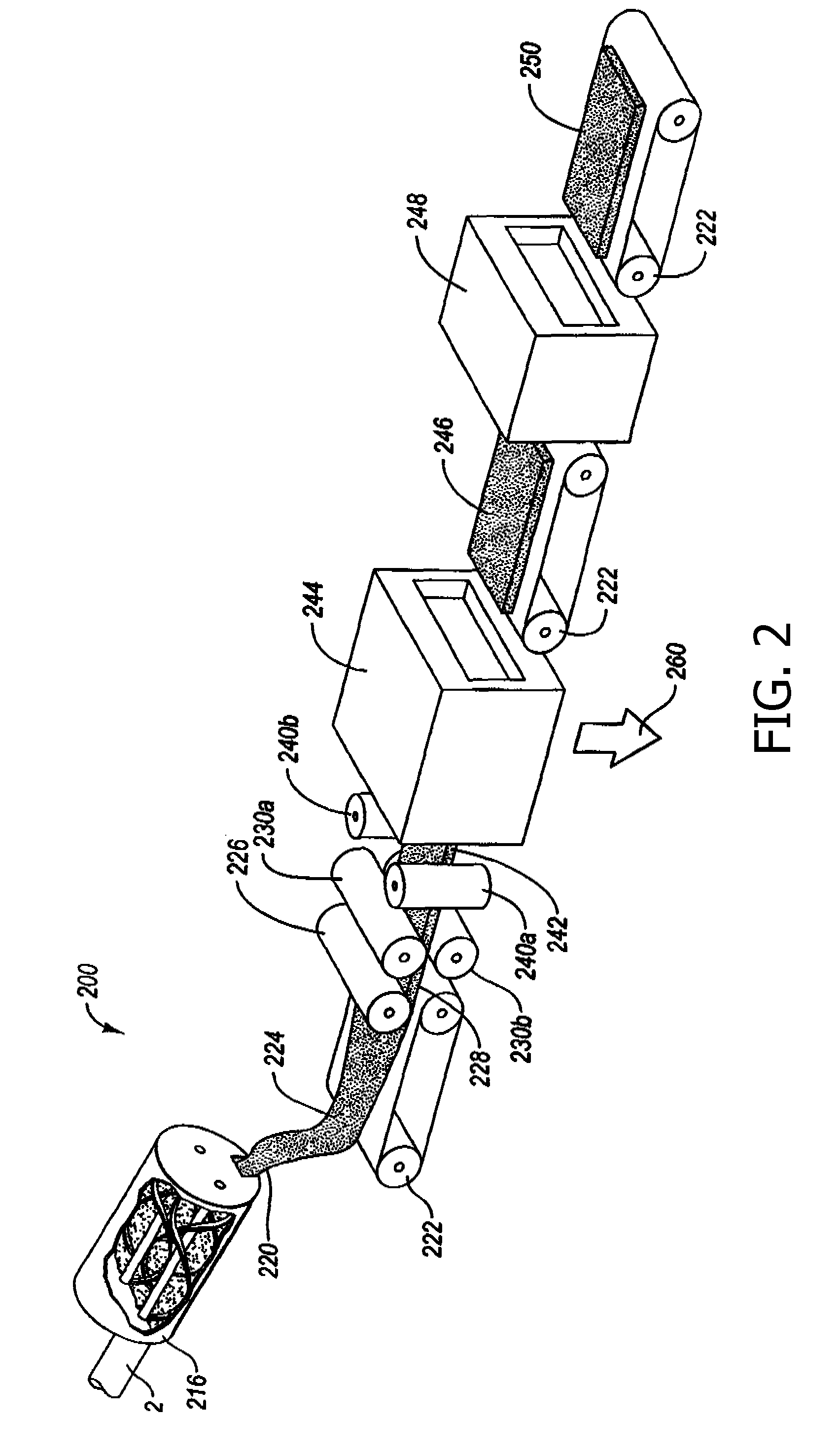

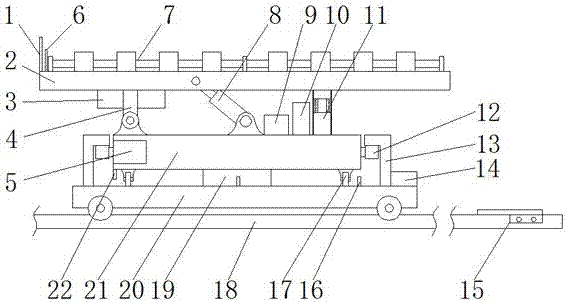

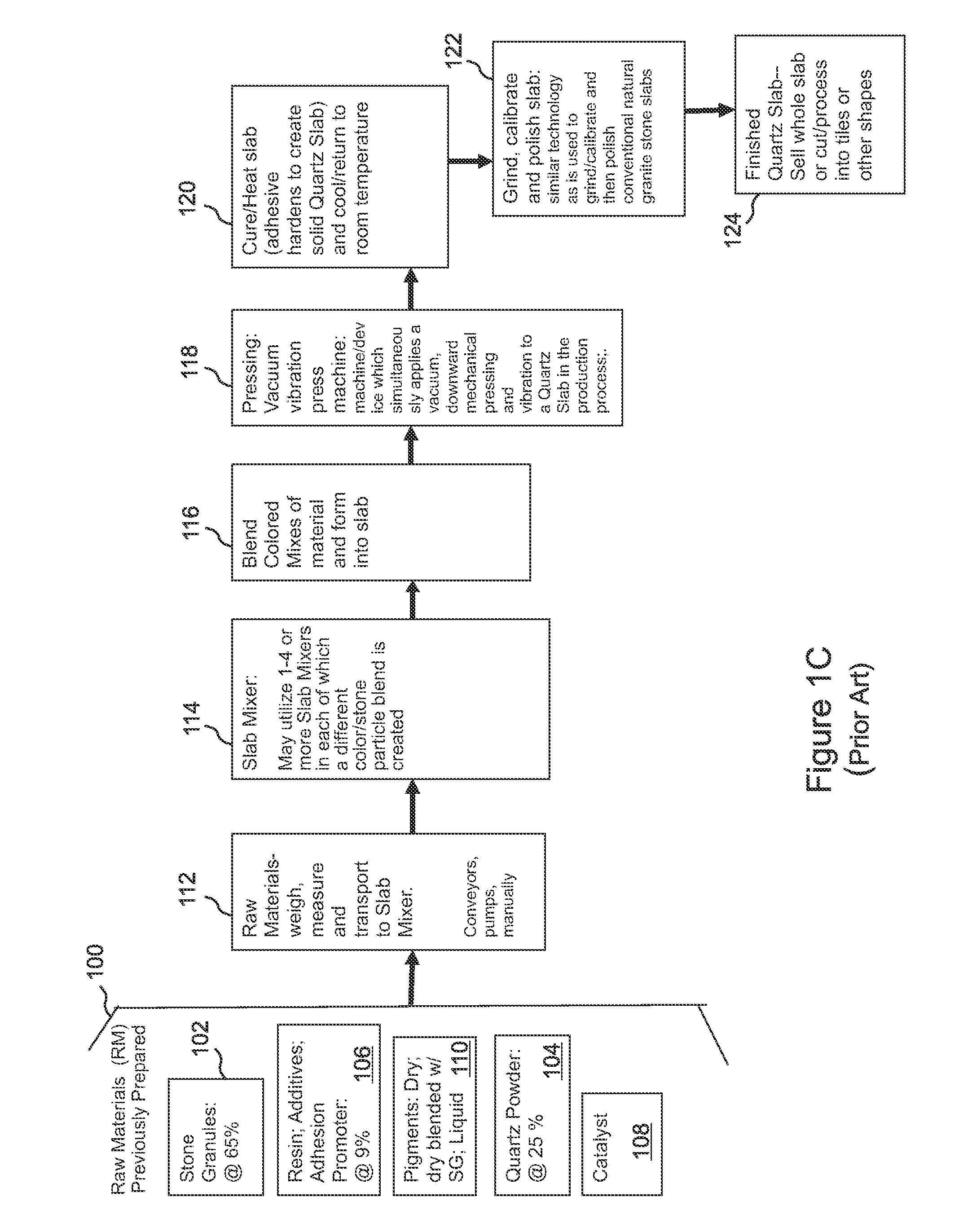

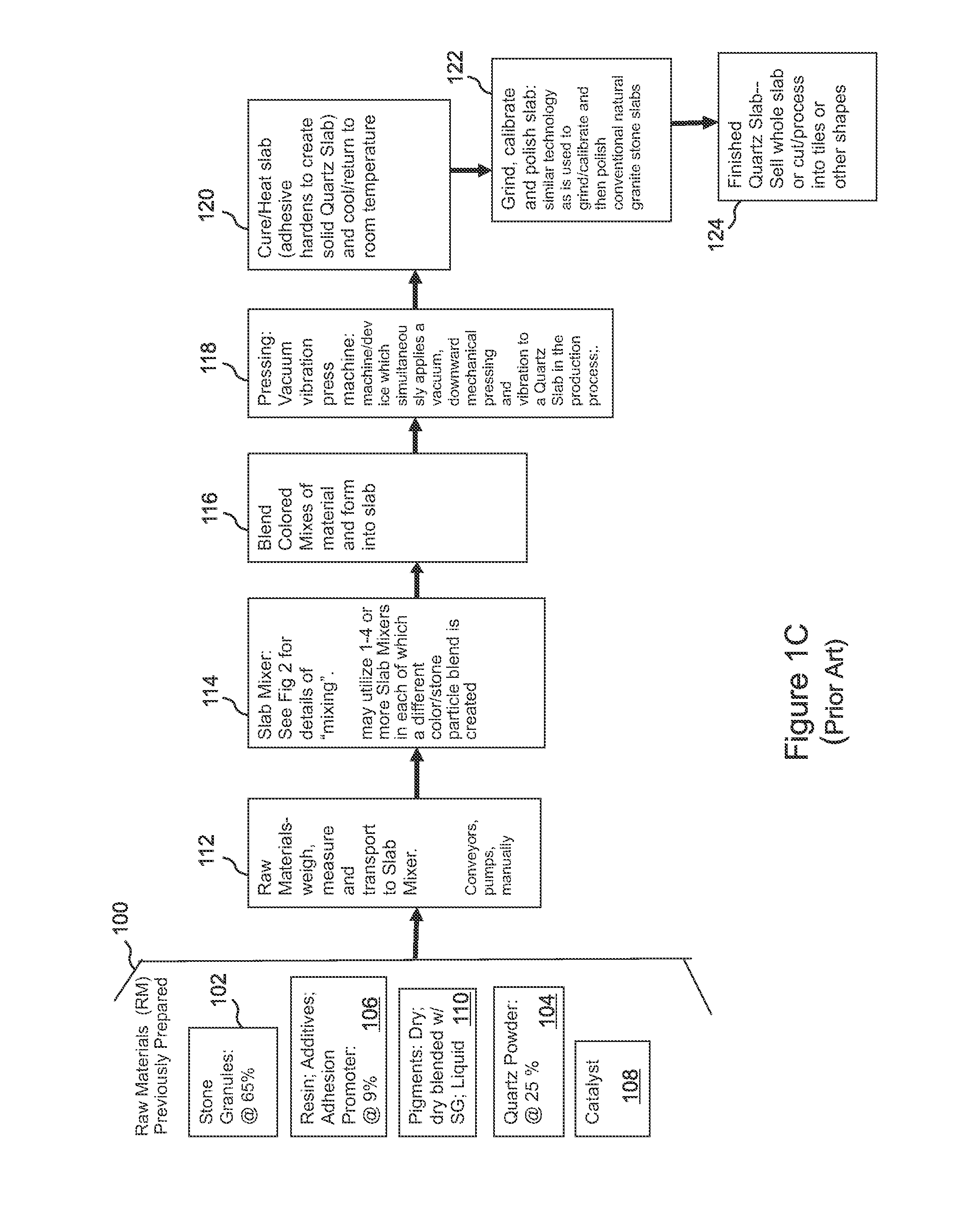

Production plant for forming engineered composite stone slabs

An engineered stone production plant includes a vacuum vibration press (“VVP”) suspended above the ground, so that a conveyor belt and / or returning empty trays or molds from a curing oven to a mixing station can pass beneath the VVP. Rigid, self-supporting trays or molds can convey slabs through the plant on rollers, which allow independent horizontal movement of the slabs during spreading and coloring / veining of the slab mixture. Embodiments include air levitation for transporting slabs into and out of the VVP. The curing oven can be air-heated. The pressing plate can be sealed with the tray or mold by walls that extend downwardly from the press plate over a flexible covering sheet, by a gasket surrounding the pressing plate, or by an angle strip surrounding the slab mixture. In embodiments, the slab size can be changed by exchanging elastomeric mold walls, or by exchanging molds and pressing platens.

Owner:GRP IND FOURNIER INC

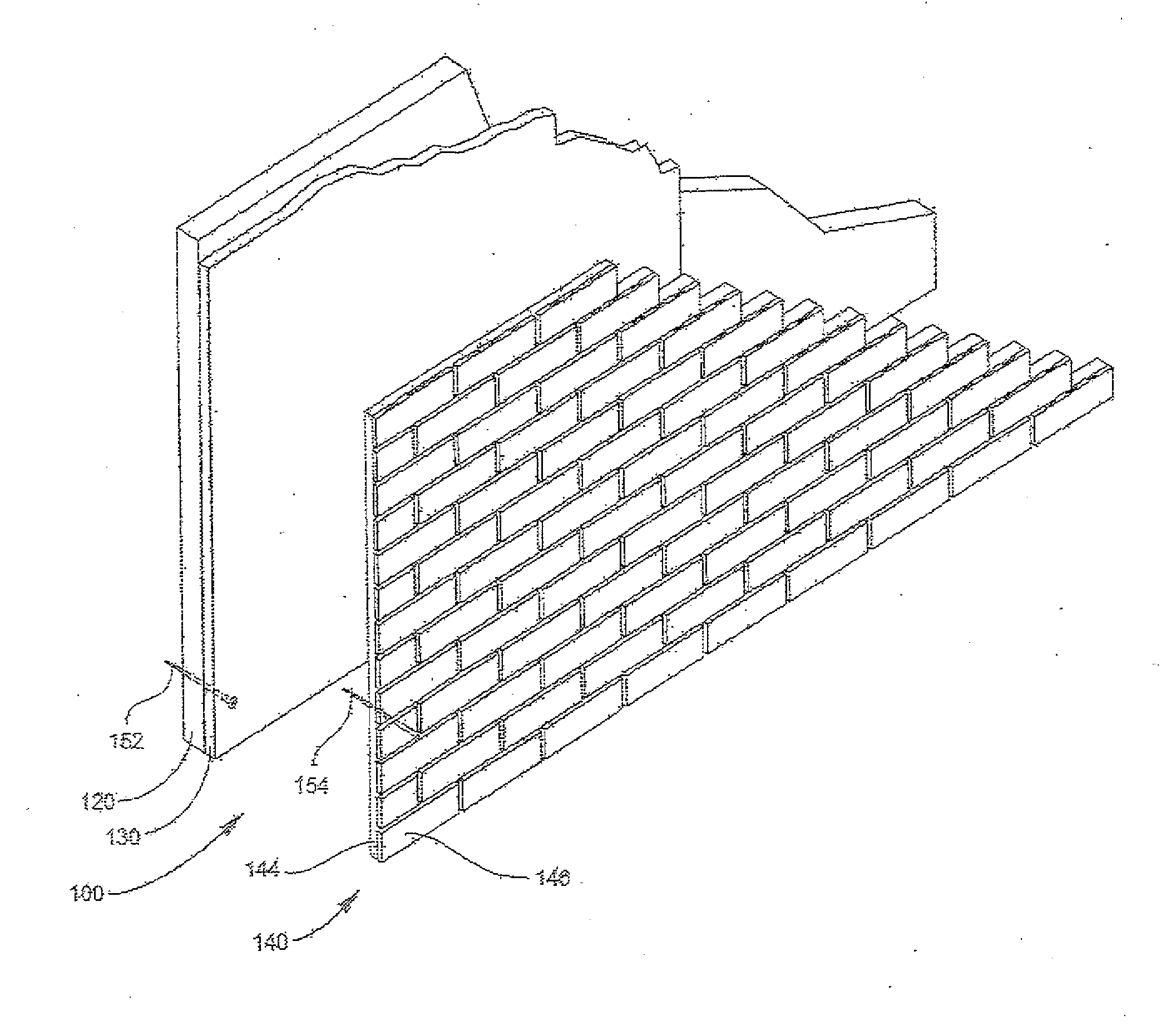

Wall panel

ActiveUS9963885B2Same aesthetic appealSame or better engineering benefitsConstruction materialCovering/liningsInsulation layerBrick

A wall panel may have a veneer layer, a middle layer made from magnesium oxide and an insulation layer made from a two-part rigid urethane pour foam. The insulation layer maybe chemically bonded to the middle layer. The veneer layer may include a poured substrate made from polyurethane or plastic. The veneer layer may further include aesthetic elements embedded in and bonded to the poured substrate. The aesthetic elements may include one or more of brick, ceramic tile, porcelain tile, natural stone, engineered stone, wood, ceramic, plastic, or vinyl. A finished surface of the aesthetic elements may extend above a top surface of the poured substrate. The poured substrate may include sand causing the top surface of the poured substrate to have an appearance of mortar.

Owner:DDP SPECIALTY ELECTRONICS MATERIALS US LLC

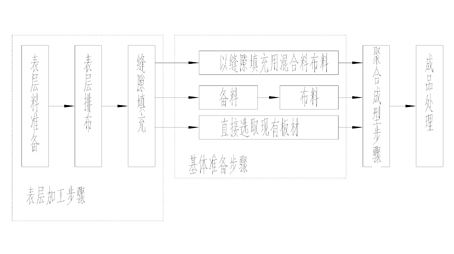

Production method for jade type macadam polymerization plate

ActiveCN102029640AGuaranteed composite strengthGuaranteed compactnessCeramic shaping apparatusSurface layerChipseal

The invention relates to the field of a construction material, namely artificial synthetic stone, in particular to a production method of a jade type macadam polymerization plate. The conversion and utilization of the jade type macadam are improved, and the steps are as follows: 1. surface layer processing steps: a. preparing a surface layer material; b. configuring a surface layer; c. filling a gap, and forming a jade type macadam surface layer; 2. substrate preparation steps: d. preparing materials; e. distributing materials, and forming substrate bed of materials; or directly distributing materials with a mixture for filling the gap, and forming the substrate bed of materials; or selecting and placing a glass plate or an aluminum-made perforated plate on the surface layer of the jade type macadam directly; 3. composite molding step; and 4.finished product processing. The invention has the advantages that the technical process is reasonable, a way of changing wastes into valuables for the jade type macadam is provided, the appreciation performance of the jade type macadam and the recreational performance of the mineral grain is utilized effectively and is beneficial to the technology upgrading of synthetic engineered stone into a recreational type product, and compared with the prior composite board, the jade type macadam polymerization plate has a wider practicability; and the polymerization plate has good wear resistance and better artistry, and the current price on market is low.

Owner:STATE GRID CORP OF CHINA +1

Thin slab of a composite material comprising a solid filler and a thermoplastic binder

InactiveUS20130130009A1Low flatnessEasy to handleSynthetic resin layered productsCeramic shaping apparatusMetallurgyThin slab

The present invention relates to an essentially isotropic slab of engineered stone, said slab having a thickness of about 2 mm to about 10 mm and preferably a width of about 0.2 m to about 3.0 m, wherein said slab is made from a composite material comprising about 50 to about 95 wt. % of solid filler and about 5 to about 50 wt. % of a thermoplastic binder, based on the total weight of the essentially isotropic slab, wherein the essentially isotropic slab has a warpage of less than about 1 mm / m. The present invention also relates to a process for manufacturing an essentially isotropic slab of engineered stone.

Owner:INNOVENT TECH

Artificial engineered stone waste residue filling polymer composite and preparing method thereof

ActiveCN110003594AEnhance the interface forceImprove performanceInjection molding machinePolymer composites

The invention discloses an artificial engineered stone waste residue filling polymer composite. The composite comprises 100 parts of a polymer base material and 0.05-80 parts of artificial engineeredstone calcium carbonate waste residues. The preparing method of the polymer composite includes the following steps of firstly, adding the artificial engineered stone calcium carbonate waste residues into a high-speed pulverizer to be superfine pulverized; secondly, mixing and stirring a polymer with the artificial engineered stone calcium carbonate waste residue powder according to a certain ratiothrough a high-speed mixer for 10-20 minutes; thirdly, extruding and granulating the mixture through a twin-screw extruder, and conducting injection molding through an injection molding machine to obtain a required product. The composite has the advantages that by enhancing the interfacial acting force between the filler and the base material, the polymer composite has excellent comprehensive performance, the production cost of the polymer composite is effectively reduced, and environmental pollution is avoided.

Owner:SICHUAN UNIV

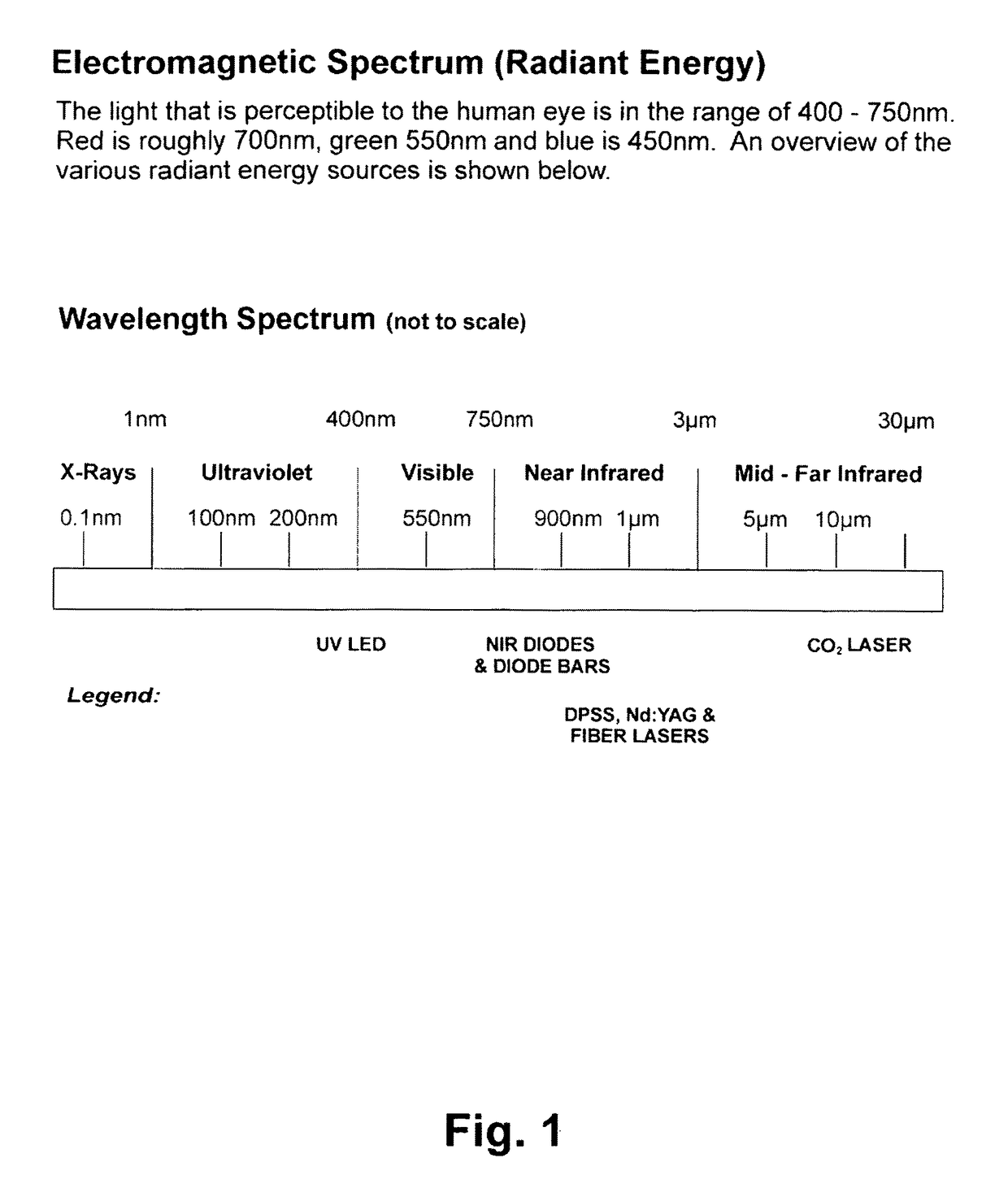

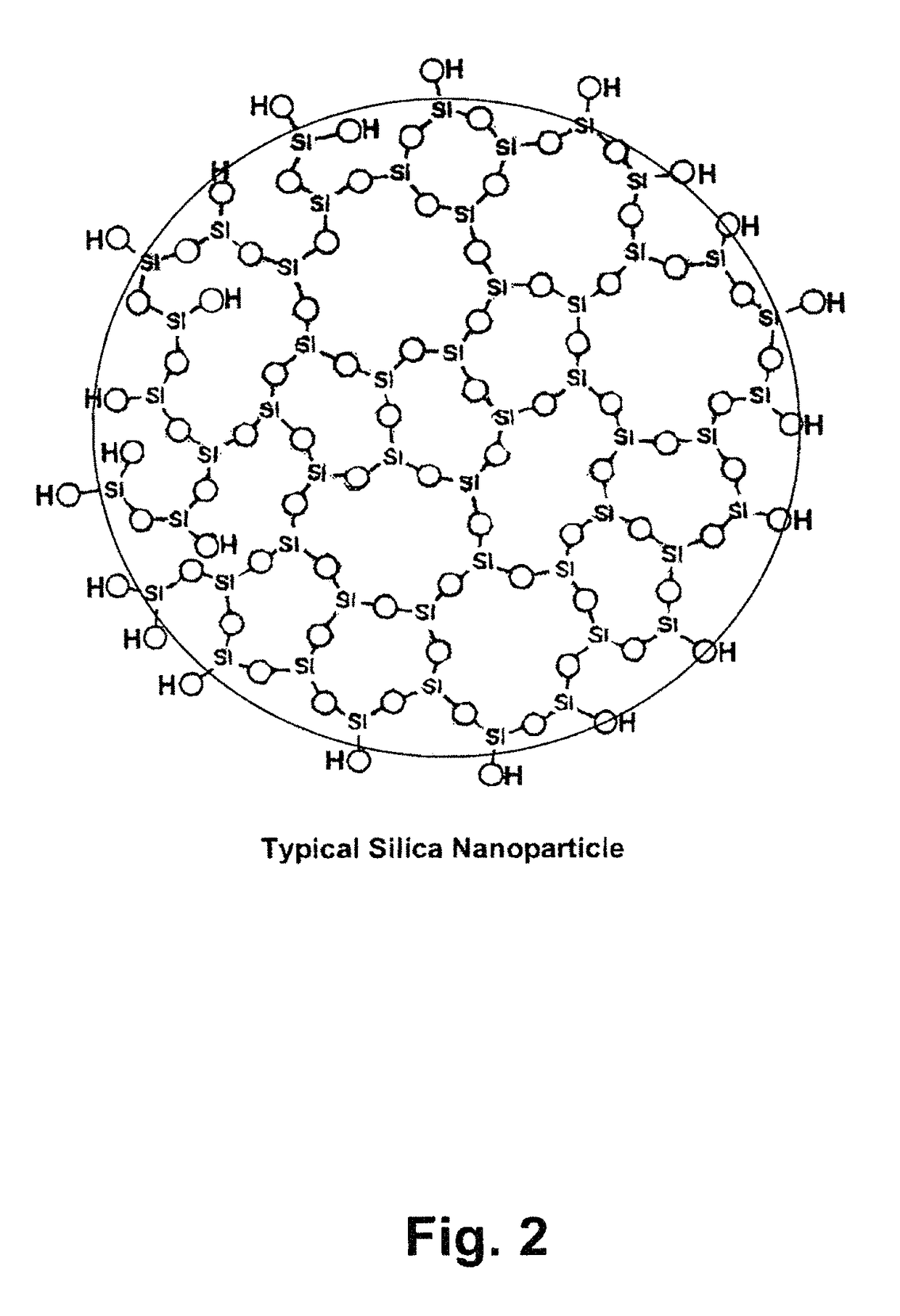

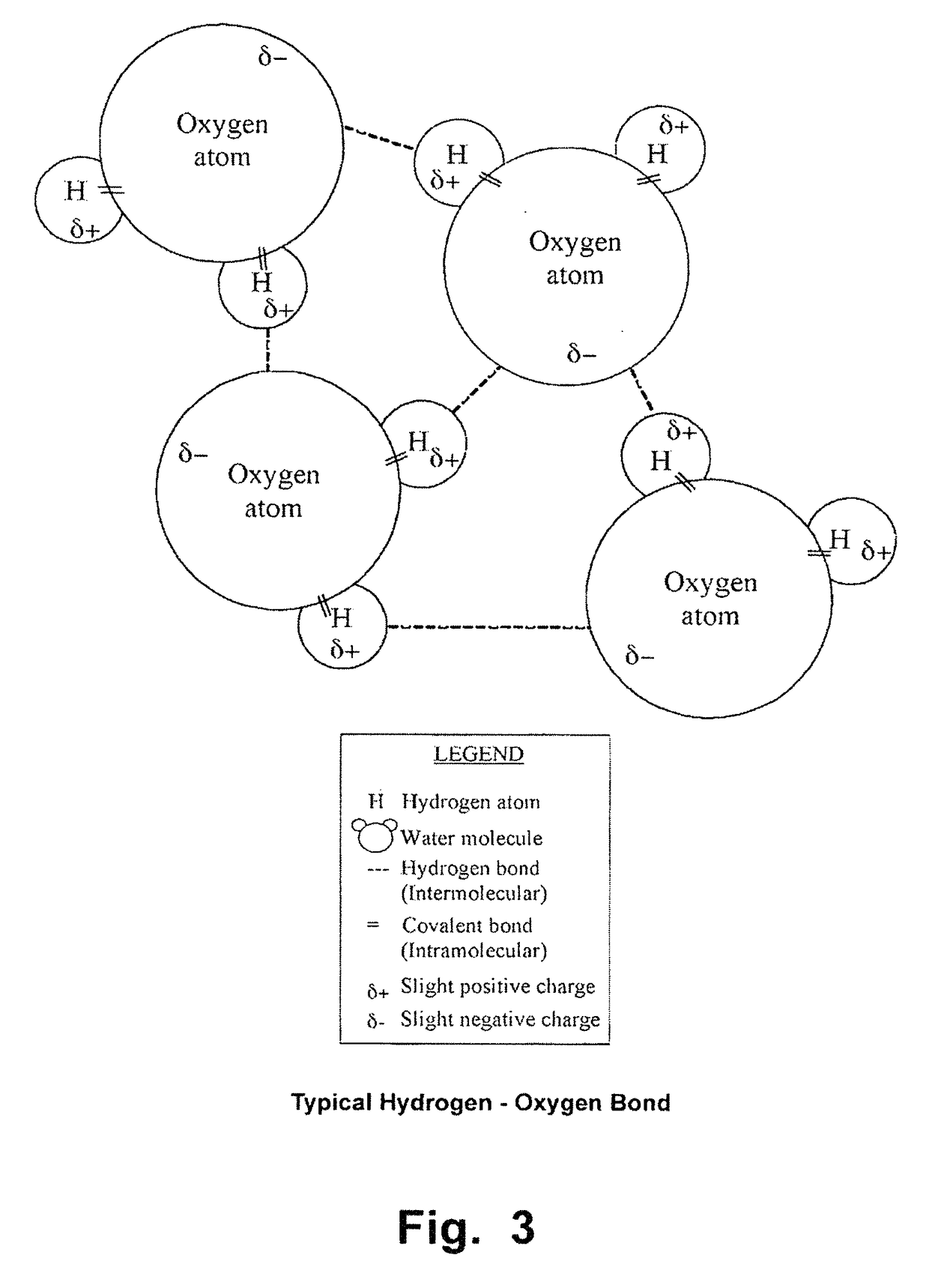

High contrast surface marking using nanoparticle materials

ActiveUS20150344712A1Promote absorptionLow melting pointRadiation applicationsLayered productsNanoscopic scaleEngineered stone

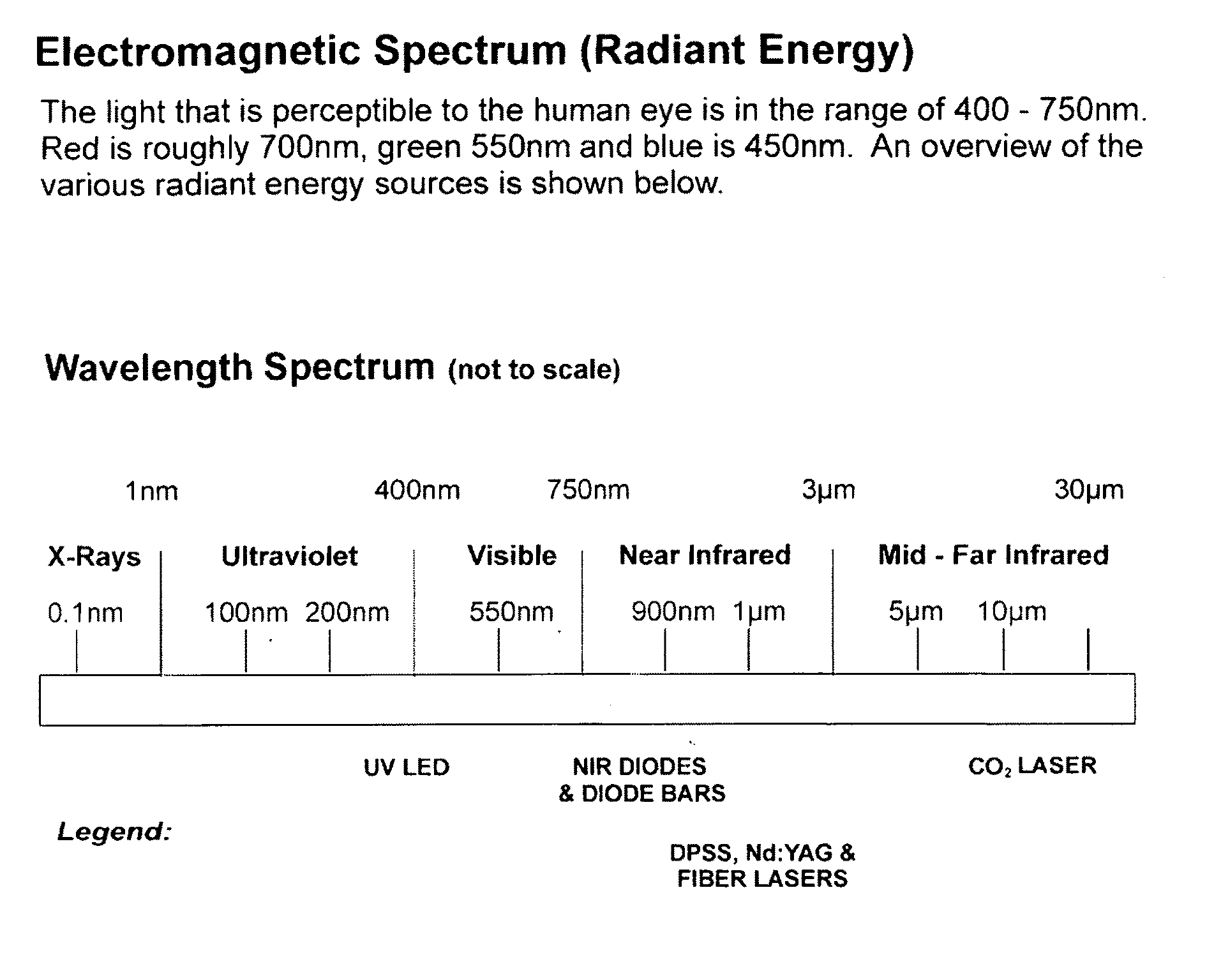

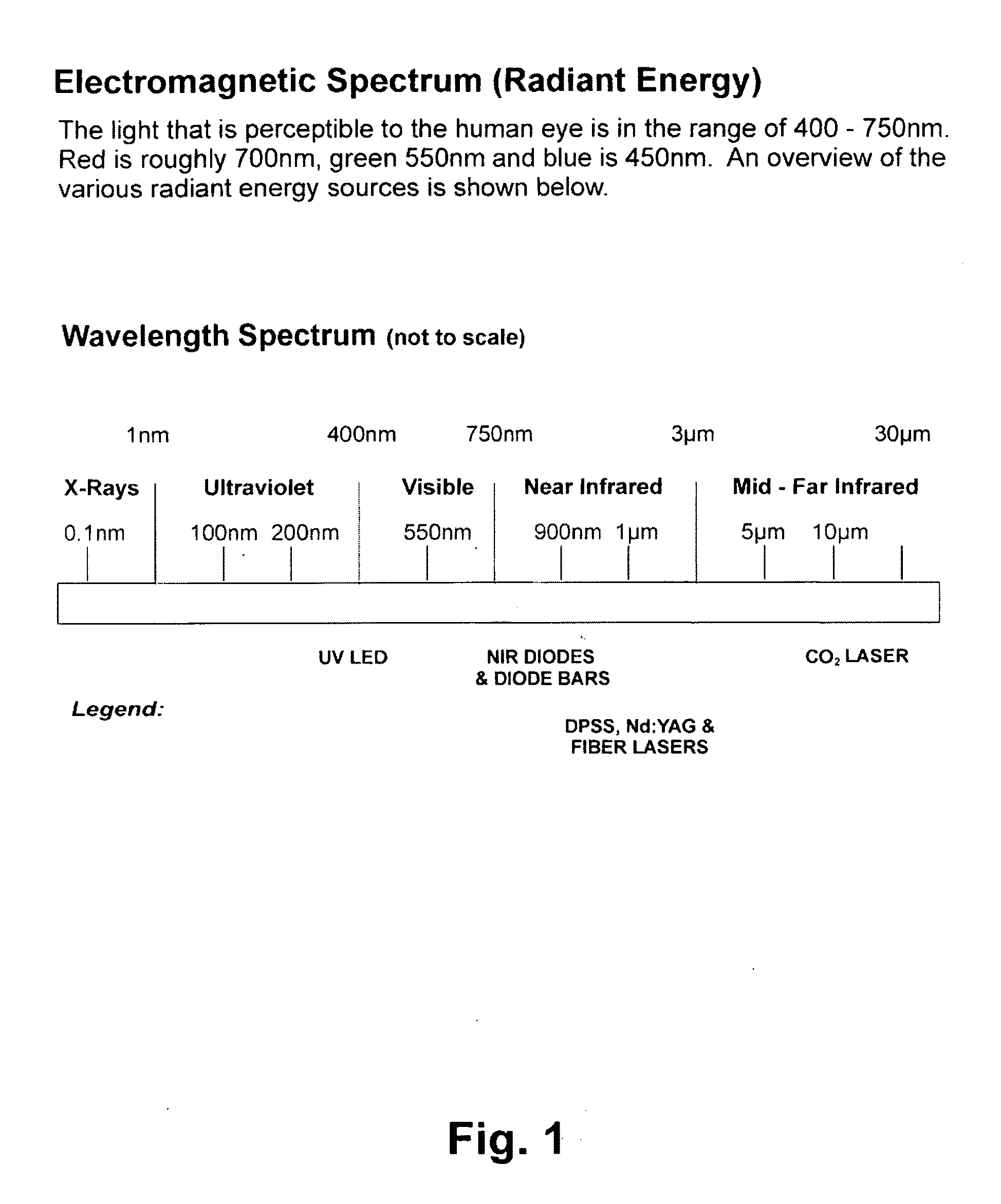

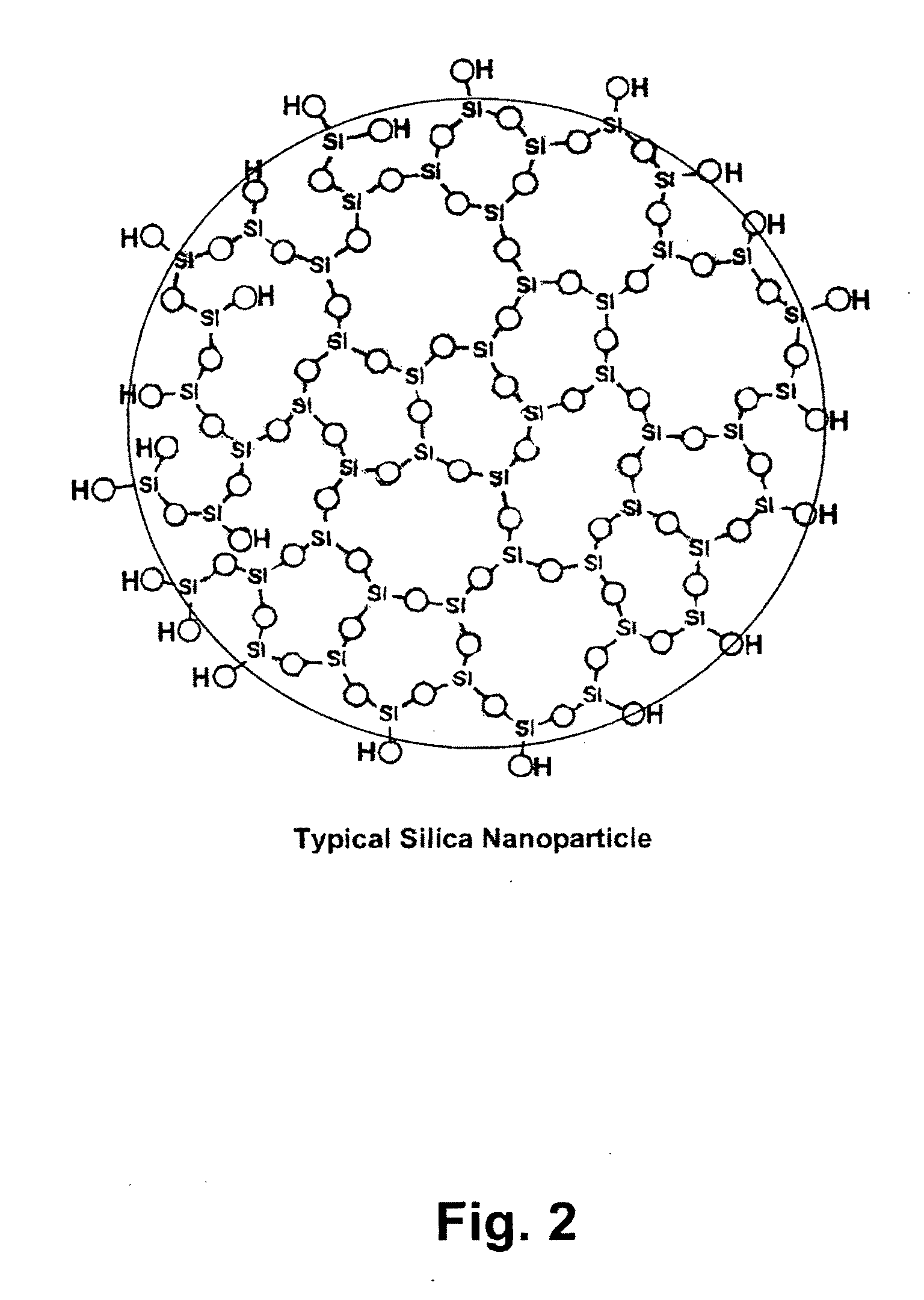

Methods and compositions are disclosed for quickly creating durable surface marks and / or decorations on substrates including metal, glass, ceramic, porcelain, natural and engineered stone, as well as plastics, polymer composites and other organic materials with color, high resolution and high contrast using inkjet technology and laser, NIR diode or UV LED energy. The improved methods and compositions are based on established and emerging sub-micron and nanoparticle technology. Most properties of nanoparticles are size dependent and do not become apparent until the particle size has been reduced to the nanometer scale. Examples of such properties include increased specific surface area, facilitating the absorption and / or scattering of visible light and laser, NIR diode or UV LED energy and the decreased melting point of such materials when their particle size is reduced to the nanometer scale. Improved results such as smoothness and durability are obtained by using nanoparticles of silica, pigments and other materials in such marking processes.

Owner:HARRISON FAMILY TRUST

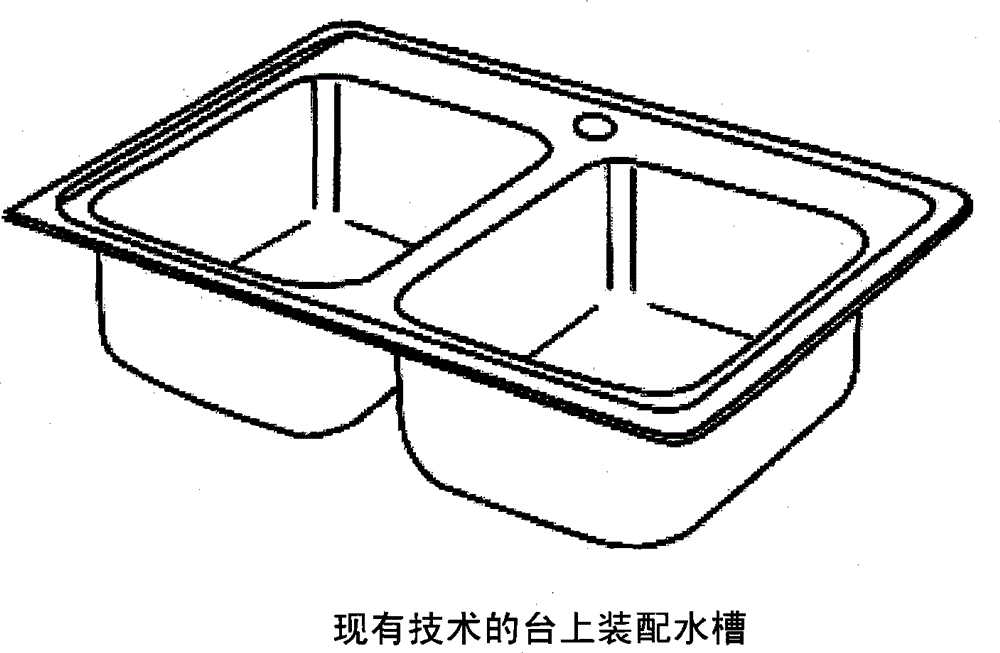

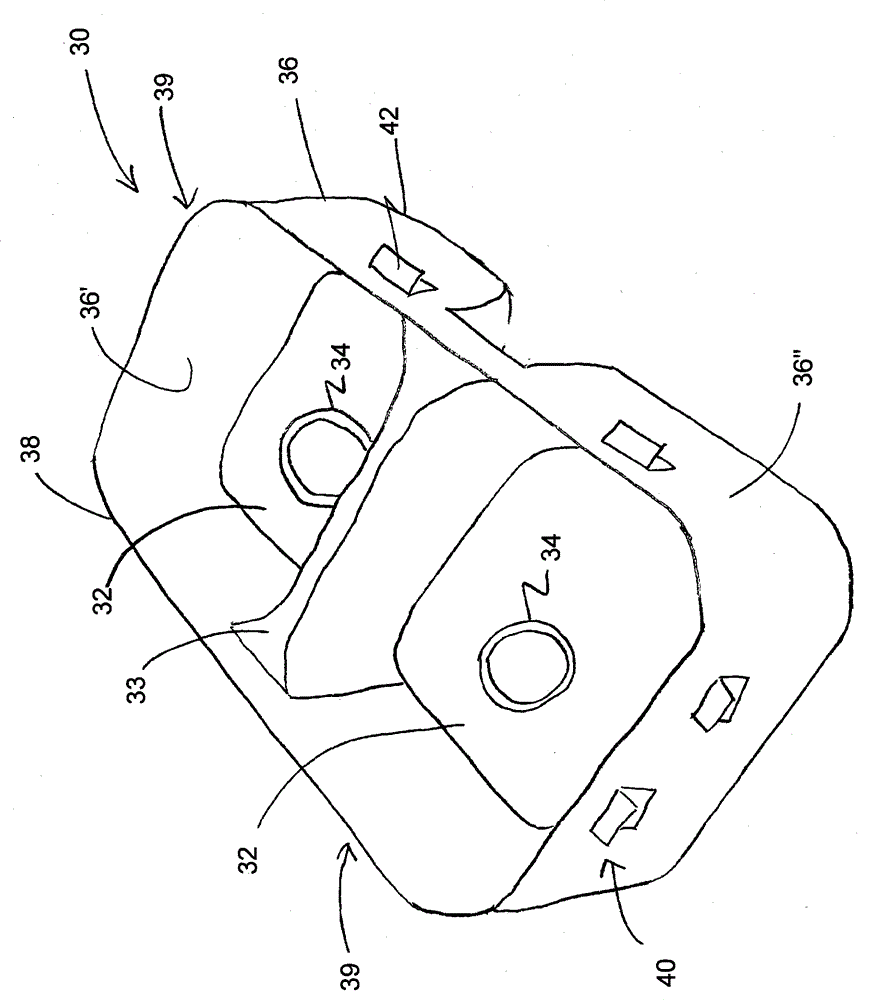

Seamless undermount stainless steel sink system

A seamless undermount stainless steel sink system includes a solid countertop constructed of granite, marble, quartz stone, quartzite, porcelain, glass, engineered stone, multi-layered and / or composite materials, and having a sink mounting aperture defining an inner periphery disposed therethrough. The system also includes a stainless steel sink having a sidewall with a rimless upper edge defining an outer periphery therearound. A mounting assembly is attached to a portion of the stainless steel sink at a predetermined mounting depth below the rimless upper edge, and an interface is formed between the stainless steel sink and the solid countertop. A sealing assembly is disposed in the interface between the rimless upper edge of the stainless steel sink and the solid countertop to prevent water, food, or other debris from getting in between the stainless steel sink and the solid countertop.

Owner:穆罕默德·霍贾奥卢

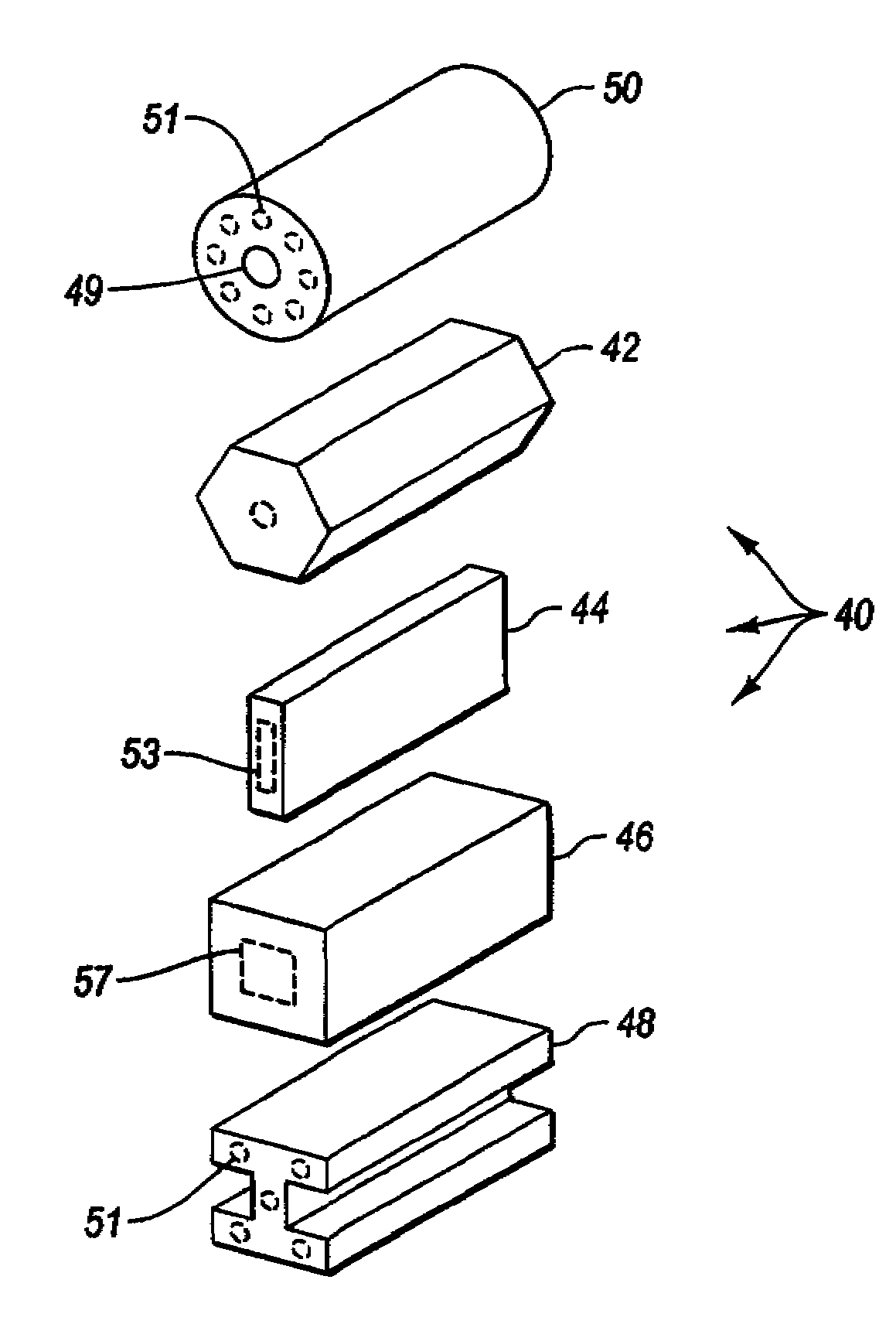

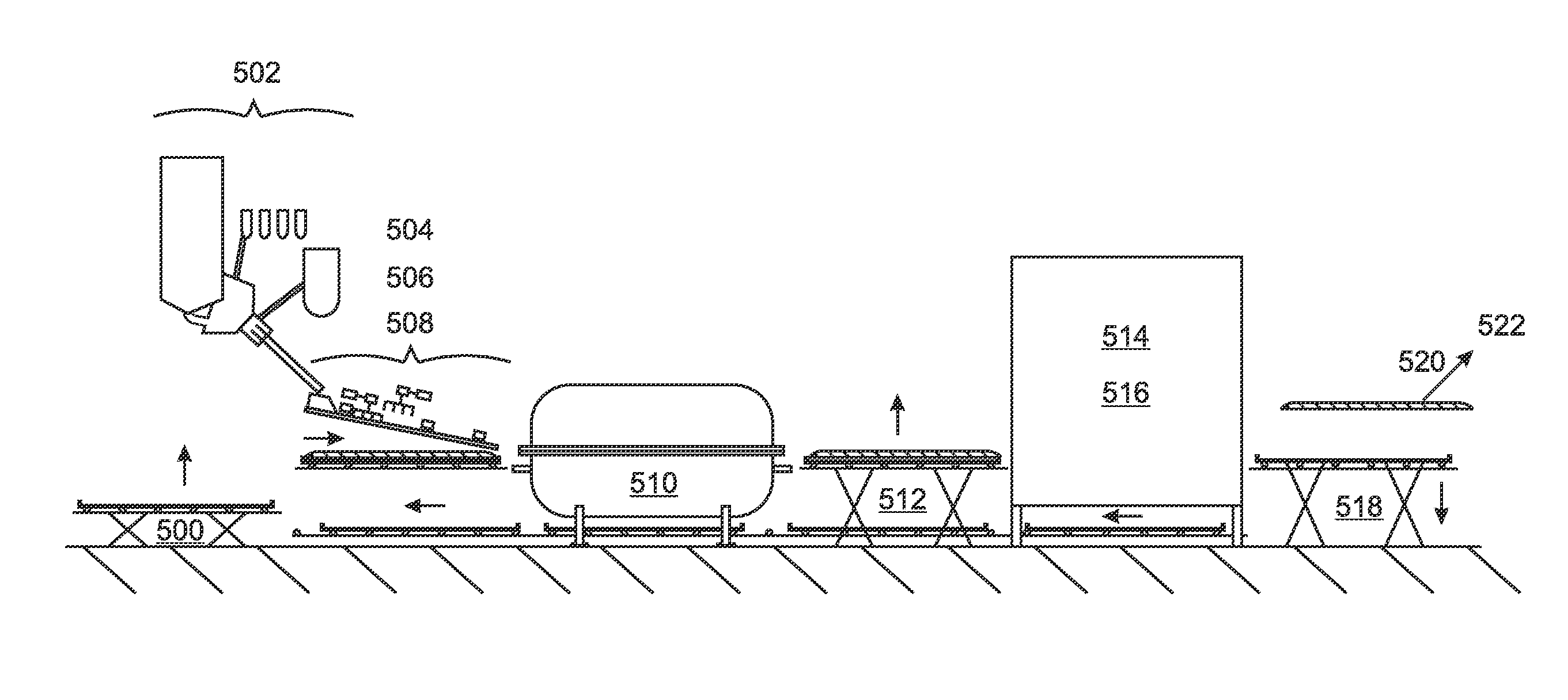

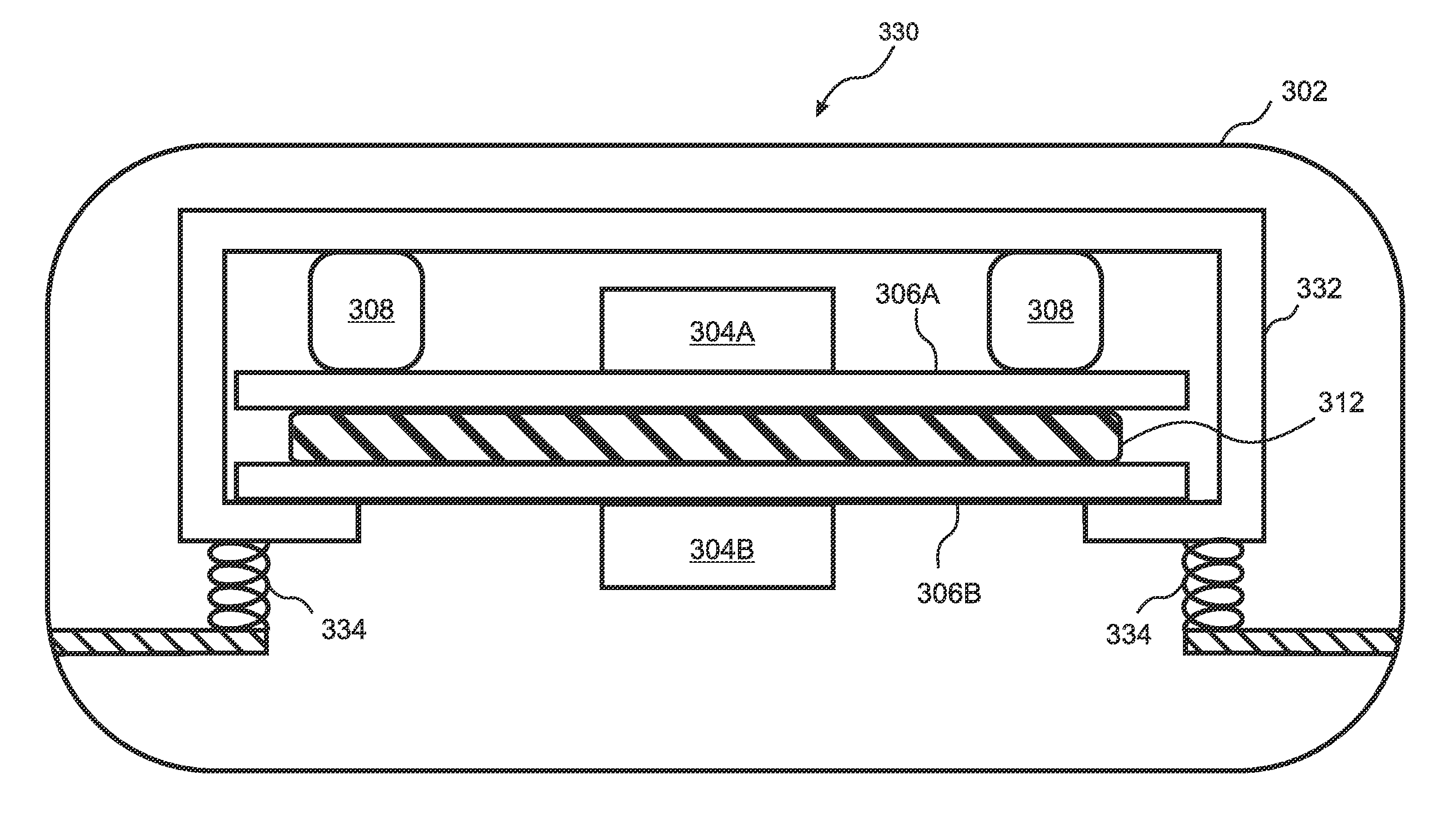

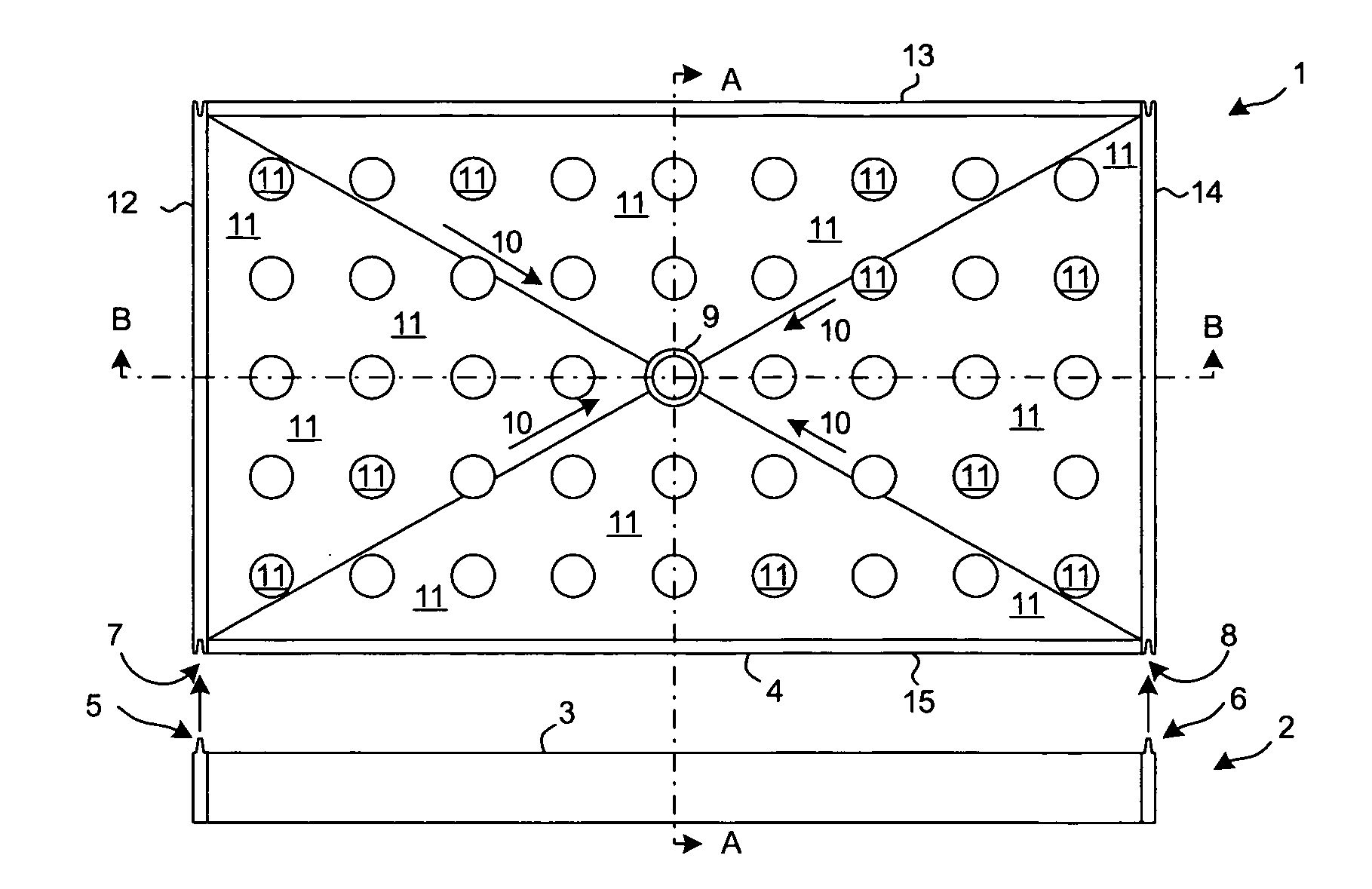

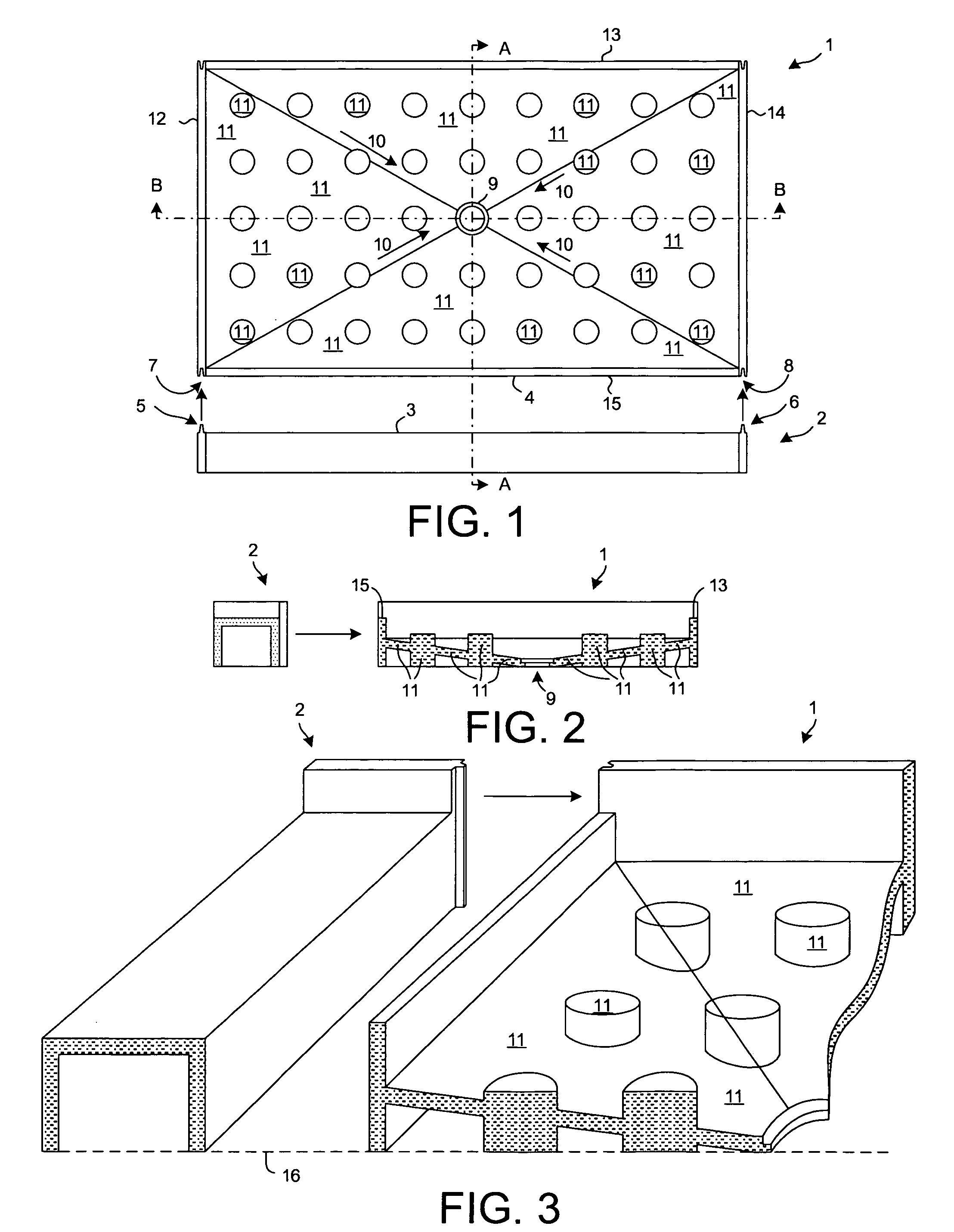

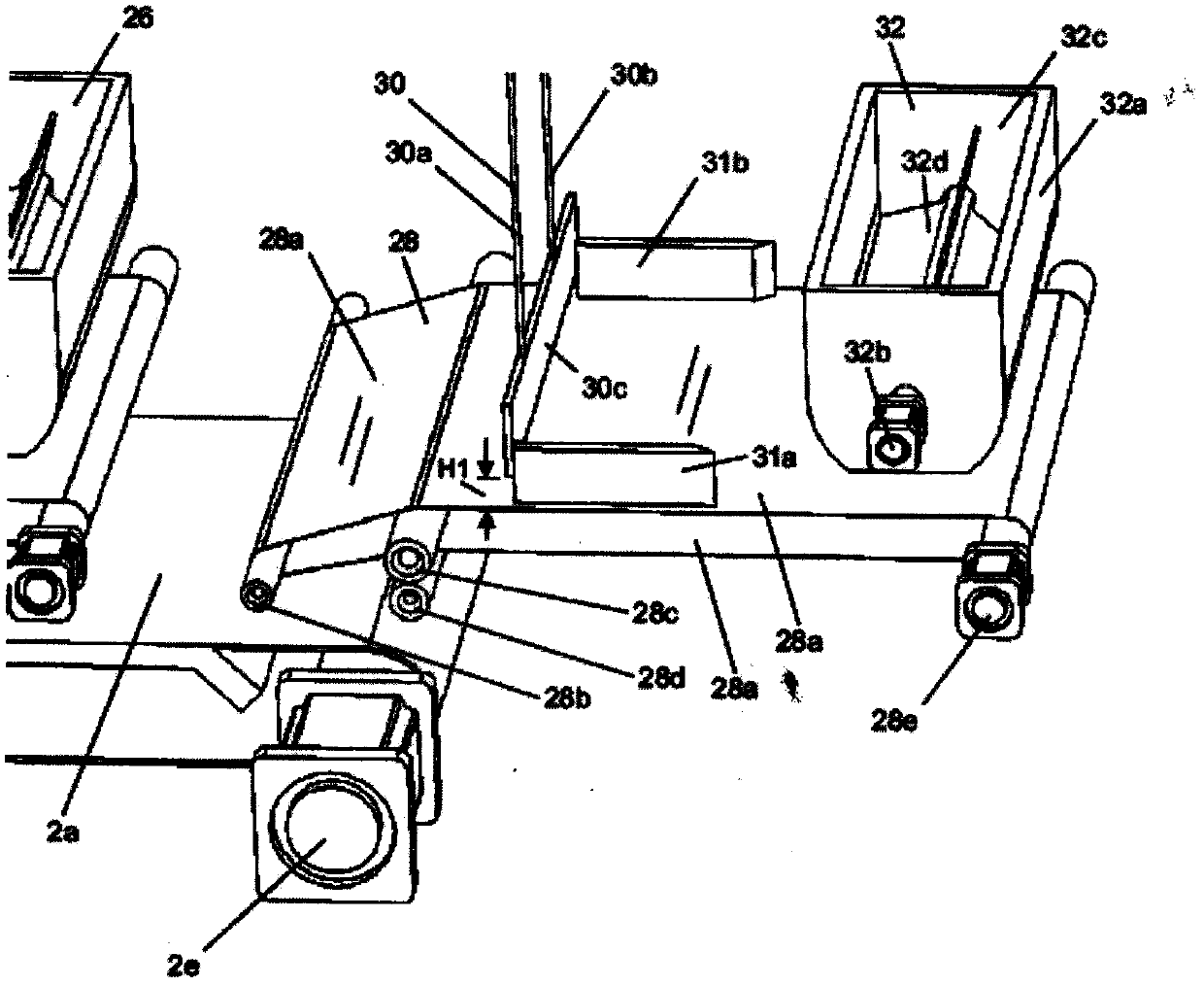

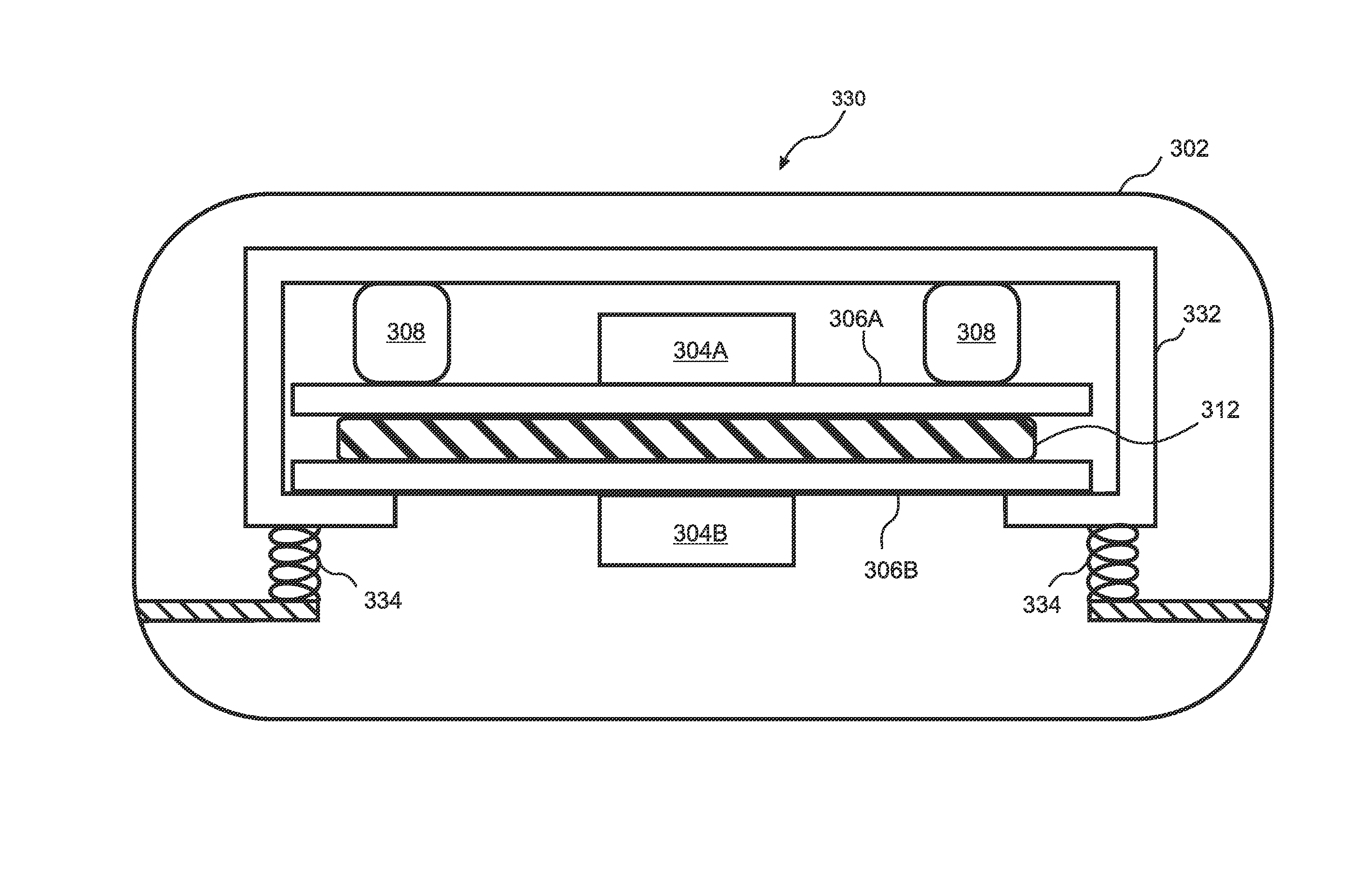

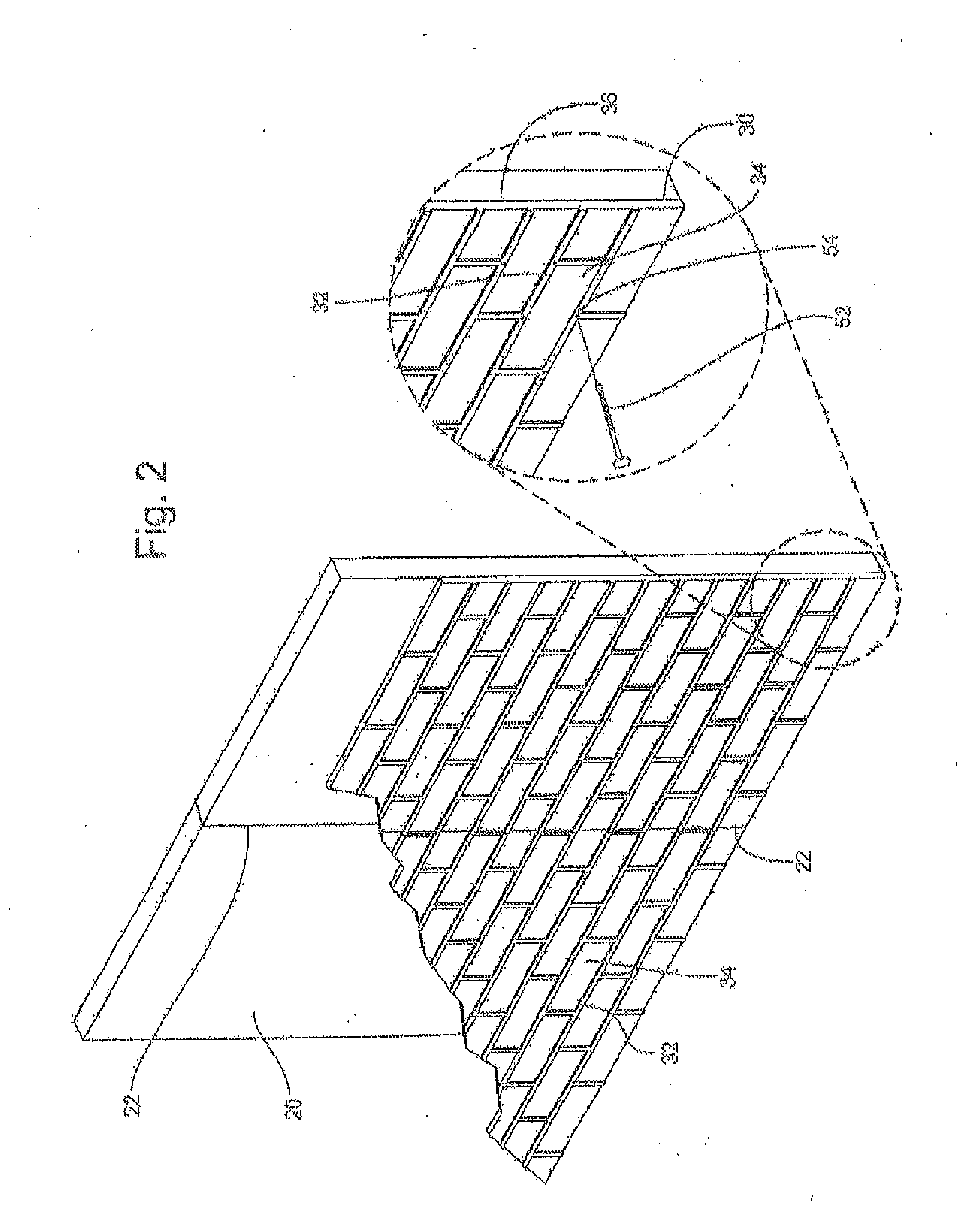

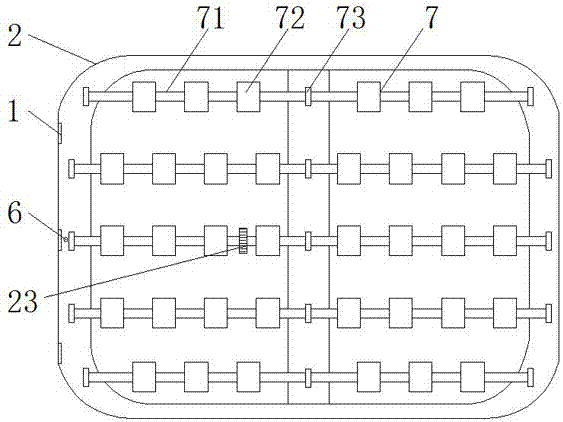

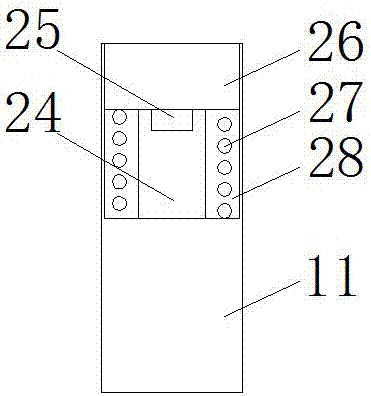

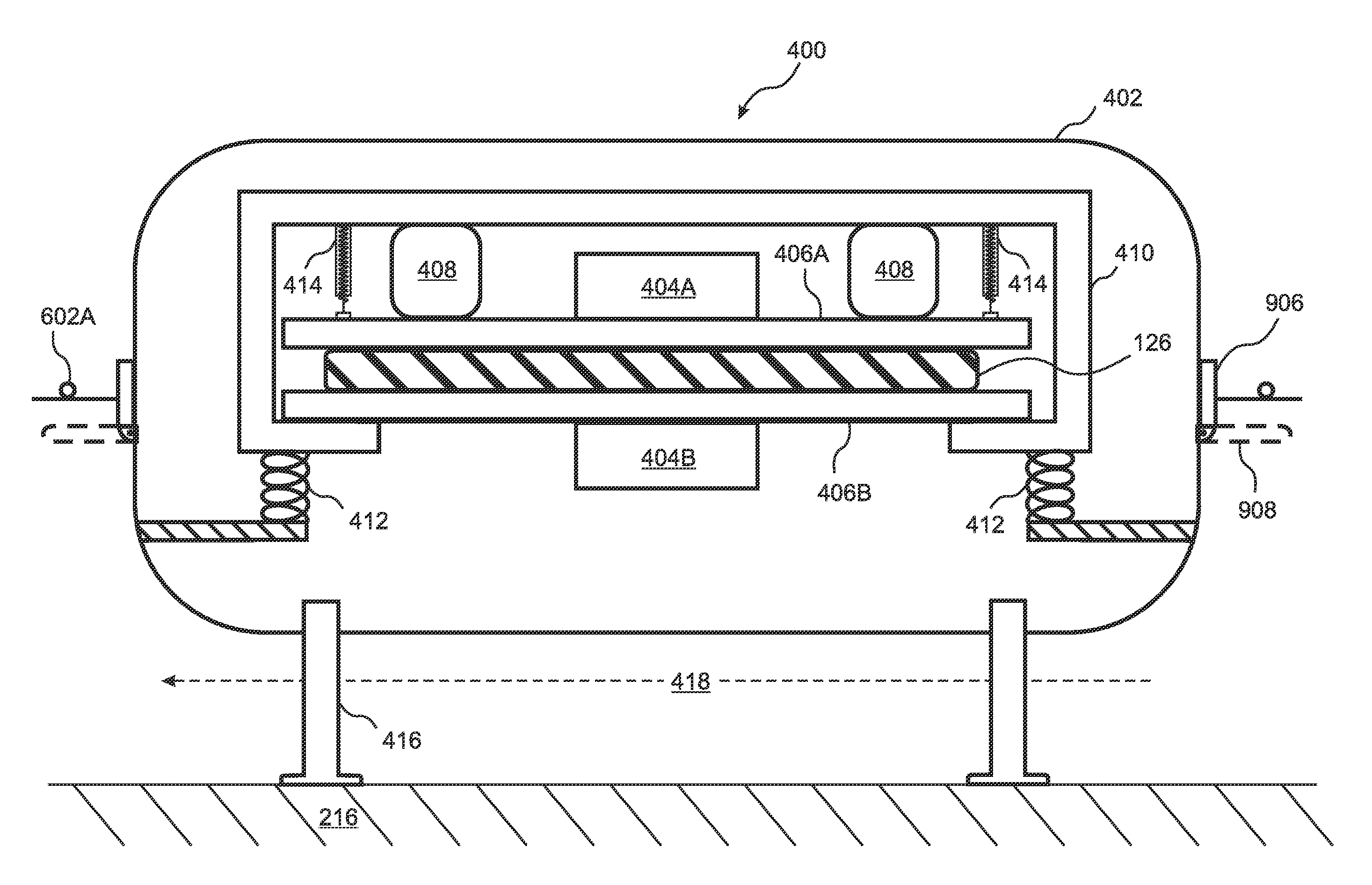

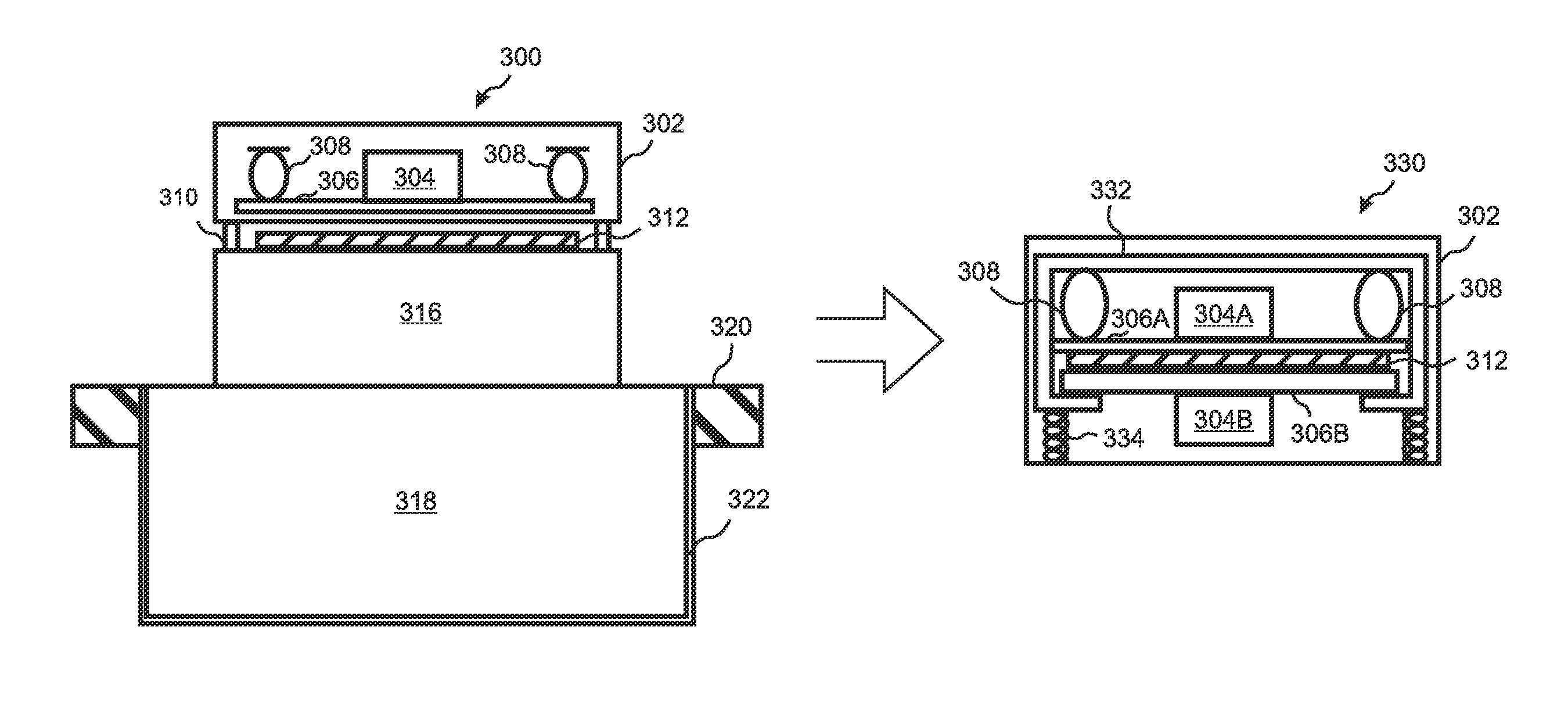

Vacuum vibration press for forming engineered composite stone slabs

A vacuum vibration press manufactures engineered stone slabs that are equal or superior in appearance and physical properties to slabs manufactured using a conventional Breton press, while weighing less, costing less to manufacture, providing shorter press cycle times, requiring less resin, and consuming less energy. In addition to providing a vibration device above the slab, the press also includes a second vibration device below the slab, which replaces the massive inertial base of a Breton press. The vibration devices can have different frequencies, amplitudes, and / or vibration axes. The press can be completely enclosed within a vacuum chamber, and vibrationally isolated from surrounding structures. In embodiments, volume reduction blocks reduce the volume to be evacuated. Embodiments use screw jacks and springs or air bags to provide controlled pressing force and precisely uniform slab thickness. Slabs can be inserted and removed on a conveyor belt, or in separate trays on rollers.

Owner:GRP IND FOURNIER INC

Infinity shower pan

A shower pan includes a draining base portion that drains to an orifice. The draining base portion includes a support structure for supporting a slab floor member (for example, a single piece of granite, marble, or engineered stone) above the orifice such that a planar upper surface of the floor member has a slight tilt. The pan is installed such that the tilt is toward a shower head. The shower enclosure is finished by cladding the enclosure walls with a finishing material (for example, granite, marble or engineered stone) such that the finishing material extends down into the pan. The floor member is placed on the support structure such that water from the shower head that falls on the floor member runs off one or more edges of the floor member and is conducted to the orifice under the floor member by a draining portion of the draining base portion.

Owner:POLIMENO JOHN

Method and system for preparing lime from waste artificial engineered stones

The invention relates to the field of preparation of building materials, and provides a method for preparing lime from waste artificial engineered stones. The method comprises the following steps: adding a nitric acid solution with the mass concentration of 25%-32% in artificial engineered stone without organic resin, reacting for 40-200 minutes, and then filtering to obtain a first solution and first filter residues, wherein the mass ratio of the waste artificial engineered stones to the nitric acid solution is 1: 37-47.5; adding sodium carbonate solids in the first solution, reacting for 35-150 minutes, and then filtering to obtain a second solution and second filter residues, wherein the mass ratio of the sodium carbonate solids to the artificial engineered stones is 1: 1.64-1.93; and firing the second filter residues at the high temperature of 900-1,100 DEG C for 2-4 hours to obtain finished lime. By the method, resources can be recycled effectively, and the quality of the prepared lime is good. The invention further provides a system for preparing the lime from the waste artificial engineered stones by using the method. The system is simple in structure, and resources can be saved effectively.

Owner:广西广厦环保科技有限公司

Method and apparatus for forming marbelized engineered stone

Owner:贺奇玻璃制造(大连)有限公司

Moldable engineered stone

This invention provides a moldable engineered stone composition comprising an ethylenically unsaturated acrylic polymer capable of being covalently crosslinked, a mineral particulate, and an ionic crosslinking agent which forms ionic bonds within the syrup of unsaturated acrylic polymer via unreacted acid groups, causing thickening prior to curing and prior to the formation of covalent bonds via the double bonds of the polymer chain. The composition is then capable of being extruded and molded in a press. Articles formed by curing the composition and methods for producing the composition are also disclosed.

Owner:SAFAS CORP

Engineered stone

ActiveUS7727435B2Small sizeEasy laminationNatural patternsSpecial ornamental structuresHigh intensitySynthetic resin

The present invention relates to an engineered stone composite produced from a mineral aggregate, a synthetic resin and a binder using compression and vibration to obtain a high strength mineral composite with a high mineral content and a method for its preparation.

Owner:SAFAS CORP

Coated particle with shimmering appearance and engineered stone containing coated particles

InactiveUS20090274909A1Synthetic resin layered productsCellulosic plastic layered productsEngineered stoneMaterials science

A coated particle having a shimmering appearance to an observer contains a refractive particle, a transparent coating on the refractive particle, reflective particles and refractive particles embedded in the coating, with one of the reflective particles or the reflective particles primarily at a surface of the coating. Also an engineered stone has a shimmering appearance due to incorporation of coated particles.

Owner:EI DU PONT DE NEMOURS & CO

Vacuum vibration press for forming engineered composite stone slabs

A vacuum vibration press manufactures engineered stone slabs that are equal or superior in appearance and physical properties to slabs manufactured using a conventional Breton press, while weighing less, costing less to manufacture, providing shorter press cycle times, requiring less resin, and consuming less energy. In addition to providing a vibration device above the slab, the press also includes a second vibration device below the slab, which replaces the massive inertial base of a Breton press. The vibration devices can have different frequencies, amplitudes, and / or vibration axes. The press can be completely enclosed within a vacuum chamber, and vibrationally isolated from surrounding structures. In embodiments, volume reduction blocks reduce the volume to be evacuated. Embodiments use screw jacks and springs or air bags to provide controlled pressing force and precisely uniform slab thickness. Slabs can be inserted and removed on a conveyor belt, or in separate trays on rollers.

Owner:GRP IND FOURNIER INC

Wall panel

ActiveUS20170037639A1Same aesthetic appealSame or better engineering benefitsConstruction materialCovering/liningsPolymer scienceInsulation layer

A wall panel may have a veneer layer, a middle layer made from magnesium oxide and an insulation layer made from a two-part rigid urethane pour foam. The insulation layer maybe chemically bonded to the middle layer. The veneer layer may include a poured substrate made from polyurethane or plastic. The veneer layer may further include aesthetic elements embedded in and bonded to the poured substrate. The aesthetic elements may include one or more of brick, ceramic tile, porcelain tile, natural stone, engineered stone, wood, ceramic, plastic, or vinyl. A finished surface of the aesthetic elements may extend above a top surface of the poured substrate. The poured substrate may include sand causing the top surface of the poured substrate to have an appearance of mortar.

Owner:DDP SPECIALTY ELECTRONICS MATERIALS US LLC

Extruded fiber reinforced cementitious products having stone-like properties and methods of making the same

InactiveUS20120270971A1Easy to moldEasy to shapeConstruction materialSolid waste managementBuilding productCement composites

A cementitious composite product that can function as a substitute for stone and solid surface materials, such as granite, marble, and engineered stone is provided. Furthermore methods for manufacturing the cementitious composite product using an extrudable cementitious composition that can be extruded or otherwise shaped into stone-like building products that can be used as a substitute for many known stone products is disclosed. In one embodiment, the cementitious composite products can be manufactured more cheaply to be as tough or tougher and more durable than stone and solid surface materials.

Owner:E KHASHOGGI INDS

Cellulose hybrid filler reinforced polymer composite material and preparation method thereof

The invention discloses a cellulose hybrid filler reinforced polymer composite material and a preparation method thereof. The material comprises the following raw materials: 100 parts of polymer matrix; 5 parts of compatilizers; and 1-40 parts of engineered stone waste / agricultural and forestry waste hybrid fillers. The preparation method includes the following steps: (1) blending the engineered stone waste and the agricultural and forestry waste, and adding water to prepare an aqueous dispersion; (2) grinding the aqueous dispersion to prepare a micro-nano hybrid filler dispersion; (3) performing suction filtration on the micro-nano hybrid filler solution, drying, and mechanically crushing to obtain micro-nano hybrid filler powder; (4) blending the micro-nano hybrid filler powder with thepolymer and the compatilizers, and stirring; and (5) extruding and granulating the mixture through a machine, and performing injection molding through an injection molding machine to obtain a corresponding product. The method has the advantages of reasonably and effectively realizing high-value utilization, avoiding environmental pollution, effectively solving the problem that cellulose is easy toagglomerate in non-polar polymer, and endowing polymer composite materials with excellent mechanical properties.

Owner:SICHUAN UNIV

High contrast surface marking using nanoparticle materials

ActiveUS9744559B2Promote absorptionLow melting pointPretreated surfacesInksSilicon dioxideNanoscopic scale

Methods and compositions are disclosed for quickly creating durable surface marks and / or decorations on substrates including metal, glass, ceramic, porcelain, natural and engineered stone, as well as plastics, polymer composites and other organic materials with color, high resolution and high contrast using inkjet technology and laser, NIR diode or UV LED energy. The improved methods and compositions are based on established and emerging sub-micron and nanoparticle technology. Most properties of nanoparticles are size dependent and do not become apparent until the particle size has been reduced to the nanometer scale. Examples of such properties include increased specific surface area, facilitating the absorption and / or scattering of visible light and laser, NIR diode or UV LED energy and the decreased melting point of such materials when their particle size is reduced to the nanometer scale. Improved results such as smoothness and durability are obtained by using nanoparticles of silica, pigments and other materials in such marking processes.

Owner:HARRISON FAMILY TRUST

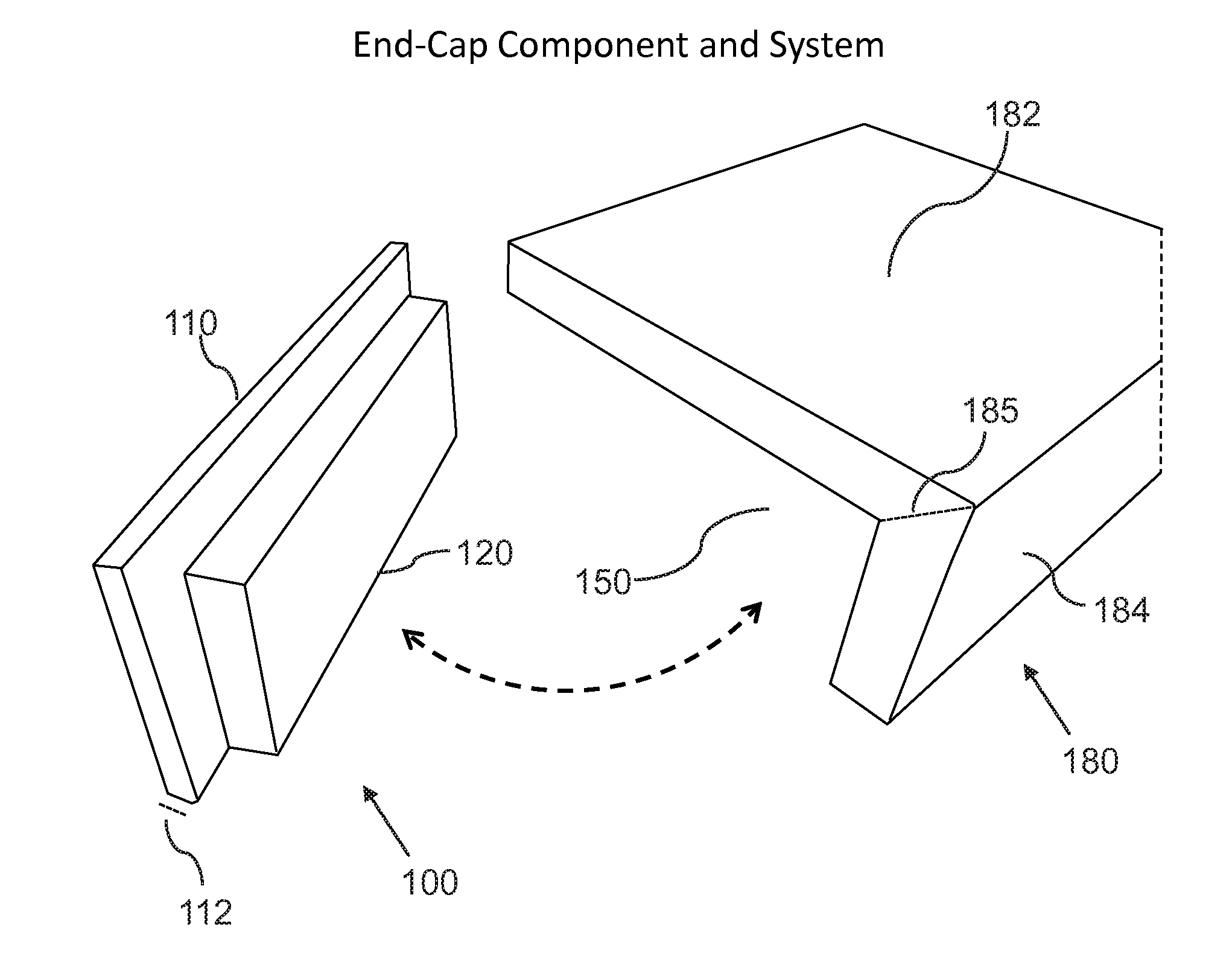

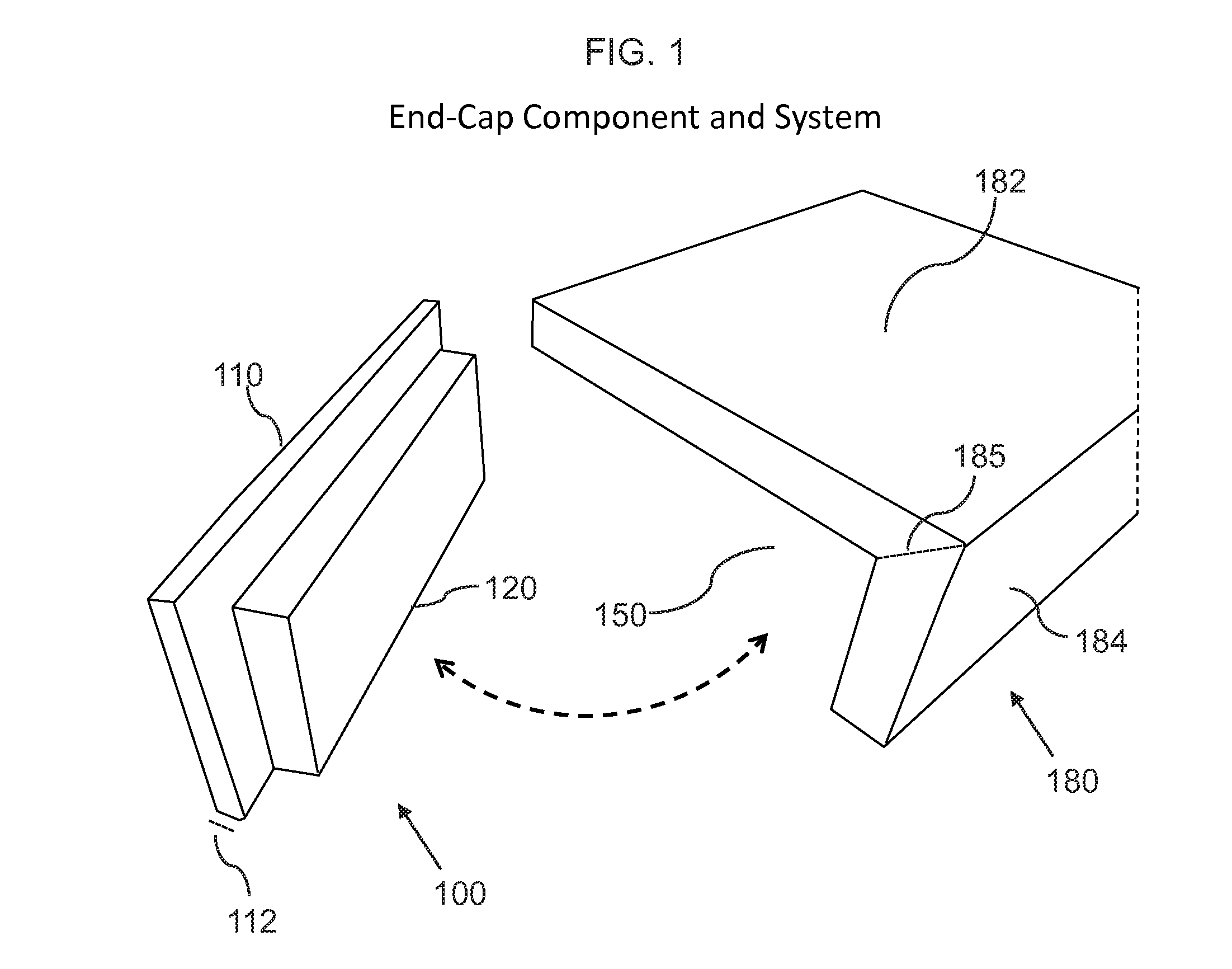

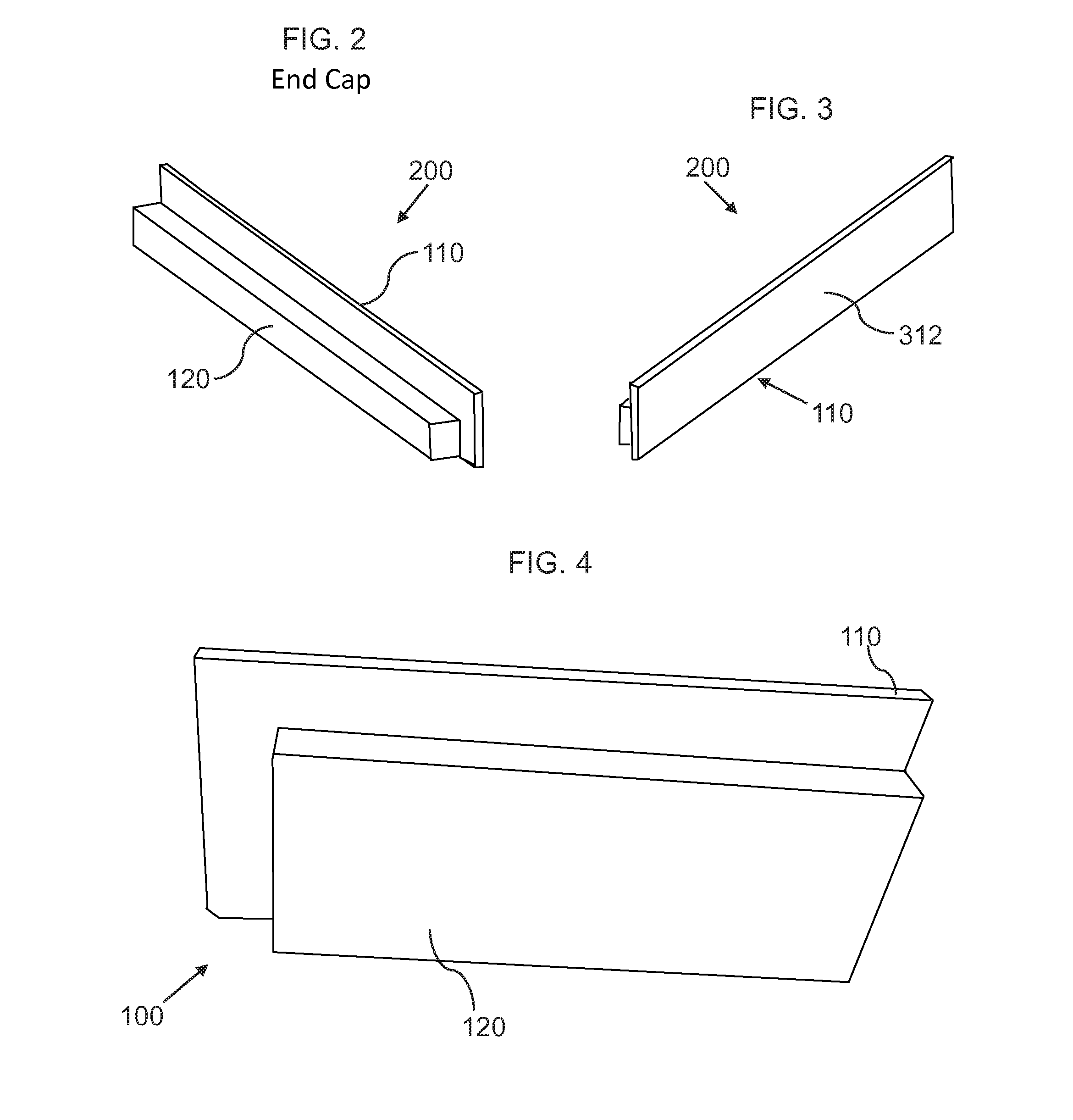

End-cap system and device for use with countertops

InactiveUS20160095438A1Efficient workflowImprove aesthetic resultLayered productsKitchen cabinetsAdhesiveFront edge

An end-cap component for installation on an open end of a countertop includes an end-cap front element, and an end-cap stabilizer, which can be solid rectangular pieces or laminated components. The end-cap component can be made in a right-side, left-side or center-mount configuration, and can be glued together with an adhesive and configured with a polished face of the end-cap front element. Also disclosed is a stabilized end-cap countertop system, including a countertop, with an upper surface element and a front edge; and an end-cap component. The system is suitable for manufacturing in stone materials, including engineered quartz, using lighter-weight parts, resulting in improved precision and efficiency of manufacturing and installation.

Owner:EZ COUNTERTOP

Decorative coated particle and engineered stone containing such particles

InactiveUS20090274895A1Synthetic resin layered productsCellulosic plastic layered productsPolymer scienceArtificial stone

A coated decorative refractive particle contains a transparent coating and either reflective particles or refractive particles embedded in the coating. Also an engineered stone contains such coated decorative particles.

Owner:EI DU PONT DE NEMOURS & CO

Natural-cross-texture engineered stone and preparation method thereof

The invention discloses natural-cross-texture engineered stone and a preparation method thereof. When the total mass of the natural-cross-texture engineered stone is counted as 100%, the raw materialsof the natural-cross-texture engineered stone comprise, 44-47% of dolomite 90-mesh sand, 46-49% of modified calcium carbonate powder, 6.3-6.6% of unsaturated polyester resin, 0.45-0.49% of mixed pigment, 0.08-0.1% of a curing agent and 0.008-0.01% of an accelerator. The preparation method comprises the steps: dividing pressed square materials into a plurality of blocks of different sizes, performing slurry spraying or other coloring modes on the surface, then putting the processed blocks back into moulds, and performing secondary press so as to obtain the engineered stone variety with cross textures close to natural textures. The quality of the engineered stone is ensured through optimization of process parameters of two pressing, and the varieties of engineered stone patterns are enriched greatly.

Owner:广东博瑞格新材料科技有限公司

Multi-angle plate toppling machine for engineered stone production

PendingCN107971922AIncrease productivityReduce labor costsGrinding feedersProduction lineEngineered stone

The invention relates to the technical field of engineered stone production and machining and particularly discloses a multi-angle plate toppling machine for engineered stone production. A rotary table is arranged on a base plate of a trolley base, a gear ring is arranged on the outer side of the rotary table, the plate blank feeding direction is adjusted by driving the rotary table to rotate through a stepping motor, and plate blank feeding of multiple production lines can be achieved through one plate toppling machine. One side of a plate toppling frame is hinged to the rotary table, and turnover action can be achieved through two telescopic driving mechanisms. When the telescopic driving mechanisms are stretched out, the plate toppling frame is pushed to turn over upwards till the upright state, and a plate blank is hung on hanging feet; and the telescopic driving mechanisms are drawn back, the plate toppling frame is pulled to turn over downwards until the horizontal state, the plate blank is placed horizontally, the plate blank is pushed to a conveying belt through a roller row and enters polishing equipment, and subsequent polishing operation is carried out. The multi-angle plate toppling machine for engineered stone production is simple and convenient to use, saves time and labor, improves production efficiency and effectively reduces human cost, and the work needing tobe completed by 5-10 persons in the past can be easily completed by one person now.

Owner:南召县兴利达岗石有限公司

Resin Composition for Engineered Stone and Engineered Stone Formed Therefrom

PendingUS20200123057A1Good weather resistanceImprove antibacterial propertiesZinc oxides/hydroxidesPolymer scienceWeather resistance

A resin composition for engineered stone according to the present invention is characterized by comprising: a matrix resin; an inorganic aggregate; and zinc oxide which has an average particle diameter of approximately 0.8 to approximately 3 μm, and in which the size ratio (B / A) between a 450 to 600 nm region peak B and a 370 to 390 nm region peak A as measured by photoluminescence is approximately 0.01 to approximately 1.0. The resin composition for engineered stone has excellent weather resistance and antibacterial properties.

Owner:LOTTE CHEM CORP

Production plant for forming engineered composite stone slabs

Owner:GRP IND FOURNIER INC

Vacuum vibration press for forming engineered composite stone slabs

ActiveUS20150266204A1Increase pressureIncrease vibrational energyCeramic shaping apparatusCheese manufactureEngineeringEngineered stone

A method of manufacturing engineered stone slabs provides slabs that are equal or superior in appearance and physical properties to slabs manufactured using a conventional Breton press, while weighing less, costing less to manufacture, providing shorter press cycle times, requiring less resin, and consuming less energy. In addition to providing a vibration device above the slab, the press also includes a second vibration device below the slab, which replaces the massive inertial base of a Breton press. The press can be completely enclosed within a vacuum chamber, and vibrationally isolated from surrounding structures. In embodiments, volume reduction blocks reduce the volume to be evacuated. Embodiments use screw jacks and springs or air bags to provide controlled pressing force and precisely uniform slab thickness. Slabs can be inserted and removed on a conveyor belt, or in rigid, self-supporting trays or molds on rollers.

Owner:GRP IND FOURNIER INC

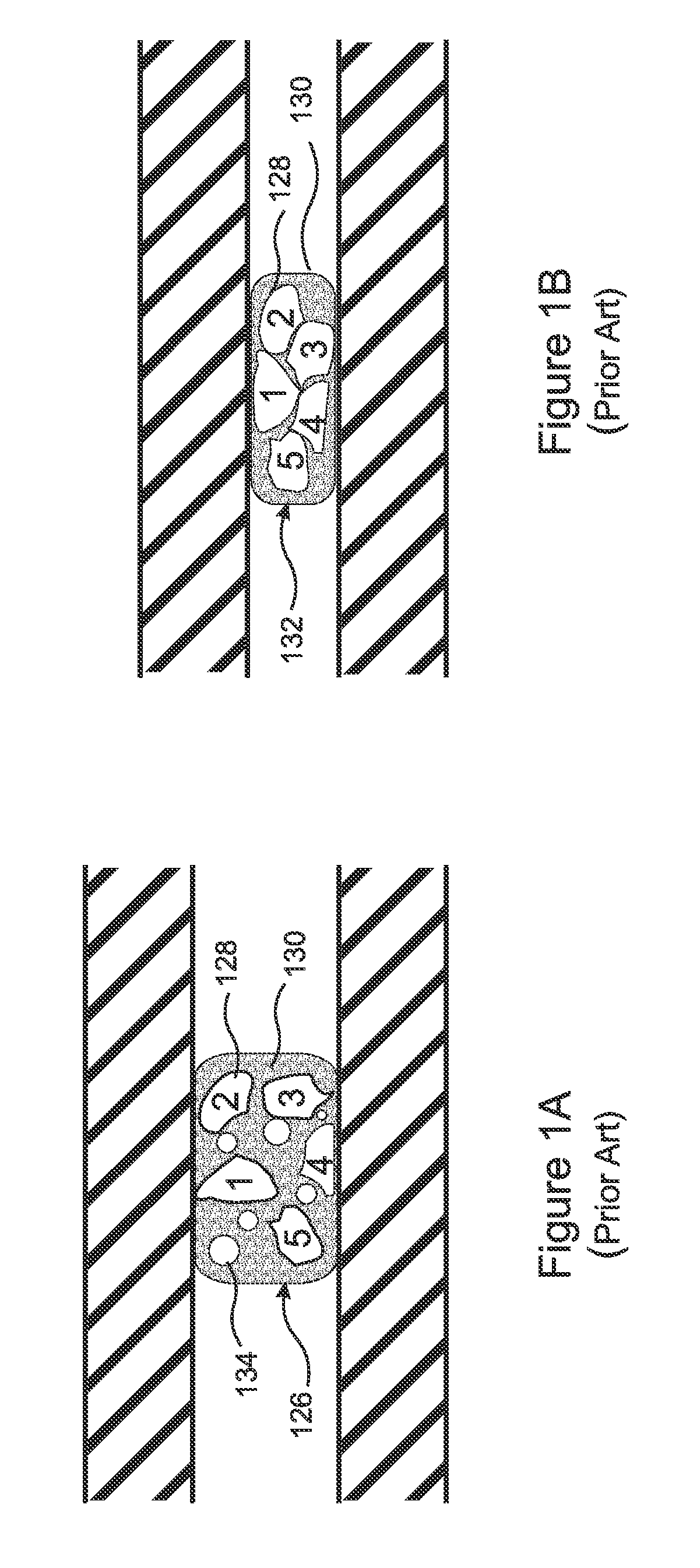

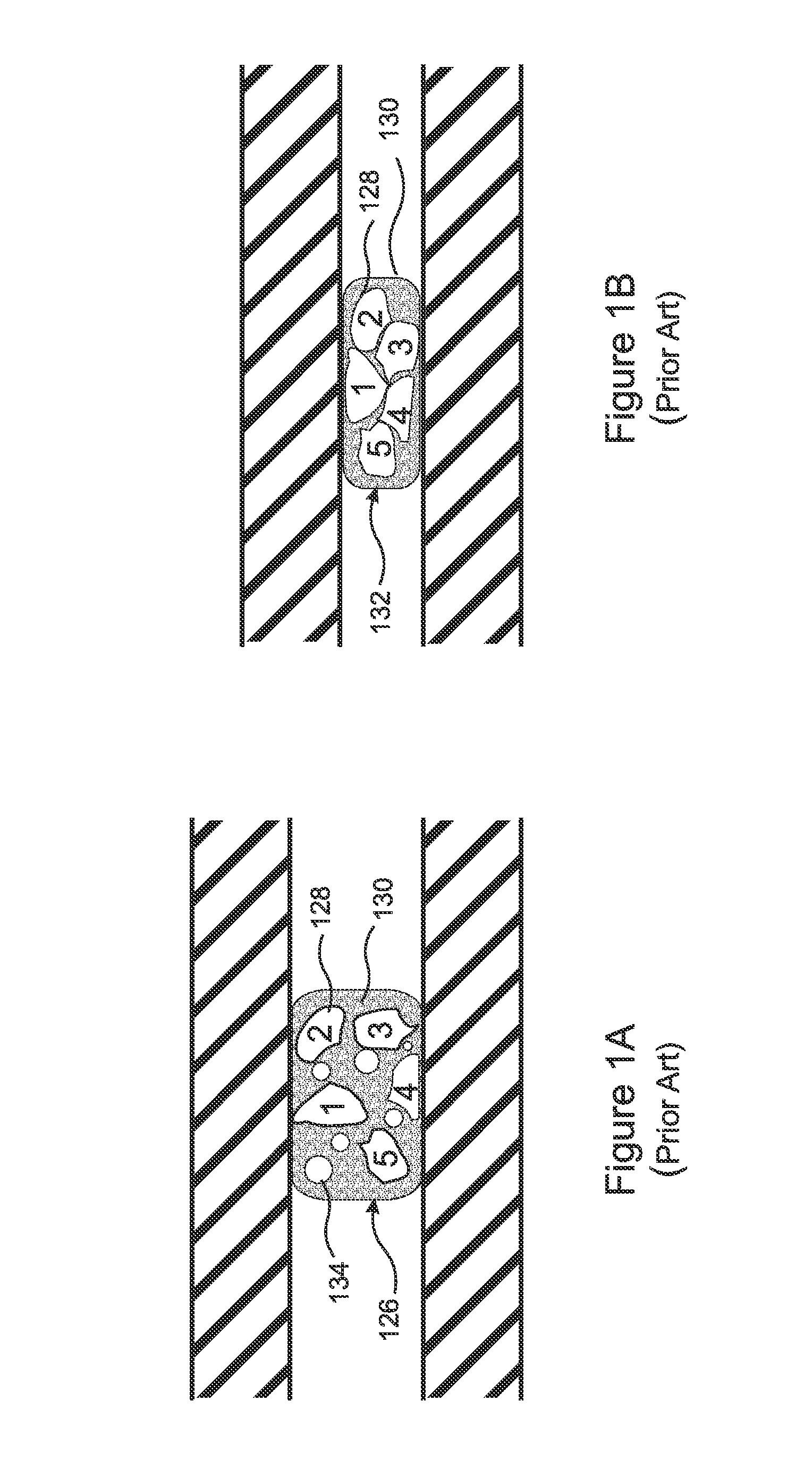

Multiple sheet building wrap for use in external wall assemblies having wet-applied facades

A multiple sheet building wrap for wrapping the structural components of a building in order to protect the underlying structural components and optional building sheathing from moisture is provided. The building wrap is particularly useful under facades such as wet applied stucco or engineered stone, demonstrating good drainage of liquid water and moisture vapor permeability. The building wrap is a composite of a water resistive barrier, a three-dimensional mesh layer and a porous intervening layer which acts to filter the stucco as it is applied. An exterior wall construction incorporating such building wrap is also provided.

Owner:WESTON THERESA ANN +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com