Multi-angle plate toppling machine for engineered stone production

A multi-angle, granite technology, applied in the direction of grinding machine parts, grinding feed movement, metal processing equipment, etc., can solve problems such as unsatisfactory effect, decreased adsorption effect, and blank slab damage, and achieve the overall effect Good, improved safety and stability, stable rotation of the turntable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

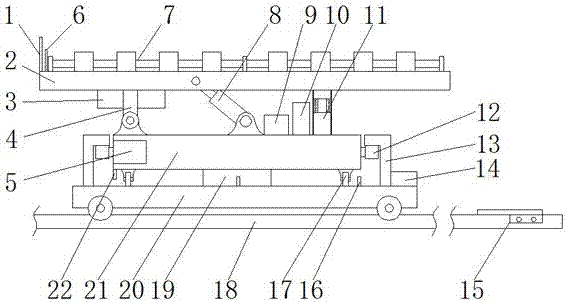

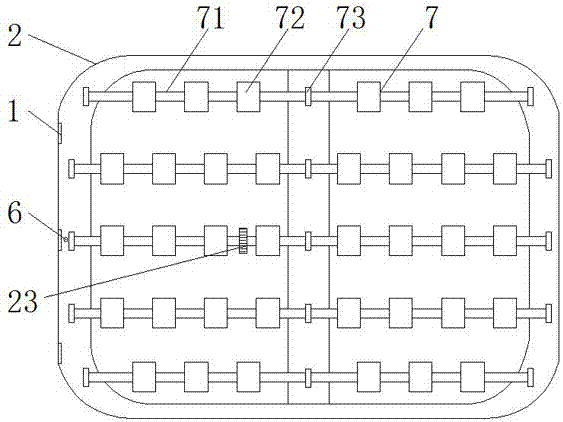

[0031] see figure 1 and 2 : a kind of multi-angle pouring machine for granite production, comprising a trolley base and an inversion frame 2, the trolley base includes a seat plate 20 and a turntable 21 arranged on the seat plate 20, and the turntable 21 is arranged on the seat plate through the shaft seat 19 at its center 20, the bottom of the turntable 21 is provided with a plurality of supporting walking wheels 17. The supporting walking wheels 17 form an effective support for the turntable 21 on the one hand, and on the other hand take the shaft seat 19 as the center of the circle to walk in a circle on the seat plate 20, which can effectively Reduce the stress on the central shaft seat 19, reduce the wear on the shaft seat 19, and prolong its service life. The seat plate 20 is provided with a ring gear 13 located outside the turntable 21. The radial section of the ring gear 13 is an inverted "L" shape, and its top has a ring-shaped inward extension, which can effectively...

Embodiment 2

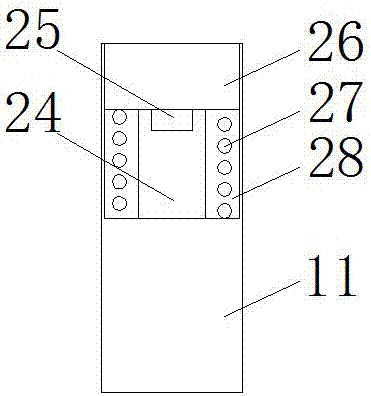

[0037] see image 3 The difference between this embodiment and Embodiment 1 is that: the top of the second supporting leg 11 is a cylindrical groove 28, and a sliding rod 24 is arranged in the cylindrical groove 28, and a sliding sleeve is set on the sliding rod 24 26 and spring 27, the spring 27 is located between the bottom surface of the sliding sleeve 26 and the bottom surface of the column groove 28, when the flip frame 2 is turned up, the spring 27 pushes the sliding sleeve 26 out of the column groove 28 for a certain distance, and the flip frame 2. When falling, it first contacts with the sliding sleeve 26, and under the action of the spring 27, a certain buffering effect is formed to reduce the impact between the falling plate frame 2 and the second outrigger 11, so that the falling plate is more relaxed. , reduce and prevent damage to the slab.

[0038] Further, the slide bar 24 is provided with a third travel switch 25, which can effectively realize the third travel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com