Production method for jade type macadam polymerization plate

A production method and technology of aggregated plates, applied in ceramic molding machines, manufacturing tools, etc., can solve problems such as difficulty in forming jade into plates, achieve the effects of reducing consumption, ensuring overall compactness, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

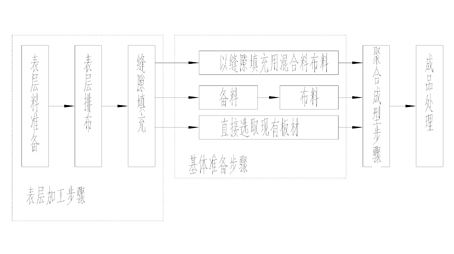

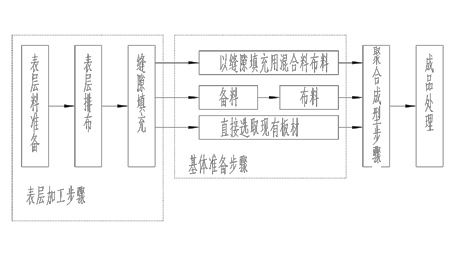

Method used

Image

Examples

Embodiment 1

[0036] Agate fragments and colored silica stones with a stone height of 3-30cm are used as the surface material to produce a 30mm-thick polymer board suitable for countertop decoration. The specific production process is: 1. Surface processing steps: agate fragments and colored silica Use a circular saw to cut into slices with a thickness of 8mm, and then cut the edges of the slices with a water jet according to the set pattern; arrange the slices on the template in sequence according to the pattern number, and cover the entire surface with a nylon mesh dedicated to stone; For gap filling, use nano-type polyester resin, silane coupling agent, curing agent and 200-800 mesh aluminum hydroxide powder to mix into a paste, wherein the nano-type polyester resin accounts for 20% of the mass of the paste, In addition, 1.5% nano-titanium dioxide powder is added to the nano-type polyester resin, and germanium stone and medical stone with a particle size of 1mm are added to the paste ...

Embodiment 2

[0038] Crystal stones and golden diamond granite fragments with a stone height of 20-30cm are used as surface materials, and light-transmitting matrix materials are used to produce light-transmitting panels. The specific production process is: jade, golden diamond granite Cut the fragments into 6mm thick slices, and then cut them into 10×10cm square plates with cutting tools; arrange them piece by piece according to the gap distance of 1-2mm; mix nano polyester resin and aluminum hydroxide powder into a paste, in which nanometer polyester resin accounts for 40% of the mass of the paste, and double the mass ratio of transparent stone particles with a particle size of 3-8mm is added, and the gap is filled together with the base material layer cloth, and the surface layer The thickness ratio to the base material layer is 1:2; in the vacuum box, the sheet-by-sheet combination process of stacking templates one by one is used to knead, press and vibrate to realize thin plate forming....

Embodiment 3

[0040] The colorful jade in the Jiuquan area of Gansu Province and the silica fragments in the Taihang Mountain area with a stone height of 5-20cm are used as the surface material, and a 12mm thick glass plate is used as the substrate to produce a light-transmitting polymer plate. The specific production process is as follows: The fragments of particle size are temporarily formed with cement first, and then cut into thin slices with a thickness of 10mm by a cutting machine. After removing the cement block, they are trimmed into a set shape; Splice and discharge the surface material sheets on the glass sheets, and fill the gaps between the sheets and the sheets with the binder mixture; carry out the lower vibration and pumping vacuum cycle layer by layer according to Example 2 to complete the forming of the polymeric board; the finished product processing only It is to grind the surface layer with a small pressure to obtain a light-transmitting polymer plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com