Automobile air conditioning tube assembly manufacturing technology

A technology for automobile air conditioning and manufacturing process, which is applied in the field of automobile air conditioning pipe assembly manufacturing technology, can solve the problems of low ductility of aluminum alloy, prone to cracking or leakage, and the corrosion resistance performance does not meet the requirements, and achieves good corrosion resistance performance. , Low manufacturing cost, and the effect of meeting the requirements of subsequent processing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

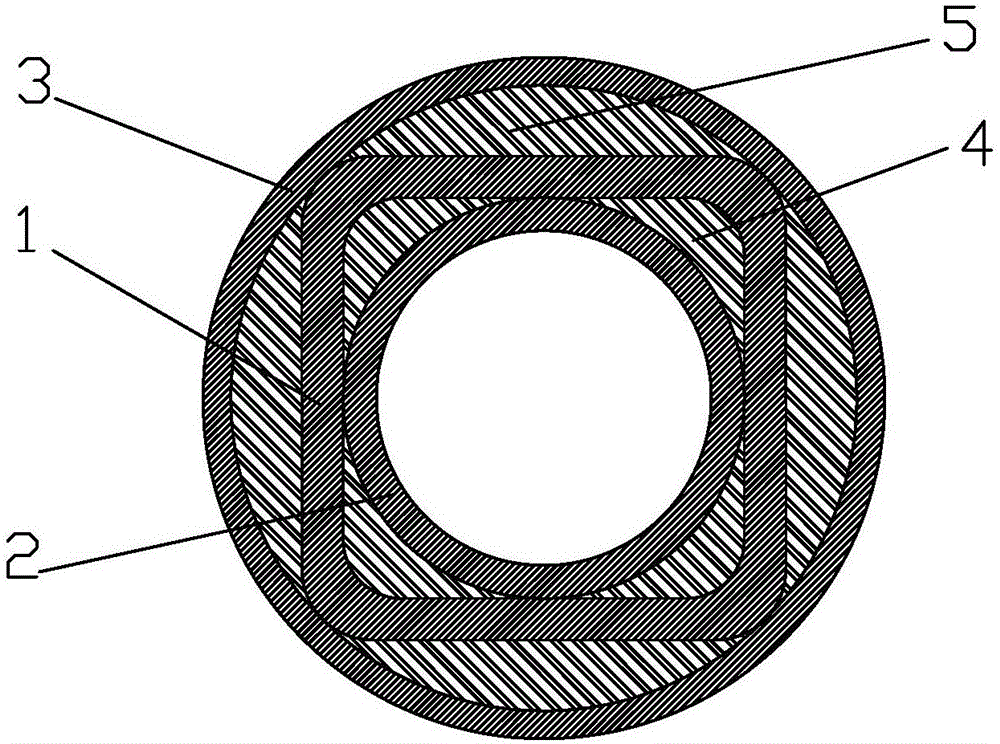

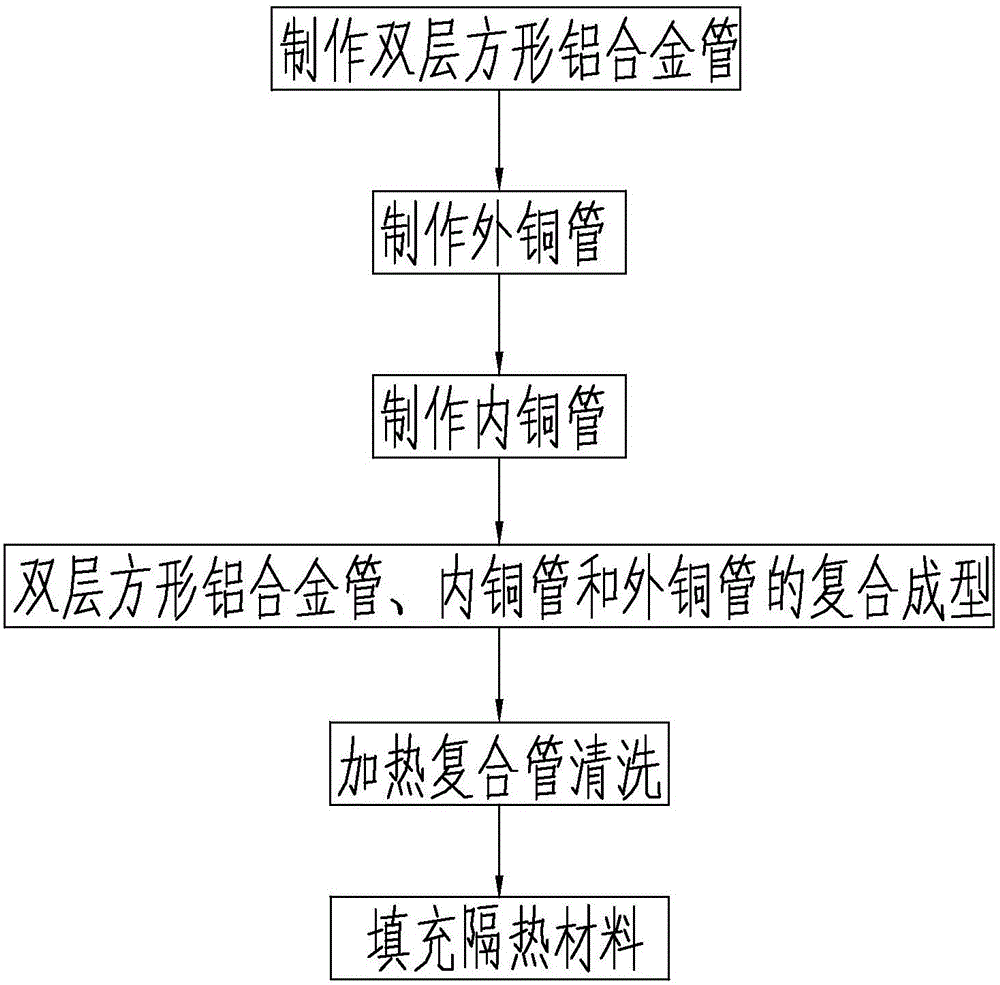

[0037] Such as Figure 1 to Figure 3 As shown, the manufacturing process of the automobile air-conditioning pipe assembly includes the following manufacturing steps:

[0038] a) Making double-layer square aluminum alloy tube 1:

[0039] 1) First take the inner aluminum alloy round billet and the outer aluminum alloy round billet, go through the heating action of the heating furnace and the piercing action of the piercing machine, then use the equalizing machine to equalize the wall thickness, and finally pass the sizing function of the sizing machine, A circular inner aluminum alloy hollow tube blank and an outer aluminum alloy hollow tube blank are respectively obtained.

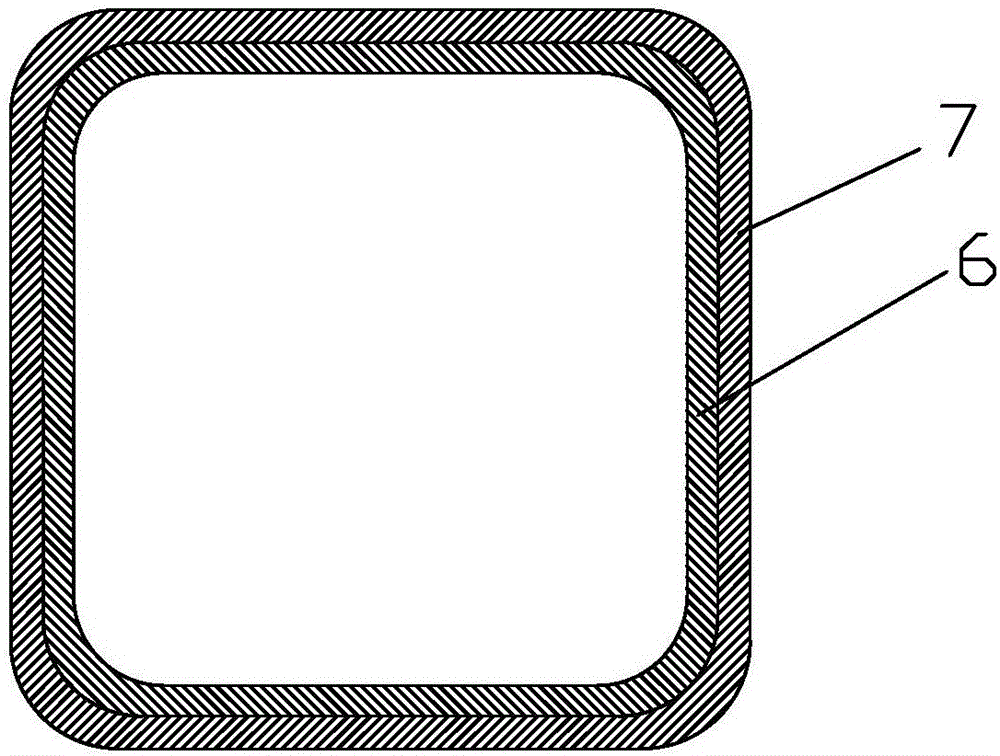

[0040] 2) The inner aluminum alloy hollow tube billet and the outer aluminum alloy hollow tube billet are stretched into the inner mold and the outer mold respectively, and the inner aluminum alloy rounded corner square tube 6 and the outer aluminum alloy rounded square tube 6 with round chamfers inside an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com