Production process of single-side-glued composite stone insulation board

A production process and thermal insulation board technology, which is applied to layered products, lamination devices, lamination, etc., can solve the problems of inability to guarantee stable bonding, waste of backing potion, and increase in production costs, and achieve a reduction in one-layer glue coating cost, ensuring aesthetics, and ensuring the effect of safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

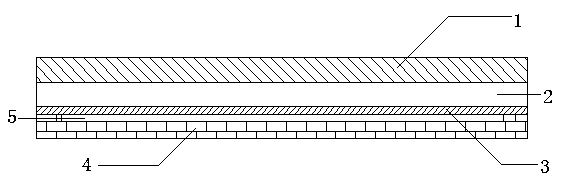

[0021] Such as figure 1 Shown is a schematic diagram of the structure of the present invention, the present invention is a single-side glue-coated composite stone insulation board production process, the production method is: pre-composite the heat-insulation material and the backing, after the compound is completed, glue is applied on one side, And composite stone.

[0022] The specific production method is as follows:

[0023] (1) Prepare insulation material and backing material, and make plate-shaped insulation layer 1 and backing layer 2 respectively;

[0024] (2) Composite the insulation layer 1 and the backing layer 2;

[0025] (3) After compounding, apply glue on the side of the insulation layer 1 away from the backing layer 2 to form the glue layer 3;

[0026] (4) Consolidate a layer of glue-coated adhesive layer 5 on the inner side of the stone material 4; through the glue-coated adhesive layer 5, the stone material 4 and the glue-coated layer 3 are combined.

[0...

Embodiment 2

[0029] Such as figure 1 Shown is a schematic diagram of the structure of the present invention, the present invention is a single-side glue-coated composite stone insulation board production process, the production method is: pre-composite the heat-insulation material and the backing, after the compound is completed, glue is applied on one side, And composite stone.

[0030] The specific production method is as follows:

[0031] (1) Prepare insulation material and backing material, and make plate-shaped insulation layer 1 and backing layer 2 respectively;

[0032] (2) Composite the insulation layer 1 and the backing layer 2;

[0033] (3) After compounding, apply glue on the side of the insulation layer 1 away from the backing layer 2 to form the glue layer 3;

[0034] (4) Consolidate a layer of glue-coated adhesive layer 5 on the inner side of the stone material 4; through the glue-coated adhesive layer 5, the stone material 4 and the glue-coated layer 3 are combined.

[0...

Embodiment 3

[0037] Such as figure 1 Shown is a schematic diagram of the structure of the present invention, the present invention is a single-side glue-coated composite stone insulation board production process, the production method is: pre-composite the heat-insulation material and the backing, after the compound is completed, glue is applied on one side, And composite stone.

[0038] The specific production method is as follows:

[0039] (1) Prepare insulation material and backing material, and make plate-shaped insulation layer 1 and backing layer 2 respectively;

[0040] (2) Composite the insulation layer 1 and the backing layer 2;

[0041] (3) After compounding, apply glue on the side of the insulation layer 1 away from the backing layer 2 to form the glue layer 3;

[0042] (4) Consolidate a layer of glue-coated adhesive layer 5 on the inner side of the stone material 4; through the glue-coated adhesive layer 5, the stone material 4 and the glue-coated layer 3 are combined.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com