Film packaging method of stretchable organic photoelectric device

A technology for optoelectronic devices and thin film encapsulation, which is applied in the fields of electrical solid devices, electrical components, semiconductor devices, etc. It can solve the problems of reduced water and oxygen barrier performance, easy to produce cracks, etc., and achieves easy operation, improved packaging performance, and excellent conformality. retouching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the features and technical contents of the present invention, please refer to the detailed description and accompanying drawings of the present invention. The accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

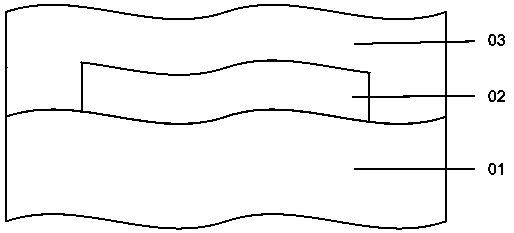

[0030] A thin film encapsulation method for stretchable organic optoelectronic devices, the thin film encapsulation structure prepared by it is sequentially provided with a stretchable organic polymer substrate 01 with high water and oxygen barrier performance, and a stretchable organic optoelectronic device 02 and inorganic / organic fusion overlapping thin film encapsulation layer 03 with high water and oxygen barrier properties, such as figure 1 Shown; Described stretchable organic optoelectronic device film encapsulation method comprises the steps:

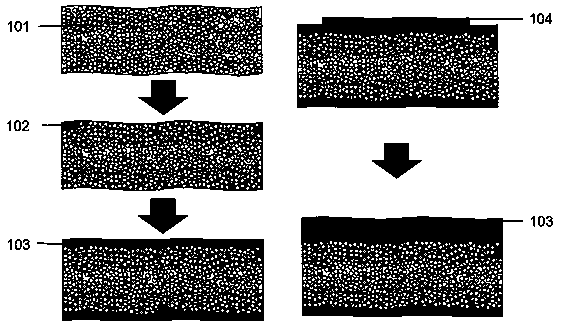

[0031] S1 Place the stretchable organic polymer substrate in the reaction chamber of atomic layer deposition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com