Leakage monitoring and positioning early-warning system in petrochemical industry and establishment method thereof

A technology of early warning system and establishment method, applied in transmission systems, electrical components, wireless communication, etc., can solve the problems of inability to collect and transmit on-site information, monitoring and early warning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

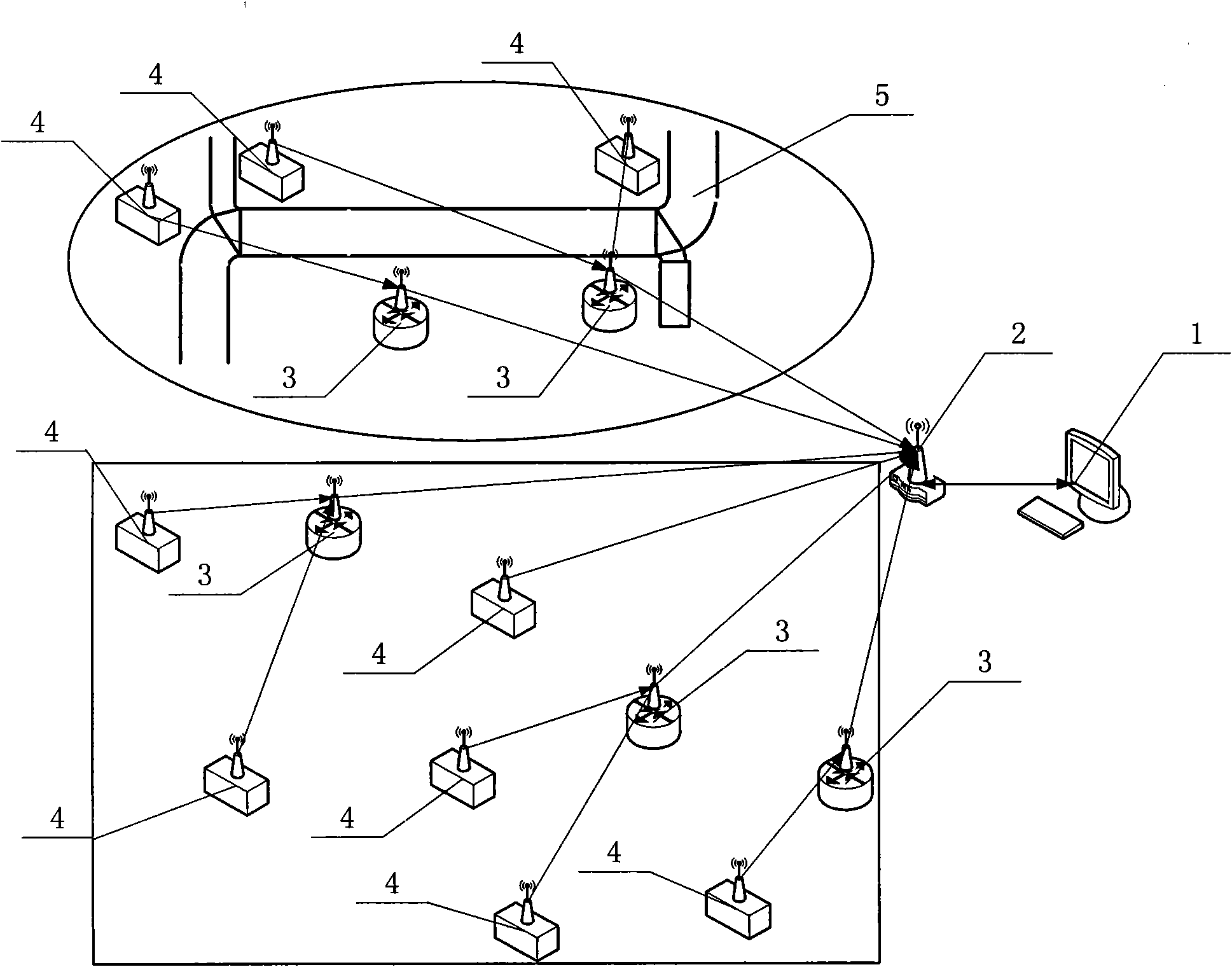

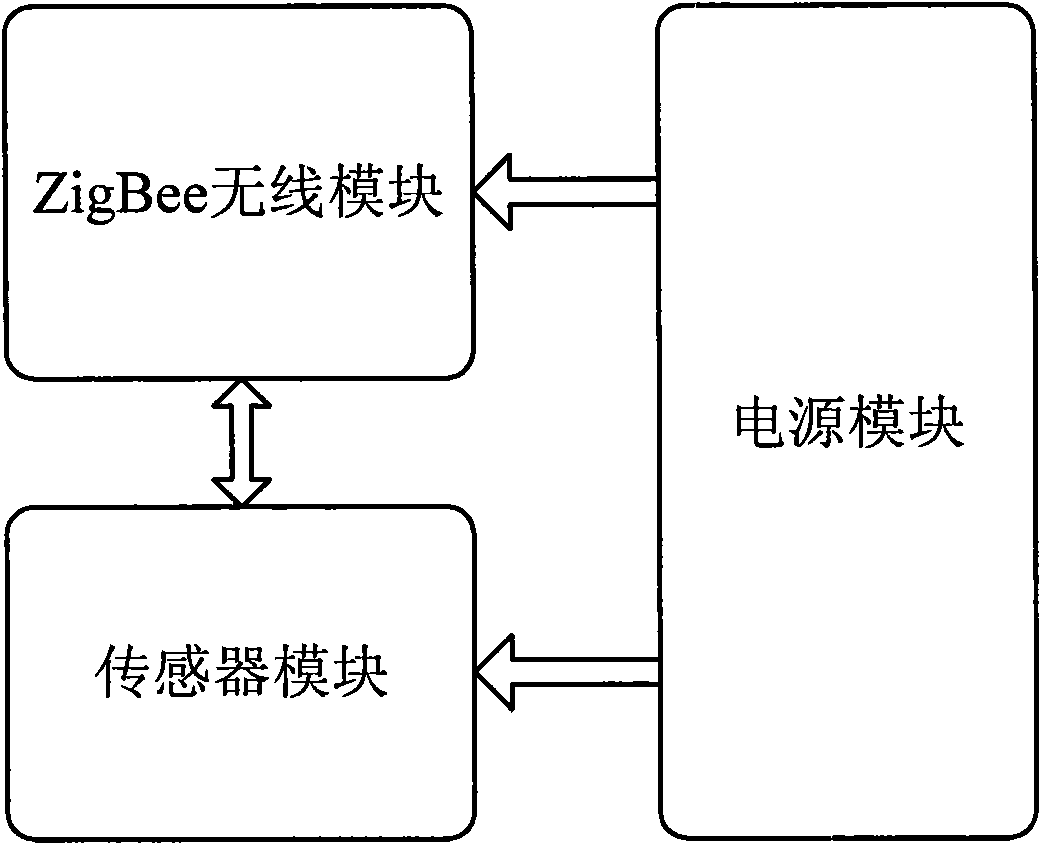

[0132] The first step, the composition of wireless network nodes

[0133] ZigBee wireless module based on ZigBee transmission protocol, a sulfur dioxide sensor ME3-SO 2 Consists of sensor module and 3.6V lithium sub-battery and such as Figure 6 The power module formed by the conversion circuit shown constitutes a wireless network node;

[0134] The second step is the deployment of wireless network nodes

[0135] Select fixed-point deployment of wireless network nodes

[0136] Deploy and install the six wireless network nodes formed in the first step near bends, joints and other leak-prone locations of pipeline equipment in the petrochemical industry;

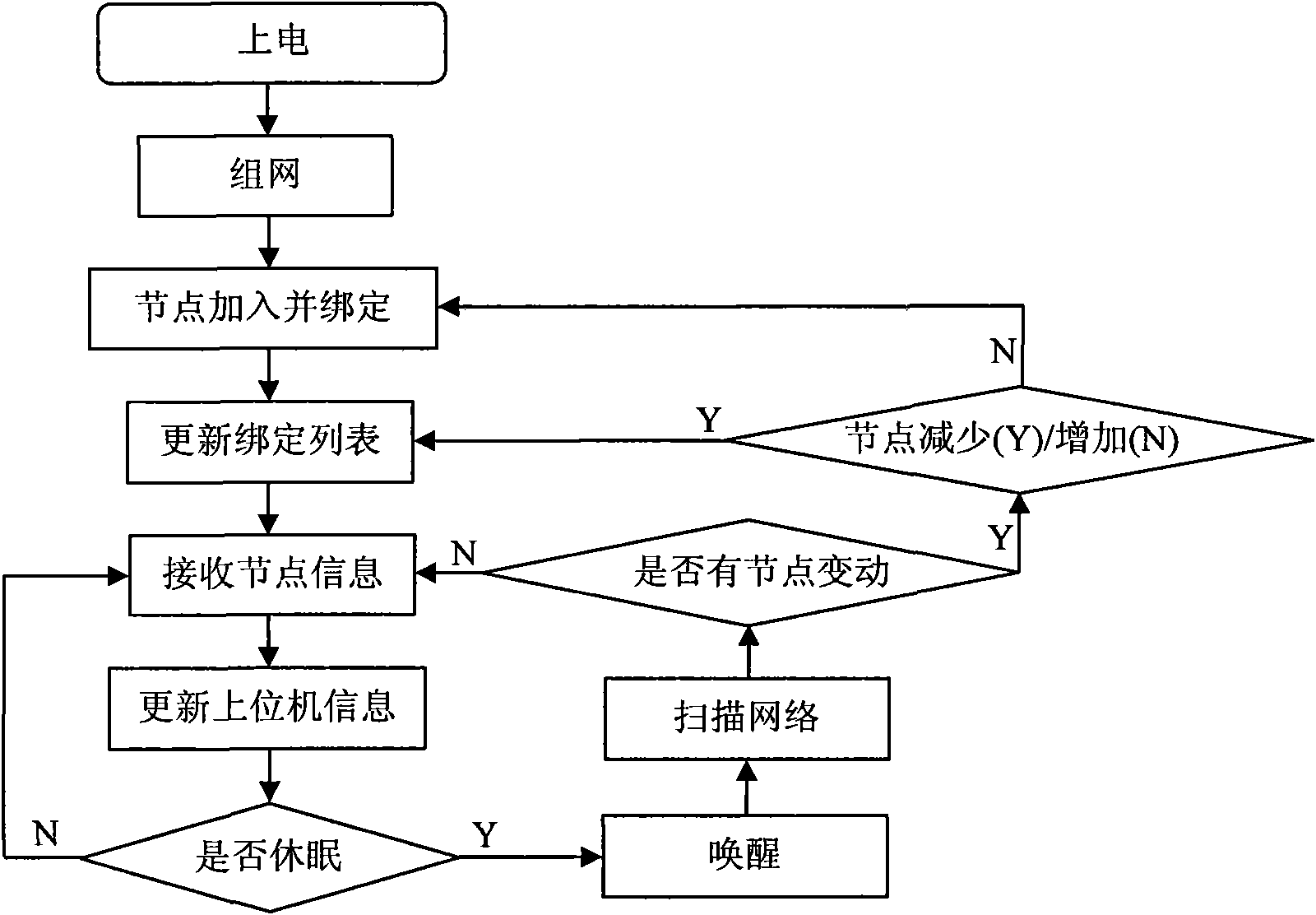

[0137] The third step, the formation of ZigBee wireless sensor mesh network

[0138]After the deployment of the wireless network nodes in the second step above is completed, the ZigBee wireless sensor network is automatically formed among the nodes through the ZigBee network dynamic self-organization technology. The process ...

Embodiment 2

[0184] The first step, the composition of wireless network nodes

[0185] The ZigBee wireless module based on the ZigBee wireless transmission protocol is used respectively with a hydrogen sulfide sensor NE-H 2 S, a carbon monoxide sensor BS4C and a sulfur dioxide sensor ME3-SO 2 Consists of sensor module and 3.6V lithium sub-battery and such as Figure 6 The power module formed by the conversion circuit shown constitutes a wireless network node;

[0186] The second step is the deployment of wireless network nodes

[0187] Dynamic deployment of selected wireless network nodes

[0188] When an accident occurs, 10 wireless network nodes obtained from the first step are deployed to the accident area according to the size of the accident area through robots or high-altitude throwing, three of which contain a hydrogen sulfide sensor NE-H 2 Wireless network nodes for sensor modules of S, three wireless network nodes for sensor modules with a carbon monoxide sensor BS4C and four w...

Embodiment 3

[0200] The first step, the composition of wireless network nodes

[0201] With embodiment 2;

[0202] The second step is the deployment of wireless network nodes

[0203] Dynamic deployment of selected wireless network nodes

[0204] When an accident occurs, five wireless network nodes obtained from the first step are deployed to the accident area according to the size of the accident area through robots or high-altitude throwing, one of which contains a hydrogen sulfide sensor NE-H 2 A wireless network node for a sensor module of S, a wireless network node for a sensor module with a carbon monoxide sensor BS4C, a wireless network node for a sensor module with a sulfur dioxide sensor ME3-SO 2 One of the wireless network nodes of the sensor module, a wireless network node of the sensor module containing an alcohol sensor TGS822TF and a wireless network node of the sensor module of an oxygen sensor KE50.

[0205] The third step, the formation of ZigBee wireless sensor mesh ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com