Organic light-emitting device packaging cover plate, organic light-emitting device and displayer

A technology of electroluminescent devices and packaging cover plates, which is applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of difficult control of the height of the packaging ring, poor uniformity of the glass gap, and high cost of OLEDs. Depth is easy to control, low cost, and easy to produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

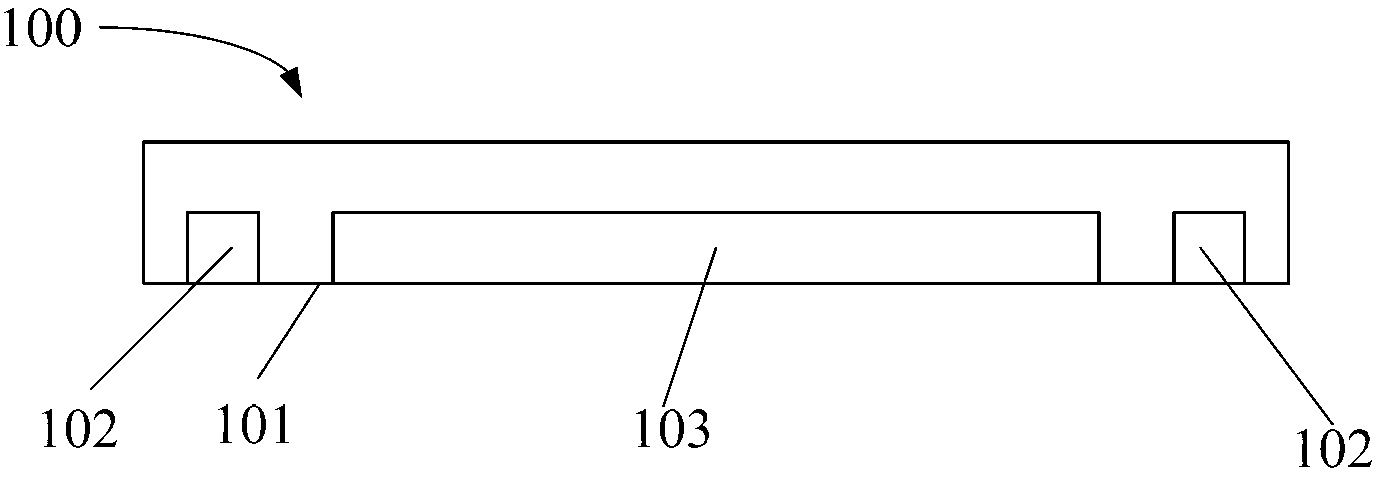

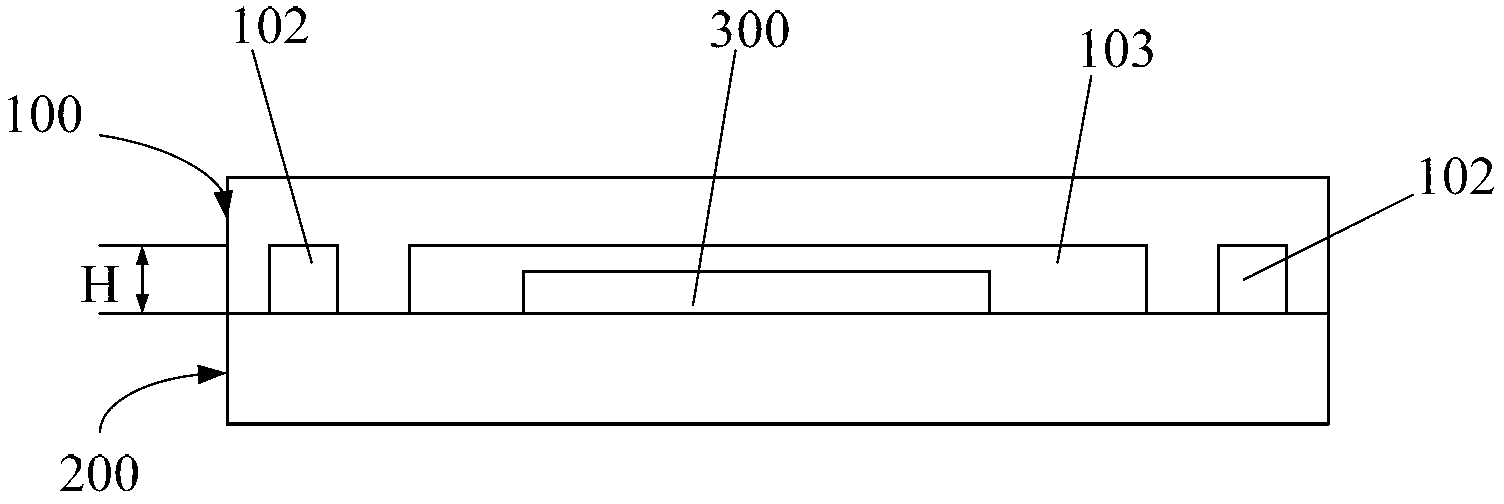

[0026] figure 2 Shown is a cross-sectional view of the packaging cover plate of the organic electroluminescent device provided by the present invention. Such as figure 2 As shown, the present invention provides a packaging cover plate 100 for an organic electroluminescent device. The packaging cover plate 100 has a packaging surface 101 for bonding with a substrate through packaging glue, and the surroundings of the packaging surface 101 form useful The groove structure 102 for accommodating the encapsulant.

[0027] Wherein, an accommodating cavity 103 for accommodating the anode layer, the organic light-emitting layer and the cathode layer in the OLED device may also be provided in the middle of the packaging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com