Antibacterial sock and preparation method thereof

An antibacterial fiber, carboxymethyl chitosan technology, applied in socks, pantyhose, biochemical fiber treatment and other directions, can solve the problems of waste water pollution, poor moisture absorption and perspiration performance of antibacterial socks, and achieve harmlessness to human body and environment. , excellent antibacterial properties and hygroscopicity, the effect of less raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

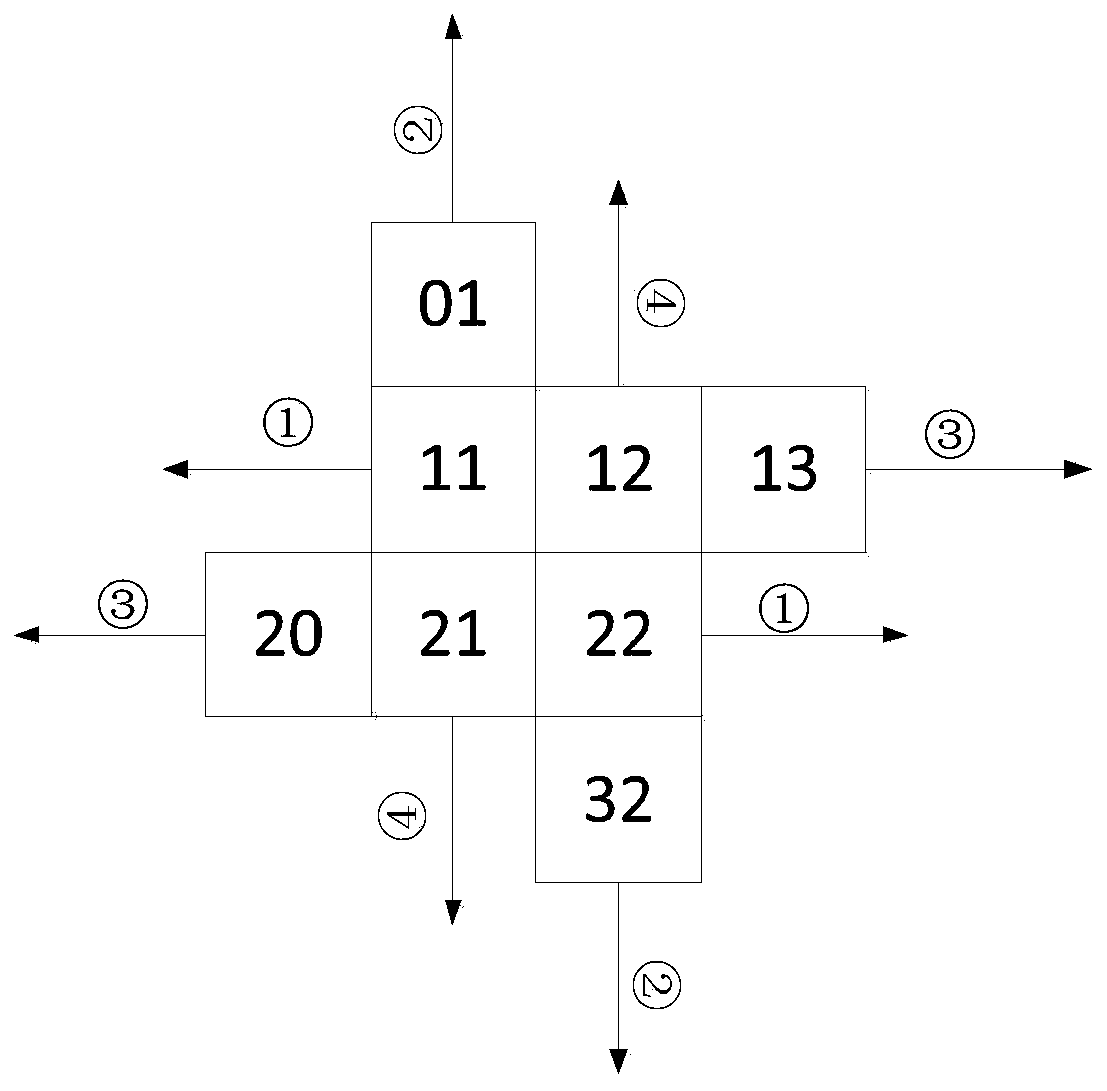

Image

Examples

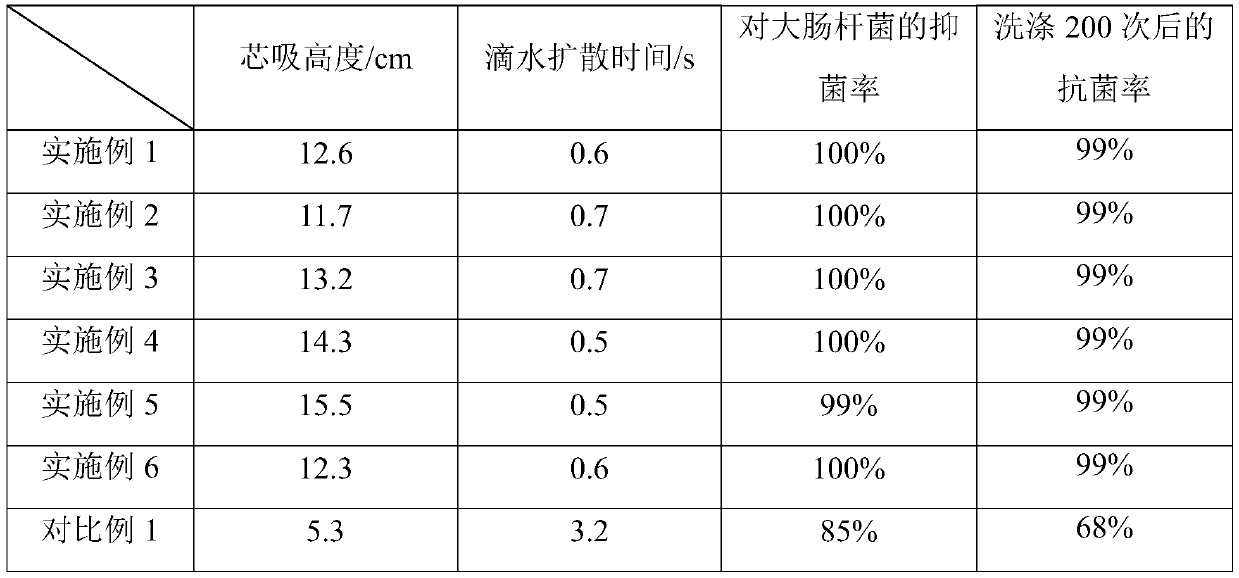

Embodiment 1

[0039] (1) Dissolve chitosan in acetic acid solution, adjust the pH to 5 with acetic acid, ultrasonically 0.5h to dissolve chitosan completely, add ethanol, let the solution stand for 36h, precipitate precipitate, filter with suction filter, use for precipitation The freeze-drying machine is freeze-dried, and the temperature of the freeze-drying machine is set at -60° C., and finally the precipitate is ground into powder to prepare carboxymethyl chitosan powder.

[0040] (2) Dissolve 1g of carboxymethyl chitosan in 100ml of deionized water, stir magnetically, add 1% GA crosslinking agent and 2% trisodium citrate reducing agent at the same time, let it stand and adjust the pH value to 5-7, Ultrasonic dispersion to obtain a stable finishing solution;

[0041] (3) The nylon fiber is placed in the finishing solution of step (2), dipped twice and rolled twice, the liquid rolling rate is 75%, and dried in an oven at 80° C. to obtain carboxymethyl chitosan modified nylon fiber.

[0...

Embodiment 2

[0045](1) Dissolve chitosan in acetic acid solution, adjust the pH to 5 with acetic acid, ultrasonically 0.5h to dissolve chitosan completely, add ethanol, let the solution stand for 36h, precipitate precipitate, filter with suction filter, use for precipitation The freeze-drying machine is freeze-dried, and the temperature of the freeze-drying machine is set at -60° C., and finally the precipitate is ground into powder to prepare carboxymethyl chitosan powder.

[0046] (2) Dissolve 1g of carboxymethyl chitosan in 100ml of deionized water, stir magnetically, add 1.2% GA cross-linking agent and 2% trisodium citrate reducing agent at the same time, let stand and adjust the pH value to 5-7, Ultrasonic dispersion to obtain a stable finishing solution;

[0047] (3) Nylon fibers are placed in the finishing solution of step (2), dipped and rolled twice, the liquid rolling rate is 75%, and dried in an oven at 80°C to obtain carboxymethyl chitosan modified nylon fibers

[0048] (4) Ad...

Embodiment 3

[0051] (1) Dissolve chitosan in acetic acid solution, adjust the pH to 5 with acetic acid, ultrasonically 0.5h to dissolve chitosan completely, add ethanol, let the solution stand for 36h, precipitate precipitate, filter with suction filter, use for precipitation The freeze-drying machine is freeze-dried, and the temperature of the freeze-drying machine is set at -60° C., and finally the precipitate is ground into powder to prepare carboxymethyl chitosan powder.

[0052] (2) Dissolve 1g carboxymethyl chitosan in 100ml deionized water, stir magnetically, add 1.2% GA cross-linking agent and 2.5% trisodium citrate reducing agent simultaneously, let stand and adjust the pH value to 5-7, Ultrasonic dispersion to obtain a stable finishing solution;

[0053] (3) Nylon fibers are placed in the finishing solution of step (2), dipped and rolled twice, the liquid rolling rate is 75%, and dried in an oven at 80°C to obtain carboxymethyl chitosan modified nylon fibers

[0054] (4) Add 12m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com