Sprayable and toughened polypropylene composition and preparation method thereof

A polypropylene composition and composition technology, applied in the field of polypropylene composition and its preparation, can solve the problems of large amount of rubber addition and high material cost, achieve surface polarity improvement, improve surface coating performance, and have good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

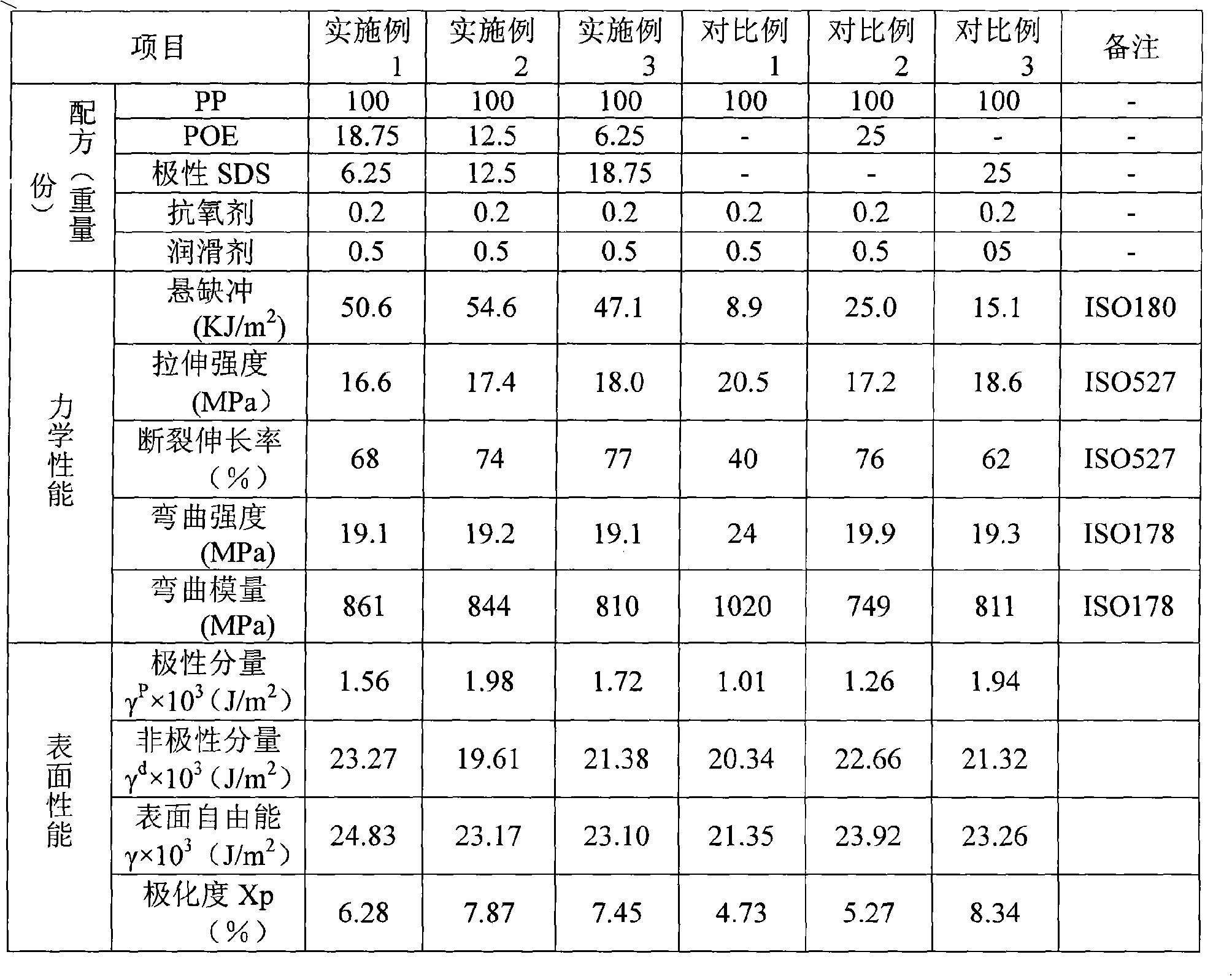

[0024] Polypropylene (K9020, Beijing Yanhua Petrochemical Co., Ltd.), ethylene-octene copolymer (POE, American DUPONT company, melt index 0.5g / 10min), polarized SDS (SDS, Baling Petrochemical Co., Ltd. company, its number-average molecular weight is 84,300, the grafting rate is 3.0%, the polar monomer is 2-vinylpyridine, 4-vinylpyridine and its isomer mixture), antioxidant B225 (Switzerland CIBA Company), lubricant (calcium stearate, Tianjin Plastic Auxiliary Factory), put into a low-speed mixer and stir evenly, so that each component is fully mixed evenly. The above mixed material was extruded and granulated in a twin-screw extruder (TE-30, Nanjing Ruiya Company) at a temperature of 190-210°C. Dry the extruded pellets in a constant temperature oven at 80°C for 6 hours, and then inject them into standard specimens at a temperature of 190-210°C for various mechanical and surface performance tests. The specific formula is shown in Table 1, wherein the contents of each component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com