Patents

Literature

58results about How to "Simple and reliable operation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

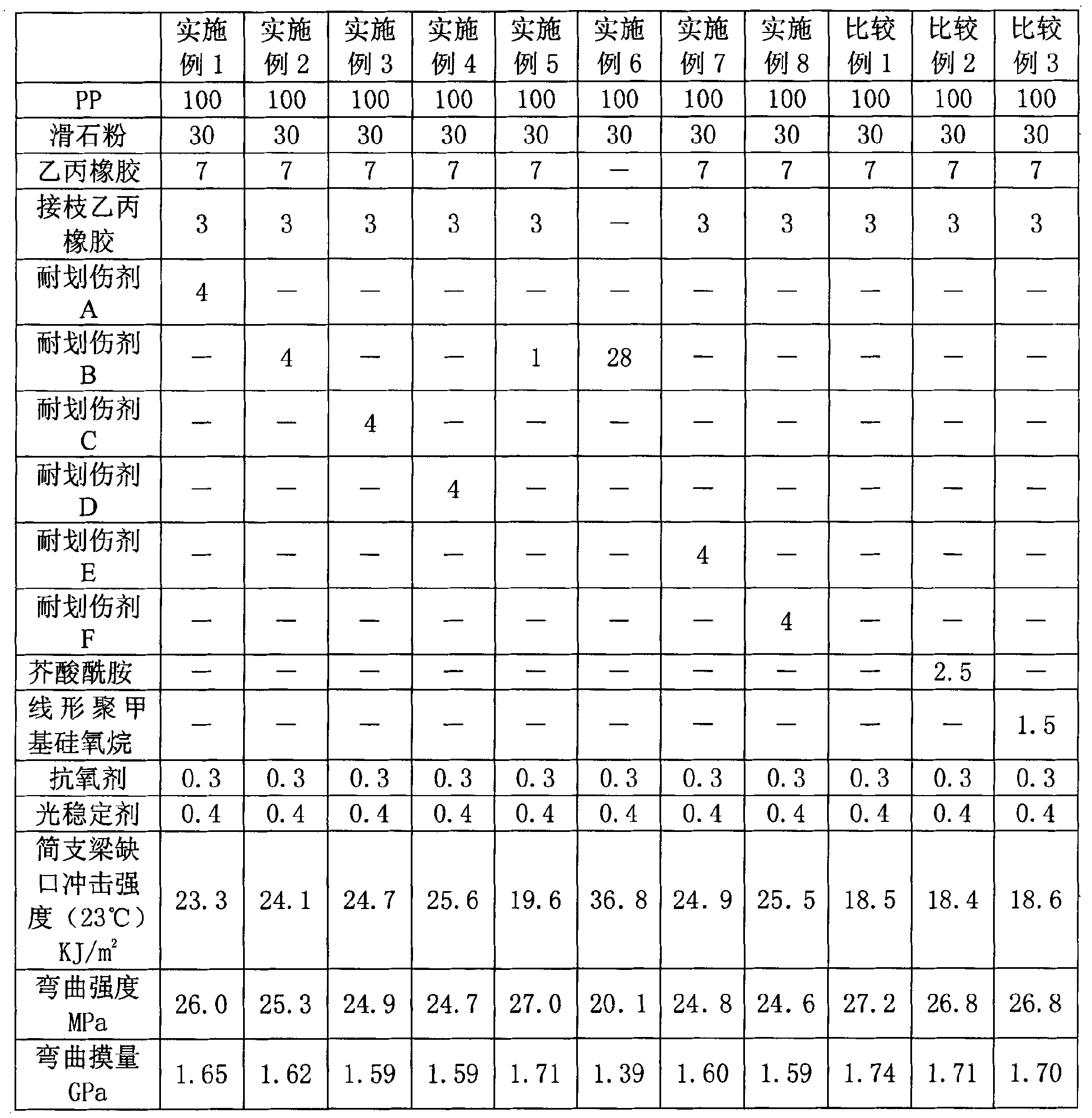

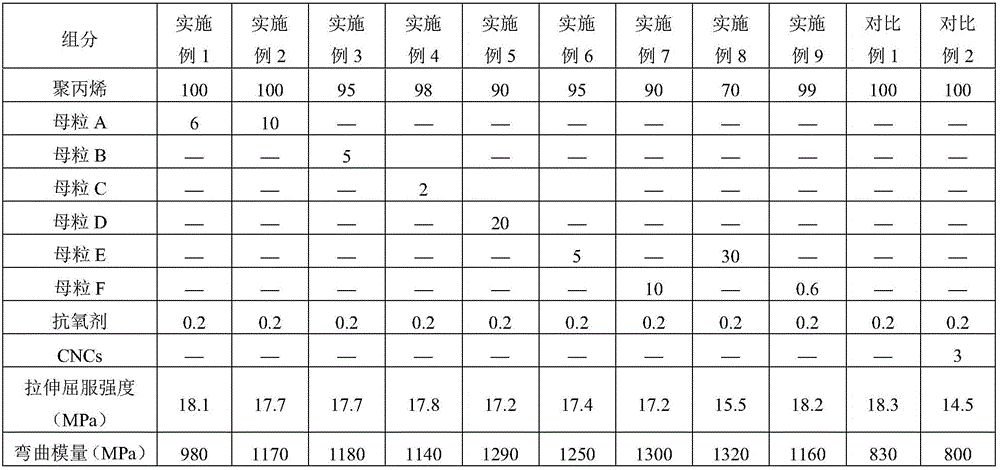

Scratch-resistant polypropylene composition and preparation method thereof

The invention provides a scratch-resistant polypropylene composition which comprises the following blended components in parts by weight: 100 parts of polypropylene resin and 0.05-30 parts of scratch-resistant agent, wherein the scratch-resistant agent is formed by blending the following components in parts by weight: 100 parts of full-vulcanized powdered butadiene styrene rubber, 1-100 parts of hydrocarbon oil and / or 1-200 parts of polysiloxane lubricant. The polypropylene composition not only has good mechanical properties of impact resistance, rigidity and the like, but also has good scratch resistance. Moreover, after the polypropylene resin is used for long time, the appearance of the product can not change. The preparation method is simple. The polypropylene composition is applicable to the products of automobile interior and exterior trim parts, electronic and electrical shells and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

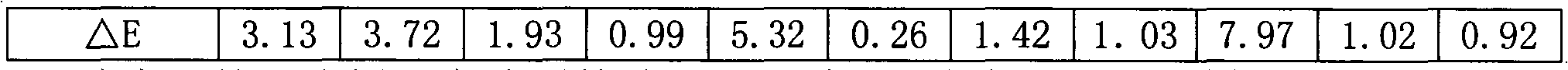

VOC (Volatile Organic Compounds)-inhibited master batch for polypropylene, and preparation method and applications thereof

ActiveCN105524350AReduce or suppress the production ofImprove adsorption capacityMicrometerOrganic compound

The invention relates to a VOC (Volatile Organic Compounds)-inhibited master batch for polypropylene, and a preparation method thereof, and an application thereof. The VOC-inhibited master batch comprises the following mixed components in parts by weight: on the basis of 100 weight parts of polypropylene, 10-60 parts of fully-vulcanized powder silicone rubber, 10-80 parts of cellulose nano crystal, and 5-40 parts of an acid absorption agent. wherein the average particle size of rubber particles in the fully-vulcanized powder silicone rubber is 0.05-1 micrometers, and the gel content is 60wt% or above; surface charge density of the cellulose nano crystal is 0.1-0.4e / nm<2>, length is 90-300 nm, and width is 5-15 nm. The VOC-inhibited master batch for polypropylene can effectively inhibiting generation of VOC in a polypropylene material, the content of a total volatile organic compound (TVOC) in the polypropylene material is lower than 50 [mu]g.C / g, so that the disadvantages in the prior art can be solved. The method has the advantages of simple and reliable operation process, low investment cost, and wide application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

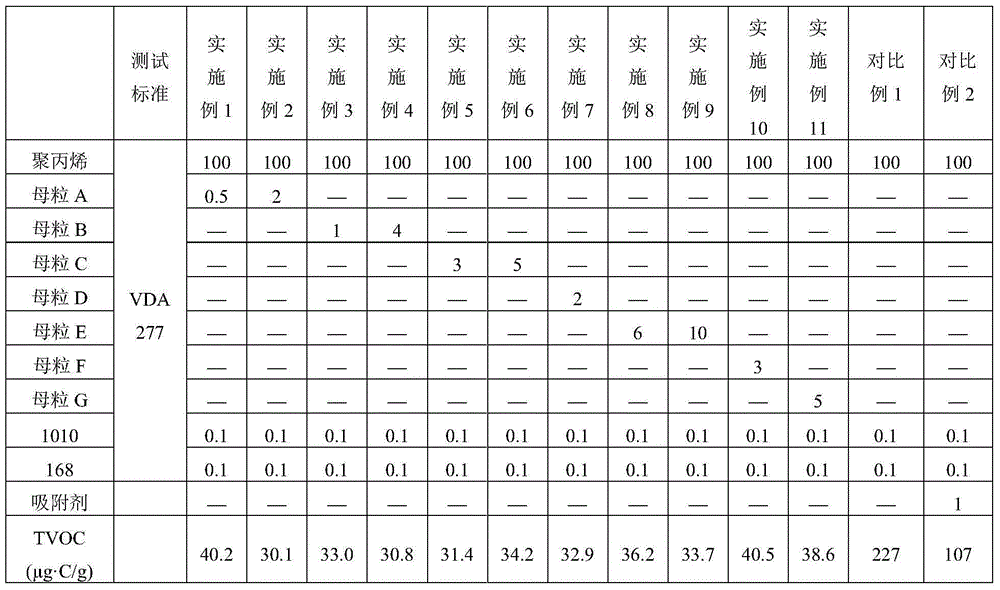

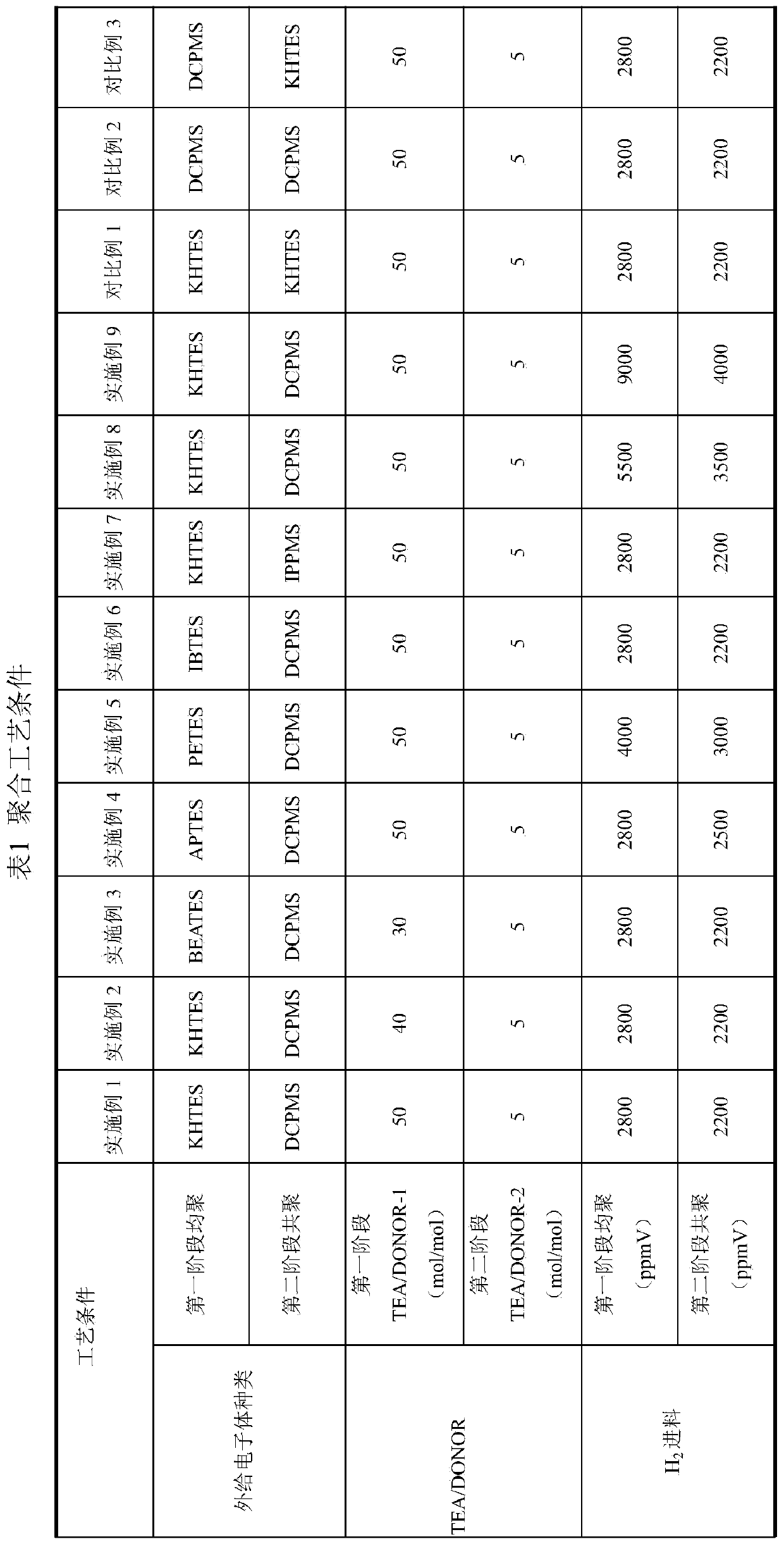

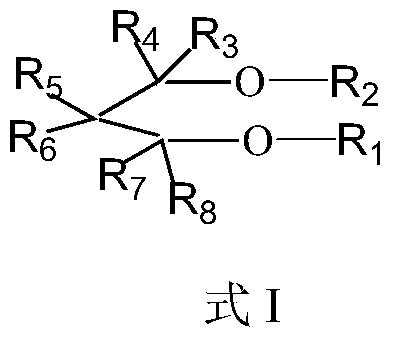

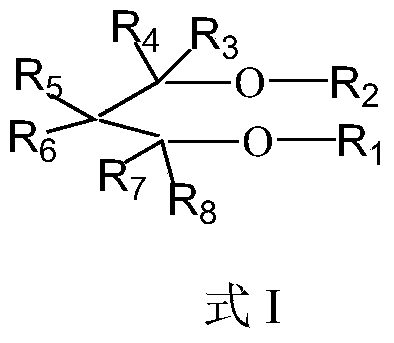

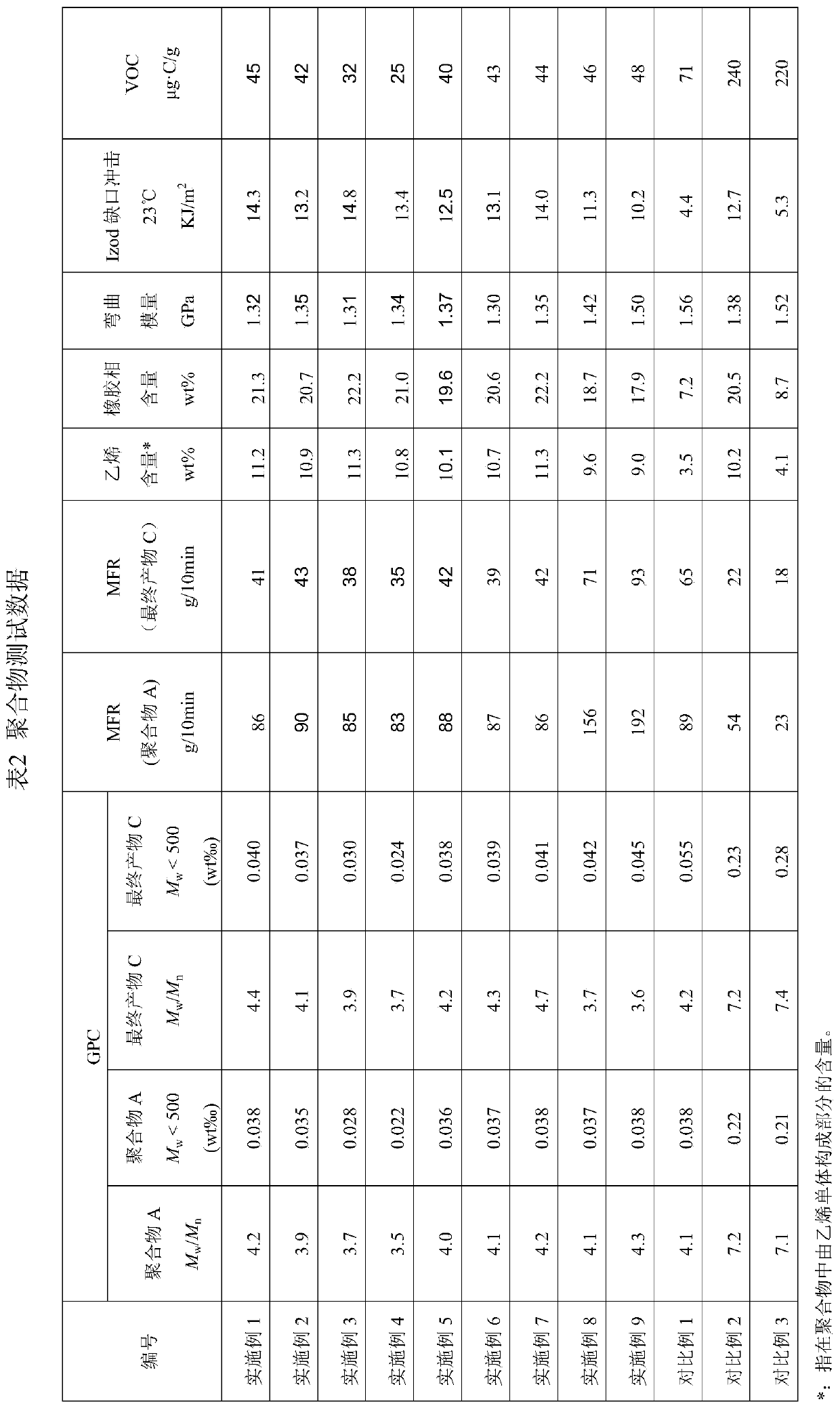

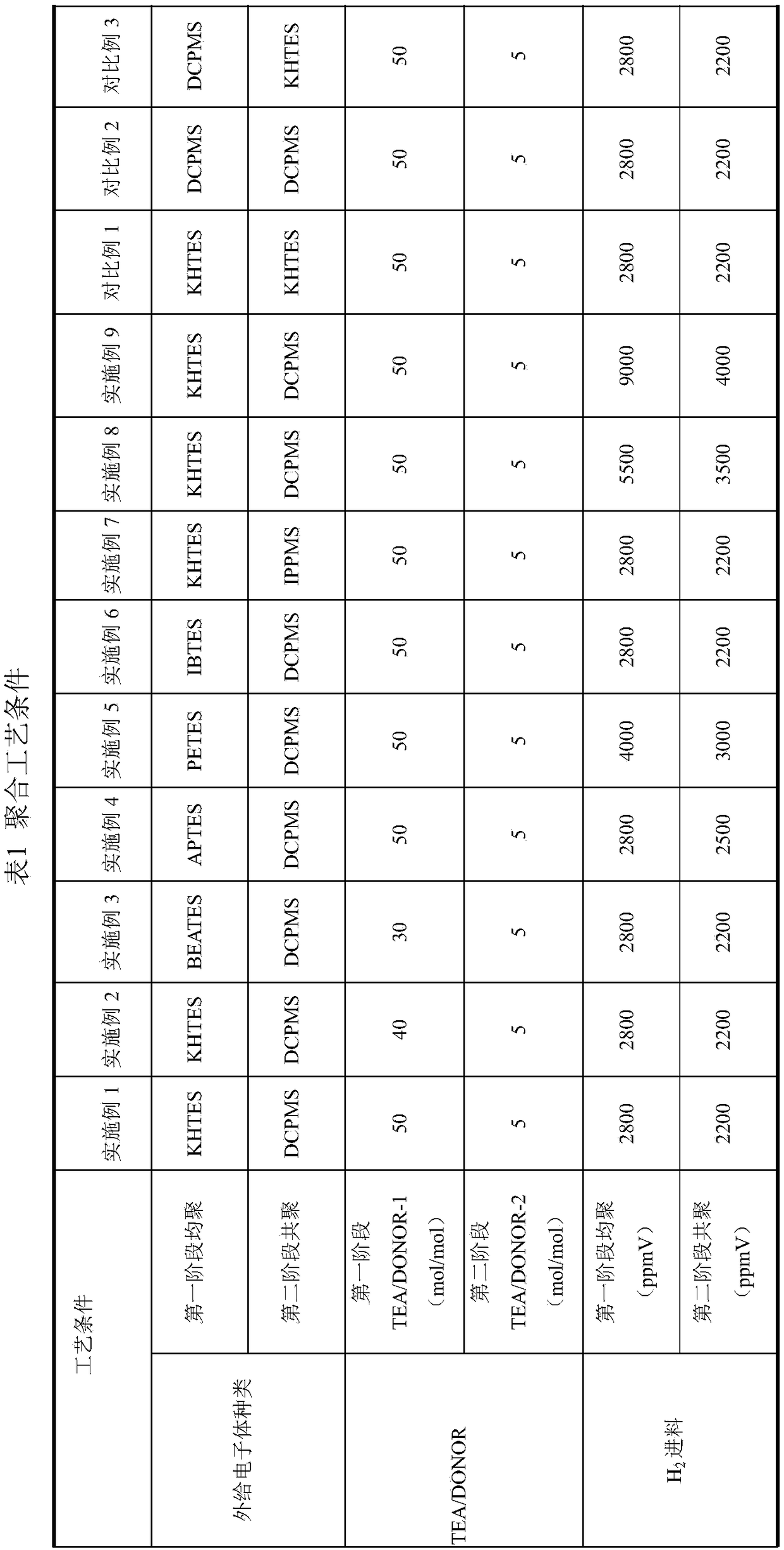

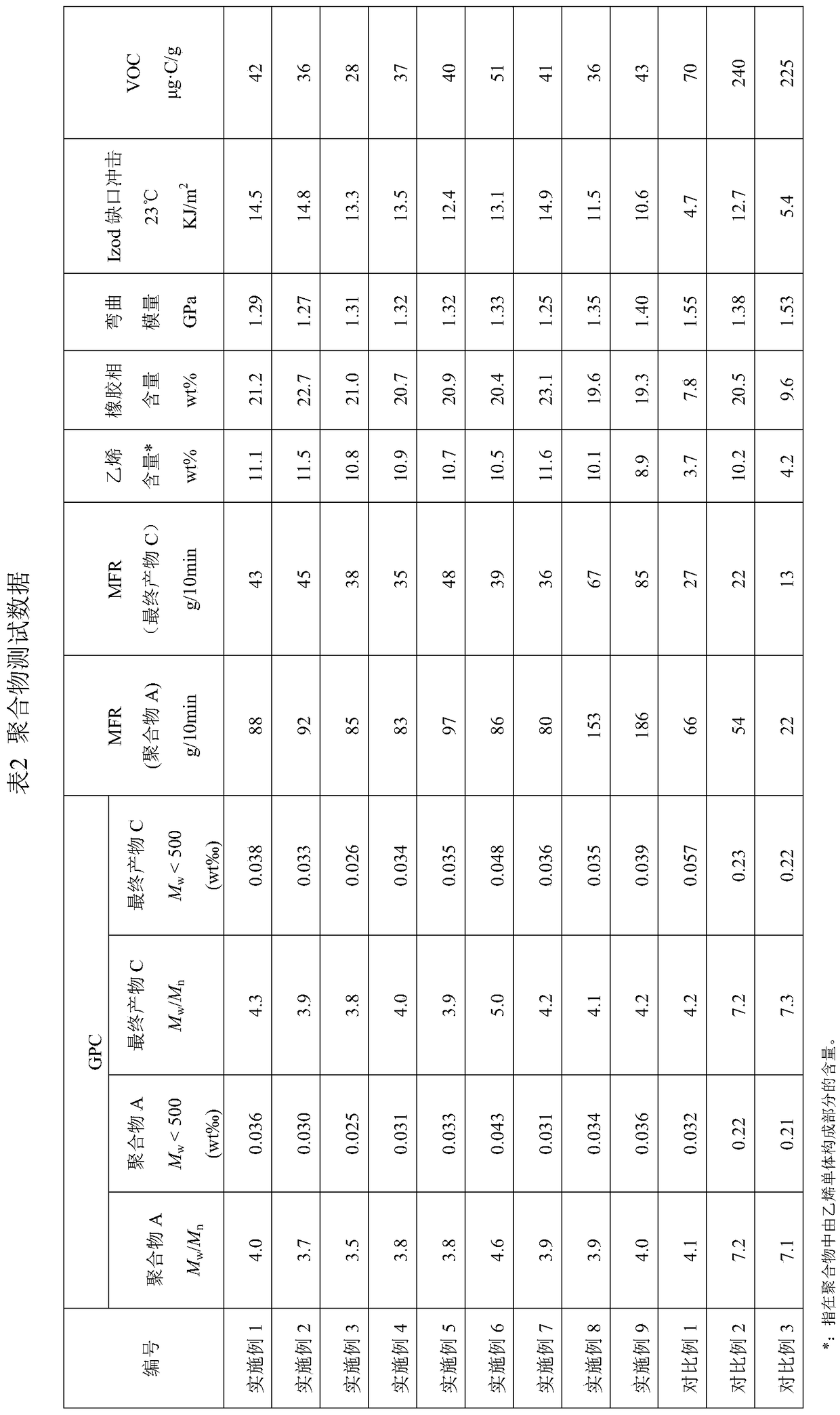

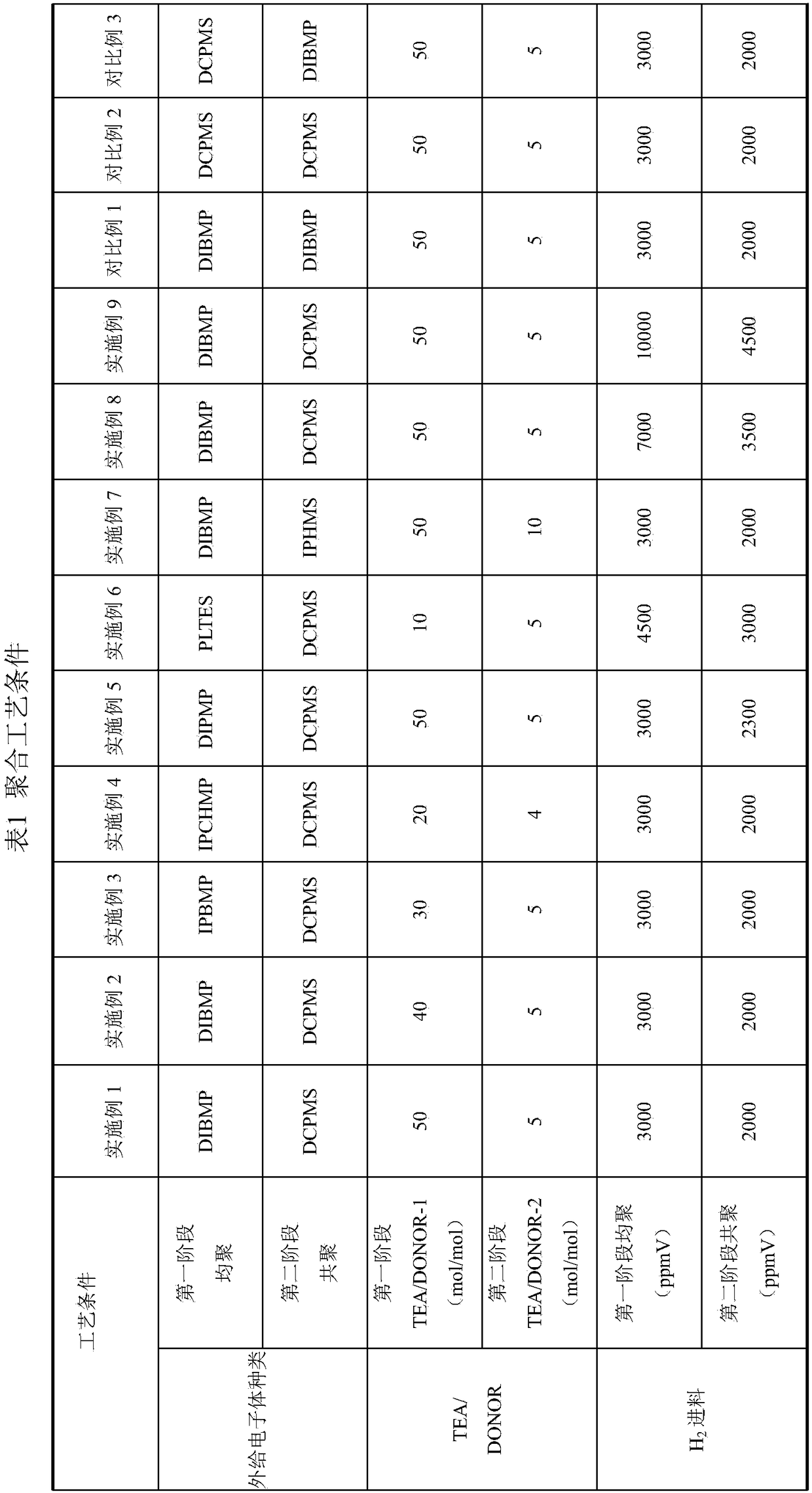

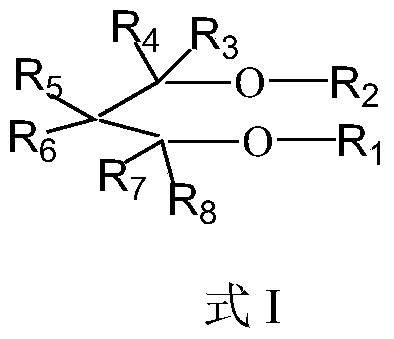

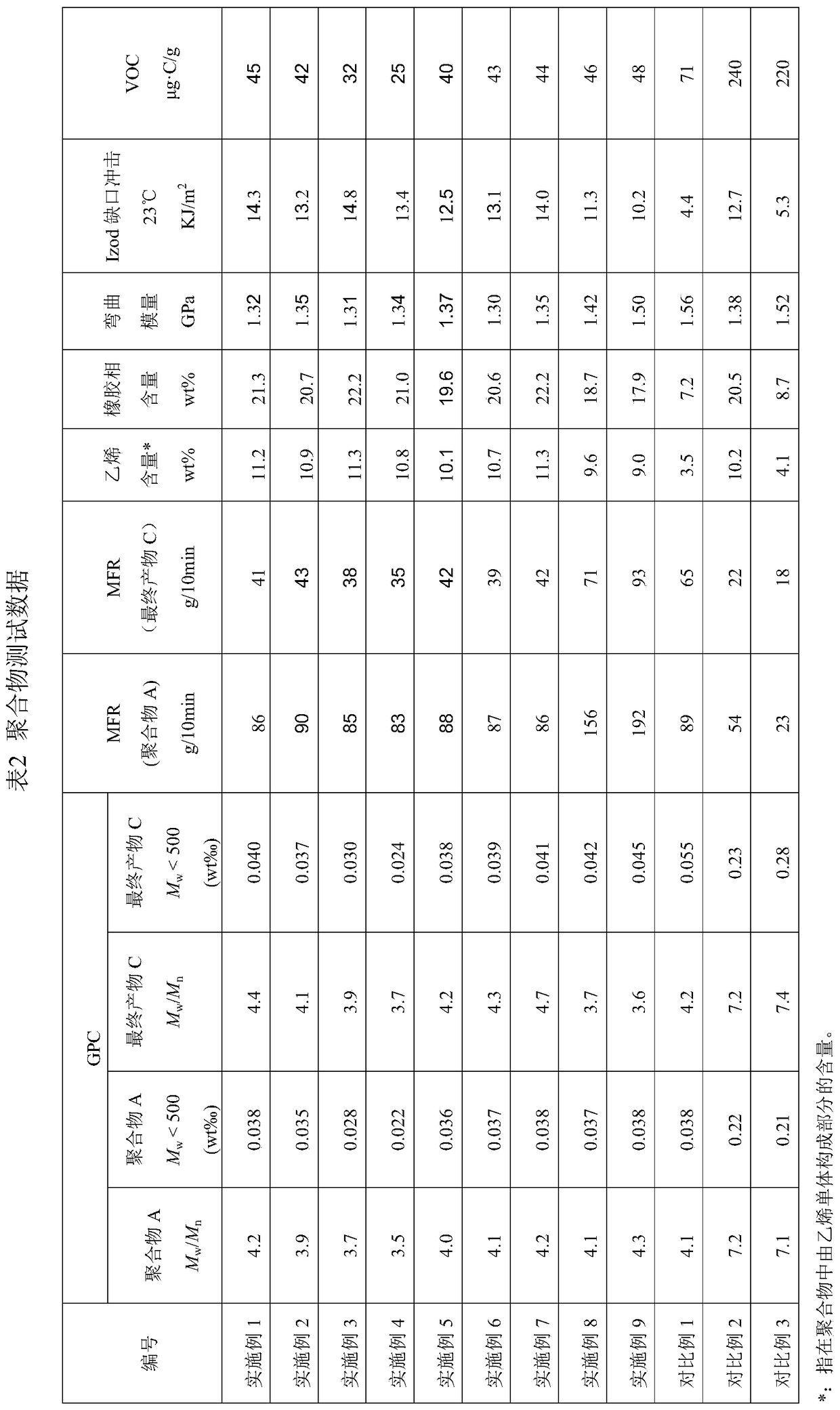

Method for preparing impact-resistant polypropylene with low VOC (Volatile Organic Compounds) content

The invention provides a method for preparing impact-resistant polypropylene with low VOC (Volatile Organic Compounds) content. The method comprises a propylene homopolymerization stage and a propylene copolymerization stage, wherein at the propylene homopolymerization stage, a propylene homopolymerization reaction is carried out in the presence of a Ziegler-Natta catalyst containing a first external electron donor and hydrogen gas so as to obtain a material flow 1 containing a homopolymerized polymer A and the catalyst, and at the propylene copolymerization stage, a propylene and alpha-olefin copolymerization reaction is carried out in the presence of the material flow 1 and a second external electron donor so as to obtain a polypropylene flow 2 containing the homopolymerized polymer A and a copolymerized polymer B; and the first external electron donor is trialkoxysilane, and the second external electron donor dialkoxysilane. According to the method, impact-resistant polypropylene products with narrow molecular-weight distribution, low ultralow-molecular-weight component content, light odor and low VOC content can be produced without special catalysts and great change on the existing processing equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing anti-shocking polypropylene with low odor and low VOC content

ActiveCN105566533AReduce manufacturing costSimple and reliable operation processHydrogenZiegler–Natta catalyst

The invention provides a method for preparing anti-shocking polypropylene with low odor and low VOC content. The method comprises the following steps: in the presence of a Ziegler-natta catalyst containing a first external electron donor, and hydrogen, performing propylene homopolymerization, thereby obtaining a material flow 1 containing a homopolymerization polymer A and the catalyst; in the propylene copolymerization period, performing polymerization reaction on propylene and alpha-olefin in the presence of the material flow 1 and a second external electron donor, thereby obtaining a material flow 2 containing the homopolymerization polymer A and a copolymerization polymer B, wherein the first external electron donor is a 1,3-diether compound; the second external electron donor is alkoxysilane. By adoption of the method, an anti-shocking polypropylene product with narrow molecular weight distribution, ultralow molecular weight component content, low odor and low VOC content can be produced without using a special catalyst or greatly changing a conventional process device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Application of sodium acetate as catalyst for preparing polyphenylene sulfide and method for preparing polyphenylene sulfide

The invention discloses application of sodium acetate as a catalyst for preparing polyphenylene sulfide and a method for preparing polyphenylene sulfide from aqueous sodium sulfide and p-dichlorobenzene which are used as raw materials, N-methylpyrrolidone used as a solvent and sodium acetate used as the catalyst. The method comprises the following concrete steps: a, dissolving aqueous sodium sulfide, sodium acetate and caustic soda flakes in N-methylpyrrolidone to obtain an aqueous sodium sulfide solution; b, dehydrating the solution in the step a to obtain a dehydrated sodium sulfide solution; c, dissolving p-dichlorobenzene in N-methylpyrrolidone to obtain a p-dichlorobenzene solution; d, mixing the dehydrated sodium sulfide solution in the step b with the p-dichlorobenzene solution in the step c, and performing polymerization reaction to obtain a reaction product; e, separating the reaction product in the step d to obtain finished polyphenylene sulfide. According to the method for preparing polyphenylene sulfide, acetate is used as the catalyst and the method has the advantage of low cost, and prepared PPS (polyphenylene sulfide) is good in linearity, high in molecular weight and excellent in comprehensive performance.

Owner:重庆瑞淼科技发展中心

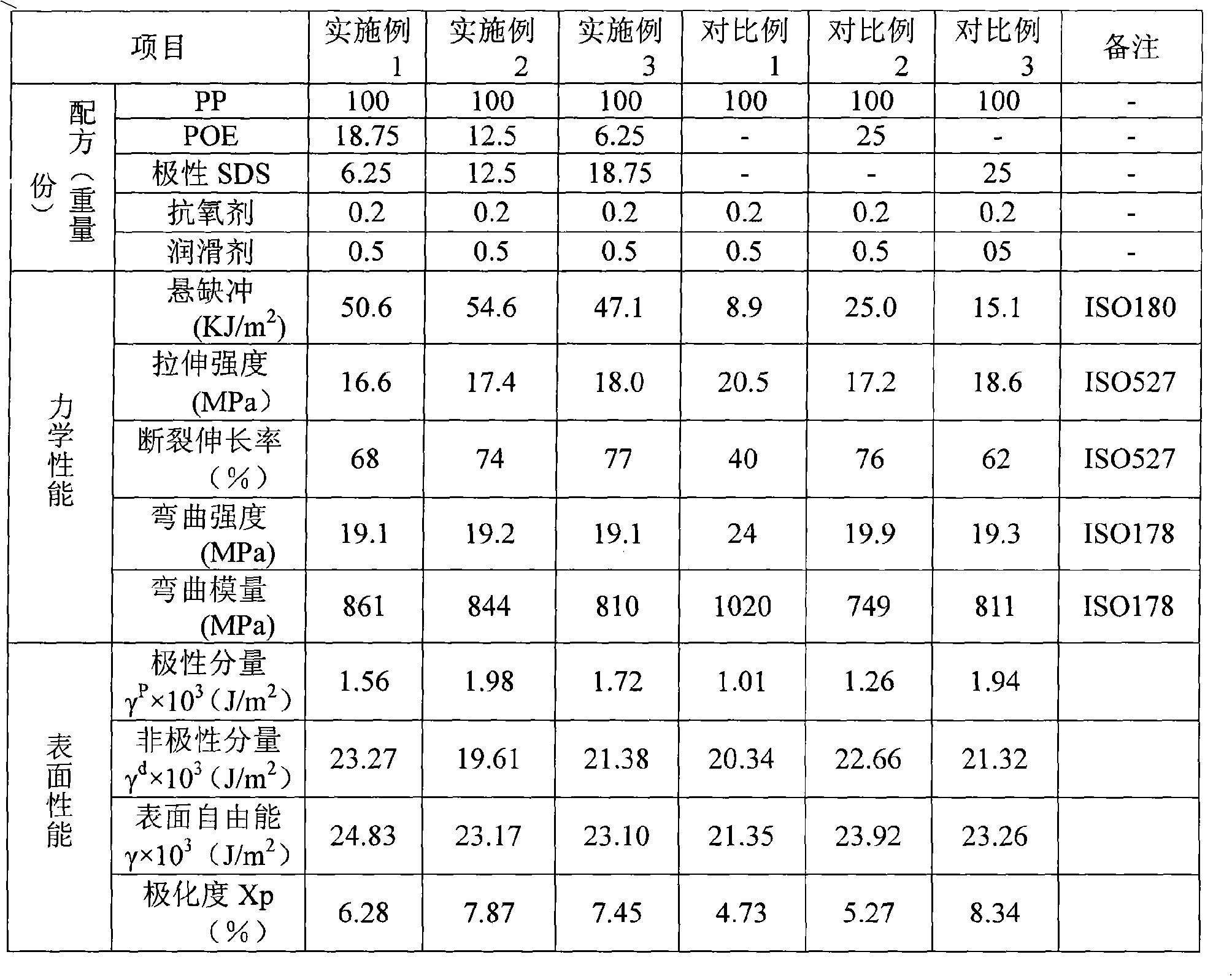

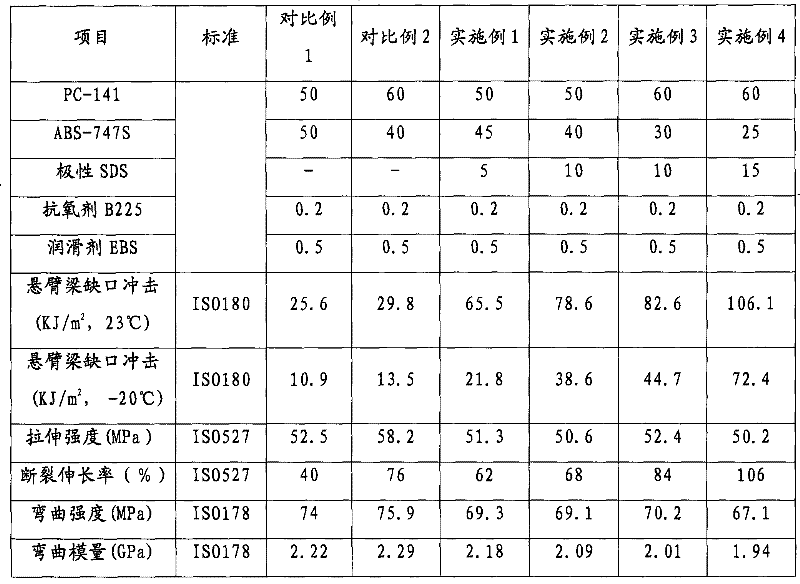

PA (polyamide)/ABS (Acrylonitrile Butadiene Styrene) composite material and preparation method thereof

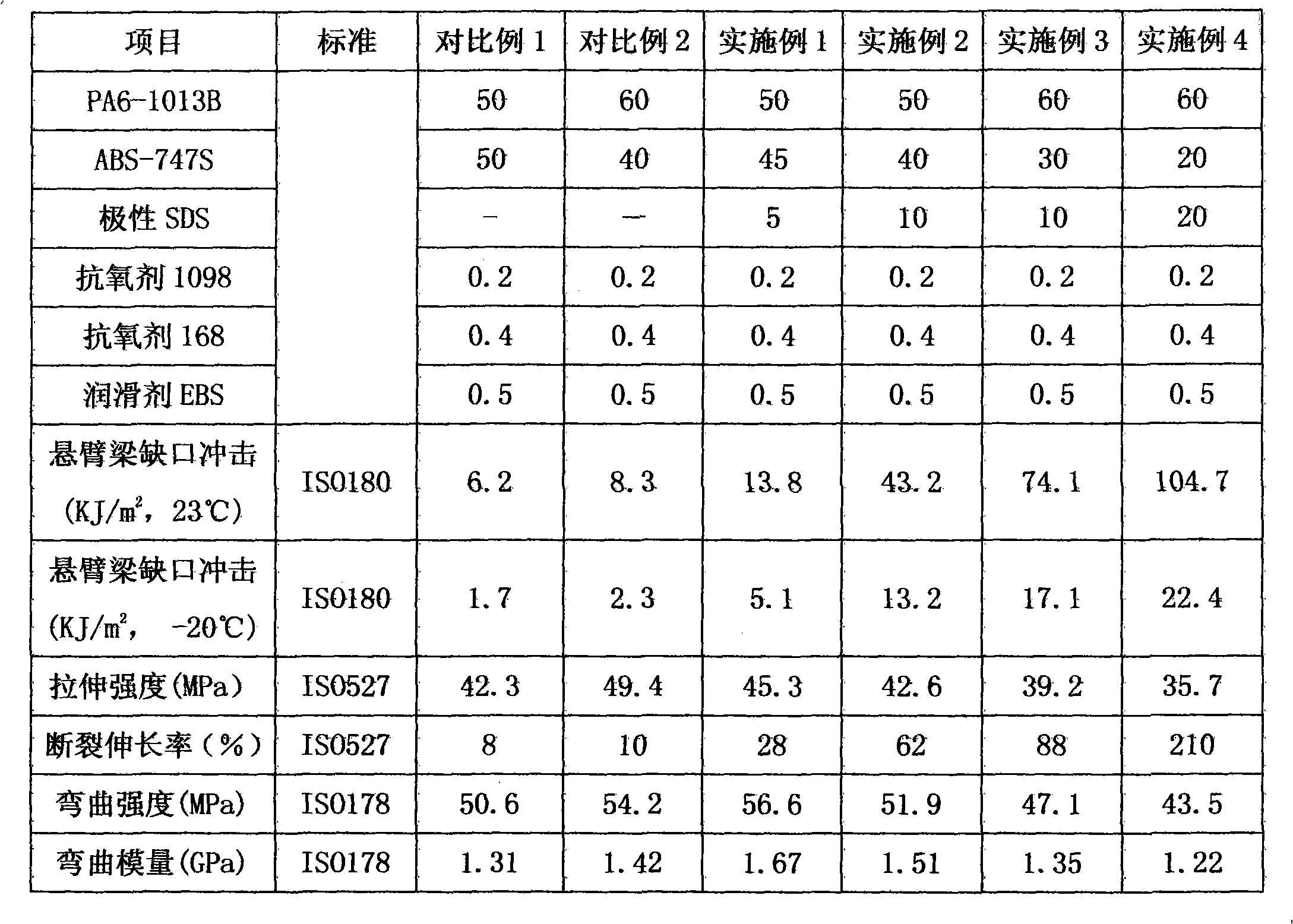

The invention discloses a PA (polyamide) / ABS (Acrylonitrile Butadiene Styrene) composite material and a preparation method thereof, relating to the technical field of high polymer materials. The PA / ABS composite material comprises 40-80 parts by weight of polyamide, 15-50 parts by weight of ABS and 5-30 parts by weight of polarization SDS (Sodium Dodecyl Sulfonate). The preparation method comprises the following steps of: evenly mixing all components, including PA, ABS and polarization SDS, in the component proportion by a mixer; fusing, mixing and extruding by double screws; and finally granulating to obtain the PA / ABS composite material. The invention better solves the problem of compatibility between PA and ABS, and the composite material has excellent comprehensive mechanical property.

Owner:CHINA PETROLEUM & CHEM CORP +1

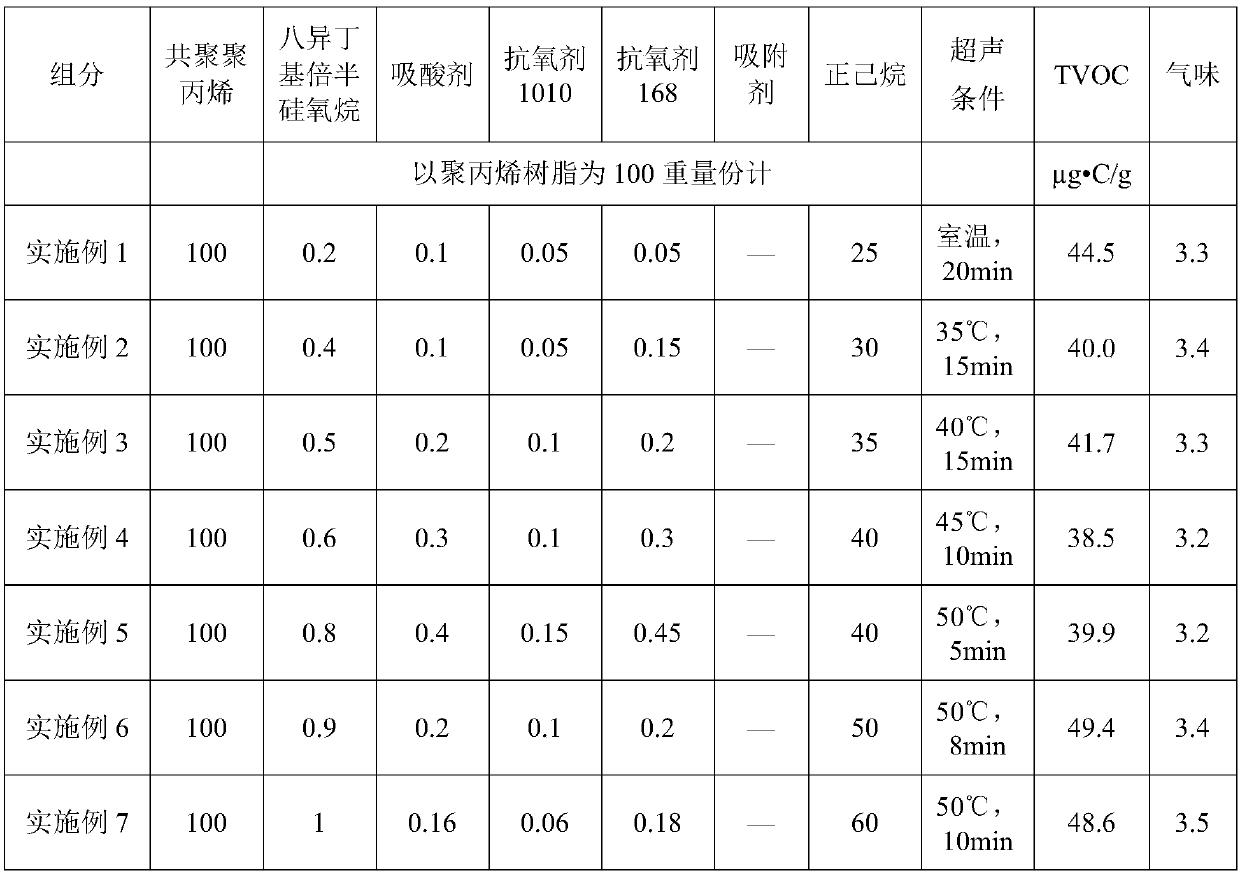

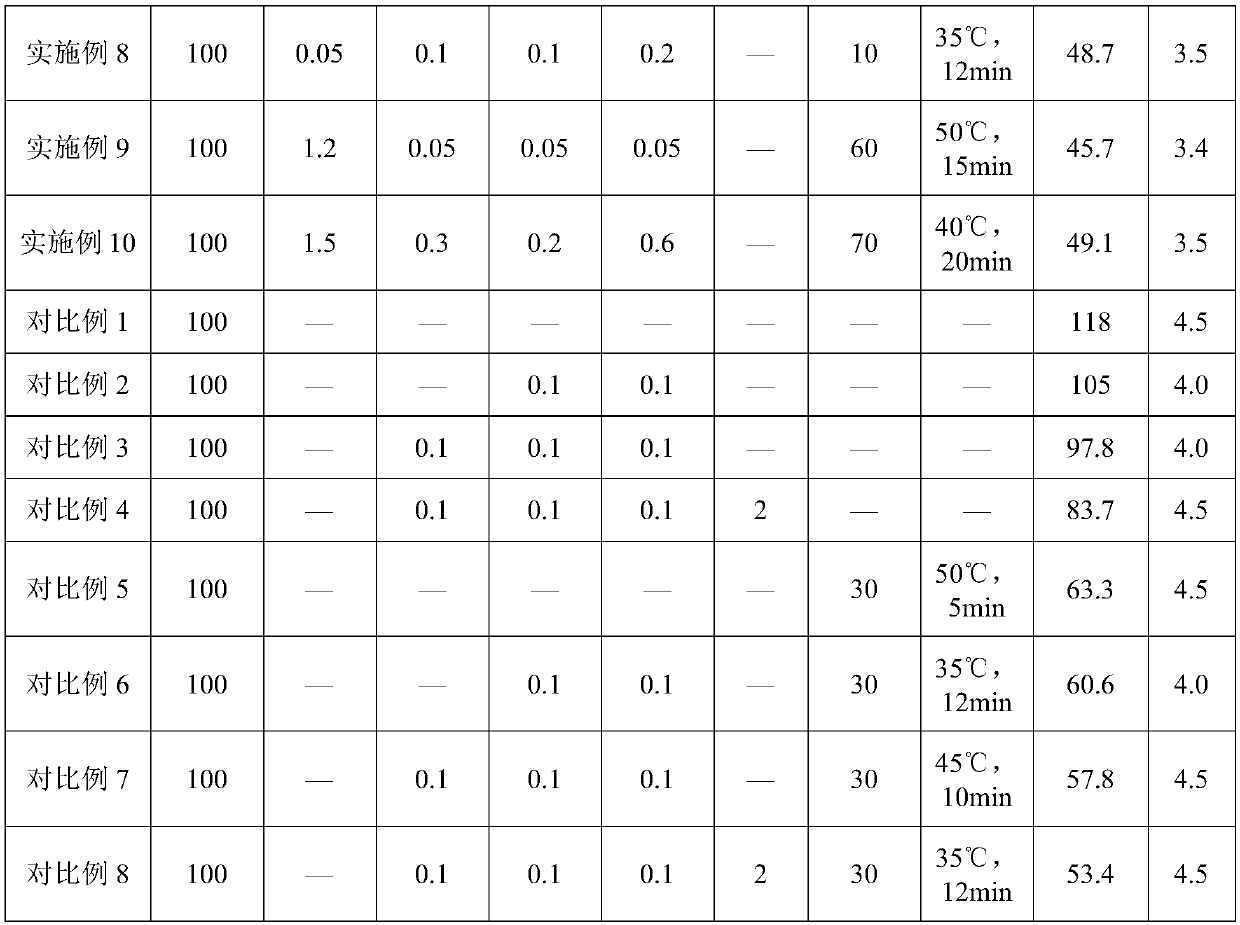

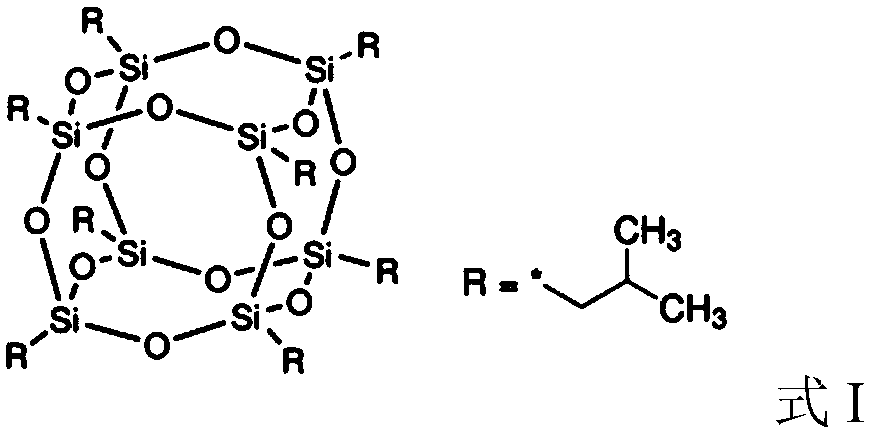

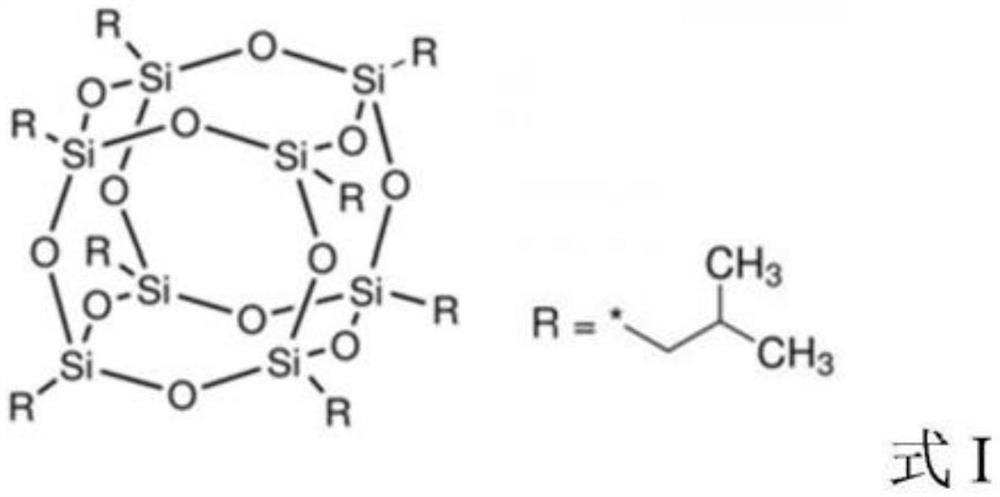

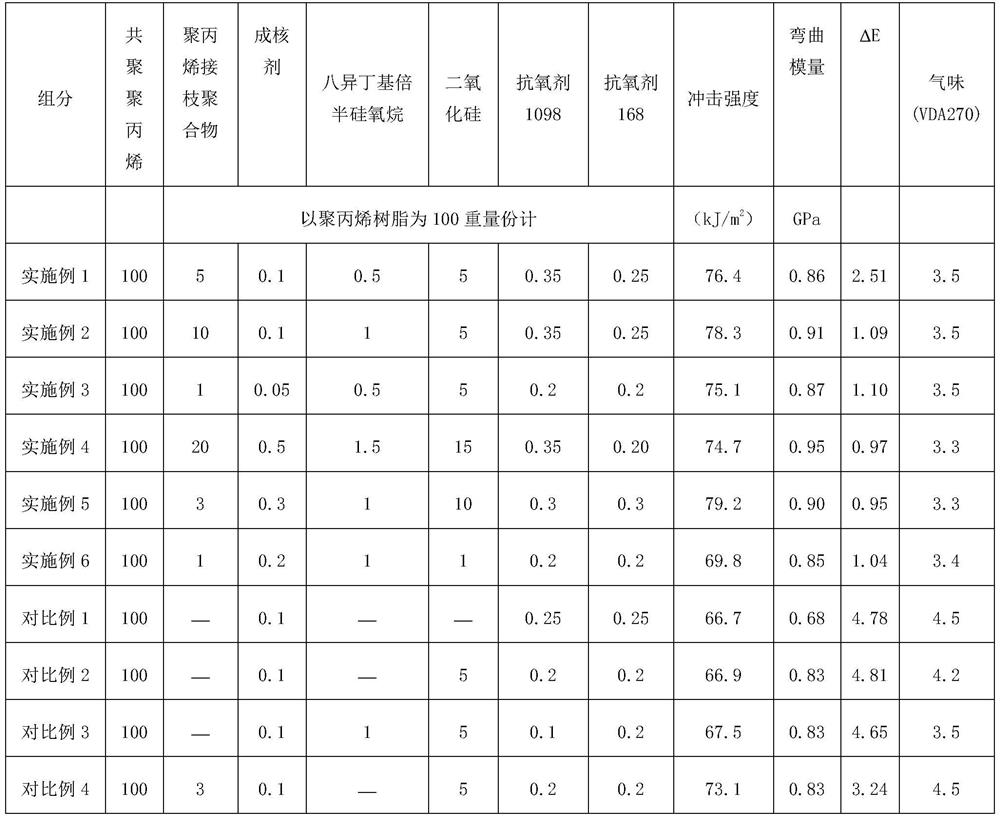

Low-VOC low-odor polypropylene resin composition and preparation method thereof

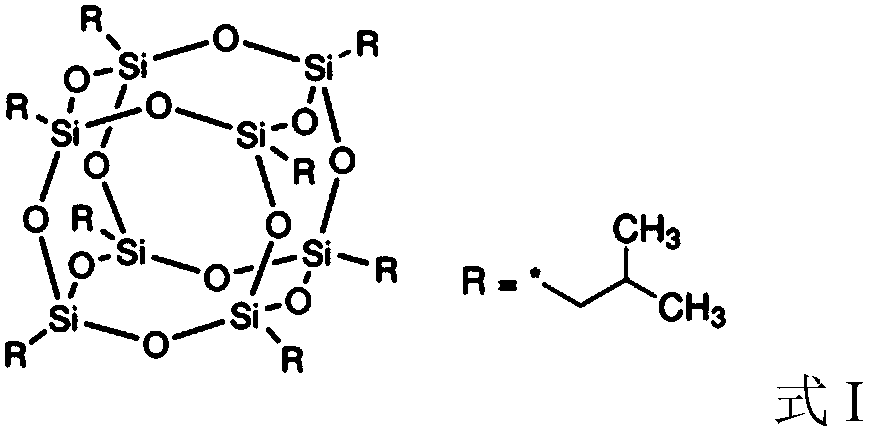

The invention belongs to the field of plastics, and relates to a low-VOC low-odor polypropylene resin composition and a preparation method thereof. The preparation method comprises: (1) dissolving octaisobutylsilsesquioxane in n-hexane to obtain the n-hexane solution of octaisobutylsilsesquioxane; (2) mixing the n-hexane solution of the octaisobutylsilsesquioxane and polypropylene powder, and drying the mixed material to achieve a constant weight; (3) uniformly mixing an acid-absorbing agent, an antioxidant and the dried material obtained in the step (2) to obtain a premix; and (4) carrying out melt blending on the premix to obtain the polypropylene resin composition. According to the present invention, the total volatile organic compound (TVOC) of the polypropylene resin composition can be significantly reduced so as to well solve the disadvantages in the prior art; the operation process is simple and reliable, and the investment cost is low; and the obtained product is suitable for high-grade vehicle interior decoration members, medical and food packaging materials, and other fields with high environmental protection requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

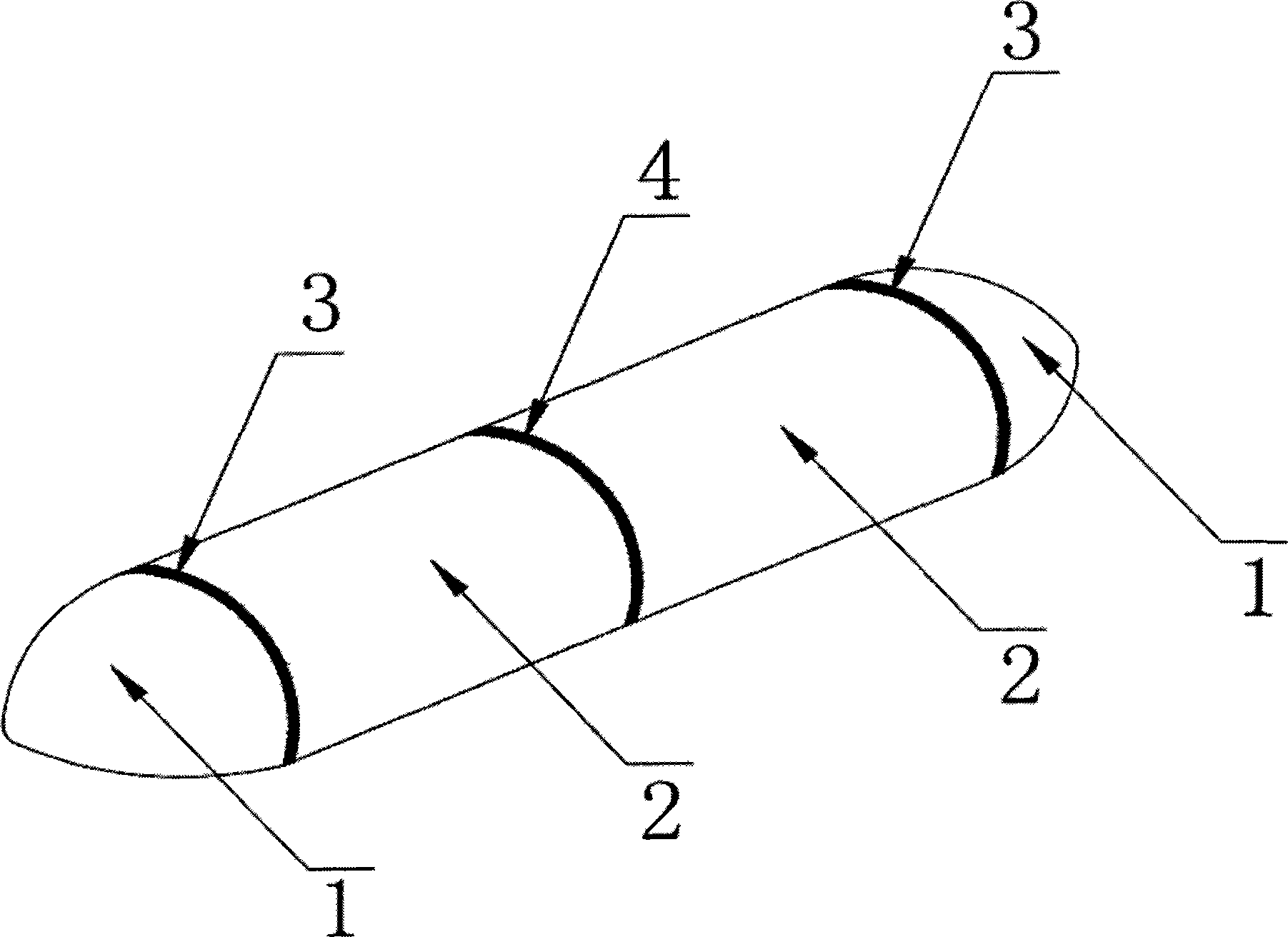

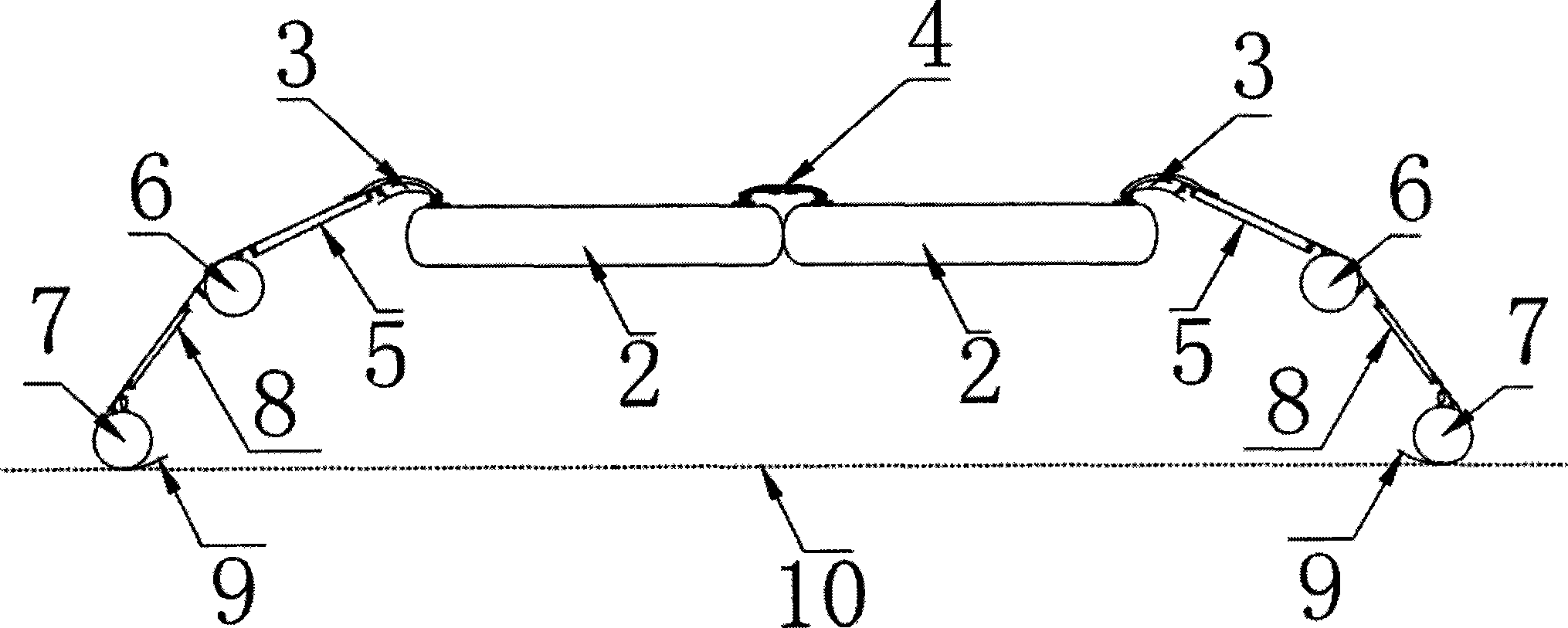

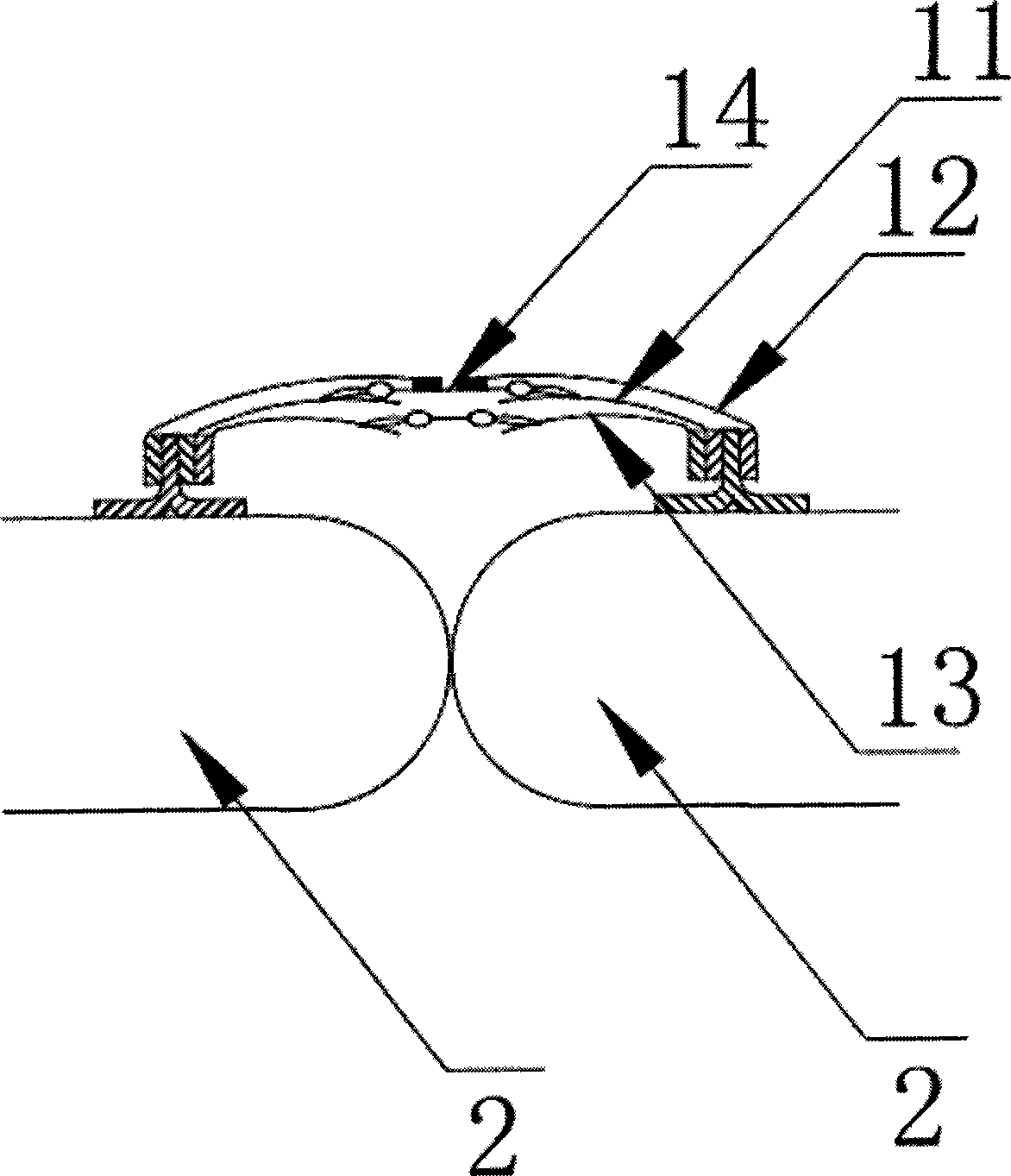

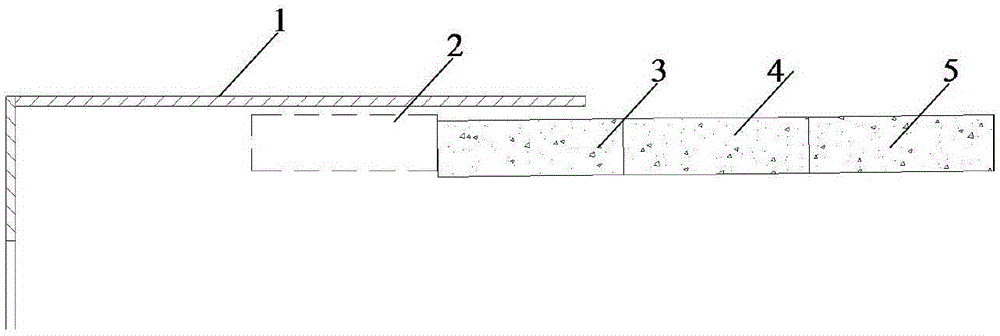

Moving type hangar

InactiveCN103850510AThe technical scheme of the mobile hangar is scientific and reasonableThe preparation process is simple and reliableParkingsManufacturing technologyPolyvinyl chloride

The invention discloses a moving type hangar, which comprises three parts of end doors, a middle main body and an accessory. The main structure of the moving type hangar disclosed by the invention adopts the modular design; the whole hanger comprises end door modules distributed on two ends of the hangar, and multiple groups of middle main body modules, wherein the end of each group of module is provided with a port; except that the end door position is fixed, the rest modules of the hangar can be subjected to unordered mutual connection. The manufacture material of the main structure of the moving type hangar is selected from one or multiple types of PVC (polyvinyl chloride) membrane material, TPU (thermoplastic urethanes) membrane material, EVA (ethylene vinyl-acetate) membrane material, acrylic ester membrane material, neoprene membrane material, butadiene styrene rubber membrane material, ETFE (ethyl tetra fluoro ethylene) membrane material, PVDF (polyvinylidene fluoride) membrane material, PTFE (polytetrafluoroethylene) membrane material and PVF (polyvinyl fluoride) membrane material. The moving type hangar is erected with an inflation method, each group of modules can be respectively curly packaged after venting, and the moving type hangar has the advantages of strong maneuverability, simple operation process, stable and reliable performance, advanced technical index, scientific structural design, cheap and abundant raw materials and mature manufacture technology and is suitable to popularize and apply within a large range in the industry.

Owner:北京云创太和科技有限公司

Sprayable and toughened polypropylene composition and preparation method thereof

The invention provides a sprayable and toughened polypropylene composition, which contains the following blended components: 100 weight parts of acrylic resin, 5 to 30 weight parts of thermoplastic polyolefin elastomer, and 5 to 30 weight parts of thermoplastic elastomer graft, wherein the thermoplastic polyolefin elastomer is an ethylene-octene copolymer; and the thermoplastic elastomer graft isa styrene-butadiene-styrene block copolymer or a graft of a styrene-pentadiene-styrene block copolymer and a polar monomer, and the polar monomer is at least one of 2-vinylpyridine, 4-vinylpyridine orisomers thereof. The sprayable polypropylene composition is prepared by melt blending of the components. The polypropylene composition has good toughness and sprayable performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Iron-supported zinc aluminate nano powder and preparation method thereof

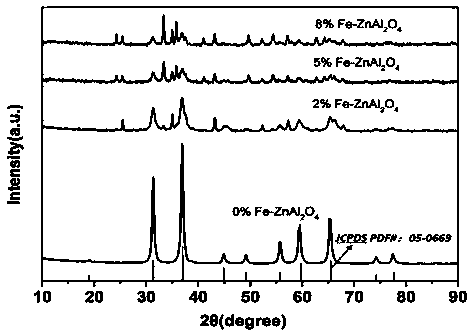

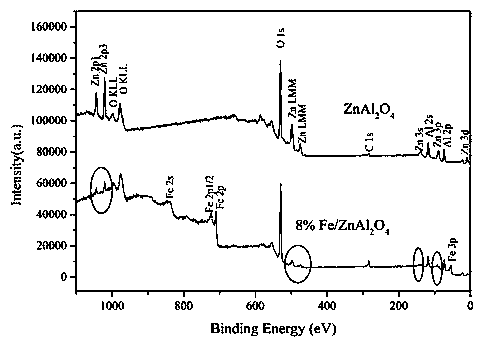

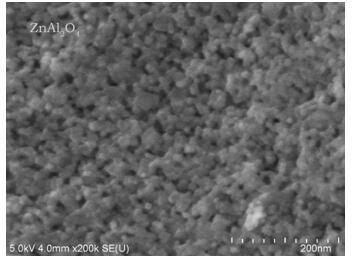

InactiveCN109095487AWell mixedUniform spherical nanoparticlesMaterial nanotechnologyIron compoundsAluminateIron salts

The invention relates to an iron-supported zinc aluminate nano powder and a preparation method thereof, and belongs to the technical field of powder material preparation. The nano powder is prepared by taking zinc salt, aluminum salt and iron salt as raw materials and adding a surfactant. The particle size of the nano powder is 20-200 nm, and the surface of the nano powder contains Fe2+ and Fe3+ ions. The nano powder takes the zinc salt, cobalt salt and the aluminum salt as raw materials, ZnAl2O4 powder is prepared from a surfactant cetyltrimethylammonium bromide (CTAB) under the assistance ofa hydrothermal method, and the obtained ZnAl2O4 powder is placed in an iron salt solution to undergo magnetic stirring, ultrasound-assisted wet process dipping, drying and sintering to obtain the iron-supported zinc aluminate nano powder. According to the iron-supported zinc aluminate nano powder, the problems that an iron load is uneven and the bonding strength of a load and a carrier is not high can be solved, the nano powder has a particle size of 20 nm to 200 nm, and the morphology is spherulitic.

Owner:KUNMING UNIV OF SCI & TECH

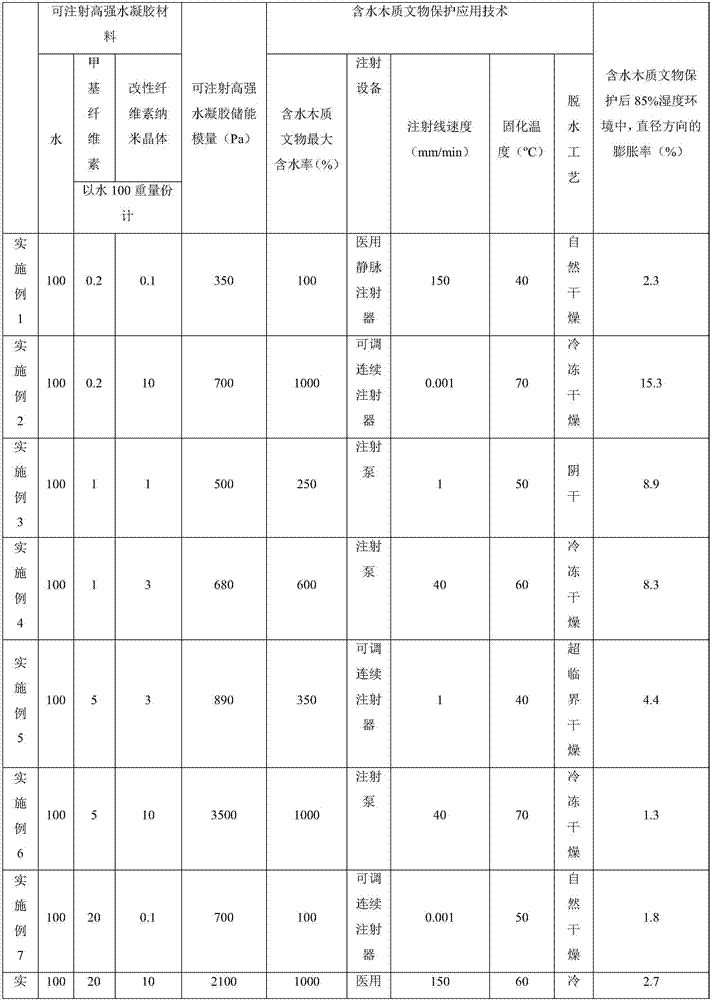

Modified cellulose nanometer crystal, high-strength hydrogel material, preparation method and application

The invention provides a modified cellulose nanometer crystal, a high-strength hydrogel material, a preparation method and an application. The modified cellulose nanometer crystal comprises a cellulose nanometer crystal body and methyl cellulose which is combined with the crystal body by an aldol condensation reaction, in the aldol condensation reaction, and the substitution degree of methyl cellulose is as follows: 0.002-0.1 hydroxyl radical in each glucose unit in a cellulose nanometer crystal is substituted. The high-strength hydrogel material is prepared by the following steps: 0.2-20 parts of methyl cellulose and 0.1-10 parts of the modified cellulose nanometer crystal are added into 100 parts of water in order to obtain mixed liquor, and stirring is carried out at a room temperaturein order to obtain the product. The application is as follows: the high-strength hydrogel material is injected along a vertical direction of water containing wooden historical relics in an injection mode; the materials are permitted to stand at 40-70 DEG C for 0.5-10 hours, in order to realize solution-gel phase transformation of the high-strength hydrogel material, and complete penetration and reinforcing of the high-strength hydrogel material; and finally dehydration treatment is carried out, and reinforcing, dehydration, and protection treatment are completed.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

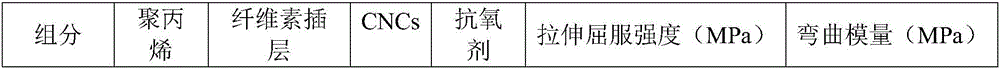

Polypropylene/cellulose intercalation nanocrystal composition and preparation method thereof

The invention relates to a polypropylene / cellulose intercalation nanocrystal composition and a preparation method thereof. The polypropylene / cellulose intercalation nanocrystal composition contains the following blended components: polypropylene and cellulose intercalation nanocrystals. According to the polypropylene / cellulose intercalation nanocrystal composition disclosed by the invention, the dispersity of CNCs in polypropylene and the interfacial compatibility of the CNCs and polypropylene are obviously improved, the thermal degradation temperature of the CNCs is effectively increased, and the composition is suitable for a melt blending and extrusion process. In addition, the crystallinity degree of the polypropylene is increased, the rigidity of the polypropylene composition is further obviously improved, the operation process is simple, and the composition is applicable to the fields of high-grade automobile materials, household appliance materials, medical and food packaging materials with high rigidity requirements and the like.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

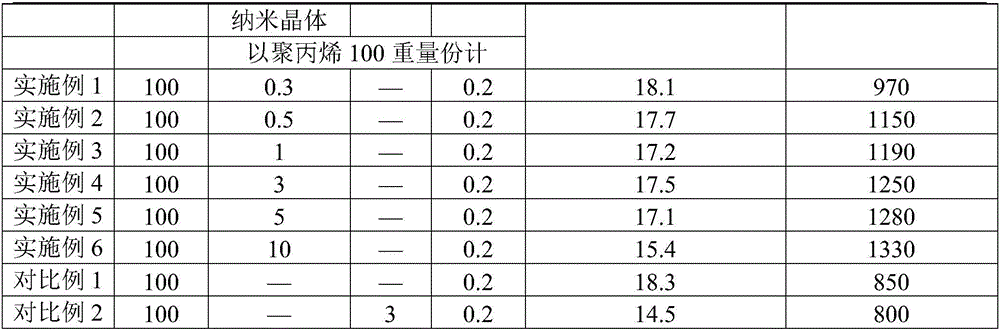

Low VOC polypropylene composite material for vehicle and preparation method thereof

ActiveCN102731901BImprove mechanical propertiesSimple and reliable operation processPolypropylene compositesVacuum pumping

The present invention relates to a low VOC polypropylene composite material for vehicle and a preparation method thereof. The polypropylene composite material comprises the following blended components, calculated by 100 weight parts of the polypropylene: 10-35 parts of toughening agent, 10-35 parts of ultra-fine talcum powder and 1-5 weight parts of fully vulcanized powder silicon rubber. The toughening agent is at least one selected from ethylene octene copolymer and EPDM; the fully vulcanized powder silicon rubber is selected from full vulcanized powder silicon rubber with average grain size of 0.05-1 mum, homogeneous structure and gel content of 60 wt% or higher; the ultra-fine talc powder has an average size of 1-13 mum. The polypropylene composite material of the invention is added with fully vulcanized powder silicon rubber to realize faster and better extraction of organic volatile matters during a vacuum pumping process and well solve a problem of to volatile organic residuals in the composite material, thereby preparing the low VOC polypropylene composite material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polypropylene/cellulose intercalation nanometer crystal masterbatch, preparation method and application thereof

ActiveCN106589602AImprove interface compatibilityRaise the thermal degradation temperatureDispersityMasterbatch

The invention relates to a polypropylene / cellulose intercalation nanometer crystal masterbatch in the field of plastics. The polypropylene / cellulose intercalation nanometer crystal masterbatch comprises the following blended components: polypropylene and a cellulose intercalation nanometer crystal. The invention also discloses a preparation method and an application for the polypropylene / cellulose intercalation nanometer crystal masterbatch. The polypropylene / cellulose intercalation nanometer crystal masterbatch provided by the invention endows a cellulose nanometer crystal and polypropylene with good interfacial compatibility by utilizing intercalation modification of long-chain alkane in the cellulose intercalation nanometer crystal, significantly improves dispersity of the cellulose nanometer crystal in polypropylene and interfacial compatibility of the cellulose nanometer crystal and polypropylene, effectively improves the thermal degradation temperature of the cellulose nanometer crystal, and is applicable to the fields like advanced automotive materials, household appliance materials and medical and food packaging materials with high rigid requirements.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Makrolon/ABS composite material and preparation method thereof

The invention provides a high-performance makrolon / ABS composite material and a preparation method thereof. The composite material mainly comprises makrolon, polyacrylonitrile-butadiene-styrol copolymer (ABS) and polar sodium dodecyl sulfate (SDS). The composite material solves the problem of compatibility between PC and ABS, greatly improves the impact strength of PC / ABS composite material, particularly low-temperature impact strength and substantially maintains other mechanical properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

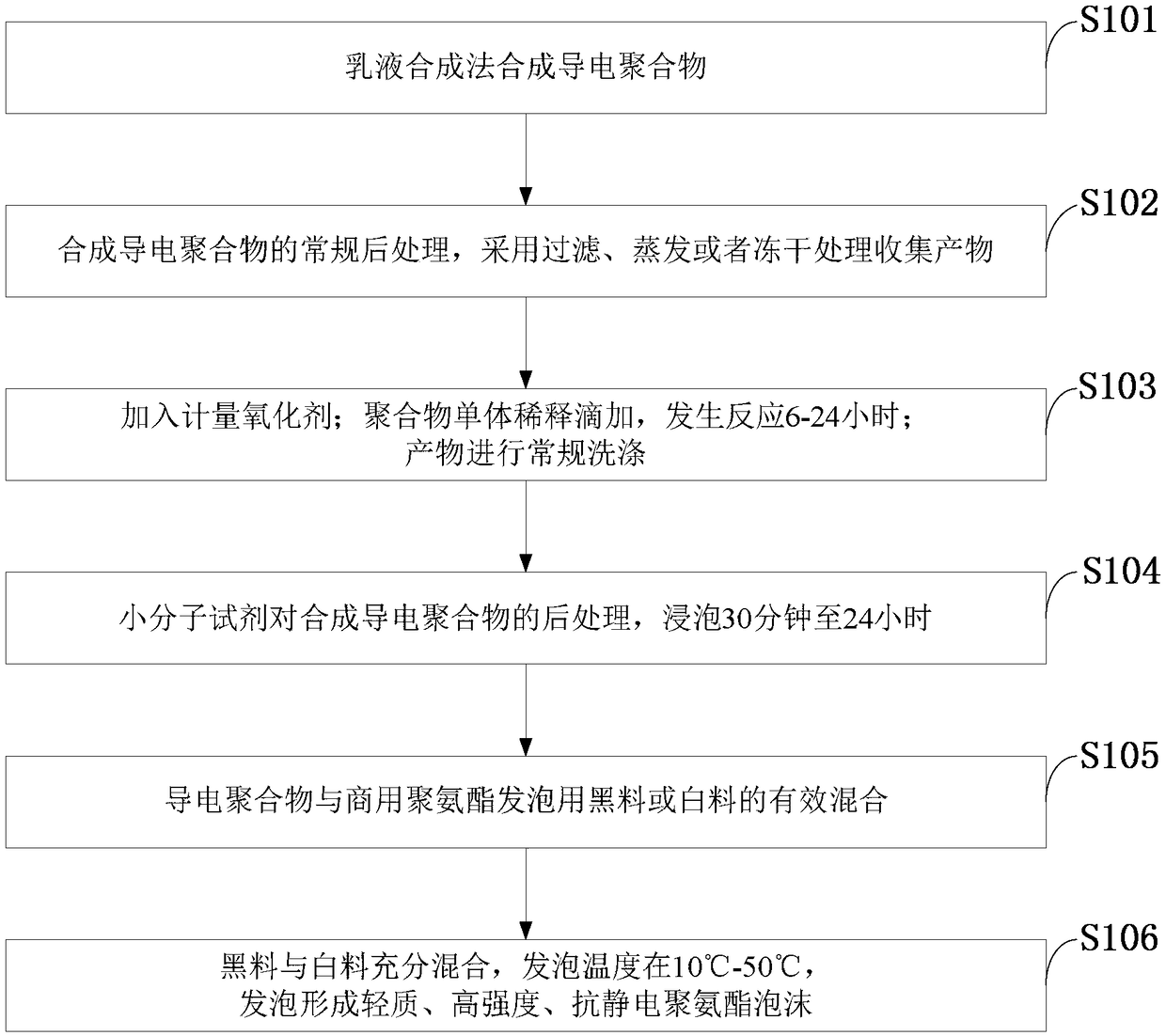

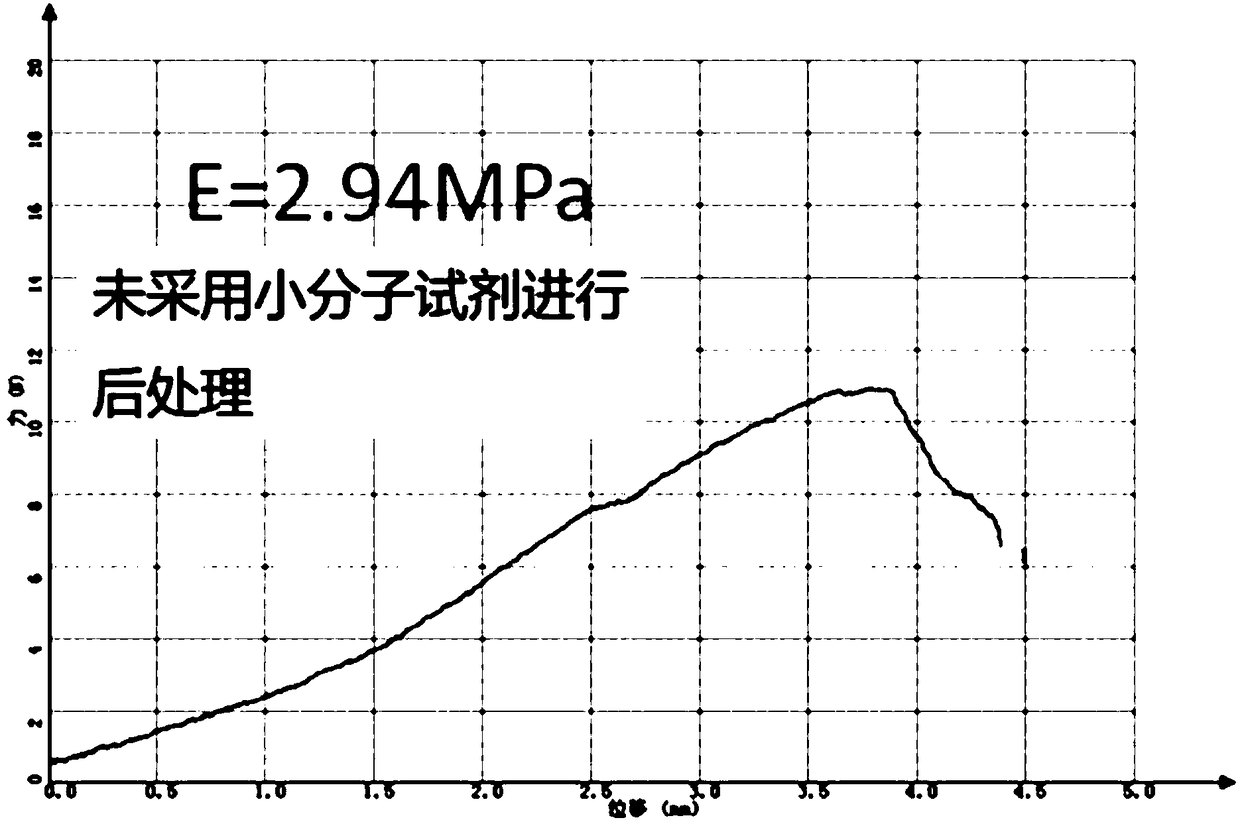

Reinforcing and antistatic light polyurethane foam and preparation method thereof

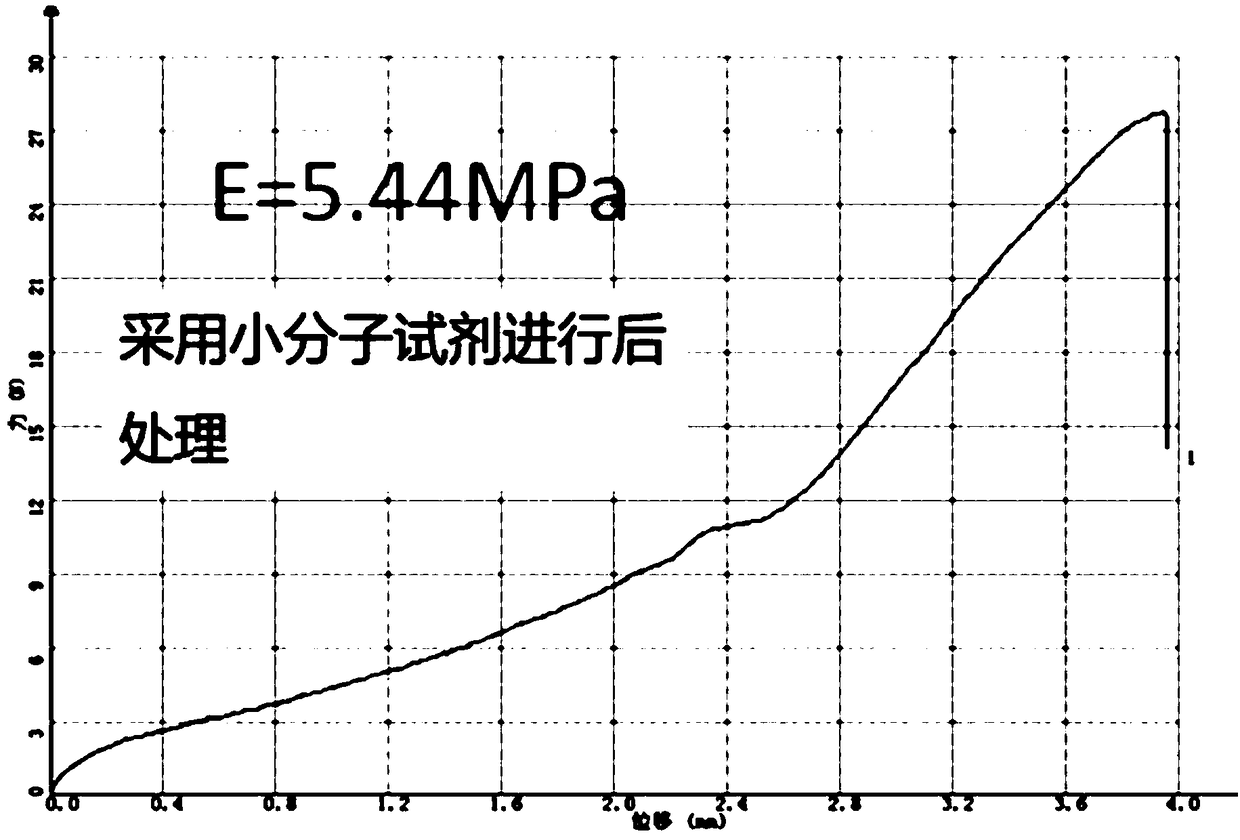

The invention belongs to the technical field of light polyurethane rigid foams and discloses a reinforcing and antistatic light polyurethane foam and a preparation method thereof. The preparation method of the reinforcing and antistatic light polyurethane foam comprises synthesizing a conductive polymer through emulsion synthesis, and then adding in measuring oxidizing agent; adding in polymer monomers in a diluted and dropwise mode for reaction for 6-24 hours; performing normal washing, filtering, evaporating or freeze-drying treatment on collected reaction products; performing normal aftertreatment on the synthesized conductive polymer by soaking the synthesized conductive polymer in micromolecular agent for 30 minutes to 24 hours, wherein the micromolecular agent participates in the reaction to achieve reinforcement of polyurethane rigid foams with increasing the density of the polyurethane rigid foams; effectively mixing the conductive polymer with commercial polyurethane foaming black materials and white materials, specifically, fully mixing the black materials and the white materials at a foaming temperature of 10-50 DEG C for foaming production to obtain the light-weight andhigh-strength antistatic polyurethane foam. The preparation method of the reinforcing and antistatic light polyurethane foam is high in foaming capacity, and the prepared reinforcing and antistatic light polyurethane foam achieves an electric conductivity rate up to 106-108 ohm / cm2, a Shore hardness of 25-90 HD and a Rockwell hardness of 15-60 HRC.

Owner:CHONGQING TECH & BUSINESS UNIV

Preparation method of low-VOC polypropylene resin and polypropylene resin prepared by method

The invention discloses a preparation method of low-VOC polypropylene resin and the polypropylene resin prepared by the method. The method comprises the following steps: before mixing and granulatingpolypropylene powder and a processing aid, soaking and extracting the polypropylene powder by a solvent, and then performing drying until the powder is free of weight loss, wherein the solvent is an alkane of C6-C8, the soaking and extracting temperature is in a range of 30-60 DEG C, the processing time is 8-72 hours, the drying temperature is 70-80 DEG C, and the drying time is 4-6 hours. The content of total volatile organic compounds (TVOC) of the polypropylene resin disclosed by the invention is lower than 40 [mu]g*C / g and the polypropylene resin can be widely applied to the fields with relatively high environmental protection requirements, such as high-grade automobile interior ornaments, medical use, food packaging materials and the like. In the preparation process, the operation process is simple and reliable, the investment cost is low, and the defects in the prior art are well solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

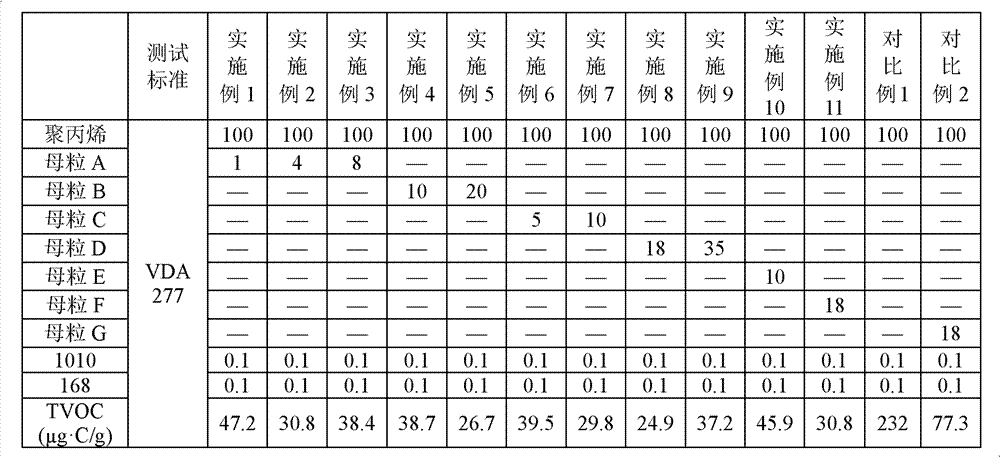

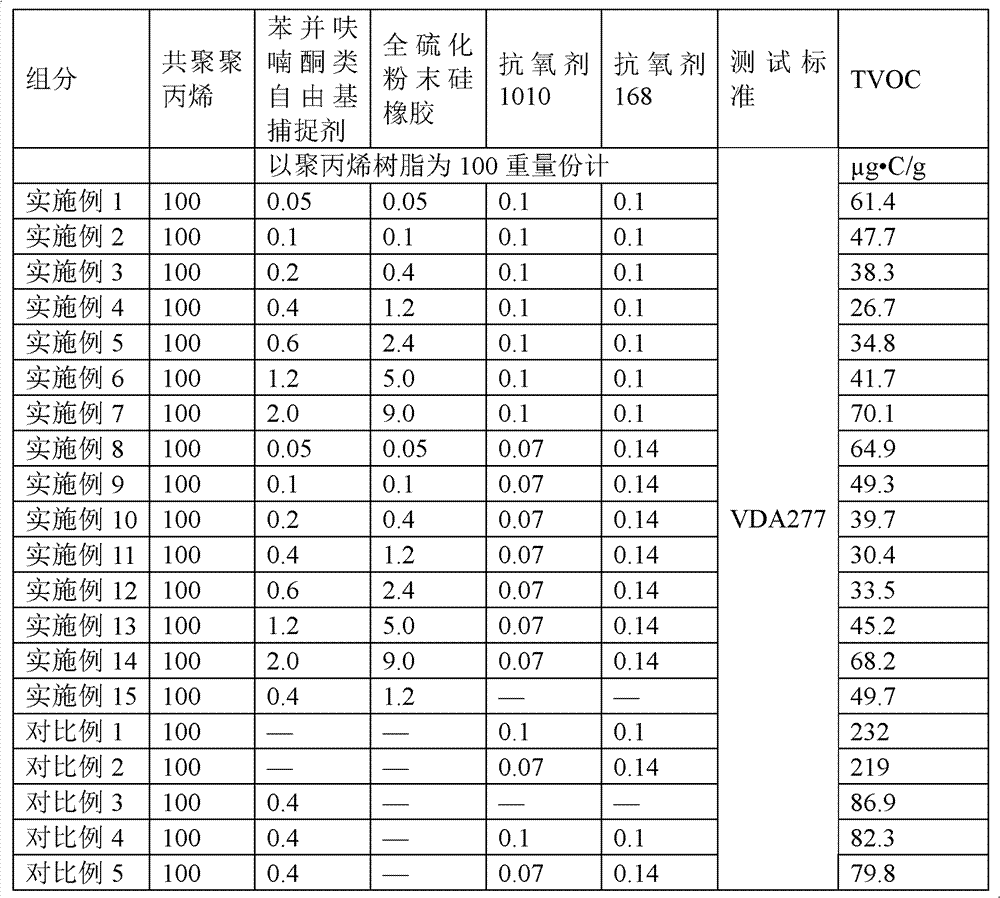

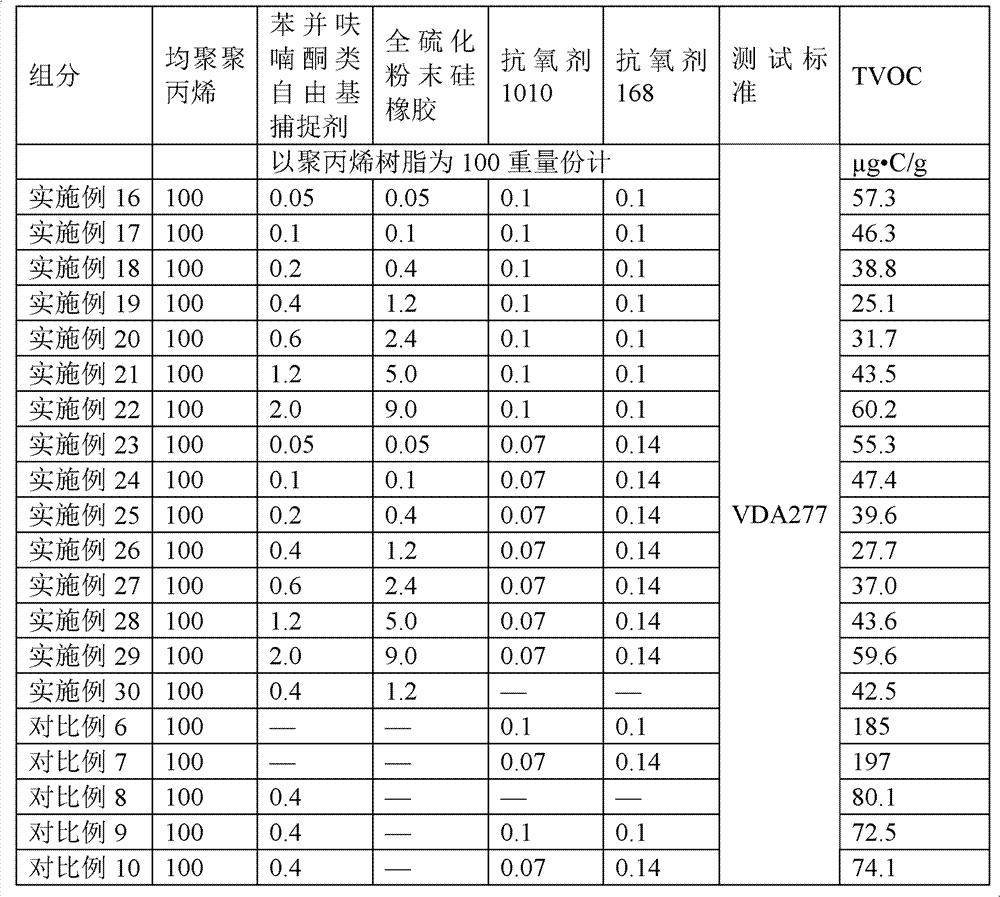

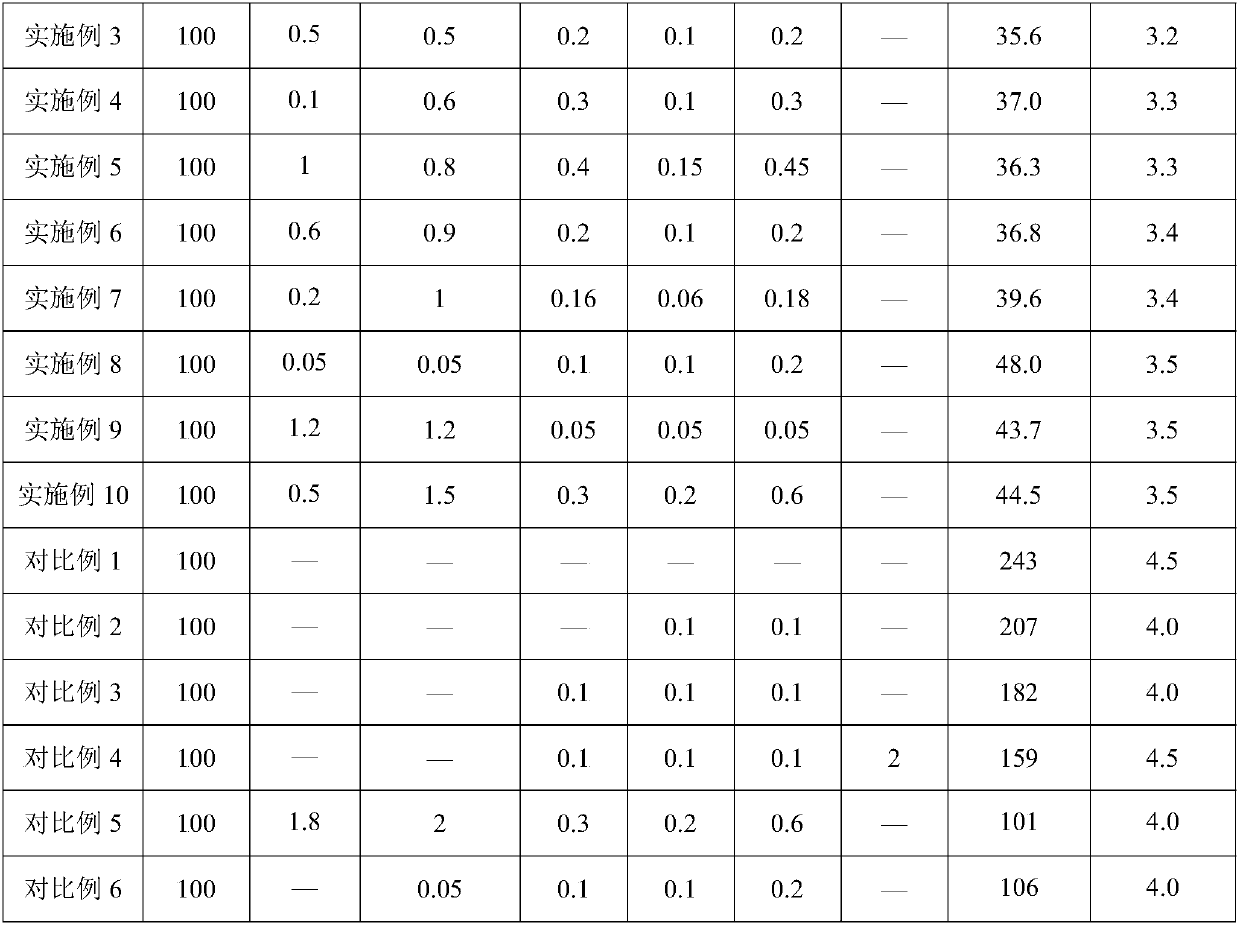

VOC (Volatile Organic Compounds)-inhibited master batch for polypropylene, and preparation method and applications thereof

The invention relates to a VOC (Volatile Organic Compounds)-inhibited master batch for polypropylene, and a preparation method thereof, and a low-VOC polypropylene composition prepared by using the VOC (Volatile Organic Compounds)-inhibited master batch. The VOC-inhibited master batch comprises the following mixed components in parts by weight: on the basis of 100 weight parts of polypropylene, 0.5-25 parts of benzofuranone free radical trapping agent, 1-40 parts of fully-vulcanized powder silicone rubber, wherein the average particle size of rubber particles in the fully-vulcanized powder silicone rubber is 0.05-1 micrometers, and the gel content is 60wt% or above. The VOC-inhibited master batch can be master-batched by melting and mixing through adding the benzofuranone free radical trapping agent and the fully-vulcanized powder silicone rubber, so that the dispersion effect of the benzofuranone free radical trapping agent can be improved, the efficiency for inhibiting VOC can be further improved, the content of total volatile organic compound in the polypropylene can be remarkably reduced, and the problem of residual volatile organic matters in the polypropylene composition can be solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

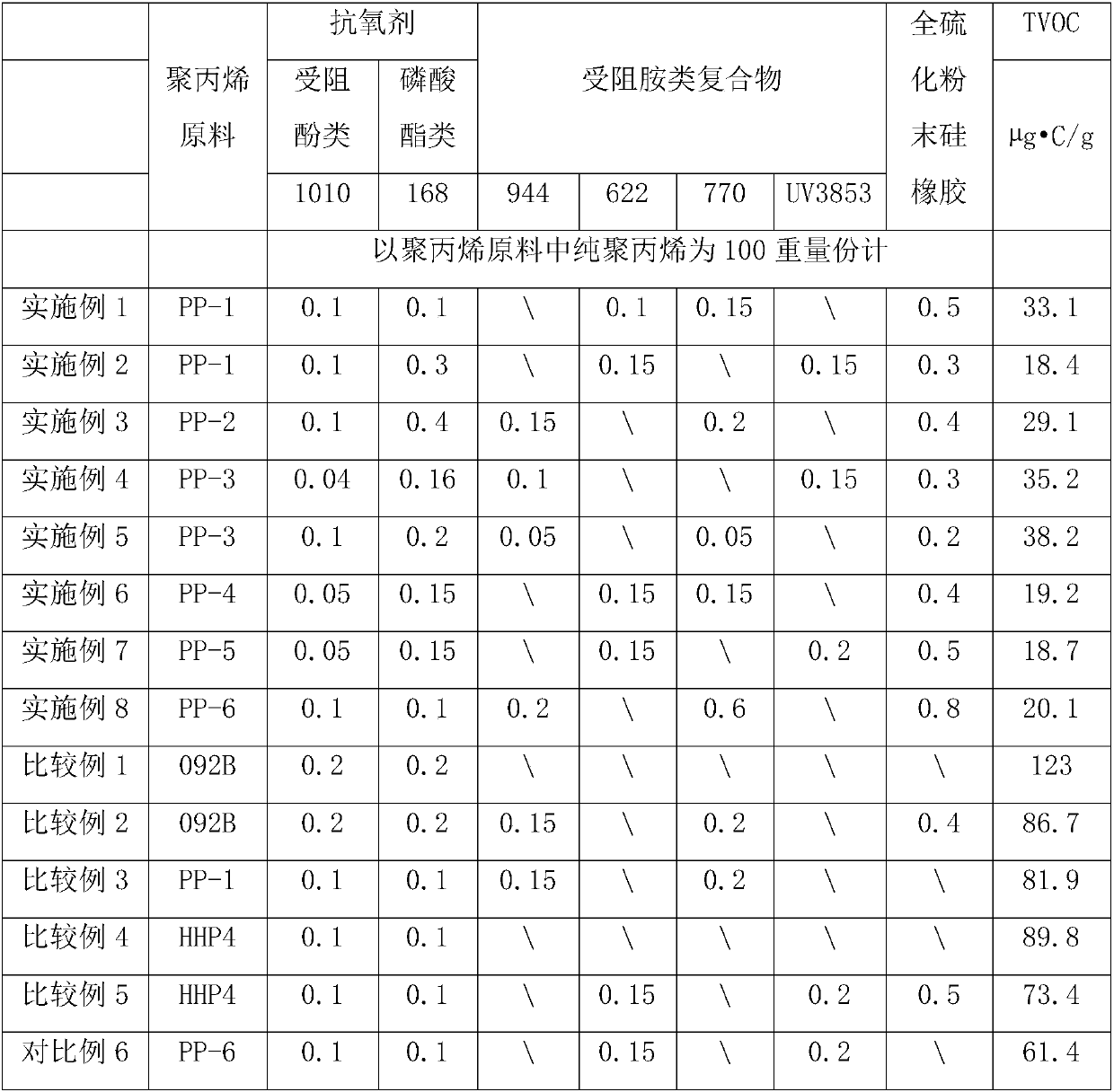

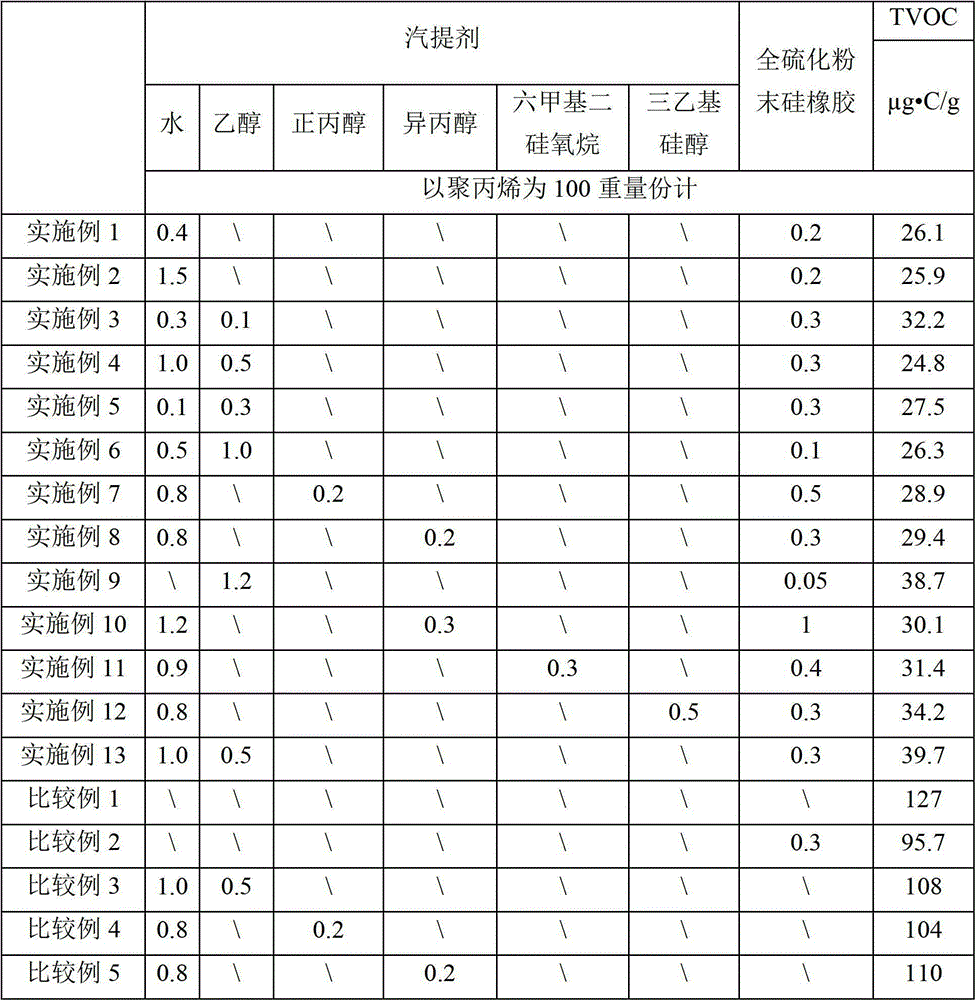

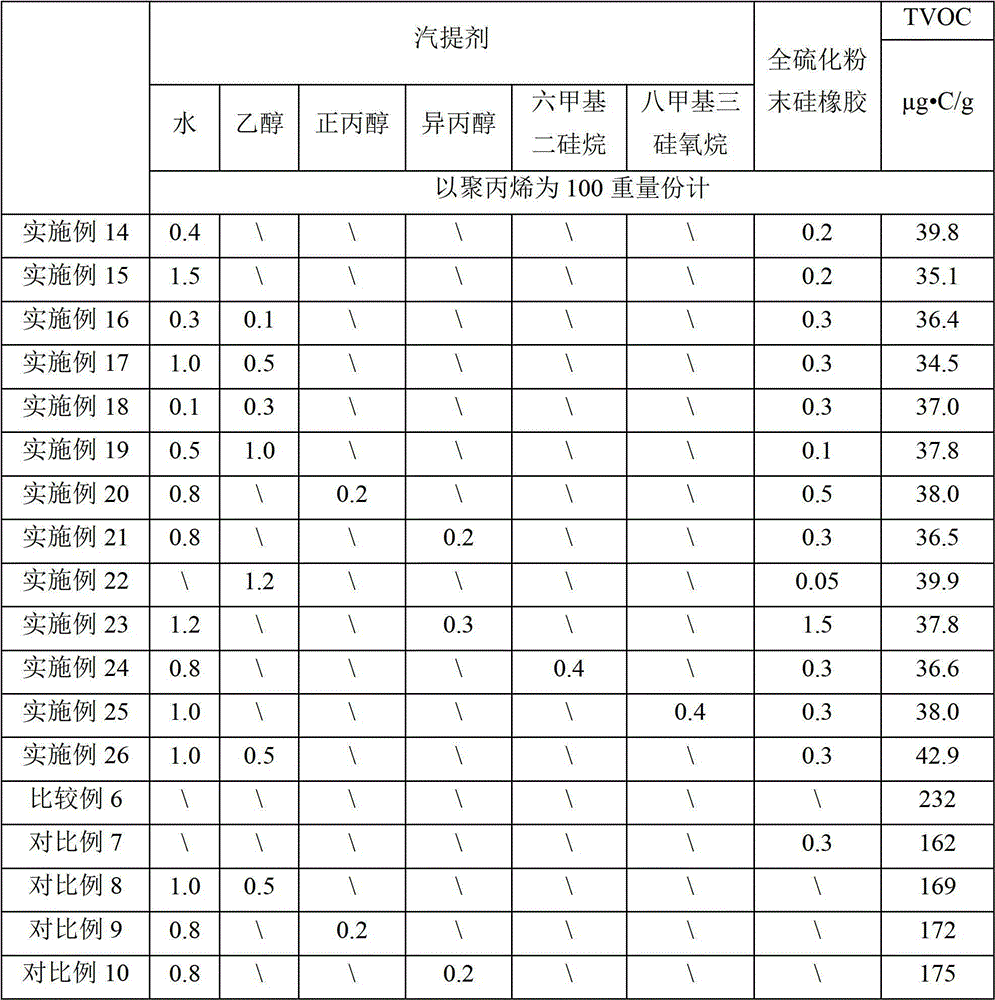

A kind of low VOC polypropylene composition and preparation method thereof

The invention relates to a low-VOC polypropylene composition and a preparation method thereof. The polypropylene composition is obtained through the melt blending of polypropylene, full-vulcanized silicone rubber powder, a striping agent and antioxidant, wherein the weight parts of the full-vulcanized silicone rubber powder, the striping agent and the antioxidant are 0.05-2, 0.2-2.0 and 0.1-0.5 respectively when the weight part of the polypropylene is 100; the average particle size of the full-vulcanized silicone rubber powder is 0.05-1mum, and the gel content of the full-vulcanized silicone rubber powder is 60wt% or more; and the stripping agent is a liquid at normal temperature, and has a boiling point of 70-170DEG C under normal pressure. The addition of the full-vulcanized silicone rubber powder, the compound antioxidant and the stripping agent substantially reduces the content of total volatile organic compounds in polypropylene and solves the residual problem of the volatile organic compounds in the polypropylene composition.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of impact-resistant polypropylene with low VOC content

The invention provides a method for preparing impact-resistant polypropylene with low VOC (Volatile Organic Compounds) content. The method comprises a propylene homopolymerization stage and a propylene copolymerization stage, wherein at the propylene homopolymerization stage, a propylene homopolymerization reaction is carried out in the presence of a Ziegler-Natta catalyst containing a first external electron donor and hydrogen gas so as to obtain a material flow 1 containing a homopolymerized polymer A and the catalyst, and at the propylene copolymerization stage, a propylene and alpha-olefin copolymerization reaction is carried out in the presence of the material flow 1 and a second external electron donor so as to obtain a polypropylene flow 2 containing the homopolymerized polymer A and a copolymerized polymer B; and the first external electron donor is trialkoxysilane, and the second external electron donor dialkoxysilane. According to the method, impact-resistant polypropylene products with narrow molecular-weight distribution, low ultralow-molecular-weight component content, light odor and low VOC content can be produced without special catalysts and great change on the existing processing equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

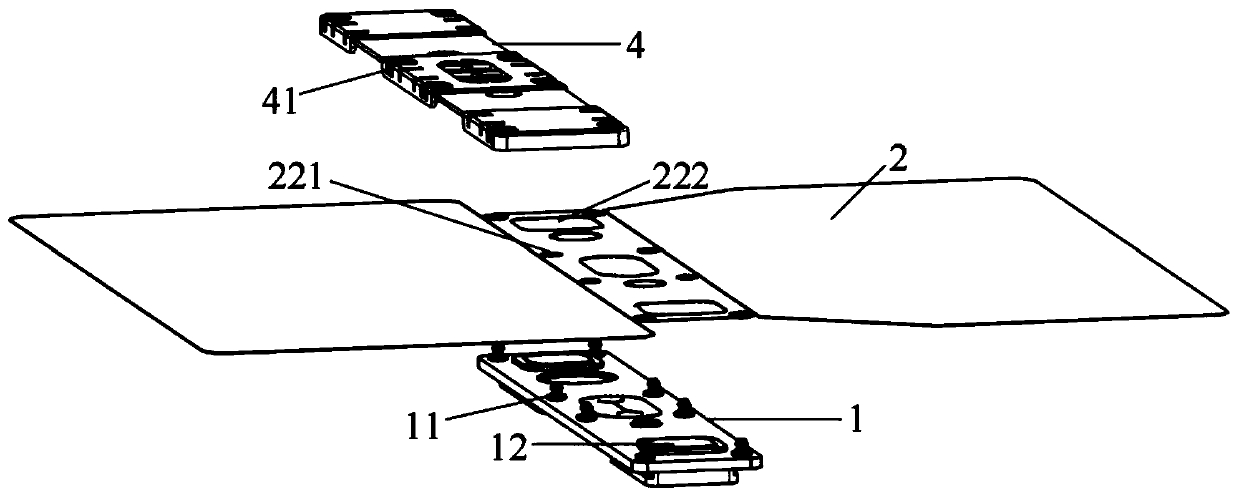

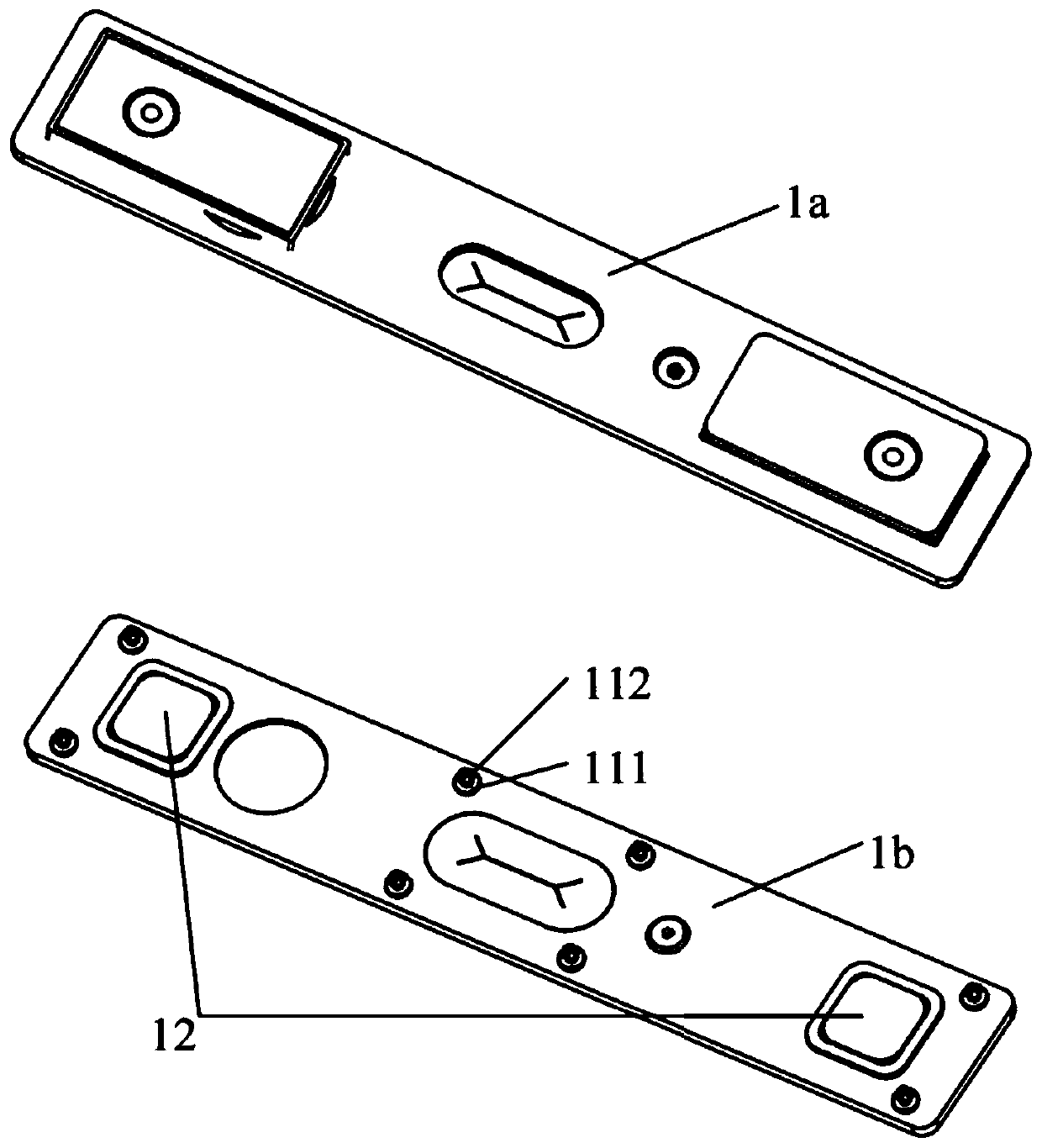

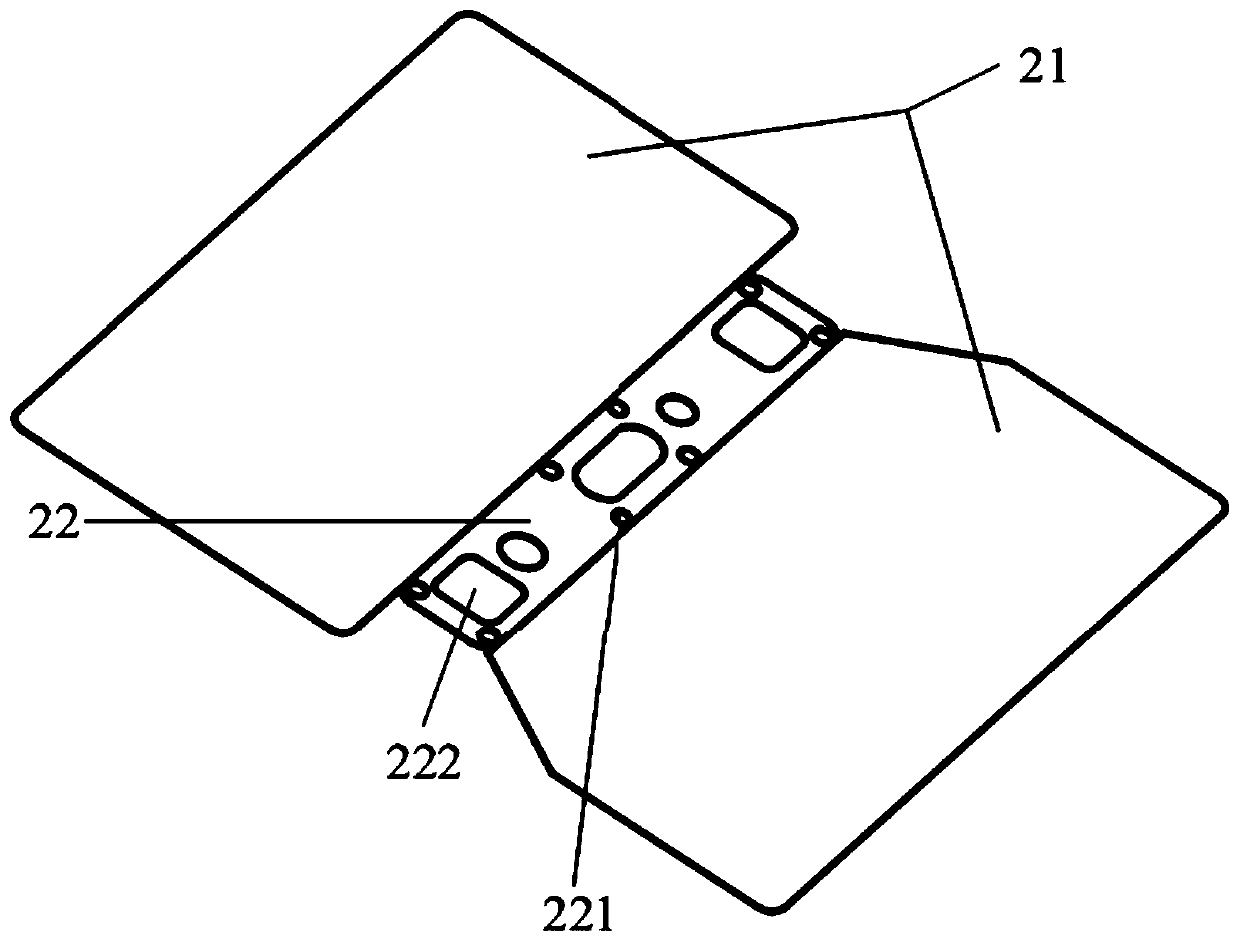

Battery cover plate assembly and assembling method and manufacturing method thereof, and battery core

PendingCN110729422AReduce weightOptimize spaceFinal product manufactureSecondary cellsPower batteryStructural engineering

The invention provides a battery cover plate assembly and an assembling method and a manufacturing method thereof, and a battery core. The battery cover plate assembly comprises a cover plate, an insulating film and a supporting sheet, wherein a plurality of buckle male heads are arranged on the cover plate, the insulating film is provided with a through hole for the buckle male heads to pass through, the supporting sheet is provided with a buckle female head matched with the buckle male head, and the insulating film is assembled between the cover plate and the supporting sheet. By optimizingthe structure of the plastic at a lower part of the cover plate, the internal space of a top cover can be optimized to a great extent, so the upper space of the battery can be saved, the weight of thecover plate assembly is reduced, and the energy density of a lithium ion power battery is improved.

Owner:湖南领湃科技股份有限公司 +4

Low VOC (Volatile Organic Compound) polypropylene composition and preparation method thereof

The invention discloses a low VOC (Volatile Organic Compound) polypropylene composition and a preparation method thereof. The VOC polypropylene composition comprises the following mixed ingredients: 100 parts by weight of polypropylene, 0.03-2 parts by weight of a benzofuran ketone free radical hunting agent and 0.05-10 parts by weight of fully vulcanized powder silicon rubber, wherein the average particle size of the rubber particle of the fully vulcanized powder silicon rubber is 0.05-1mu m; the fully vulcanized powder silicon rubber has a cross-linking structure; and the gel content is 60wt% or higher. According to the VOC polypropylene composition, by using the method that the fully vulcanized powder silicon rubber and the benzofuran ketone free radical hunting agent are added, the VOC content of a low polypropylene composition is greatly reduced, the operation process is simple, and the composition is applicable to the fields of high-class automotive upholsteries, medical and food package materials, and the like with high requirements on environmental-friendliness.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of impact-resistant polypropylene with low odor and low VOC content

ActiveCN105566533BReduce manufacturing costSimple and reliable operation processPolymer sciencePtru catalyst

The invention provides a method for preparing anti-shocking polypropylene with low odor and low VOC content. The method comprises the following steps: in the presence of a Ziegler-natta catalyst containing a first external electron donor, and hydrogen, performing propylene homopolymerization, thereby obtaining a material flow 1 containing a homopolymerization polymer A and the catalyst; in the propylene copolymerization period, performing polymerization reaction on propylene and alpha-olefin in the presence of the material flow 1 and a second external electron donor, thereby obtaining a material flow 2 containing the homopolymerization polymer A and a copolymerization polymer B, wherein the first external electron donor is a 1,3-diether compound; the second external electron donor is alkoxysilane. By adoption of the method, an anti-shocking polypropylene product with narrow molecular weight distribution, ultralow molecular weight component content, low odor and low VOC content can be produced without using a special catalyst or greatly changing a conventional process device.

Owner:CHINA PETROLEUM & CHEM CORP +1

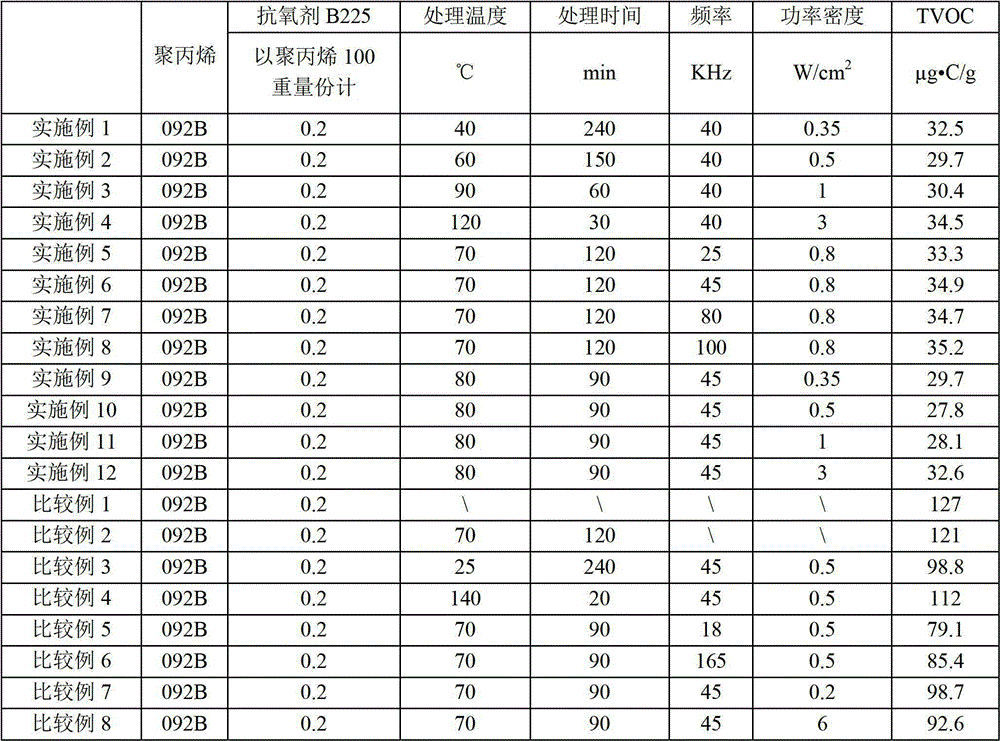

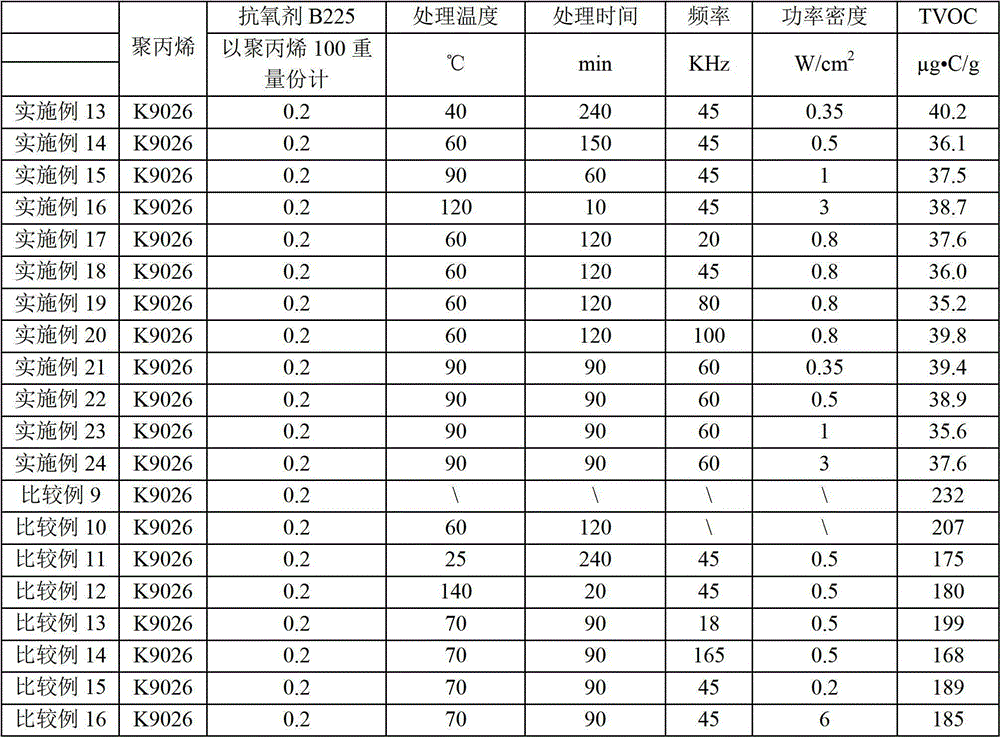

A kind of preparation method of low-voc polypropylene resin

The invention provides a preparation method of a low-VOC polypropylene resin. The preparation method comprises a step that ultrasonic extraction pretreatment of a raw material polypropylene resin is carried out in a water bath at 40-120DEG C, wherein the sound frequency is 20-160KHz, and the sound power density is 0.35-5W / cm<2>. The ultrasonic pretreatment of the polypropylene resin substantially reduces the content of total volatile organic compounds (TVOCs) in a polypropylene material, and makes the TVOCs of the polypropylene resin to be lower than 50mug.C / g, so the residual problem of the VOCs in the polypropylene resin is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-VOC low-odor polypropylene resin composition and preparation method thereof

ActiveCN111087679AImprove thermal stabilityImprove adsorption capacityPolymer scienceModified carbon

The invention relates to the field of plastics, and provides a low-VOC low-odor polypropylene resin composition and a preparation method thereof. The low-VOC low-odor polypropylene resin composition is prepared from the following blended components: polypropylene, a modified carbon nano tube, octaisobutyl silsesquioxane, an acid acceptor and an antioxidant, wherein relative to 100 parts by weightof polypropylene, the modified carbon nano tube accounts for 0.04 to 1.6 parts by weight, the octaisobutyl silsesquioxane accounts for 0.04 to 1.8 parts by weight, the acid acceptor accounts for 0.05to 1 part by weight, and the antioxidant accounts for 0.05 to 1 part by weight; and the modified carbon nano tube is a multi-walled carbon nano tube coated with divinyl benzene. The polypropylene composition has a low VOC (volatile organic compound) content and smell, the total VOC content can be lower than 50 [mu]g.C / g, and the smell can reach 3.5 grade or below.

Owner:CHINA PETROLEUM & CHEM CORP +1

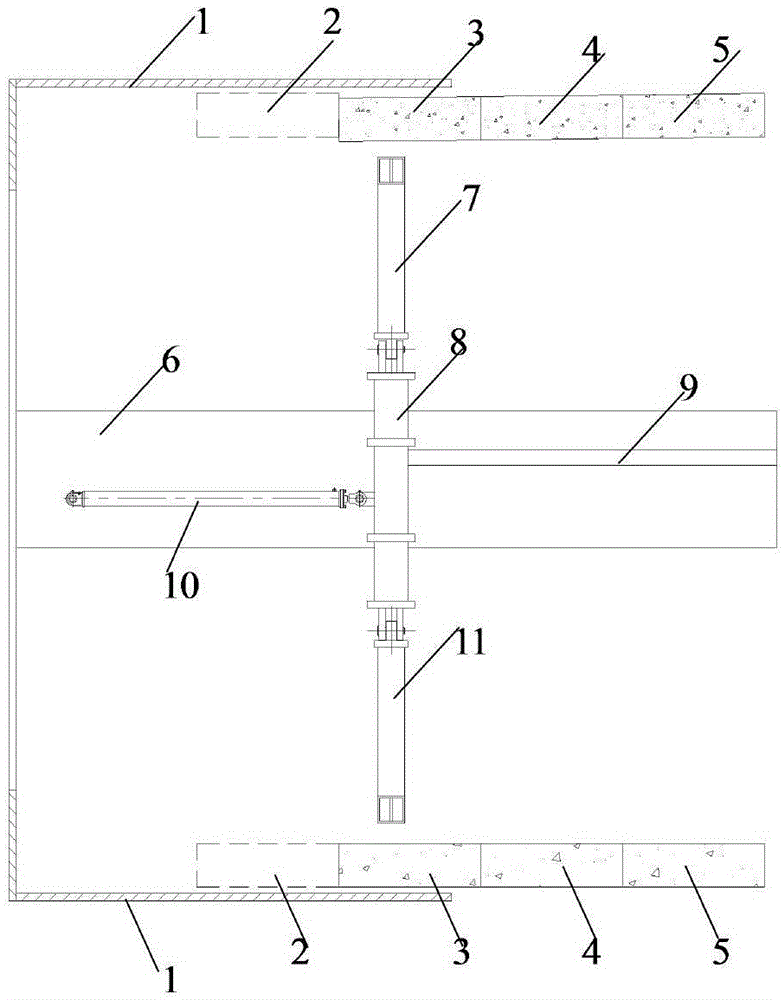

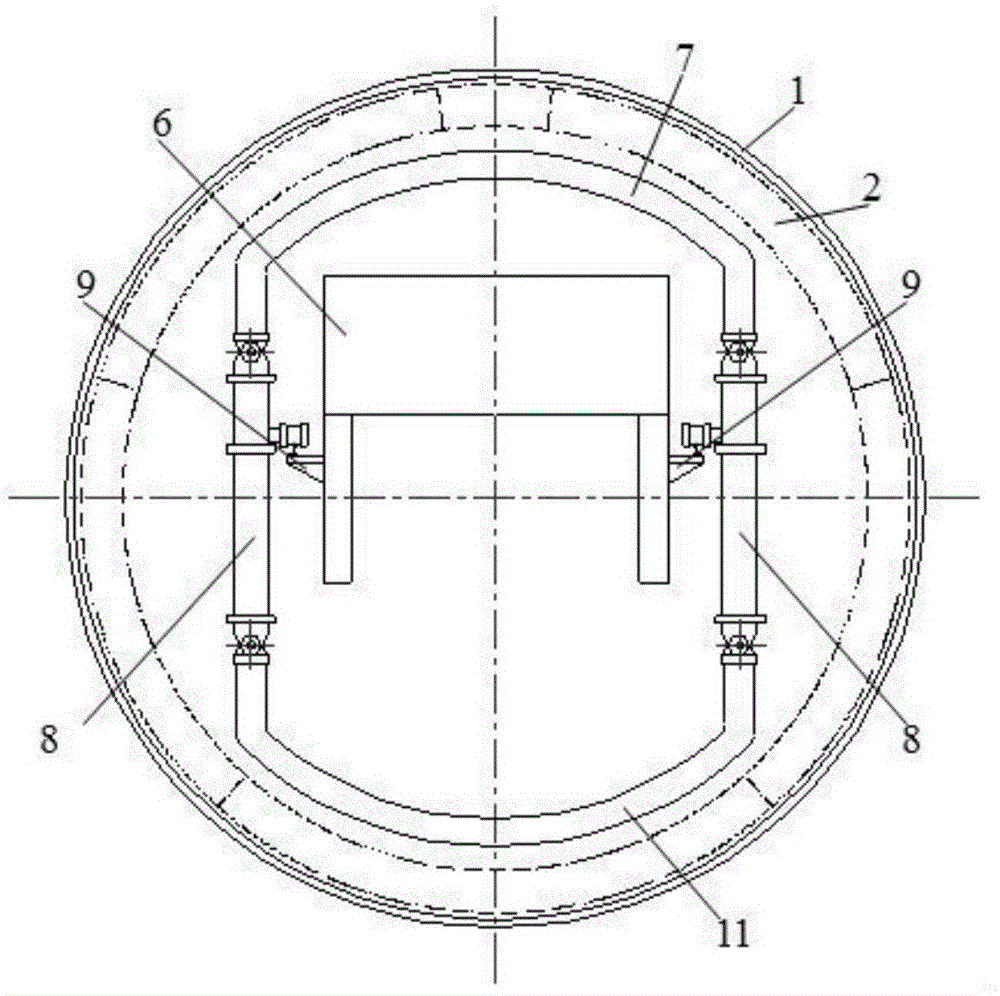

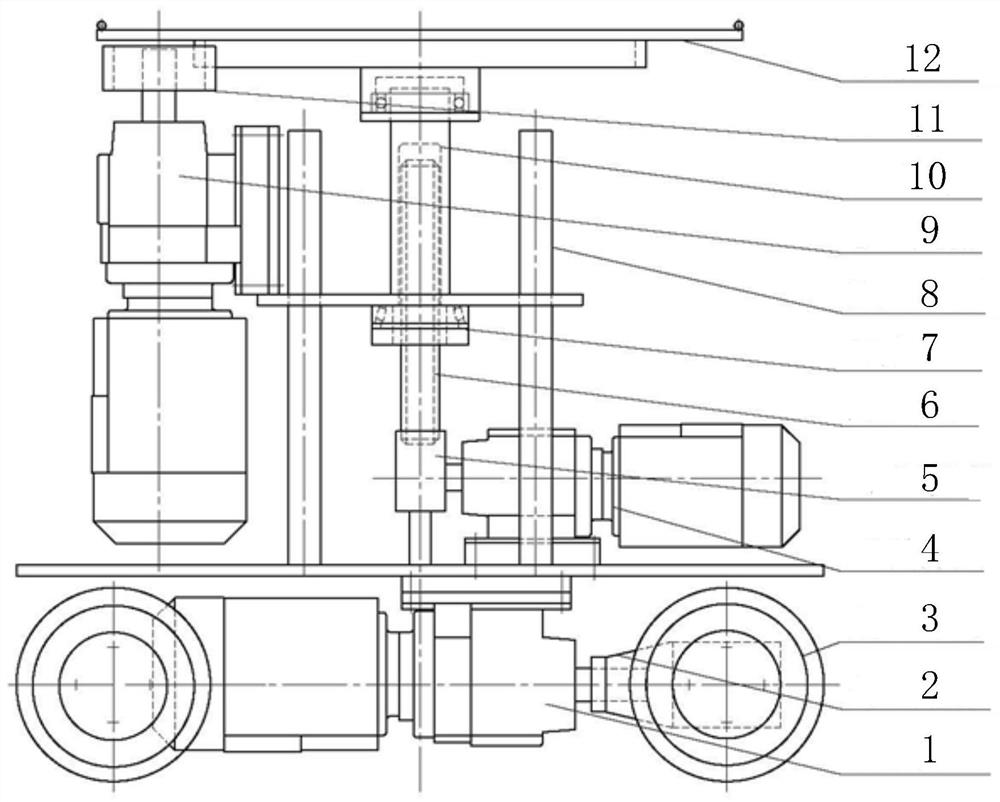

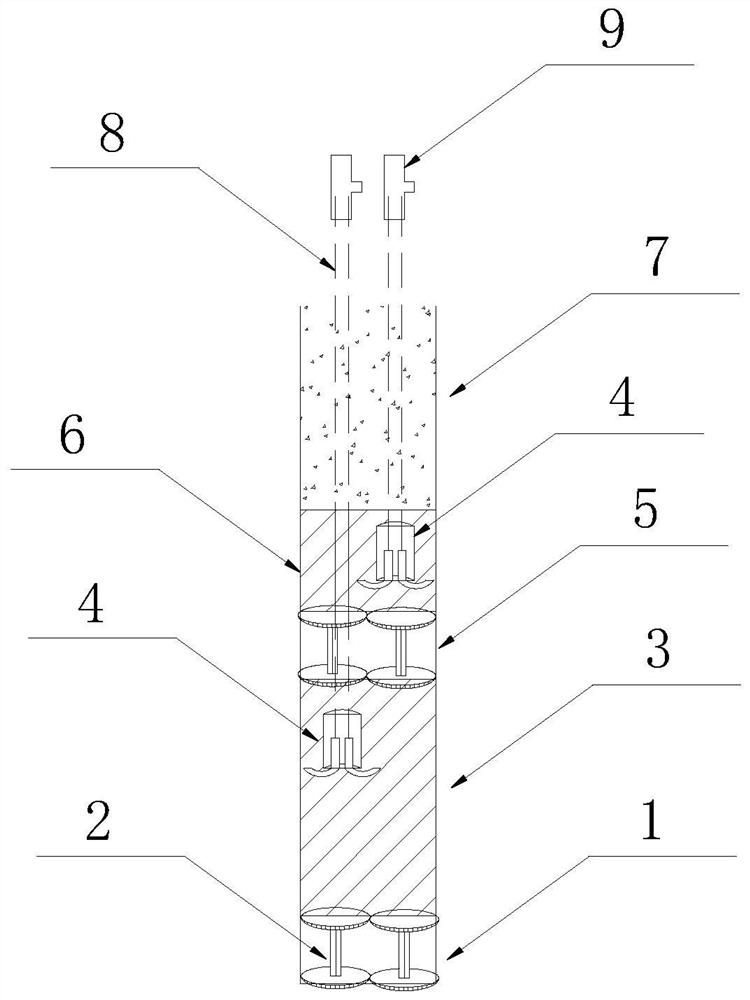

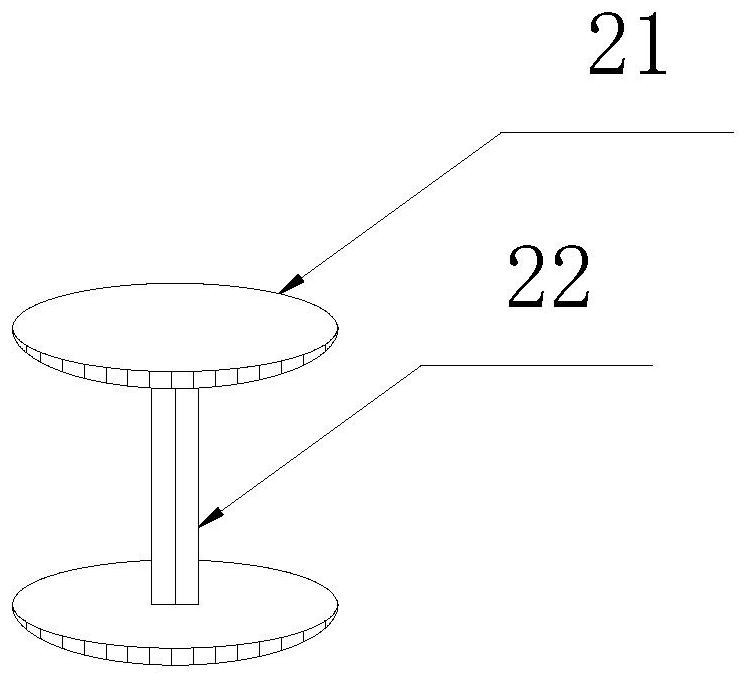

Rectangular shield tunnel lining-shaped rectification device and rectification method

InactiveCN105134246ASimple and reliable operation processEnsure construction safetyUnderground chambersTunnel liningBuilding construction

The invention provides a rectangular shield tunnel lining-shaped rectification device and a rectification method. An upper beam and a lower beam are driven by a top supporting device to extend along a vertical direction, so a multi-ring lining ring is pressed against; the shape of the multi-ring lining ring can be maintained and rectified; a problem of difficulty in assembling for post-pipe sheets due to bearing deformation of the tunnel lining can be effectively solved; the rectification device can be simply and reliably operated; top supporting action points of the upper beam and the lower beam are formed on a seam crossing part of two lining rings; and damage to the lining can be avoided and construction safety can be guaranteed.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Low-odor impact-resistant scratch-resistant polypropylene composition and preparation method thereof

The invention relates to a low-odor impact-resistant scratch-resistant polypropylene composition and a preparation method thereof, belonging to the field of plastics. The low-odor, impact-resistant and scratch-resistant polypropylene composition can comprise the following blended components in parts by weight: polypropylene, hydrophobic fumed silica, a polypropylene graft polymer and octaisobutyl silsesquioxane, the material comprises the following components in parts by weight: 100 parts of polypropylene, 0.5-18 parts of hydrophobic fumed silica, 0.5-24 parts of polypropylene graft polymer and 0.02-2 parts of octaisobutyl silsesquioxane. The odor of the polypropylene resin composition disclosed by the invention can be remarkably reduced, the odor can reach 3.5 grade or below, the scratch resistance is greatly improved, the rigidity is improved while the impact property is improved, the defects in the prior art are well overcome, and the polypropylene resin composition is simple and reliable in operation process, relatively low in investment cost and suitable for the field of pipes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-VOC-content polypropylene resin and preparation method thereof

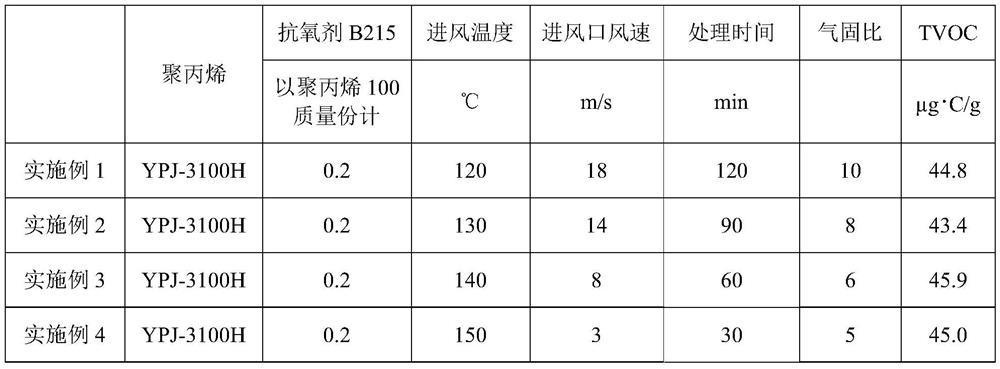

The invention belongs to the field of polypropylene resin, and relates to low-VOC-content polypropylene resin and a preparation method thereof. The method comprises the following steps that polypropylene is pretreated through a fluidized drying bed, then the treated polypropylene is dried in a vacuum oven, then the dried polypropylene and a processing aid are blended, extruded and granulated, and the pretreatment conditions of the fluidized drying bed include the conditions that the air inlet temperature is 80-150 DEG C, the air speed of an air inlet is 1-25 m / s, the gas-solid ratio is larger than or equal to 3, and the pretreatment time is 30-120 min. According to the low-VOC-content polypropylene resin and the preparation method thereof, the polypropylene is treated by adopting the fluidized drying bed, the content of total volatile organic compounds in a polypropylene material is remarkably reduced, and the problem of residues of volatile organic compounds in the polypropylene resin is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

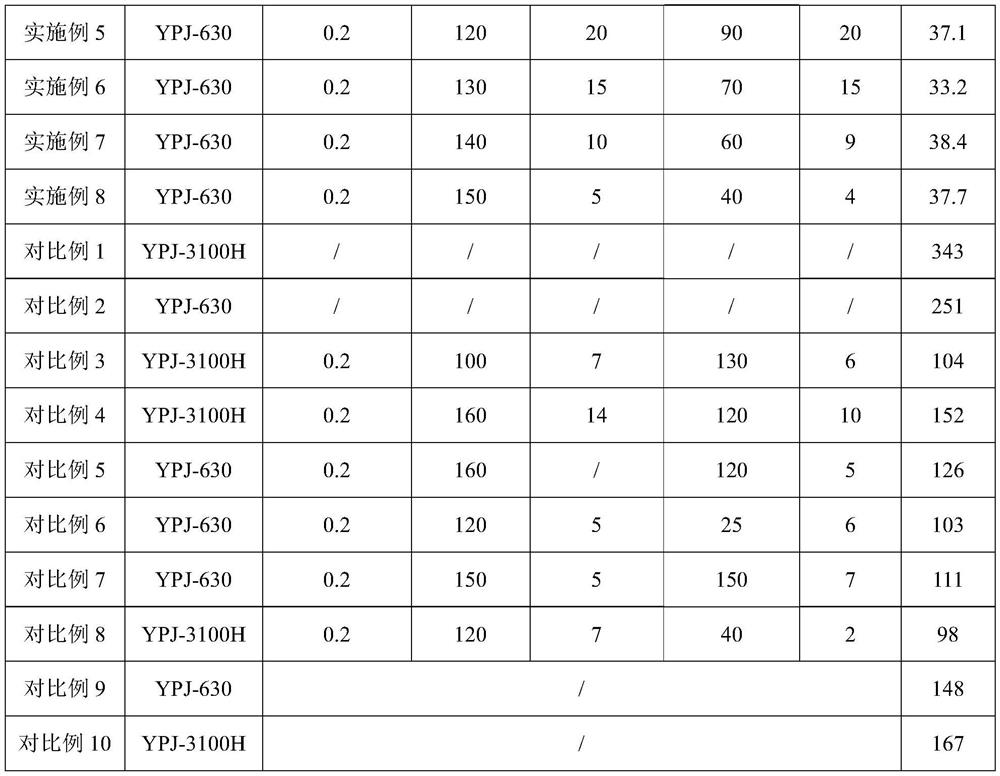

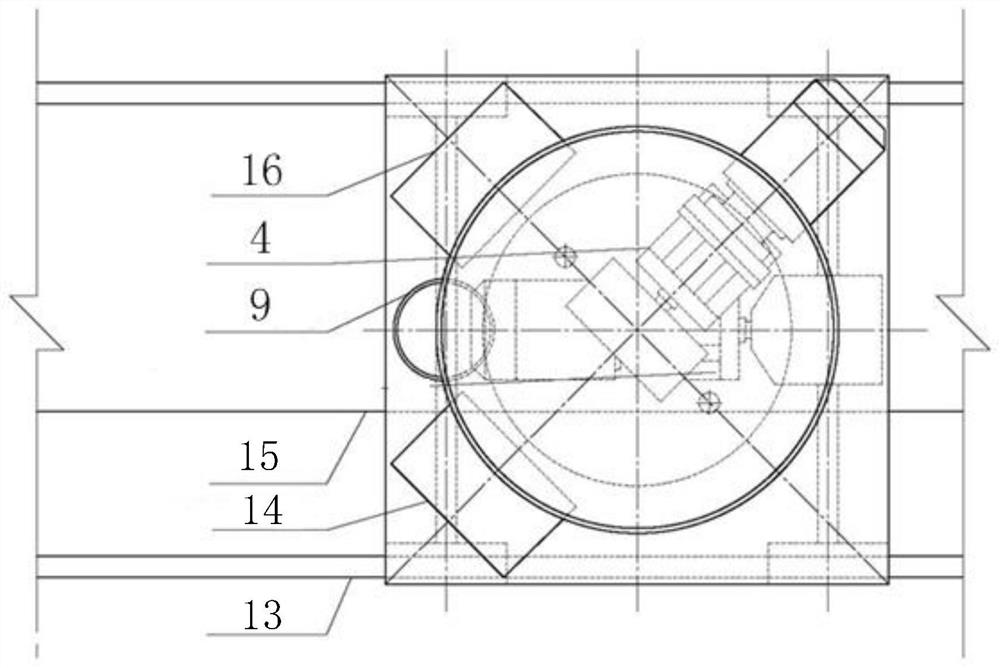

Cement solidification system and method for radioactive waste treatment and application

InactiveCN111613359ALow investment costLower Disposal CostsRadioactive decontaminationWireless controlControl system

The invention discloses a cement solidification system and method for radioactive waste treatment and application. The system comprises a three-axis rail car, a rail, a scale detection system and a wireless control system. The three-axis rail car comprises a horizontal moving system, a vertical lifting system and a rotating system, the horizontal moving system, the vertical lifting system and therotating system respectively comprise a motion speed reducer, a lifting speed reducer or a rotating speed reducer, and the three-axis rail car is controlled by the wireless control system to move on arail and realize lifting and rotating. The scale detection system is used for detecting the position of the three-axis rail car on the rail in real time. The wireless control system is used for receiving the position information, detected by the scale detection system, of the three-axis rail car and judging whether the motion speed reducer or the lifting speed reducer or the rotating speed reducer is started or not according to the detected position information. According to the invention, the problems of high equipment cost, complexity and poor applicability caused by adoption of a cement solidification line in treatment of radioactive wastes in the prior art are solved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

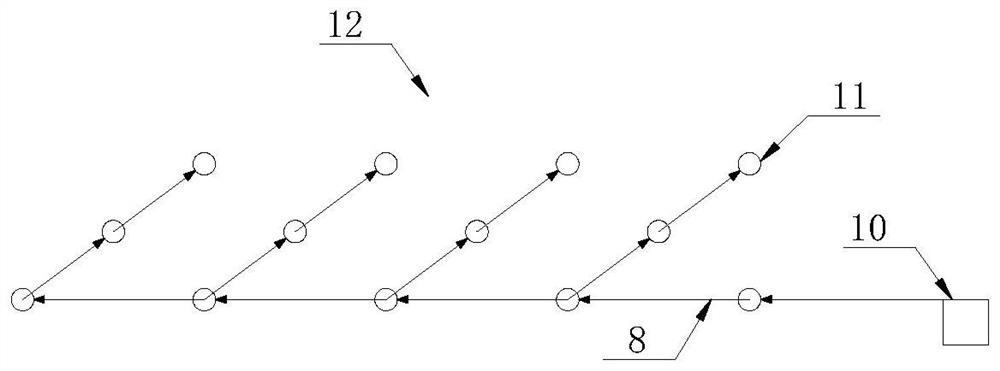

Deep hole blasting vibration reduction method

The invention discloses a deep hole blasting vibration reduction method, which belongs to the technical field of deep hole blasting, and comprises the following steps of: respectively arranging a hole bottom support interval section, a lower explosive filling section, an inter-hole support interval section, an inter-hole explosive filling section and a rock powder filling section in each blast hole from bottom to top according to a distance, and charging the two explosive filling sections in sections; meanwhile, a water interval or an air interval is formed in the two interval sections through the supporting frame, then segmented blasting is carried out, the explosive use amount and the maximum section explosive amount are reduced, then blasting vibration is reduced, the blasting effect is improved, no bottom root exists after blasting, the blasting cost is reduced, the mine economic benefits are improved, and practicability is high.

Owner:ANHUI MASTEEL MINING RESOURCES GRP NANSHAN MINING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com