Polypropylene/cellulose intercalation nanocrystal composition and preparation method thereof

A technology of polypropylene cellulose and nanocrystals, which is applied in the field of polypropylene compositions, can solve problems such as poor compatibility and low thermal degradation temperature of CNCs, and achieve improved dispersion, improved interface compatibility, and high thermal degradation temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

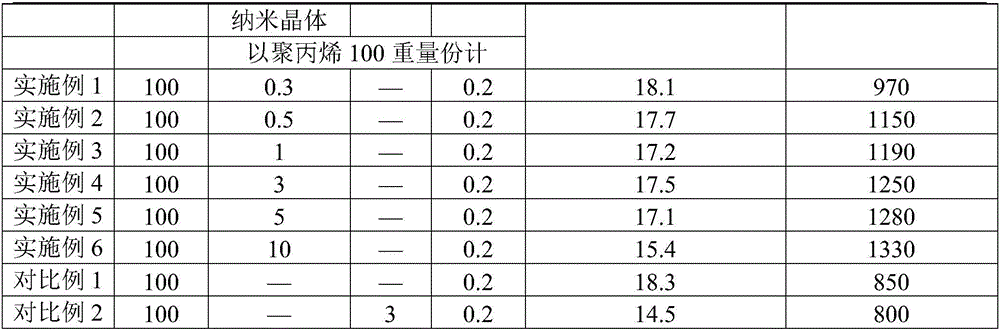

Embodiment 1

[0053] The cellulose intercalation nanocrystals (average length 80nm, average width 4nm, average height 70nm, the substitution degree of long-chain alkane substituted CNCs hydroxyl functional group is 67%, the thermal degradation initiation temperature (N 2 Atmosphere) is 240°C, sulfur content is 0, Chinese Academy of Forestry Wood Industry Research Institute) and the antioxidant (antioxidant 1010, belongs to hindered phenolic antioxidant, the chemical name is four [β-( 3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, and antioxidant 168, which belong to phosphate antioxidants, the chemical name is tris(2,4-di-tert-butylphenol) Phosphite, the weight ratio of antioxidant 1010 and antioxidant 168 is 1:2, and both are fully mixed to obtain described premix from Germany BASF company); Propylene (K9026, Sinopec Beijing Yanshan Branch) was put into a high-speed mixer, and stirred at a speed of 300 rpm for 3 minutes to fully mix the components; The BUSS mixing u...

Embodiment 2

[0062] The cellulose intercalation nanocrystals (average length 200nm, average width 6nm, average height 50nm, the degree of substitution of long-chain alkane substituted CNCs hydroxyl functional groups is 45%, and the thermal degradation initiation temperature (N 2 Atmosphere) is 220°C, sulfur content is 0, Wood Industry Research Institute of Chinese Academy of Forestry Sciences) and the antioxidant (antioxidant 1010, belongs to hindered phenolic antioxidant, the chemical name is four [β-( 3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, and antioxidant 168, which belong to phosphate antioxidants, the chemical name is tris(2,4-di-tert-butylphenol) Phosphite, the weight ratio of antioxidant 1010 and antioxidant 168 is 1:2, and both are fully mixed to obtain described premix from Germany BASF company); Propylene (K9026, Sinopec Beijing Yanshan Branch) was put into a high-speed mixer, and stirred at a speed of 300 rpm for 3 minutes to fully mix the component...

Embodiment 3

[0071] The cellulose intercalation nanocrystal (average length 50nm, average width 4nm, average height 80nm, the degree of substitution of long-chain alkane substituted CNCs hydroxyl functional group is 67%, the thermal degradation initiation temperature (N 2 Atmosphere) is 260 ℃, sulfur content is 0, Wood Industry Research Institute of Chinese Academy of Forestry Sciences) and the antioxidant (antioxidant 1010, belongs to hindered phenolic antioxidant, the chemical name is four [β-( 3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, and antioxidant 168, which belong to phosphate antioxidants, the chemical name is tris(2,4-di-tert-butylphenol) Phosphite, the weight ratio of antioxidant 1010 and antioxidant 168 is 1:2, and both are fully mixed to obtain described premix from Germany BASF company); Propylene (K9026, Sinopec Beijing Yanshan Branch) was put into a high-speed mixer, and stirred at a speed of 300 rpm for 3 minutes to fully mix the components; The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com