PA (polyamide)/ABS (Acrylonitrile Butadiene Styrene) composite material and preparation method thereof

A composite material and polyamide technology, applied in the field of ultra-high toughness PA/ABS composite material and its preparation, can solve the problems of low melt viscosity, large difference in solubility parameters, poor compatibility, etc., and achieve simple and reliable operation process , low cost, and the effect of improving impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

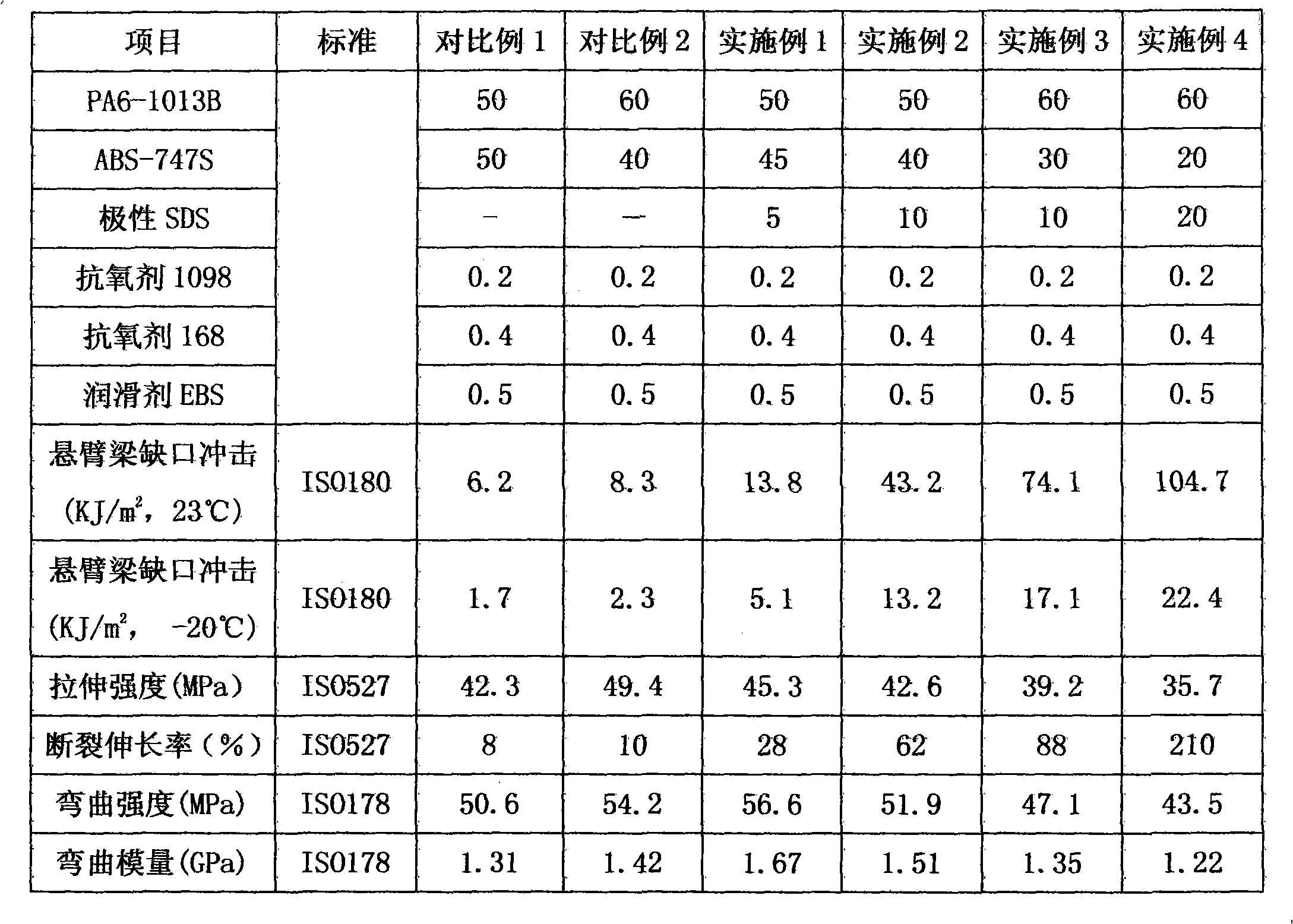

[0025] Polycaprolactam (PA6-1013B, Japan UBE Company, dried at 100°C for 6 hours), ABS (ABS-747S, Taiwan Chimei Company, dried at 90°C for 4 hours), polarized SDS (SDS, Baling Petrochemical Co., Ltd. , its number-average molecular weight is 84,300, polar block weight content 3.0%), antioxidant (1098 and 168, Swiss CIBA company), lubricant (EBS, Shanghai), put into low-speed mixer and stir evenly, make each The ingredients are thoroughly mixed evenly. Then the above mixed material was extruded and granulated in a BUSS kneading unit (MKD-30, Swiss BUSS company) at a temperature of 220° C. to 240° C. The extruded pellets were dried in a constant temperature oven at 95°C for 6 hours, and then injected into standard specimens at a temperature of 230°C to 250°C for various mechanical property tests. The content of each component is calculated in parts by weight. The test standards and mechanical performance results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com