Modified cellulose nanometer crystal, high-strength hydrogel material, preparation method and application

A technology of nanocrystals and cellulose, which is applied in the field of preparation of high-strength hydrogel materials, modified cellulose nanocrystals, and can solve the problems of uneven polymerization, long processing cycle, low conversion rate, etc., to improve mechanical properties, process The effect of short cycle time and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

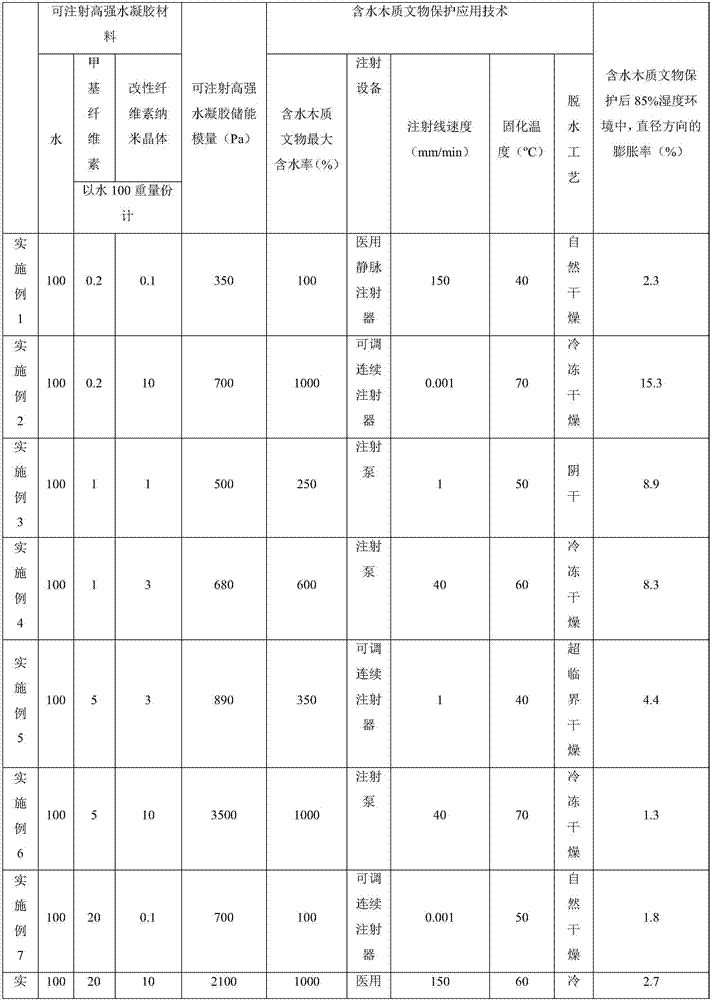

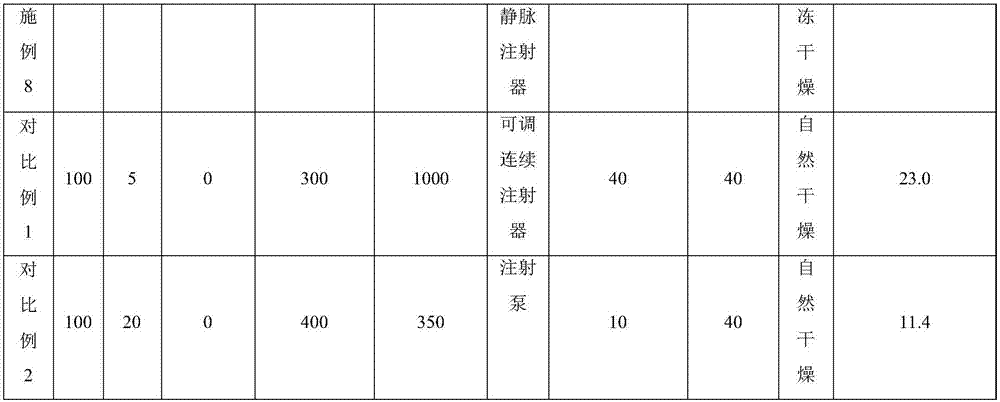

Examples

Embodiment 1

[0088] raw material:

[0089] Methylcellulose: molecular weight 40000, methoxy substitution degree 35%, Sinopharm Chemical Reagent Co., Ltd.;

[0090] Modified cellulose nanocrystals: crystallinity 99%, average length 50nm, average width 3nm, average height 3nm, surface charge density 0.10e / nm 2 , degree of methylcellulose substitution, 0.002 hydroxyl groups per glucose unit are substituted, Institute of Wood Industry, Chinese Academy of Forestry;

[0091] water.

[0092] Mix the above-mentioned methyl cellulose and modified cellulose nanocrystals with water, stir at room temperature, inject the mixed aqueous solution along the longitudinal direction of the water-containing wooden cultural relics by injection, regulate the storage temperature of the water-containing wooden cultural relics, and keep it for 0.5 hours to achieve The solution-gel phase transition of the injectable high-strength hydrogel material completes the osmotic reinforcement of the injectable high-strength h...

Embodiment 2

[0097] raw material:

[0098] Methylcellulose: molecular weight 180000, methoxy substitution degree 25%, Sinopharm Chemical Reagent Co., Ltd.;

[0099] Modified cellulose nanocrystals: crystallinity 80%, average length 1000nm, average width 60nm, average height 10nm, surface charge density 0.02e / nm 2 , degree of substitution of methyl cellulose, 0.1 hydroxyl groups per glucose unit are substituted, Institute of Wood Industry, Chinese Academy of Forestry;

[0100] water.

[0101] Mix the above methyl cellulose, modified cellulose nano crystals and water, stir at room temperature, and inject the solution along the longitudinal direction of the water-containing wooden cultural relics by means of injection. Regulate the storage temperature of the water-containing wooden cultural relics and keep it for 10 hours to realize the solution-gel phase transition of the injectable high-strength hydrogel material, and complete the osmotic reinforcement of the injectable high-strength hydr...

Embodiment 3

[0106] raw material:

[0107] Methyl cellulose: molecular weight 180,000, methoxy substitution degree 35%, Sinopharm Chemical Reagent Co., Ltd.;

[0108] Modified cellulose nanocrystals: crystallinity 90%, average length 500nm, average width 50nm, average height 10nm, surface charge density 0.05e / nm 2 , degree of methylcellulose substitution, 0.05 hydroxyl groups per glucose unit are substituted, Institute of Wood Industry, Chinese Academy of Forestry;

[0109] water.

[0110] Mix the above methyl cellulose, modified cellulose nano crystals and water, stir at room temperature, and inject the solution along the longitudinal direction of the water-containing wooden cultural relics by means of injection. Regulate the storage temperature of the water-containing wooden cultural relics and keep it for 3 hours to realize the solution-gel phase transition of the injectable high-strength hydrogel material, complete the osmotic reinforcement of the injectable high-strength hydrogel of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com