Low-VOC low-odor polypropylene resin composition and preparation method thereof

A polypropylene resin, low-odor technology, applied in the preparation of polypropylene resin composition, low-VOC low-odor polypropylene resin composition field, can solve the problems of adsorption balance, limited effect, complex components, etc., to achieve slow release , improve the equilibrium distribution coefficient, and the effect of efficient adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

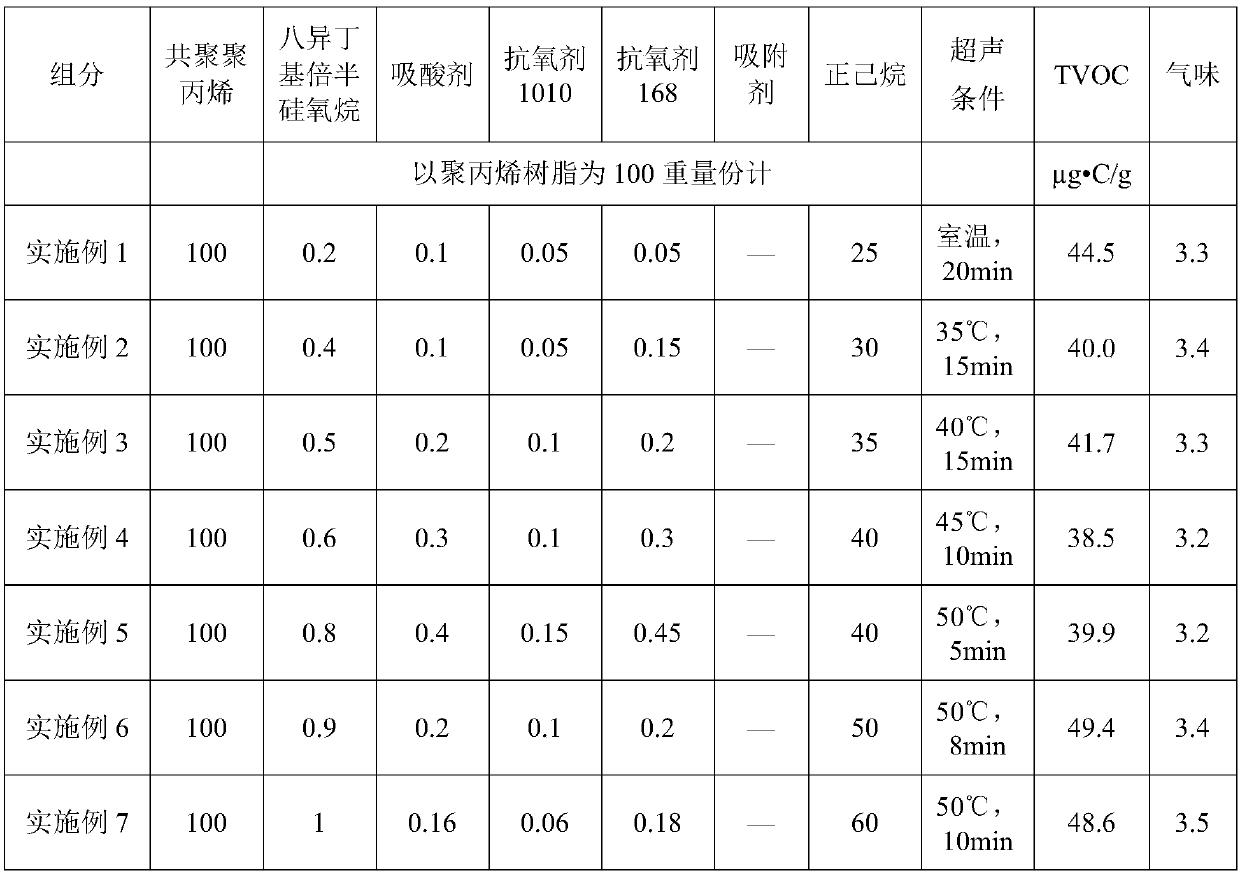

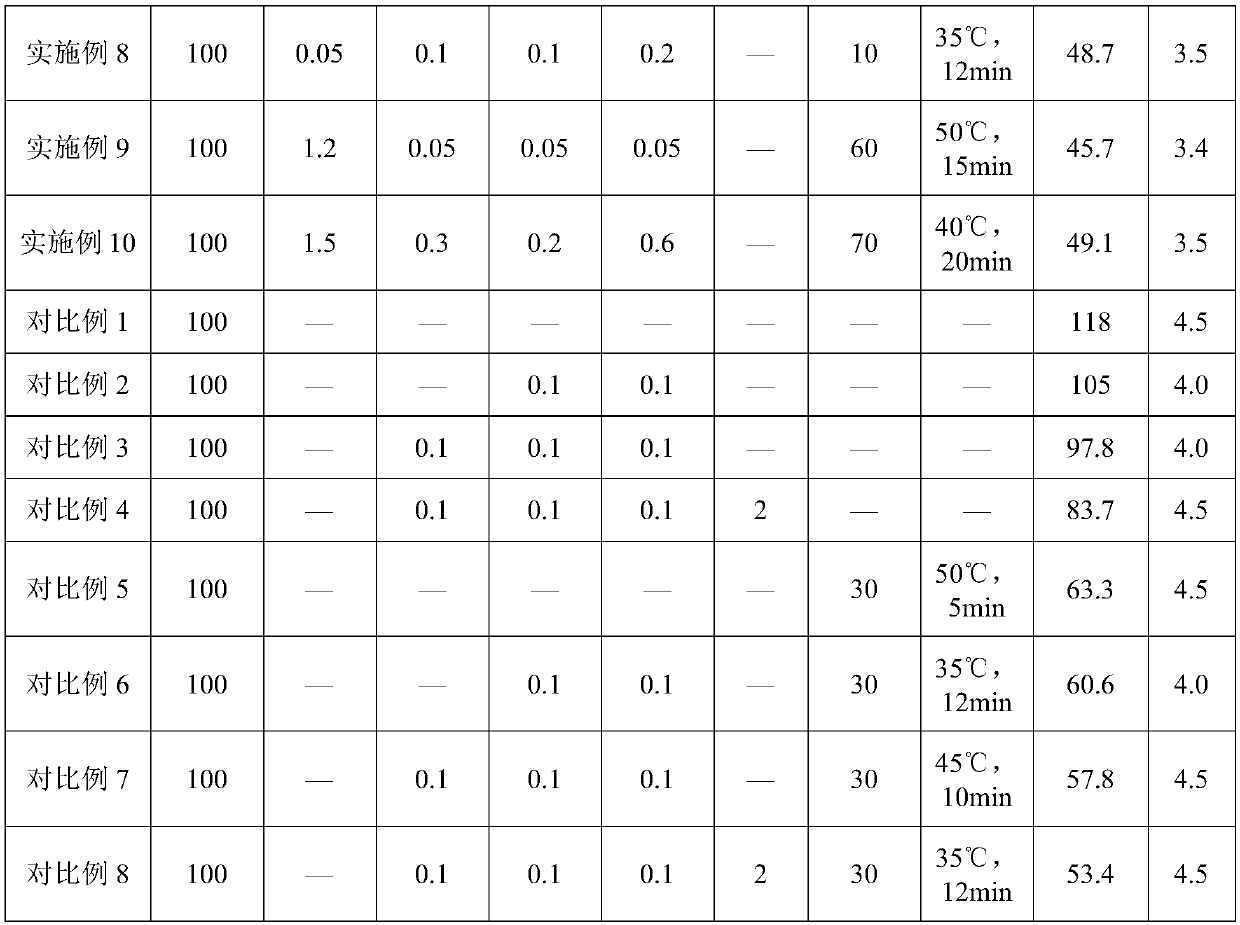

[0045] Examples 1-10 are used to illustrate the low-VOC and low-odor polypropylene resin composition of the present invention and its preparation method.

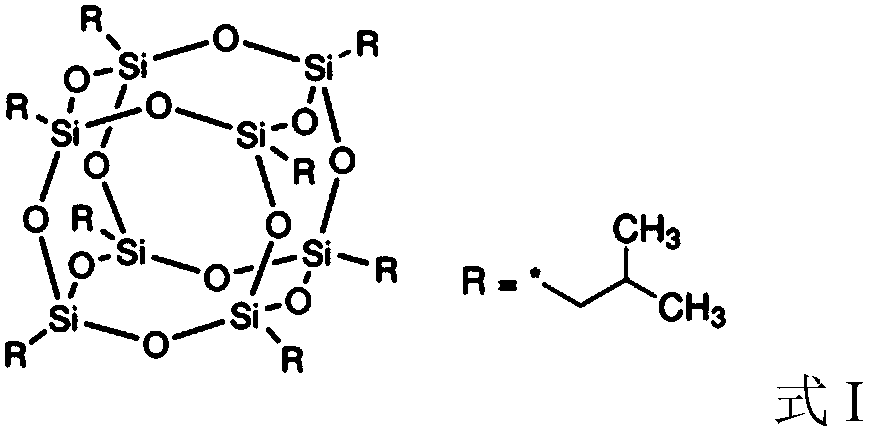

[0046] The octaisobutylsilsesquioxane (MS0825, American Hybridplastic Company) was dissolved in n-hexane (Beijing Sinopharm) to obtain an n-hexane solution of octaisobutylsilsesquioxane. Mix the obtained solution and polypropylene powder (HHP4 powder, Sinopec Maoming Branch) at room temperature to 50°C under the action of ultrasonic waves for 5-20 minutes, and then place the obtained polypropylene powder in a vacuum drying oven to dry until constant weight . The acid absorbing agent (calcium stearate, Tianjin Gangchang Chemical Co., Ltd.) and antioxidant (antioxidant 1010, belonging to hindered phenolic antioxidant, chemical name tetrakis [β-(3,5- Di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, and antioxidant 168, belong to phosphate antioxidants, the chemical name is three (2,4-di-tert-butylphenol) phos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com