Low VOC polypropylene composite material for vehicle and preparation method thereof

A composite material and polypropylene technology, which is applied in the field of low-VOC polypropylene composite materials and its preparation, can solve the problems of volatilization of volatile organic compounds and limited effect, and achieve the effect of reducing VOC, low input cost, and simple and reliable operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

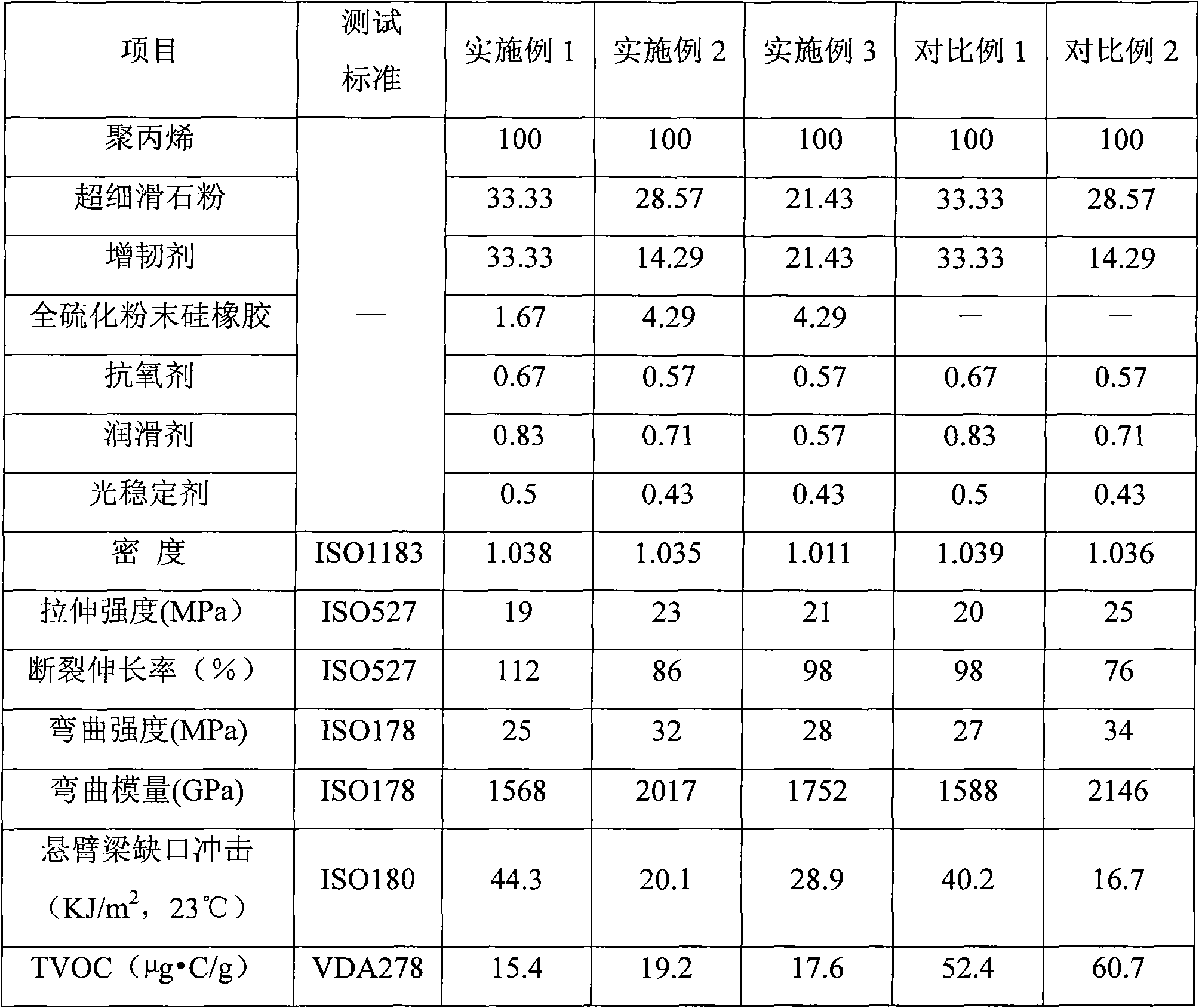

Examples

Embodiment 1~3

[0024] Polypropylene (K9020, Beijing Yanhua Petrochemical Co., Ltd.), superfine talcum powder (average particle diameter 6.5 μm, Liaoning Haicheng Powder Material Co., Ltd.), toughening agent [the toughening agent used in embodiment 1 is ethylene -octene copolymer (POE, U.S. DUPONT company), the toughening agent used in embodiment 2 and 3 is EPDM (EPDM, Japan JSR company)], fully vulcanized powder silicone rubber (VP-602, average particle diameter 0.1μm, gel content 90wt%; Beijing Research Institute of Chemical Industry), antioxidant (Irganox 1010 and Irgafos 168 compounded at a weight ratio of 1:1), lubricant (calcium stearate), light stabilizer (UV3853 ) into a high-speed mixer, and stirred at a speed of 300 rpm for 3 minutes to fully mix the components evenly. Subsequently, the above-mentioned mixed materials were extruded and granulated under the condition of maintaining a vacuum degree of -0.09MPa through the BUSS mixing unit (MKD-30, Swiss BUSS company) in the range of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com