VOC (Volatile Organic Compounds)-inhibited master batch for polypropylene, and preparation method and applications thereof

A polypropylene and masterbatch technology, applied in the field of plastics, can solve problems such as compatibility and persistence, and achieve the effect of delaying release, preventing emission and improving dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of cellulose nanocrystals is as follows: according to GB / T2677.6-1994, GB / T2677.8-1994, GB / T2677.10-1995, sequentially remove the extract, lignin and hemicellulose in the wood, Cellulose samples were obtained by freeze-drying, and then cellulose nanocrystals were prepared according to the method reported by Gray D.G. (Biomacromolecules. 2005, 6(2):1048-1054.).

[0046] The specific steps include: 1. Wood pulp is ground into 40-mesh cellulose powder by a grinder; 2. The cellulose powder is added to 64 wt% sulfuric acid aqueous solution at a sulfuric acid / cellulose feeding ratio of 15 mL / g, and reacted for 30 minutes under stirring at 45°C. 3. Pour 10 times the volume of deionized water into the reaction solution to terminate the hydrolysis reaction. 4. Centrifuge the solution in the previous step (centrifugation speed is 10000rpm / min, centrifugation time is 15min), pour the upper layer solution to remove sulfuric acid molecules, and repeat this ste...

Embodiment 1~11

[0056] Preparation of low VOC polypropylene composition:

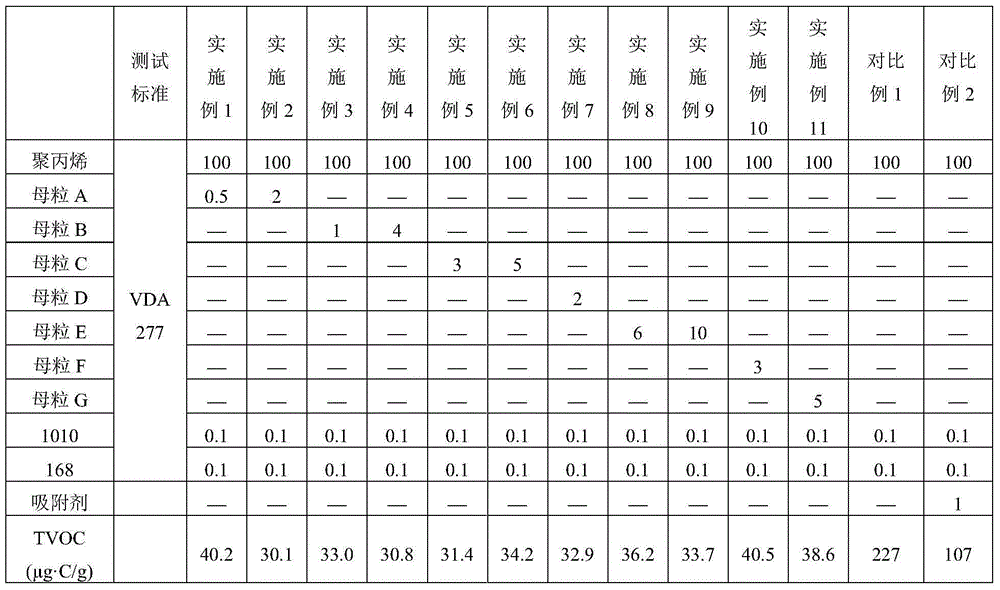

[0057] Put polypropylene (K9020, Sinopec Beijing Yanshan Branch), the above VOC suppression masterbatch for polypropylene and other processing aids into a high-speed mixer, and stir for 3 minutes at a speed of 300 rpm to make each component fully well mixed. Subsequently, the above-mentioned mixed material is passed through a BUSS kneading unit in the range of 190°C to 230°C, and extruded and granulated under the condition of maintaining a vacuum degree of -0.08MPa to obtain a polypropylene material with low VOC content. Its specific formula is shown in Table 2, wherein the content of each component is calculated in parts by weight.

[0058] The extruded pellets were dried in a constant temperature oven at 80°C for 2 hours, and the TVOC was tested according to the standard VDA277 of the German Federation of Automobile Industries. The specific performance results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com