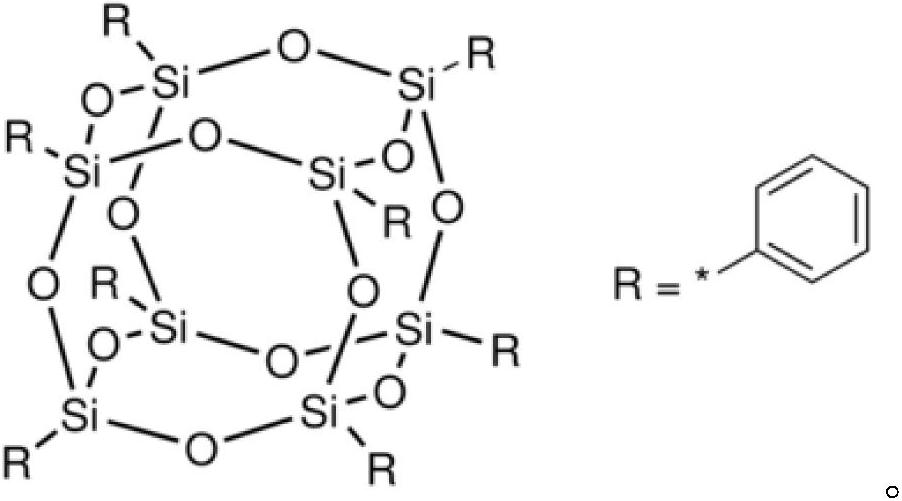

Low-voc and low-odor masterbatch for polypropylene and its preparation method and application

A polypropylene, low-odor technology, applied in the field of plastics, can solve the problems of complex components, limited effect, adsorption balance, etc., to improve the dispersion effect, slow down the emission, and improve the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

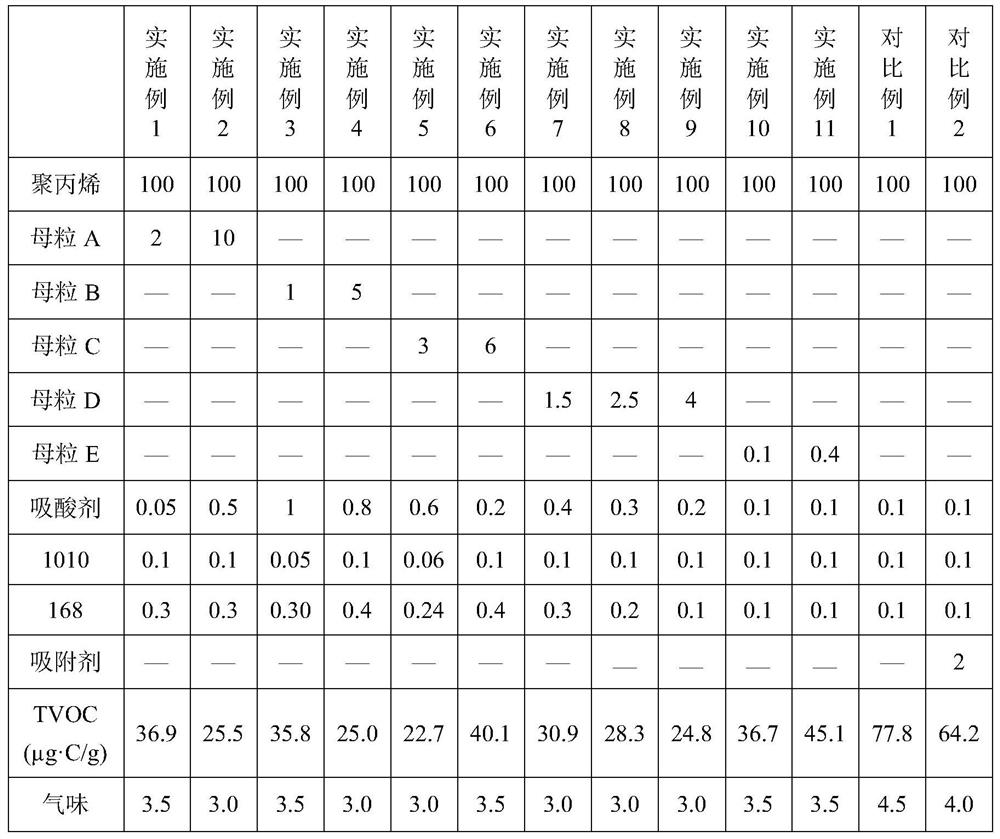

[0045] Preparation of low-VOC and low-odor polypropylene composition:

[0046] Put polypropylene (HHP4, Sinopec Maoming Branch), the above-mentioned low-VOC and low-odor masterbatch for polypropylene, antioxidant, acid absorbing agent and other processing aids into a high-speed mixer, at a speed of 300 rpm Stir for 3 minutes to fully mix the ingredients. Then, the above-mentioned mixture is passed through a BUSS kneading unit in the range of 190°C to 230°C, and extruded and granulated under the condition of maintaining a vacuum degree of -0.08MPa to obtain a polypropylene material with low VOC content and low odor. Its specific formula is shown in Table 2, wherein the content of each component is calculated in parts by weight.

[0047] The extruded pellets were dried in a constant temperature oven at 80°C for 2 hours. The TVOC was tested according to the standard VDA277 of the German Federation of Automobile Industries, and the odor test was tested according to the standard V...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com