A kind of high-strength electronic protective clothing TPU film material and preparation method thereof

A film material and electronic technology, applied in the field of polymer material synthesis, can solve the problems of low temperature resistance, elongation, hydrolysis resistance, unsatisfactory heat resistance, product side reactions, many crystal points, moisture permeability, poor air permeability, etc. , to achieve good antistatic performance, improve antistatic performance, and strengthen the effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the modified graphene that adopts in the embodiment is as follows:

[0037] Graphene oxide, silane coupling agent (KH-570), absolute ethanol and deionized water were mixed and ultrasonically dispersed, then heated for silanization reaction, and N 2 , and finally washed with absolute ethanol and suction filtered to obtain silanized graphene oxide.

Embodiment 1

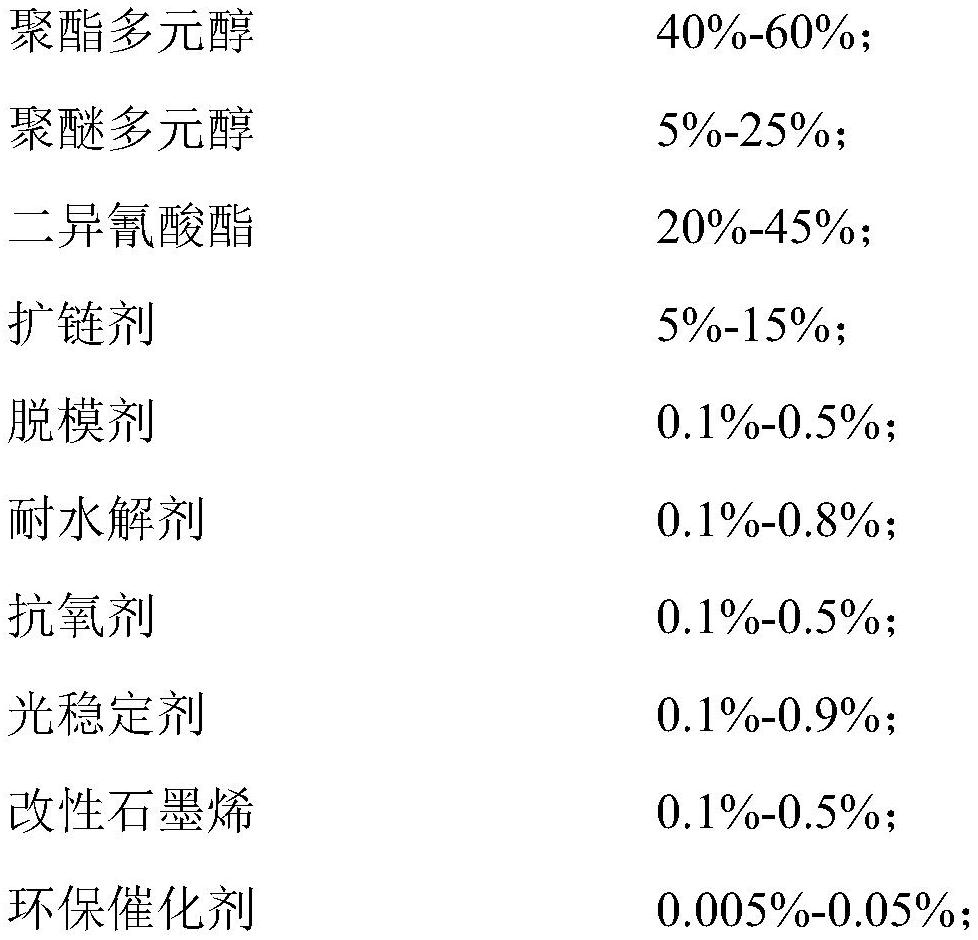

[0039] A high-strength electronic protective clothing TPU film material is made of the following raw materials in weight percentage:

[0040]

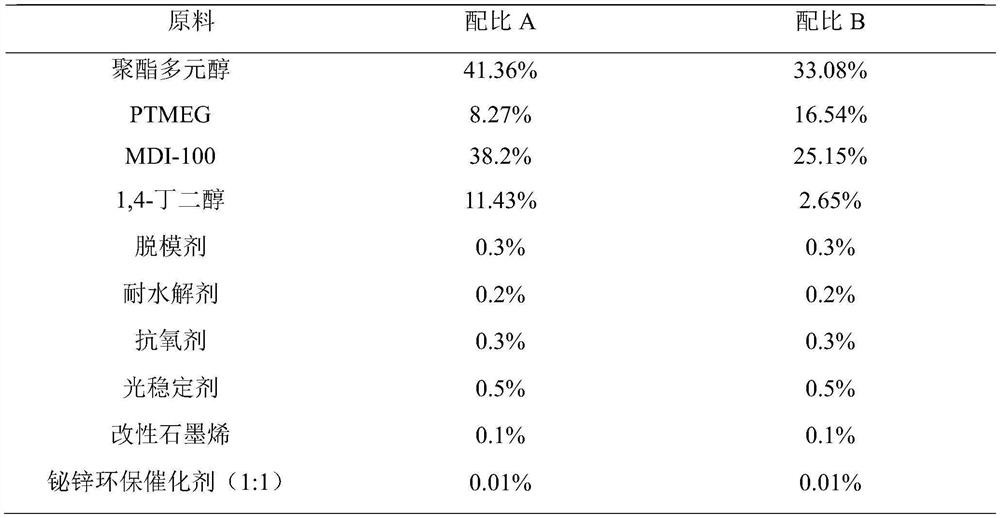

[0041] Described polyester polyol is polybutylene adipate, and polyester polyol number-average molecular weight is 2000; Polyether type polyol is PTMEG, and number-average molecular weight is 1000, and reaction hard segment 50%, r value (NCO / OH molar ratio) 0.98, synthesized by proportioning A and proportioning B respectively.

[0042] Preparation Process:

[0043] 1. Mix polyester and polyether polyol, control the material temperature at 110°C, pull vacuum to remove moisture, control the moisture below 0.03%, then add light stabilizer, antioxidant, mold release agent, and modified graphene in sequence , Resistant to hydrolysis agent, the material kettle is stirred and circulated;

[0044] 2. Quantitative premixing of polyester polyol, polyether polyol and 1,4-butanediol at 120°C by means of a metering pump, heating the diisocyan...

Embodiment 2

[0047] A high-strength electronic protective clothing TPU film material is made of the following raw materials in weight percentage:

[0048]

[0049]

[0050]Described polyester polyol is polybutylene adipate, and polyester polyol number-average molecular weight is 2000; Polyether type polyol is PTMEG, and number-average molecular weight is 1000, and reaction hard segment 50%, r value (NCO / OH molar ratio) 0.98, synthesized by proportioning A and proportioning B respectively.

[0051] Preparation Process:

[0052] 1. Mix polyester and polyether polyol, control the material temperature at 110°C, pull vacuum to remove moisture, control the moisture below 0.03%, then add light stabilizer, antioxidant, mold release agent, and modified graphene in sequence , Resistant to hydrolysis agent, the material kettle is stirred and circulated;

[0053] 2. Quantitative premixing of polyester polyol, polyether polyol and 1,4-butanediol at 120°C is achieved through a metering pump, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com