A kind of low VOC polypropylene resin composition and preparation method thereof

A technology of polypropylene resin and composition, which is applied in the field of low-VOC polypropylene resin composition and its preparation, can solve problems such as compatibility and durability, and achieve the effects of delayed release, delayed discharge, and simple and reliable operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

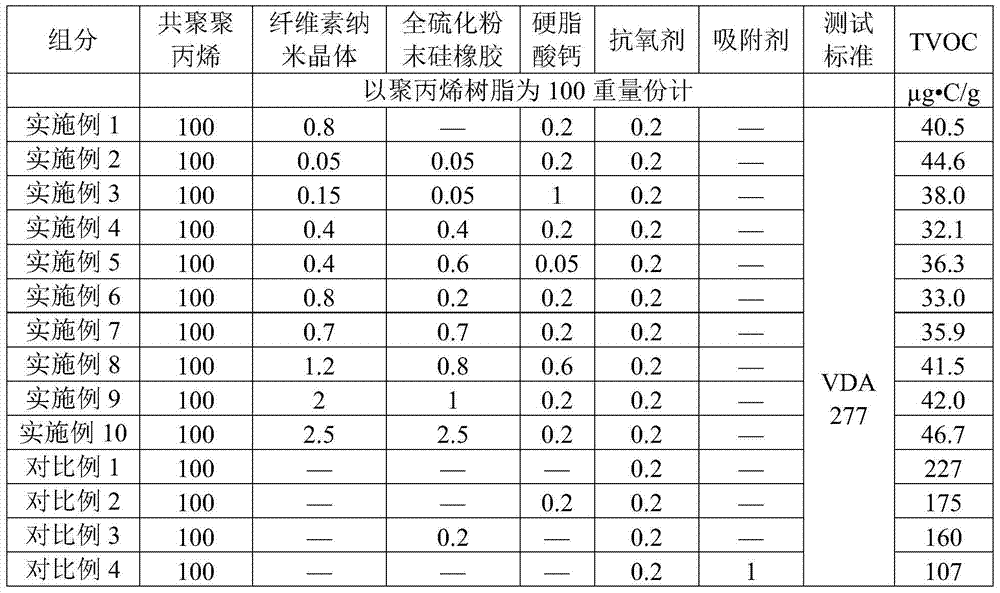

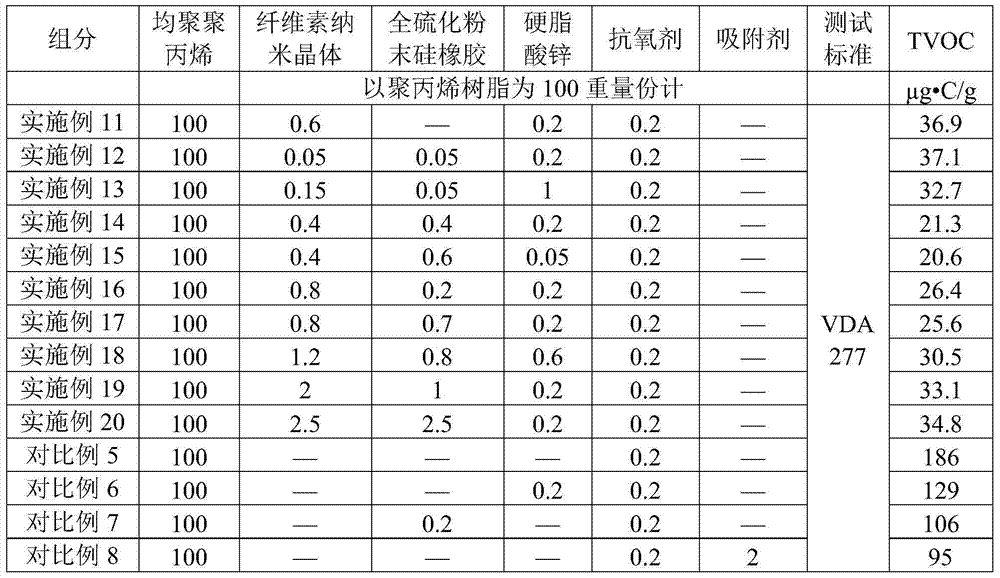

Examples

Embodiment 1~6

[0040] The cellulose nanocrystal (average BET specific surface area 250m 2 / g, average length 150nm, average width 9nm, average surface charge density 0.2e / nm 2 , Chinese Academy of Forestry Sciences) and the fully vulcanized powder silicone rubber (brand VP-602, average particle size 0.1 μm, gel content 90wt%; Beijing Research Institute of Chemical Industry) fully mixed to obtain the VOC inhibitor; then obtained The VOC inhibitor and copolymerized polypropylene (K9020, Sinopec Beijing Yanshan Branch), acid absorbing agent (calcium stearate, Tianjin Gangchang Chemical Co., Ltd.), antioxidant (antioxidant 1010, belong to hindered Phenolic antioxidants, the chemical name is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, and antioxidant 168, which belongs to phosphate antioxidants, chemical Named as three (2,4-di-tert-butylphenol) phosphite, the weight ratio of antioxidant 1010 and antioxidant 168 is 1:2, the two are from BASF, Germany) and pu...

Embodiment 7

[0045] The cellulose nanocrystal (average BET specific surface area 300m 2 / g, average length 100nm, average width 7nm, average surface charge density 0.3e / nm 2 , Chinese Academy of Forestry, its specific preparation method is different from the preparation method of cellulose nanocrystals in Examples 1-6 only in the reaction time under stirring at 45°C in step 2, which is 45min, and other steps are the same as in Examples 1-6 The preparation method of cellulose nanocrystals is the same) and the fully vulcanized powder silicone rubber (brand VP-602, average particle diameter 0.05 μm, gel content 75wt%; Beijing Research Institute of Chemical Industry) is fully mixed to obtain the VOC inhibitor; The VOC inhibitor that will be obtained is mixed with polypropylene (K9020, Sinopec Beijing Yanshan Branch), acid absorbing agent (calcium stearate, Tianjin Gangchang Chemical Co., Ltd.), antioxidant (antioxidant 1010, It belongs to the hindered phenolic antioxidant, the chemical name i...

Embodiment 8

[0048] The cellulose nanocrystals (average BET specific surface area 100m 2 / g, average length 300nm, average width 15nm, average surface charge density 0.1e / nm 2, Chinese Academy of Forestry, its specific preparation method is different from the preparation method of cellulose nanocrystals in Examples 1 to 6 only in the sulfuric acid / cellulose feed ratio in step 2, which is 8.75mL / g, and other steps are the same as in Example 1 The method for preparing cellulose nanocrystals in ~6 is the same) and the fully vulcanized powdered silicone rubber (brand VP-602, average particle diameter 1 μm, gel content 60wt%; Beijing Research Institute of Chemical Industry) is fully mixed to obtain the VOC inhibitor ; Then the VOC inhibitor obtained with polypropylene (K9020, Sinopec Beijing Yanshan branch), acid absorbing agent (calcium stearate, Tianjin Gangchang Chemical Co., Ltd.), antioxidant (antioxidant 1010, which belongs to the hindered phenolic antioxidant, the chemical name is tetra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com