Low-VOC low-odor polypropylene resin composition and preparation method thereof

A polypropylene resin and composition technology, which is applied in the field of low VOC and low odor polypropylene resin composition and the preparation of low VOC and low odor polypropylene resin composition, can solve the problems of limited effect, complex components, adsorption balance and the like , to achieve the effect of improving efficiency, improving dispersion effect and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] According to a specific embodiment, the preparation method includes the following steps:

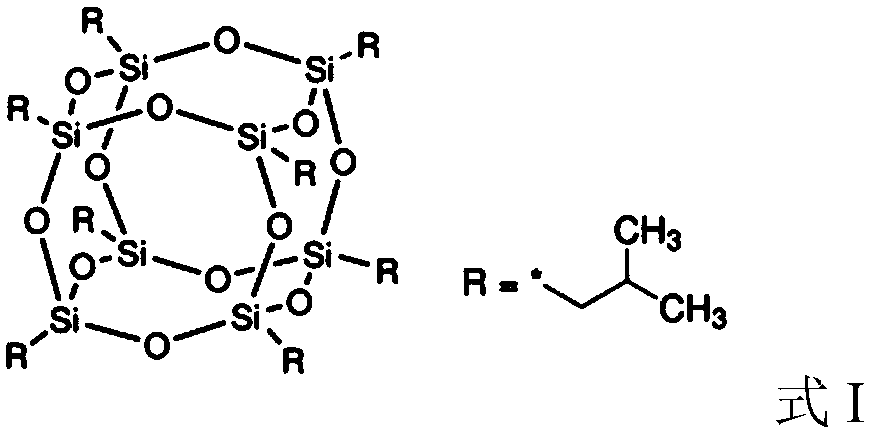

[0040] (1) Mix the modified carbon nanotubes, octaisobutylsilsesquioxane, acid absorbing agent and antioxidant uniformly to obtain a VOC suppression mixture;

[0041] (2) uniformly mixing the VOC suppression mixture and the polypropylene to obtain a premix;

[0042] (3) Melt-blending the premix to obtain the polypropylene resin composition.

[0043] According to the present invention, in step (2), the polypropylene is preferably dry treated polypropylene. The mixing in both steps (1) and (2) is preferably dry mixing.

[0044] In order to remove VOC better, it is preferable to keep the vacuum degree of the vacuum system of the equipment above -0.05MPa, more preferably above -0.08MPa during the melt blending.

[0045] In addition, in the process of processing, according to the needs of practical applications, after melt blending, various moldings can also be carried out, so that ...

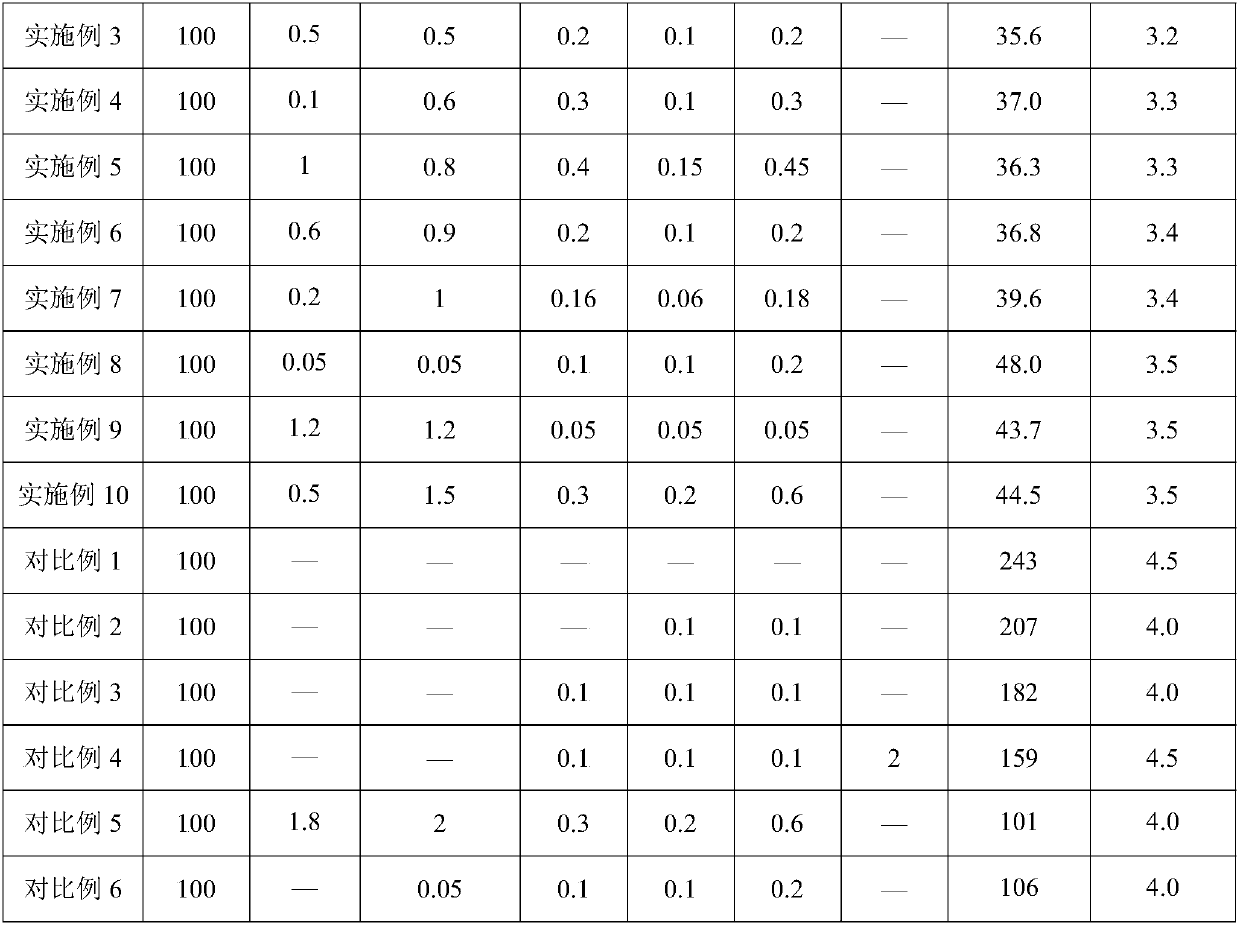

Embodiment 1-10

[0050] Examples 1-10 are used to illustrate the low-VOC and low-odor polypropylene resin composition of the present invention and its preparation method.

[0051] Modified carbon nanotubes (multi-walled carbon nanotubes coated with divinylbenzene, DVB-CNTs-1, Beijing University of Chemical Technology, 30nm in diameter, 10μm in length, and 30nm in thickness of the cladding layer), eight isobutyl times Semisiloxane (MS0825, American Hybridplastic Company), acid absorbing agent (calcium stearate, Tianjin Gangchang Chemical Co., Ltd.), antioxidant (antioxidant 1010, belongs to hindered phenolic antioxidant, chemical name is Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, and antioxidant 168, belong to phosphate antioxidants, the chemical name is three (2,4-di tert-butylphenol) phosphite, both from BASF, Germany) into a high-speed mixer, stirred at a speed of 300 rev / min for 2 minutes, fully mixed the components to obtain the VOC inhibitor mixture; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com