Method for preparing impact-resistant polypropylene with low VOC (Volatile Organic Compounds) content

A technology of polypropylene and propylene, which is applied in the field of preparation of impact polypropylene with low VOC content, and can solve problems such as increased cost, high VOC content, and relatively large impact on material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The propylene polymerization reaction is carried out on a set of 25Kg / hr propylene polymerization device, which mainly includes a pre-complexation reactor, a pre-polymerization reactor, a first loop reactor, a second loop reactor and a third gas phase reactor.

[0056] Polymerization method and steps are as follows:

[0057] (1) Pre-complexation reaction

[0058] The main catalyst (DQC-602 catalyst, provided by Beijing Aoda Branch of Sinopec Catalyst Company, Ti content: 2.4wt%, Mg content: 18.0wt%, di-n-butyl phthalate content: 13.0wt%) flow rate is 0.8g / hr, the cocatalyst (triethylaluminum, TEA) flow rate is 6.33g / hr, the first external electron donor (3-aminopropyltriethoxysilane, KHTES) flow rate is 0.60g / hr, TEA / The KHTES ratio was 50 (mol / mol), and the pre-complexation reaction was performed at 6° C. for 8 minutes.

[0059] (2) Prepolymerization reaction

[0060] The pre-complexed catalyst system is continuously added to the continuous stirred tank pre-polyme...

Embodiment 2

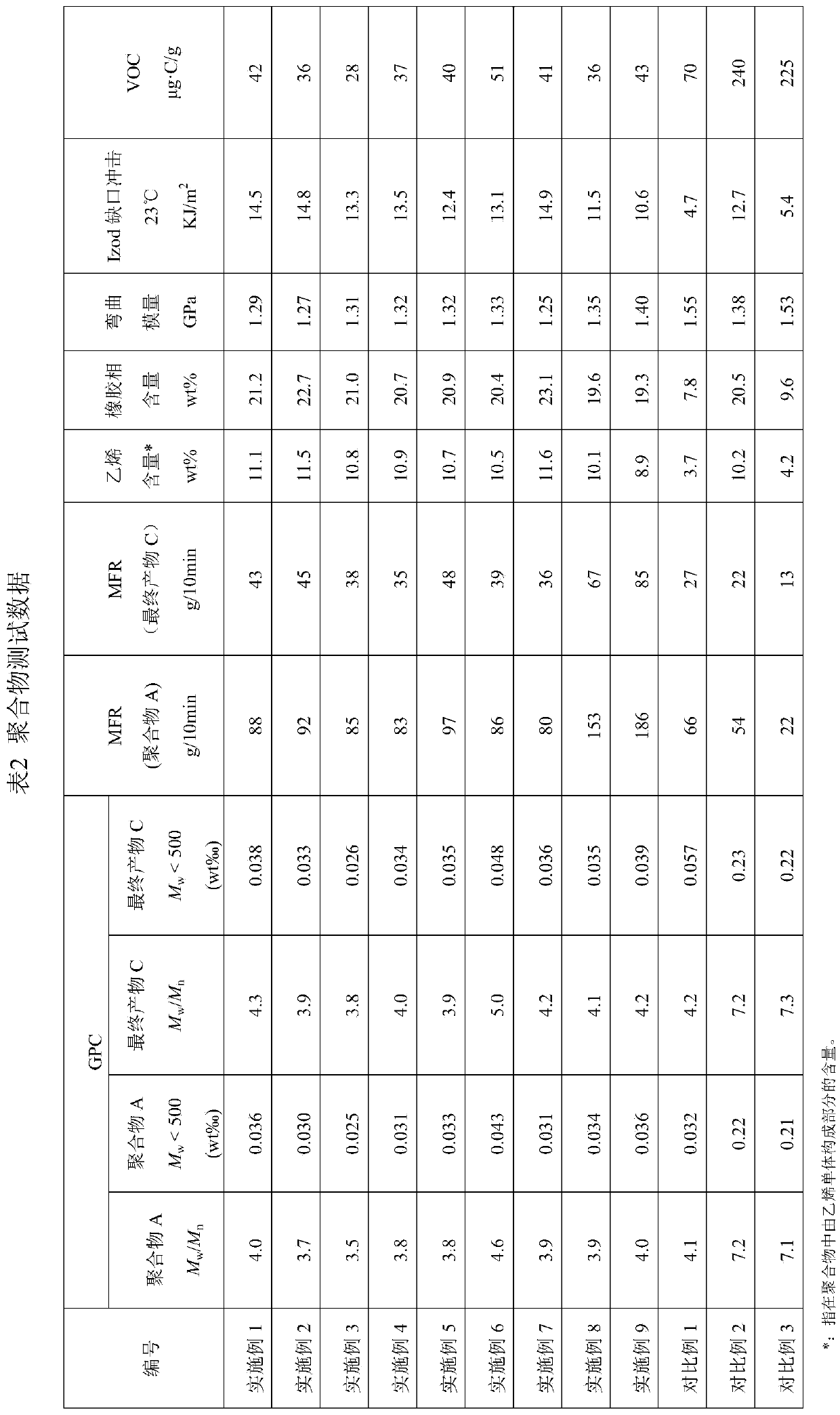

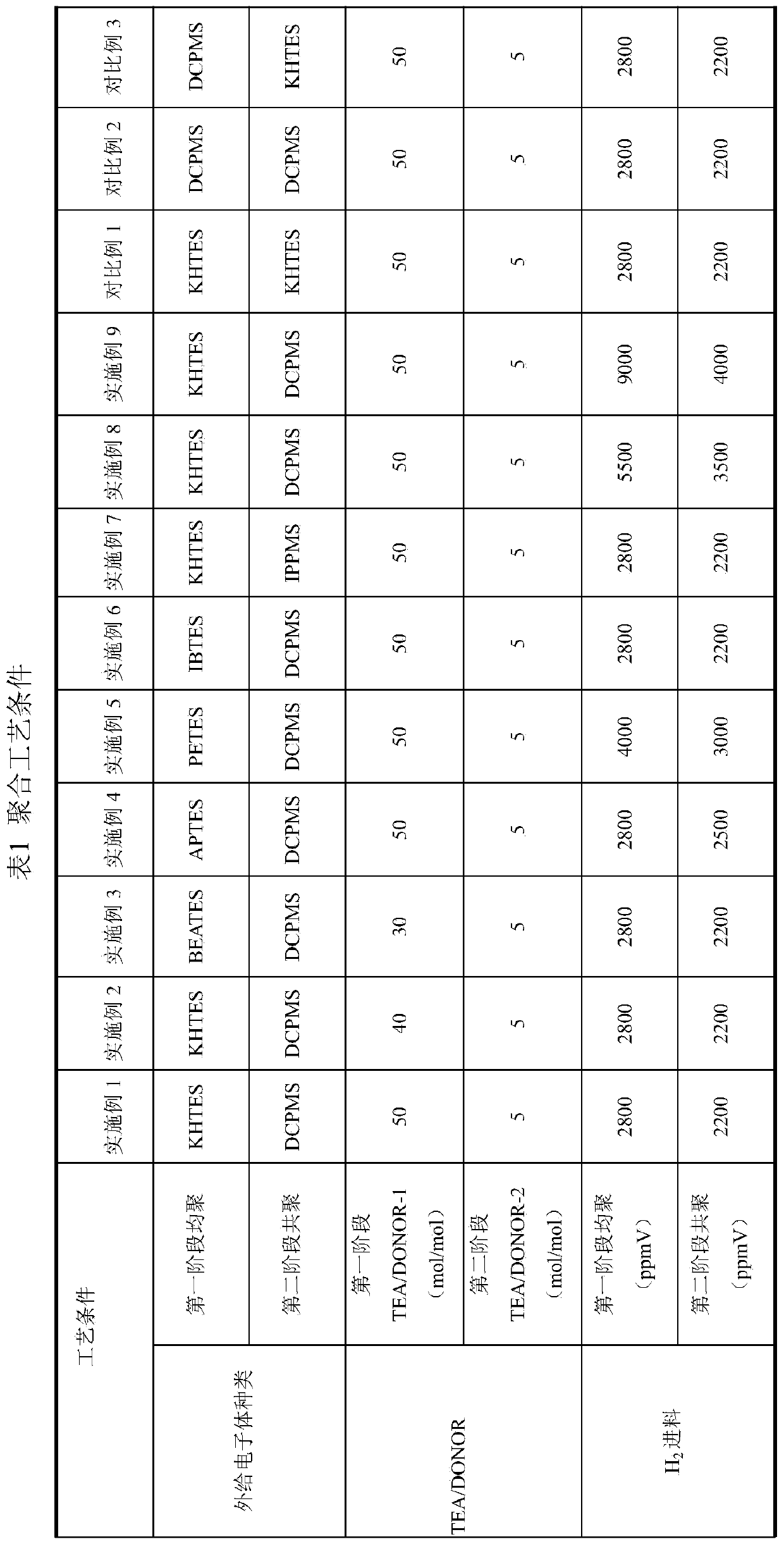

[0068] The catalyst used in embodiment 2, pre-complexation and polymerization process conditions are identical with embodiment 1. The difference from Example 1 is that the amount of the first external electron donor KHTES is increased, and TEA / KHTES is changed to 40 (mol / mol). The specific process parameters of this embodiment and the performance test results of the obtained polymer are listed in Table 1 and Table 2.

Embodiment 3

[0070] The catalyst used in embodiment 3, pre-complexation and polymerization process conditions are identical with embodiment 1. The difference from Example 1 is that the first external electron donor KHTES is changed to diethylaminotriethoxysilane (BEATES), and TEA / BEATES is changed to 30 (mol / mol). The specific process parameters of this embodiment and the performance test results of the obtained polymer are listed in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com